IntelligentAg ENGAGE SPREADCONTROL User manual

ENGAGE® SPREADCONTROL

INSTALLATION MANUAL

Document revision: 1.2

Last revised: October 23, 2020

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 2 of 48

Engage® SpreadControl

Installation Manual

© 2018-20 Intelligent Agricultural Solutions. All Rights Reserved.

Engage® SpreadControl Installation Manual. All content within is copyrighted by Intelligent

Agricultural Solutions, and may not be reprinted without permission.

The content of this manual is furnished for informational use only, is subject to change without

notice, and should not be construed as a commitment by Intelligent Agricultural Solutions.

Intelligent Agricultural Solutions assumes no responsibility or liability for any errors or

inaccuracies that may appear in the content contained in this guide.

Patent pending. Engage, SpreadControl, Intelligent Agricultural Solutions, Intelligent Ag,

Intelligent Ag Monitoring Solutions, IAS, and the IAS logo are trademarks or registered

trademarks of Intelligent Agricultural Solutions. All other trademarks are property of their

respective owner.

Intelligent Agricultural Solutions, 1810 NDSU Research Circle North, Fargo, ND 58102 USA.

Visit us online at www.intelligentag.com/support

Record of Revision

Revision

Number Change Description Revision

Date

Inserted

By

0.1 Prototype release 4/29/19 AAL

0.2 Updated hardware for POC3 8/29/19 AAL

1.0 Initial production release 7/01/20 AAL

1.1 Updated wiring diagram 7/15/20 AAL

1.2

Updated tool list, PM4X hardware list and bracket

install procedures, conveyor drive manifold

procedures, and wiring diagram. Added harnessing

steps.

10/23/20 AAL

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 3 of 48

Table of Contents

1. Getting started .......................................................................................................................4

1.1. About Engage® SpreadControl...................................................................................4

1.2. Compatible Floaters ....................................................................................................4

1.3. Required Tools and Equipment...................................................................................4

1.4. Installation Overview ...................................................................................................5

2. Installing the Gateway 260.....................................................................................................6

3. Installing the Wi-Fi Antenna ...................................................................................................8

4. Installing PM4Xs ..................................................................................................................12

5. Installing Motor-Mounted Conveyor Drive Manifold .............................................................15

5.1. Removing Existing Manifold ......................................................................................16

5.2. Installing Engage® SpreadControl Manifolds............................................................16

6. Installing Funnel Boxes........................................................................................................19

6.1. Removing Factory Funnel Boxes ..............................................................................20

6.2. Installing the Funnel Box Actuators...........................................................................20

6.3. Installing the Engage® SpreadControl Funnel Boxes ...............................................22

7. Installing Section Switches ..................................................................................................23

8. Connecting Harnessing........................................................................................................24

8.1. Connecting Harnessing .............................................................................................24

8.2. Routing Harnessing...................................................................................................46

8.3. Installing the PM4X bracket cover.............................................................................46

9. Configuring Machine Settings and Calibrating Funnel Boxes..............................................47

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 4 of 48

1. Getting started

CAUTION:

Remove the battery disconnect switch key and fold the booms up before

beginning installation.

1.1. About Engage® SpreadControl

Engage SpreadControl is a retrofit section control system for your floater. The system

communicates with your floater's existing GPS mapping system to prevent overlap by opening

and closing sections on your floater.

1.2. Compatible Floaters

Engage SpreadControl can be installed on the following models of TerraGator Air Max Precision

floaters:

•TG7300/TG7300B

•TG8300/TG8300B

•TG8400/TG8400B

•TG9300B

NOTE: Engage SpreadControl is not currently compatible with TerraGator C Series floaters.

1.3. Required Tools and Equipment

You will need the following tools and equipment to install Engage SpreadControl:

•Crescent wrench

•Dry cloth

•9/16” wrench and socket

•7/16” wrench (qty. 2) and socket

•15/16” wrench

•7/8” wrench

•Pick, breaker bar, and penetrating fluid (optional for uninstalling existing manifold)

•Torque wrench

•M13 socket

•Wire cutter

•Electrical tape

•Deutsch terminal removal tool or small screwdriver

•Raven hardware/software (from a Raven dealer)

oCable Adapter Viper 4 to 3 Pin ISO Bus (1-115-0172-247)

oISO Section Control Unlock (1-077-0180-149)

oKit Viper 4+ W/O GPS Single/Multi VRA (1-117-5010-010BM)

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 5 of 48

1.4. Installation Overview

□Install the Gateway 260

□Install PM4Xs

□Install motor-mounted conveyor drive manifolds

□Install funnel boxes

□Connect harnessing

□Configuring Machine Settings and Calibrating Funnel Boxes

NOTE: Detailed wiring diagrams are found in Appendix A.

