1

0TABLE OF CONTENTS

0 TABLE OF CONTENTS _____________________________________________________ 1

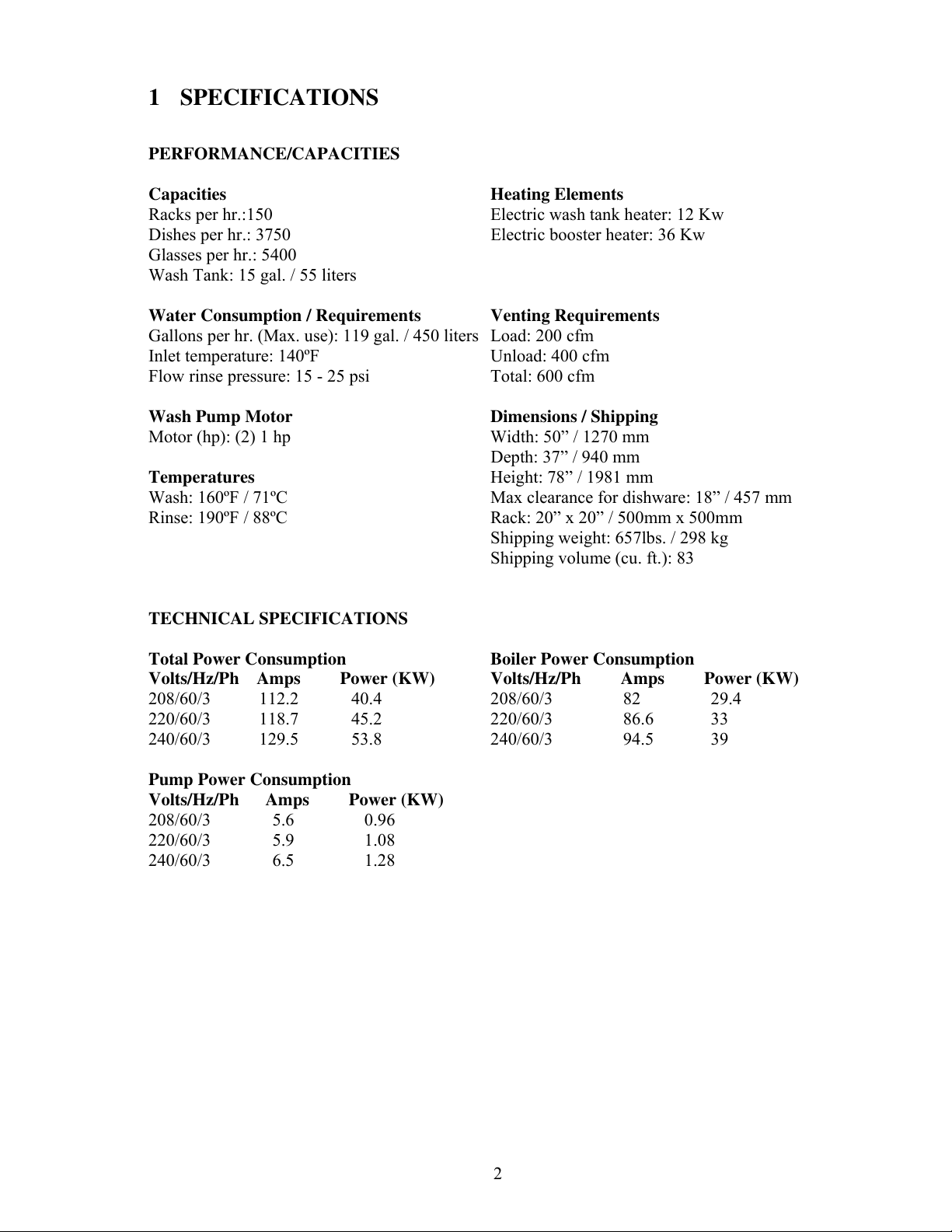

1 SPECIFICATIONS __________________________________________________________ 2

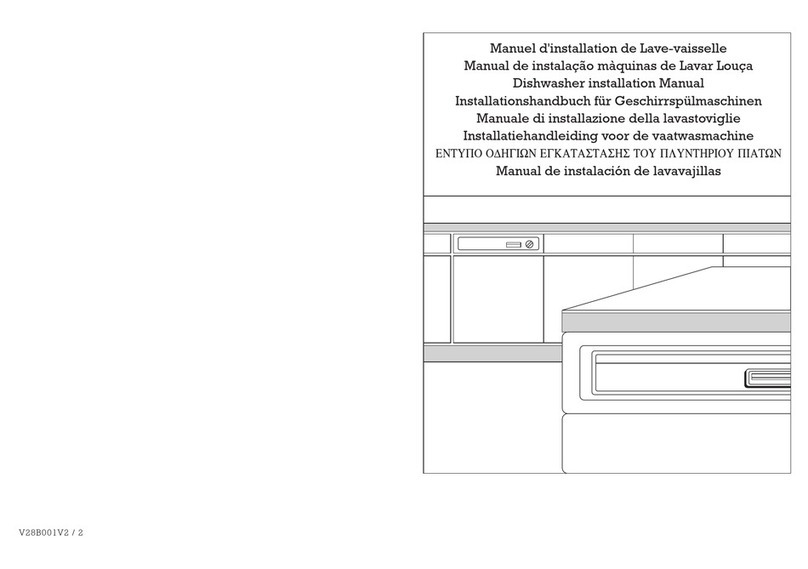

2 INSTALLATION ___________________________________________________________ 3

2.1 VISUAL INSPECTION __________________________________________________ 3

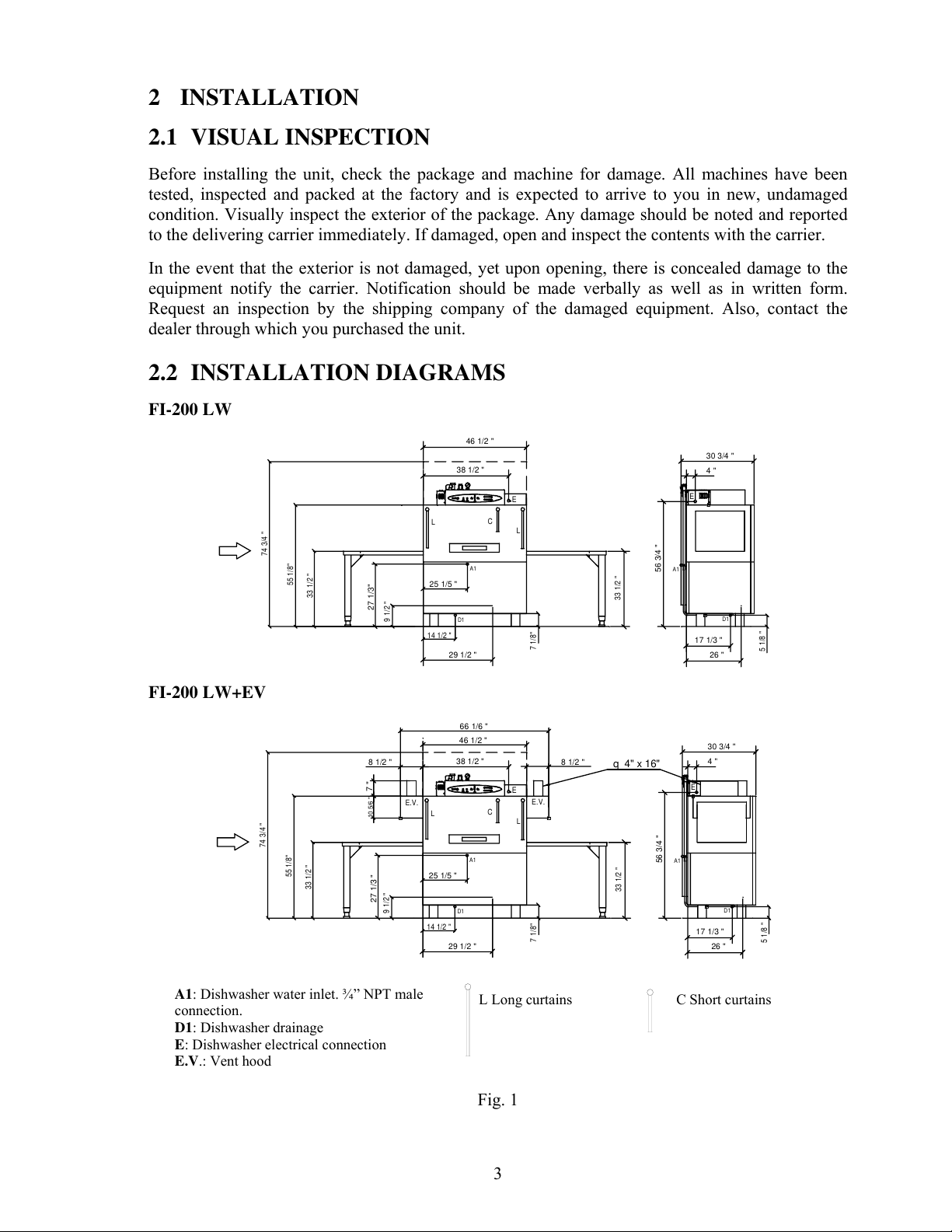

2.2 INSTALLATION DIAGRAMS ____________________________________________ 3

2.3 DATA PLATE _________________________________________________________ 4

