- 9 -

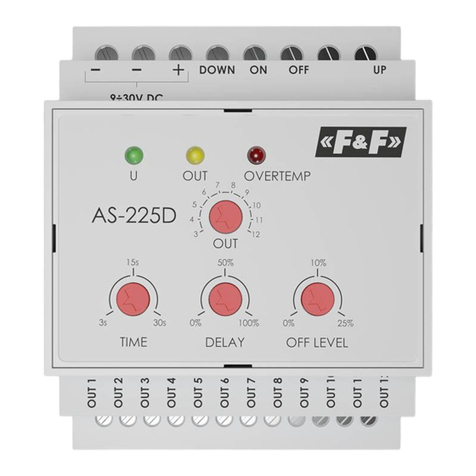

power supply 10÷27 V DC

maximum load current (AC-1) 6 A

power consumption

standby 0.15 W

on 0.6 W

control triggered with 10÷27 V DC level

switch-on time (adjustable) 1 s÷15 min.

power signalling LED green

operation and movement direction signalling 2×LED red

working temperature -25÷50°C

terminal 2.5 mm² screw terminals

tightening torque 0.4 Nm

dimensions 1 module (18 mm)

installation on TH-35 rail

protection level IP20

F&F products are covered by a 24-month warranty from the date

of purchase. The warranty is only valid with proof of purchase.

Contact your dealer or contact us directly.

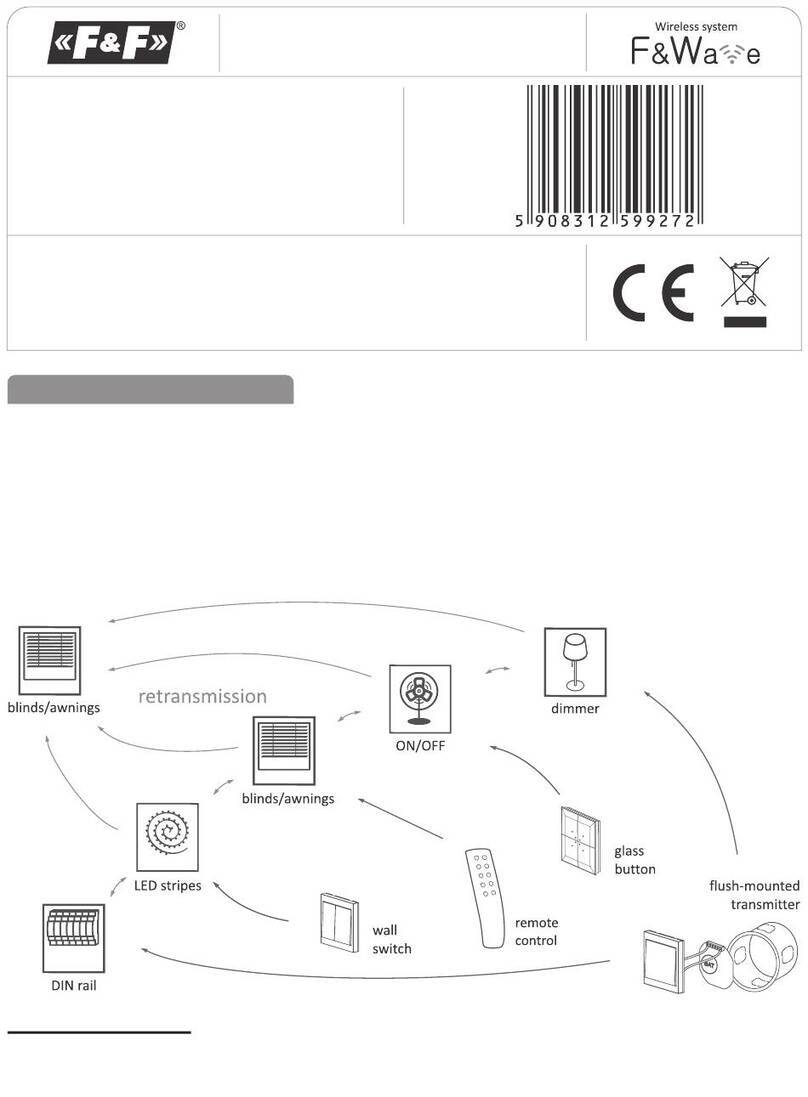

F&F Filipowski sp. j. declares that the device is in conformity

with the essential requirements of The Low Voltage Directive

(LVD) 2014/35/EU and the Electromagnetic Compatibility (EMC)

Directive 2014/30/UE.

The CE Declaration of Conformity, along with the references to

the standards in relation to which conformity is declared, can

be found at www.fif.com.pl on the product page: www.fif.com.pl

from the product subpage.