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 6 of 48

2. Installing the Gateway 260

The Gateway 260 is a computing platform that sends data to the VT.

Number of Times Performed

Once per system

Required Tools and Equipment

•7/16” wrench (qty. 2) (for gateway mounting bracket)

•9/16” wrench (for U-bolts)

Required Parts

Part name Part number Quantity

Gateway 260

153510-000084

1

¼” flat washer

352012-000002

4

Gateway mounting bracket

353070-000079

1

¼"-20 nut

356060-000075

4

U-bolt

356060-000152

2

¼-20 x 2-1/4” screw

356060-000295

4

Installation Location

Mount the gateway between the cab and bins. The mounting location must be at least 8 inches

(20 cm) away from the operator to ensure safe operation.

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 7 of 48

Installing the Gateway 260

1. Position the Gateway 260 on the mounting bracket so that the connectors face down

when the bracket is mounted on the beam. If another orientation must be used, the

connectors should not face up.

NOTE: The text on the gateway label will be upside down.

2. Secure the gateway to the mounting bracket using the provided screws, washers, and

nuts as shown in the image above.

3. Mount the bracket to the beam using u-bolts and the provided nuts.

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 8 of 48

3. Installing the Wi-Fi Antenna

The Wi-Fi antenna sends information from the SpreadControl system to the VT.

Number of Times Performed

Once per system

Required Tools and Equipment

•Wrench set

Required Parts

Part name Part number Quantity

SMA cap

251015-000139

2

SMA terminator jack

251015-000272

1

Wi-Fi antenna

252005-000010

1

U-bolt

352013-000007

or

356060-000152

2

Antenna bracket

353070-000083

1

3/8" locknut

(for square u-bolt)

356060-000094 4

3/8" washer

(for square u-bolt)

356060-000239 4

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 9 of 48

Installation Location

Mount the Wi-Fi antenna on the bin between the cab and bins. Mount it at least 2 feet (60 cm)

away from the operator and at least 8 inches (20 cm) from the gateway to ensure safe

operation.

If you don’t have a beam behind the cab, find a beam within 6 feet of the cab that has line of

sight to the cab.

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 10 of 48

Installing the Wi-Fi Antenna

1. Thread the Wi-Fi antenna cables through the hole in the mounting bracket and through

the nut. Tighten the nut to secure the antenna to the bracket. Do not over-torque.

2. Mount the bracket on a beam behind the cab using the u-bolts and locknuts. If you don’t

have a beam behind the cab, find a beam within 6 feet of the cab that has line of site to

the cab.

3. Connect the Cellular Main and Wi-Fi/BT antenna cables to the gateway.

4. Cap the 433 MHz antenna cable with the SMA terminator jack. Zip-tie the cable to the

other cables.

5. Cover connectors 5 and 6 with the provided caps.

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 11 of 48

Routing Loose Harnessing

Coil any loose harnessing around a hydraulic line or existing electrical wire and ensure that

harnessing will not get pinched when you fold the booms up. Secure all harnessing to the

implement using cable ties.

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 12 of 48

4. Installing PM4Xs

The PM4Xs control the system.

Number of Times Performed

One to three times per system (once per bin)

Required Tools and Equipment

•9/16” wrench and socket (for PM4X bolts)

•7/16” wrench and socket (for bracket mounting bolts)

Required Parts

Part name Part number Quantity

PM4X

153510-000046

3

PM4 Bracket

353070-000373

1

3/8” x 3-3/4” Bolt

356060-000029

6

1/4" x 1-1/4" Bolt

356060-000074

4

1/4" Lock Nut

356060-000075

8

1/4" Washer

356060-000173

4

Installation Location

Installed on the outside of the control box where the Raven controllers are located.

