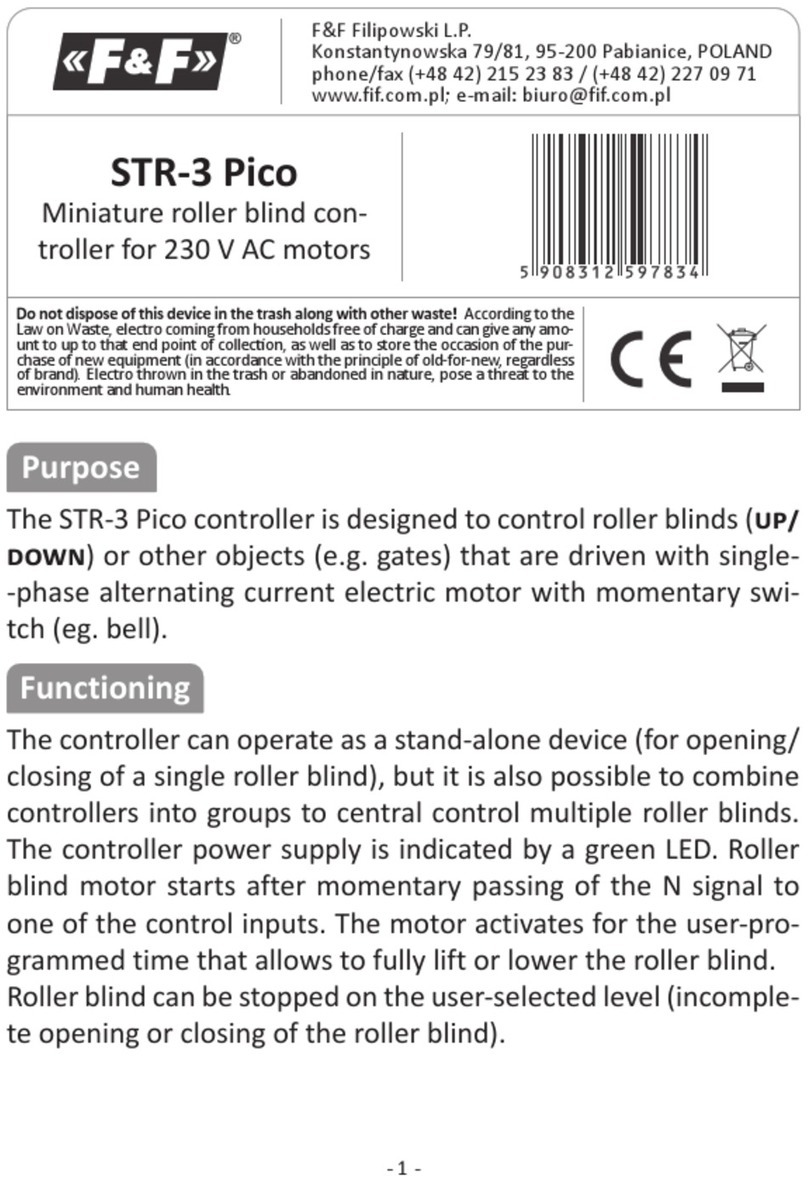

Purpose

Functioning

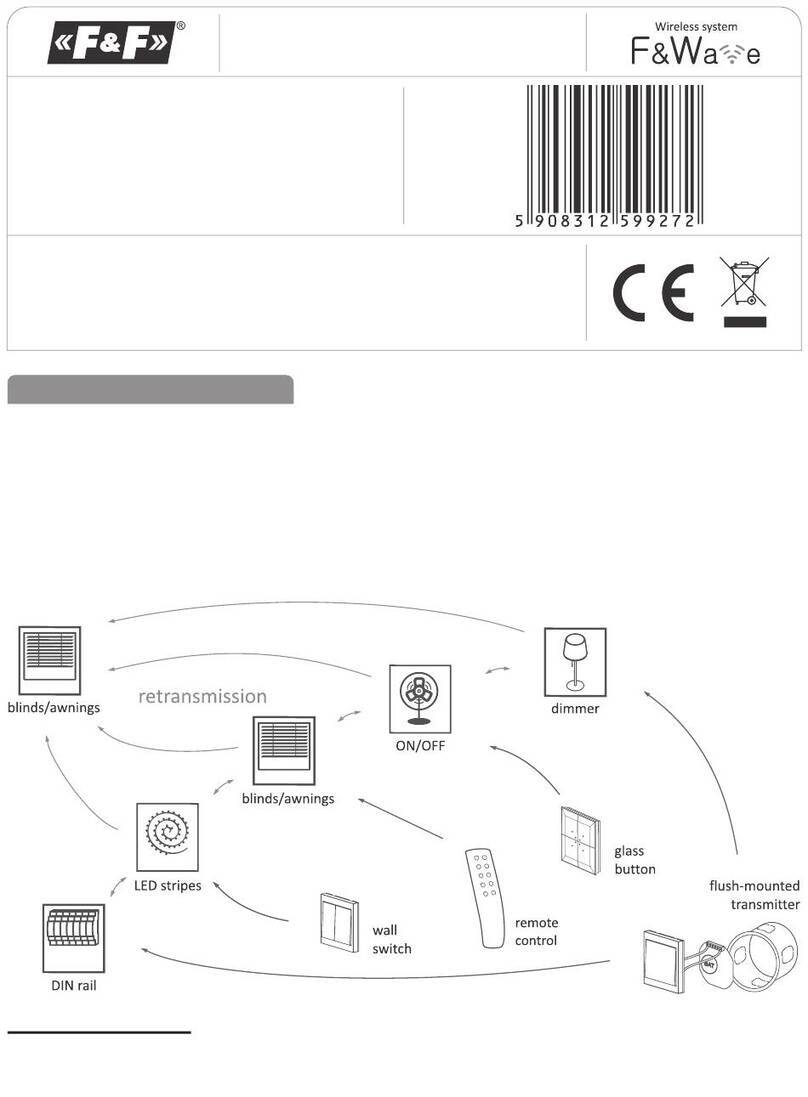

The roller blind controller STR-2 is designed for controlling roller blinds

(up and down movement) or other devices (for example, gates) that

are driven by a single-phase AC electric motor and operated by means

of momentary switches (for example, bell-pushes). The controller can

operate as an independent unit (designated for opening/closing one

roller blind) as well as the controllers can be combined into groups that

enable the central controlling of many roller blinds

Supplied the relay is to sigal by shine of green LED U. The roller blind

motor is activated by the momentary switching of a current pulse (L or

N) to one of the control inputs. The motor is activated at a time

programmed previously by the user. The activation time programmed

enables the complete lifting or lowering of the roller blind. Also, there

is a possibility of stopping the rolled blind activated at a level selected

by the user (non-complete opening or closing of the roller blind).

