6 FASTER TM T– Issue 00

FAS INTERNATIONAL S.p.A. Via Lago di Vico, 60 SCHIO (VI) – tel. +39 0445 502011 – fax +39 0445 502010 - e-mail: info@fas.it

E

N

G

L

I

S

H

-

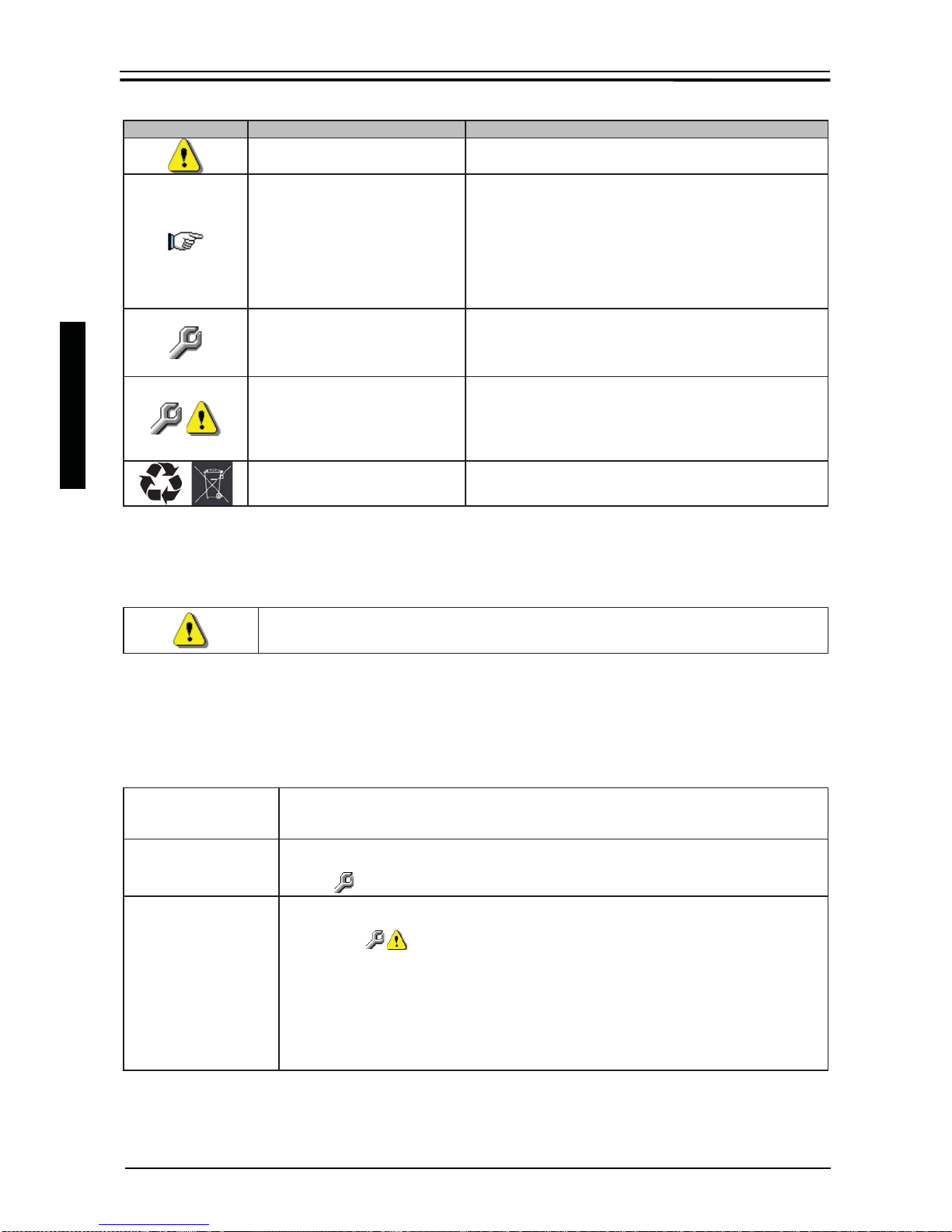

1.5 CONSULTATION GUIDE

SYMBOL MEANING COMMENT

DANGER Indicates a danger, even mortal, for the User.

WARNING

Indicates a warning or notes on key functions or useful

information.

Pay careful attention to those parts of the text

indicated by this symbol.

The maintenance personnel are requested to take a

measurement value, check a signal, check the correct

position of any machine element, etc. prior to

performing a determined command or operation.

ROUTINE MAINTENANCE

By routine maintenance, it is intended: the reloading

operations, setting the control parameters, emptying

out the coins, and the cleaning operations in the areas

in contact with the food products.

EXTRAORDINARY

MAINTENANCE

By extraordinary maintenance, it is intended: the more

complex maintenance operations (mechanical,

electrical, etc.) in particular situations, or those agreed

with the user which are not considered ordinary

maintenance.

RECYCLING Obligation to dispose of the materials respecting the

environment.

Pay particular attention to those parts of the text which are written in bold type, with larger letters or

underlined as these are used to highlight particularly important operations or information.

The enclosed wiring diagrams are intended for use exclusively by specialised technical personnel authorised

by the manufacturer to carry out extraordinary maintenance operations and checks.

It is strictly prohibited to use the wiring diagrams to modify the machine.

Throughout the manual, when referring to the machine, the terms "at the front" or "front" indicate the door

side while the terms "at the back" or "rear" indicate the other side; the terms "right" and "left" refer to the

operator facing the front of the machine.

For each operation to be carried out on the machine, a level of expertise (see below) is given to indicate the

persons qualified to perform the operation concerned.

Final user Person without specific expertise able to perform the operations of purchasing and

retrieving the product only by using the controls displayed on the machine or by

following the instructions given on the display.

Ordinary

maintenance

operator

Person capable of carrying out the operations in the above point and, in addition, of

operating on the machine following the instructions in this manual marked with the

symbol .

Extraordinary

maintenance

operator

Person capable of carrying out the operations in the above points and, in addition,

of operating on the machine following the instructions in this manual marked with

the symbols . In each case, the specialised technicians must also be capable

of operating with the protections disabled and therefore in reduced safety

conditions. Any operations to be carried out with the parts of the machine in

movement and/or on live equipment must only be performed in exceptional cases

and once the impossibility of operating in suitable safety conditions has been

established. Access to these areas should be permitted only to persons with a

practical knowledge and experience of the machine, particularly in matters of safety

and hygiene.

The operations described in this manual relative to each phase of the life cycle of the machine have been

carefully analysed by the manufacturer. The number of operators and the level of expertise requested are

therefore the most suitable for best performing each specific operation.