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 13 of 48

Installing PM4Xs

1. Remove the chute covers from the main control box.

2. Position the PM4Xs on the bracket as shown in the image below so that the serial

number is visible. It doesn’t matter which PM4 installed in which location.

NOTE: The text on the PM4X label will be upside down.

3. Thread a bolt through the sides of each unit and the mounting plate.

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 14 of 48

4. Remove the four corner screws and their hardware on the control box shown below.

Save the nuts for installing the bracket in the next step.

5. Thread the provided screws through the control box so that the threads face outwards,

then install in this order on each screw: existing nut, bracket, washer, new nut. Hand-

tighten a nut to secure the bracket.

NOTE: Do not install the bracket cover until the harnessing is complete in Section 8.

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 15 of 48

5. Installing Motor-Mounted Conveyor Drive Manifold

The motor-mounted conveyor drive manifold controls the rate of the conveyors and the flow rate

of material.

Number of Times Performed

Two or four times per system (twice for one bin system, four times for two bin system)

Required Tools and Equipment

•15/16” wrench (for hydraulic fitting)

•7/8” wrench (for hydraulic fitting)

•Pick, breaker bar, and penetrating fluid (optional for uninstalling existing manifold)

•M13 socket

•Torque wrench

Part name Part number Quantity

Left motor-mounted conveyor drive manifold

353070-000345

2

Right motor-mounted conveyor drive manifold

353070-000346

2

Mounting Bolts

Shipped with manifold

8

O-rings

Shipped with manifold

2

Installation Location

Installed on the back right and back left side of the floater where the factory bypass manifolds

are located.

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 16 of 48

5.1. Removing Existing Manifold

1. Make note of which hydraulic line connects into each fitting of the existing bypass

manifolds. Disconnect the two hydraulic lines and plug the lines.

2. Uninstall the four mounting bolts from the existing bypass manifolds and remove the

manifolds and the o-rings behind them.

NOTE: You may need to use a breaker bar, penetrating fluid, or paint might need to be

scraped off of the mounting bolt heads in order to remove them.

5.2. Installing Engage® SpreadControl Manifolds

Identify the left manifold and the right manifold using the pictures below.

Left manifold

(hose on top)

Right manifold

(hose on bottom)

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 17 of 48

Installing Left Manifolds

1. Install a new o-ring in the area that you removed the old one, then position the manifolds

as shown in the image above. Make sure that the o-ring between the manifold and

conveyor drive is properly seated.

2. Secure each manifold to the conveyor drive using the 4 bolts provided with the manifold.

Torque in a star pattern to 22 ft-lbs.

3. Re-connect the two hydraulic lines to each manifold’s top hose extension and right side

fitting.

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 18 of 48

Installing Right Manifolds

1. Install a new o-ring in the area that you removed the old one, then position the manifolds

as shown in the image above. Make sure that the o-ring between the manifold and

conveyor drive is properly seated.

2. Secure each manifold to the conveyor drive using the 4 bolts provided with the manifold.

Torque in a star pattern to 22 ft-lbs.

3. Re-connect the two hydraulic lines to each manifold’s bottom fitting and left side fitting.

4. Check the seal to make sure that there are no leaks.

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 19 of 48

6. Installing Funnel Boxes

CAUTION:

The Engage® SpreadControl funnel box is heavy. Use proper precautions

such as steel toe boots and gloves. Lifting and installing the

box may require two

people.

The Engage SpreadControl funnel boxes open and close individual sections to control the flow

of product on each side of the floater.

Number of Times Performed

Twice per system

Required Tools and Equipment

•Pliers

•Dry cloth

Required Parts

Part name Part number Quantity

Right funnel box

153510-000141

1

Left funnel box

153510-000144

1

Dielectric grease

350550-000006

varies

Actuator

353070-000309

2

Actuator pin

353070-000311

4

Zip ties

356070-000062

100

Installation Location

Replaces the factory funnel boxes in the back of the floater.

Engage® SpreadControl Installation Manual

600840-000060, rev. 1.2 Page 20 of 48

6.1. Removing Factory Funnel Boxes

Undo the latch on the existing funnel boxes. Pull the boxes out.

