6

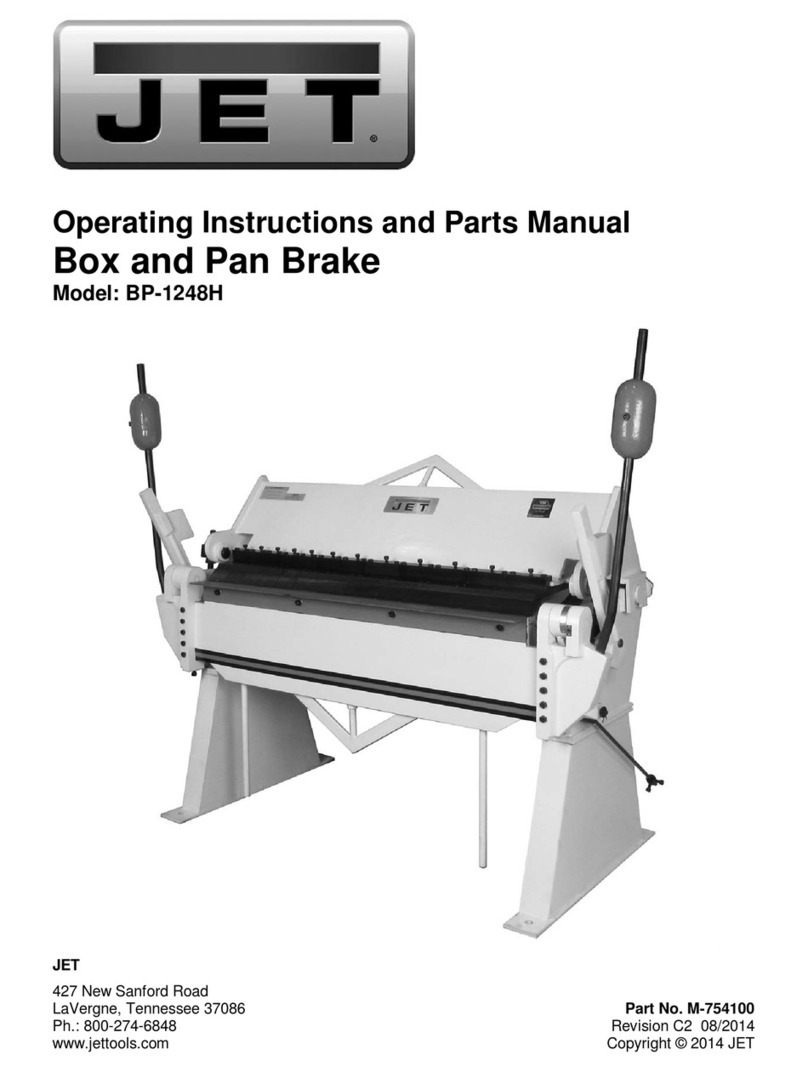

Parts List

Index No Part No Description Size Qty

1...............BP1696F-01.............Finger,3"................................................................................................5

2...............BP1696F-02.............Finger,4"................................................................................................2

3...............BP1696F-03.............Finger,5"................................................................................................5

4...............BP1696F-04.............Finger,6"................................................................................................8

5...............HB1697F-05 ............Hex Head Screw ................................................M16×35......................2

6...............HB1697F-06 ............Cover....................................................................................................2

7...............HB1697F-07 ............Spring....................................................................................................2

8...............HB1697F-08 ............Clamp Handle R.H.................................................................................1

9...............HB1697F-09 ............Clamp Handle L.H.................................................................................1

10.............HB1697F-10 ............Toggle Ass'y L.H. .................................................................................1

11.............HB1697F-11 ............Toggle Ass'y R.H. .................................................................................1

12.............HB1697F-12 ............C-Clip.................................................................20...............................2

13.............HB1697F-13 ............Brass Bushing....................................................26×20.2×20................2

14.............BP1697F-14.............Finger Clamp.......................................................................................28

15.............HB1697F-15 ............Socket Cap Screw..............................................M12×35.................... 30

16.............HB1697F-16 ............Hex Head Screw ................................................M12×80......................6

17.............HB1697F-17 ............Hex Nut..............................................................M12 ...........................7

18.............HB1697F-18 ............Hex Head Screw ................................................M16×50......................2

19.............HB1697F-19 ............Plain Washer......................................................16...............................2

20.............HB1697F-20 ............Step Bracket Comp.L.H.........................................................................1

21.............HB1697F-21 ............Step Bracket Comp.R.H.........................................................................1

22.............HB1697F-22 ............Brass Pivot Pin......................................................................................2

23.............HB1697F-23 ............Swivel Pin Ass'y ....................................................................................2

24.............HB1697F-24 ............Hex Nut..............................................................M24............................4

25.............HB1697F-25 ............C-Clip.................................................................32...............................2

26.............HB1697F-26 ............Gauge Stop...........................................................................................1

27.............HB1697F-27 ............Socket Cap Screw..............................................M10×30......................6

28.............HB1697F-28 ............Gauge Ring...........................................................................................1

30.............HB1697F-30 ............Sping Washer.....................................................12...............................7

31.............HB1697F-31 ............Gauge Rod............................................................................................1

32.............HB1697F-32 ............Cotton Pin..........................................................4×35...........................1

33.............TS-1492031.............Hex Head Screw ................................................M12×35......................6

34.............TS-1505051.............Socket Cap Screw..............................................M10×35......................7

35.............TS-1550071.............Plain Washer......................................................10...............................7

36.............HB1697F-36 ............Angle Bar..............................................................................................1

37.............TS-1516011.............Socket Head Flat Screw.....................................M10×20....................12

38.............HB1697F-38 ............Insert Bar ..............................................................................................1

39.............HB1697F-39 ............Support,Apron Ass'y L.H........................................................................1

40.............HB1697F-40 ............Support,Apron Ass'y R.H.......................................................................1

41.............HB1697F-41 ............Fixing Plate ...........................................................................................2

42.............TS-1492051.............Hex Head Screw ................................................M12×50......................8

43.............TS-2360121.............Plain Washer......................................................12...............................8

44.............HB1697F-44 ............Counterweight .......................................................................................2

45.............HB1697F-45 ............Counterweight Rod................................................................................2

46.............HB1697H-46............Stand ....................................................................................................2

47.............TS-1525041.............Set Screw...........................................................M10×20......................2

48.............HB1697H-48............Bending Handle.....................................................................................2

49.............TS-1491031.............Hex Head Screw ................................................M10×25......................4

50.............TS-1506031.............Socket Cap Screw..............................................M12×30......................2

800...........BP1696F-800...........Holddown Ass'y.....................................................................................1

802...........HB1697H-802..........Base Ass'y ............................................................................................1

803...........HB1697F-803 ..........Apron Ass'y...........................................................................................1