Technical data

Warranty

CE declaration

E211214

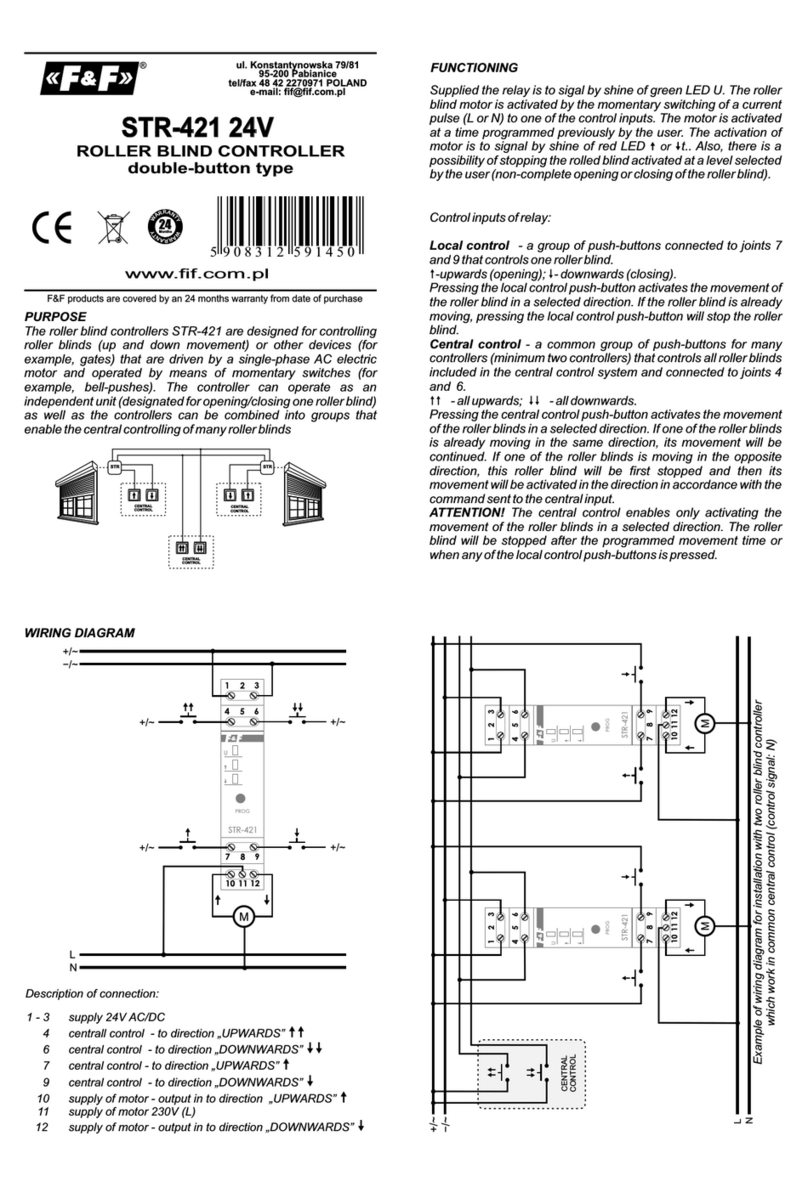

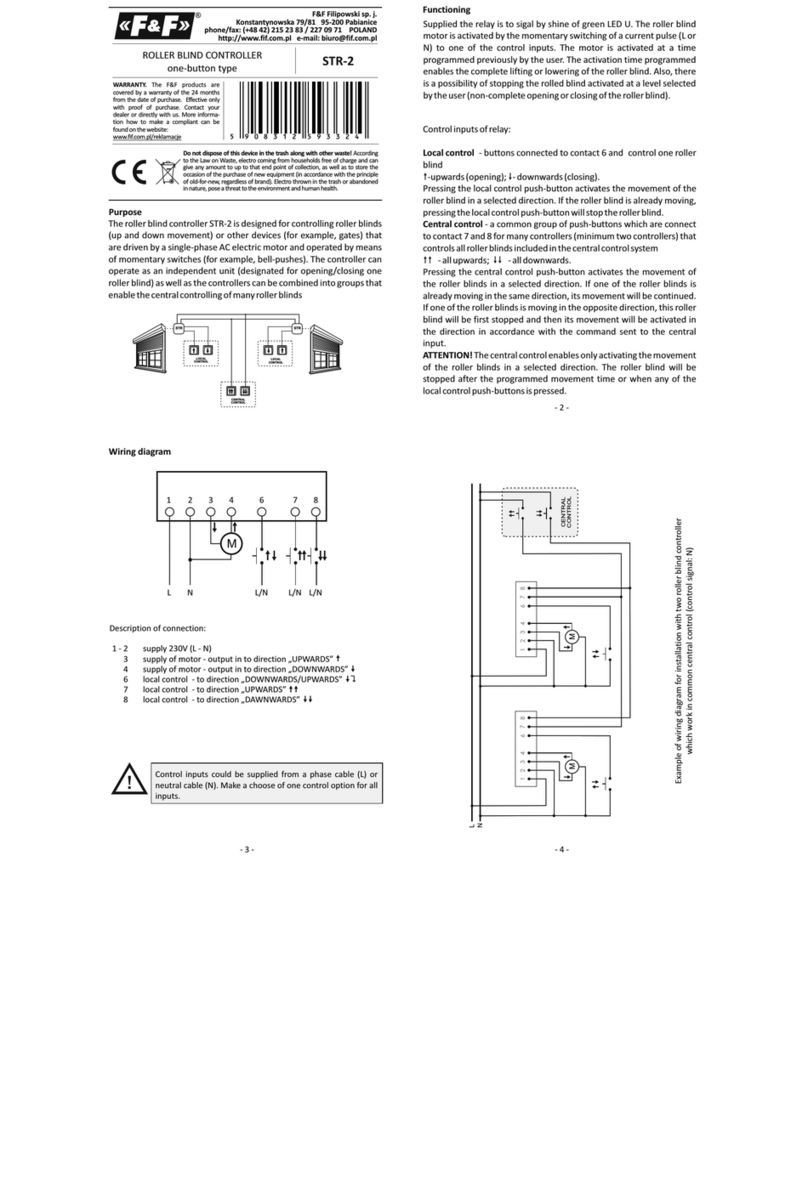

Mode with 2 local buttons

1-3 power supply 10÷27 V DC

4 central control – ↑↑ direction

6 central control – ↓↓ direction

7 local control – ↑ direction

9 local control – ↓ direction

10 motor power supply – terminal A

12 motor power supply – terminal B