6.2. Installing the Funnel Box Actuators

1. Apply dielectric grease on the two actuator connectors.

2. Install zip ties around the cables and the actuator so that the cables stay in the grooves

on the actuator.

3. Unscrew the four thumb screws from the cover and remove the cover.

Other manuals for ENGAGE SPREADCONTROL

1

Table of contents

Other IntelligentAg Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Unimec

Unimec FG 33-06 Operating, maintenance, spare parts manual

Zipper Mowers

Zipper Mowers CLIPPER II instruction manual

Modern

Modern 003-7445 Operator's manual

agri supply

agri supply 72508 Operation and parts manual

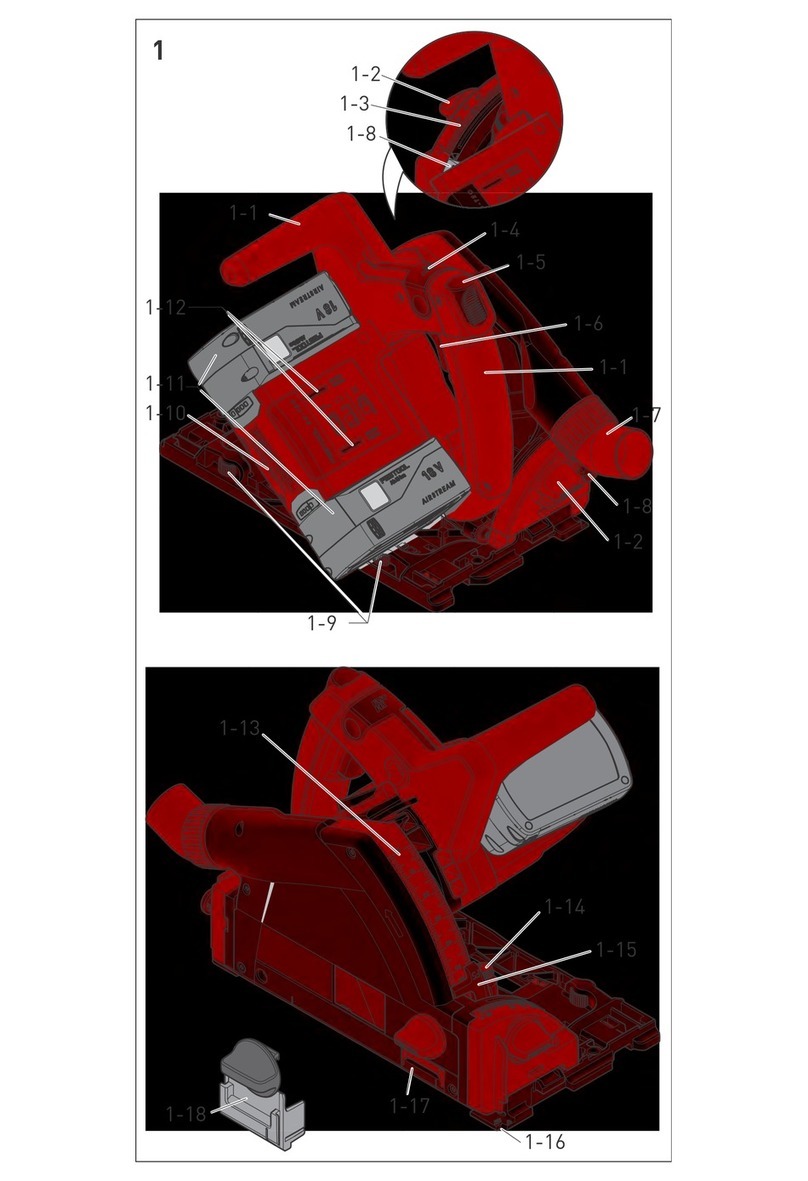

Festool

Festool TSC 55 REB Original operating manual

Land Pride

Land Pride RB3772 Operator's manual

AMVAC

AMVAC SmartBox Parts and Operator's Manual

LOFTNESS

LOFTNESS GrainLogix GBU 12 Owner's manual and parts book

Amazone

Amazone TL 3000 instruction manual

WIL-RICH

WIL-RICH 5810 Assembly manual

Tar River Implements

Tar River Implements RR-248 Operator's manual

LOFTNESS

LOFTNESS Draper Windrower Shredder 30 Owner's manual and parts book