2.4 POSITIONING _________________________________________________________ 4

2.5 WATER INSTALLATION________________________________________________ 4

2.6 WATER DRAINAGE____________________________________________________ 6

2.7 ELECTRICAL CONNECTION ____________________________________________ 6

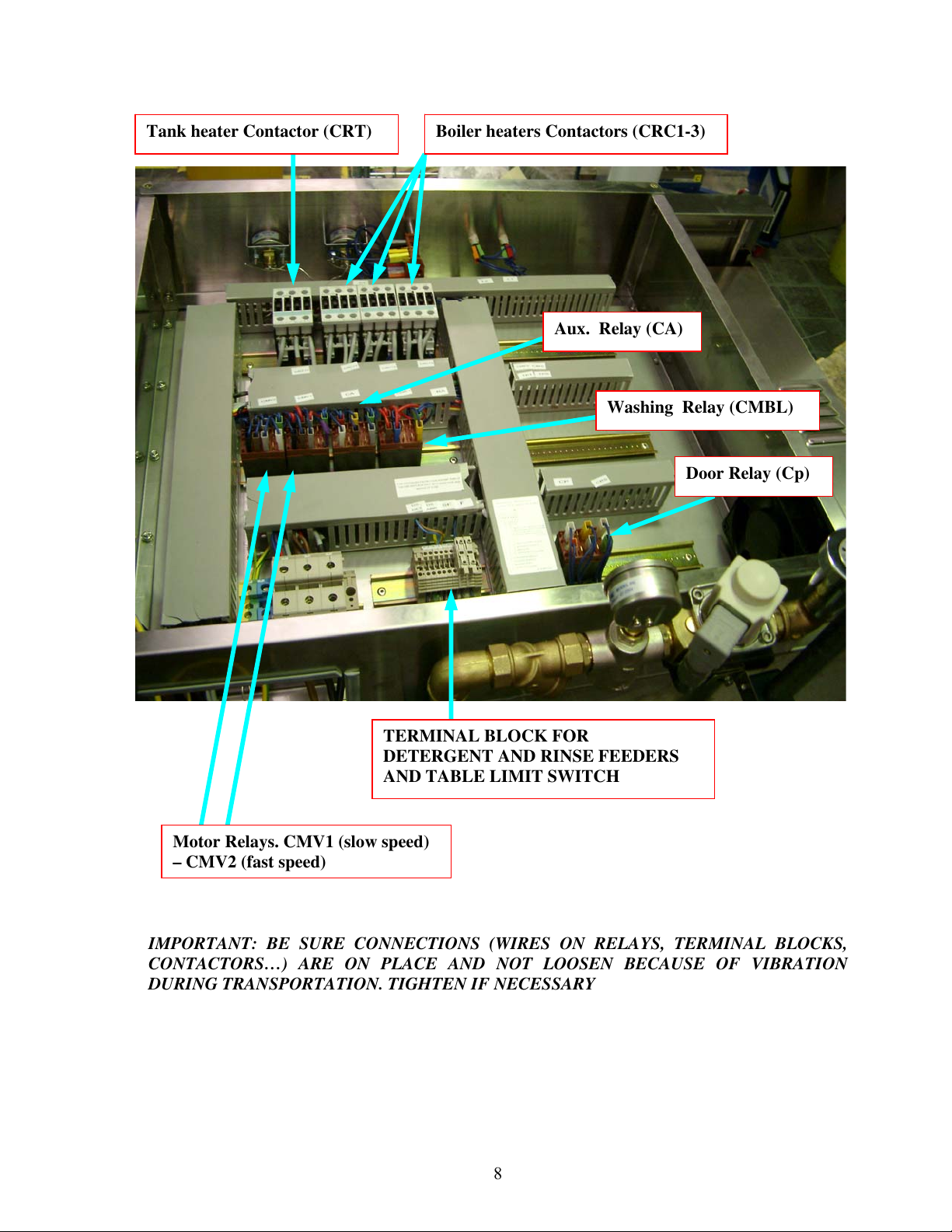

2.8 CHEMICAL AND TABLE LIMIT SWITCH CONNECTIONS___________________ 7

3 INSTALLATION / START UP CHECKLIST_____________________________________ 9

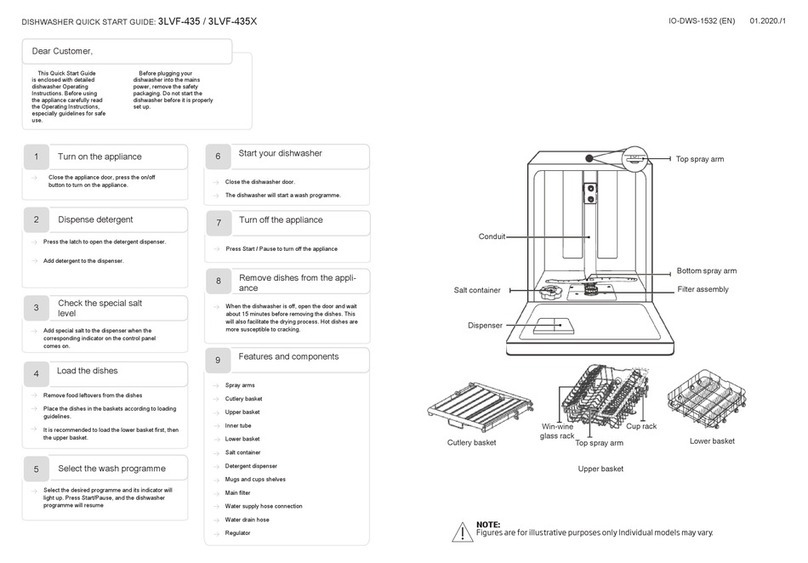

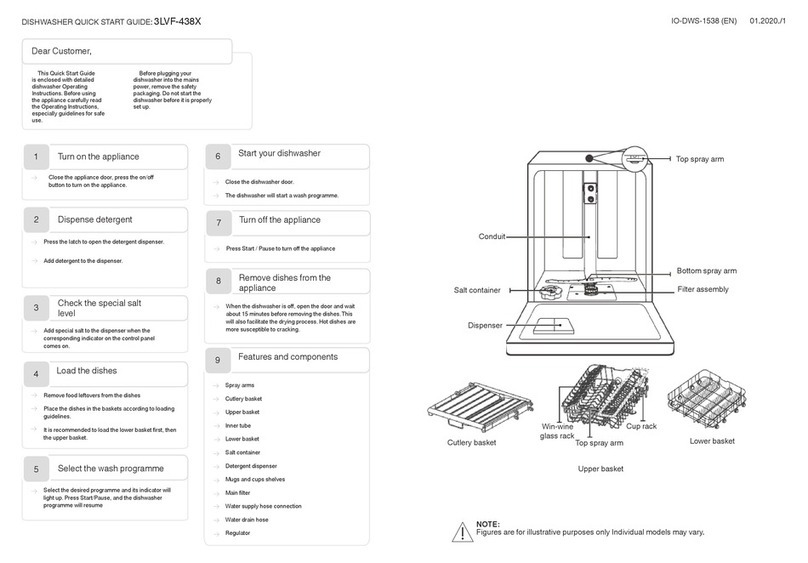

4 USE _____________________________________________________________________ 10

4.1 USE OF THE APPLIANCE ______________________________________________ 10

4.2 ADVICE ON HOW TO WASH CORRECTLY_______________________________ 11

5 MAINTENANCE __________________________________________________________ 13

6 CLUTCH AJUSTMENT_____________________________________________________ 14

7 TROUBLESHOOTING _____________________________________________________ 15

8ELECTRICAL DIAGRAM __________________________________________________ 18

9COMPONENTS ___________________________________________________________ 19

10 WIRING SCHEMATIC _____________________________________________________ 20

11 RECOMMENDED SPARE PARTS____________________________________________ 21

12 FAGOR COMMERCIAL LIMITED WARRANTY _______________________________ 22

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read this manual thoroughly before installing or servicing this

equipment. We recommend all service performed by an authorized service technician. Follow the

instructions and guidelines to ensure that your warranty remains in effect.

FOR START UP OF THE MACHINE GO THROUGH POINTS 3, 4 AND 5, IN ORDER TO

BE SURE THAT THE INSTALLATION HAS BEEN DONE PROPERLY AND IN ORDER TO

FAMILIARIZE THE ENDUSER WITH THE MACHINE REGARDING USE AND

MAINTENANCE OF THE MACHINE.