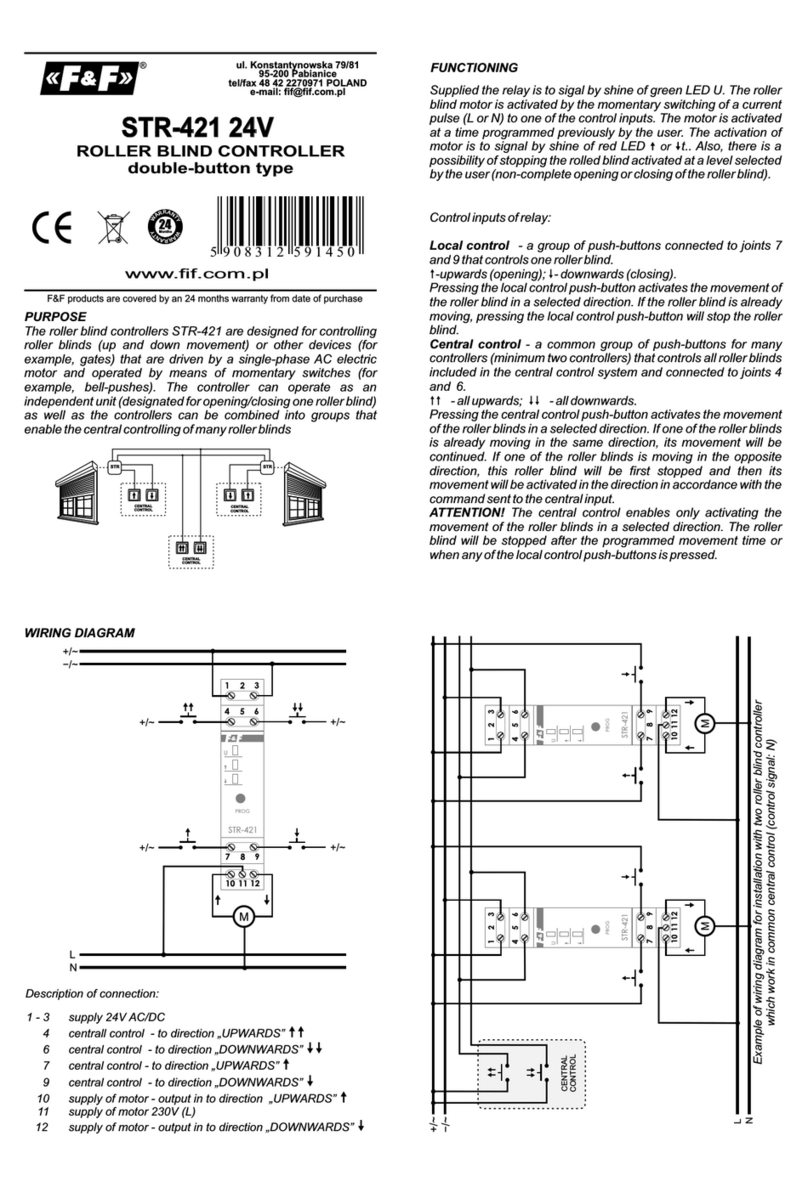

Control inputs of relay:

Local control - buttons connected to contact 6 and control one roller

blind

-upwards (opening); - downwards (closing).

Pressing the local control push-button activates the movement of the

roller blind in a selected direction. If the roller blind is already moving,

pressing the local control push-button will stop the roller blind.

Central control - a common group of push-buttons which are connect

to contact 7 and 8 for many controllers (minimum two controllers) that

controls all roller blinds included in the central control system

- all upwards; - all downwards.

Pressing the central control push-button activates the movement of

the roller blinds in a selected direction. If one of the roller blinds is

already moving in the same direction, its movement will be continued.

If one of the roller blinds is moving in the opposite direction, this roller

blind will be first stopped and then its movement will be activated in

the direction in accordance with the command sent to the central

input.

ATTENTION! The central control enables only activating the movement

of the roller blinds in a selected direction. The roller blind will be

stopped after the programmed movement time or when any of the

local control push-buttons is pressed.

Ź

ŹŹ

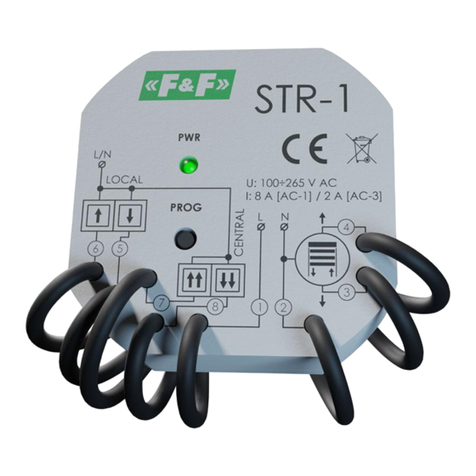

Wiring diagram

LOCAL

CONTROL

CENTRAL

CONTROL

LOCAL

CONTROL

STR

STR

Description of connection:

1 - 2 supply 230V (L - N)

3 supply of motor - output in to direction „UPWARDS”

4 supply of motor - output in to direction „DOWNWARDS”

6 local control - to direction „DOWNWARDS/UPWARDS”

7 local control - to direction „UPWARDS”

8 local control - to direction „DAWNWARDS”

“

”

”?

““

””

Control inputs could be supplied from a phase cable (L) or

neutral cable (N). Make a choose of one control option for all

inputs.

Example of wiring diagram for installation with two roller blind controller

which work in common central control (control signal: N)

1 2 34678

M

L N L/N L/N L/N

MM

L

N

CENTRAL

CONTROL

467831 2467831 2

F&F Filipowski sp. j.

Konstantynowska 79/81 95-200 Pabianice

phone/fax: (+48 42) 215 23 83 / 227 09 71 POLAND

http://www.fif.com.pl e-mail: biuro@fif.com.pl

WARRANTY. The F&F products are

covered by a warranty of the 24 months

from the date of purchase. Effective only

with proof of purchase. Contact your

dealer or directly with us. More informa-

tion how to make a compliant can be

found on the website:

www.fif.com.pl/reklamacje

ROLLER BLIND CONTROLLER

one-button type

Do not dispose of this device in the trash along with other waste! According

to the Law on Waste, electro coming from households free of charge and can

give any amount to up to that end point of collection, as well as to store the

occasion of the purchase of new equipment (in accordance with the principle

of old-for-new, regardless of brand). Electro thrown in the trash or abandoned

in nature, pose a threat to the environment and human health.

STR-2

5 9 0 8 3 1 2 5 9 3 3 2 4

- 3 - - 4 -

- 2 -