FASTERHOLT FM4550 Installer manual

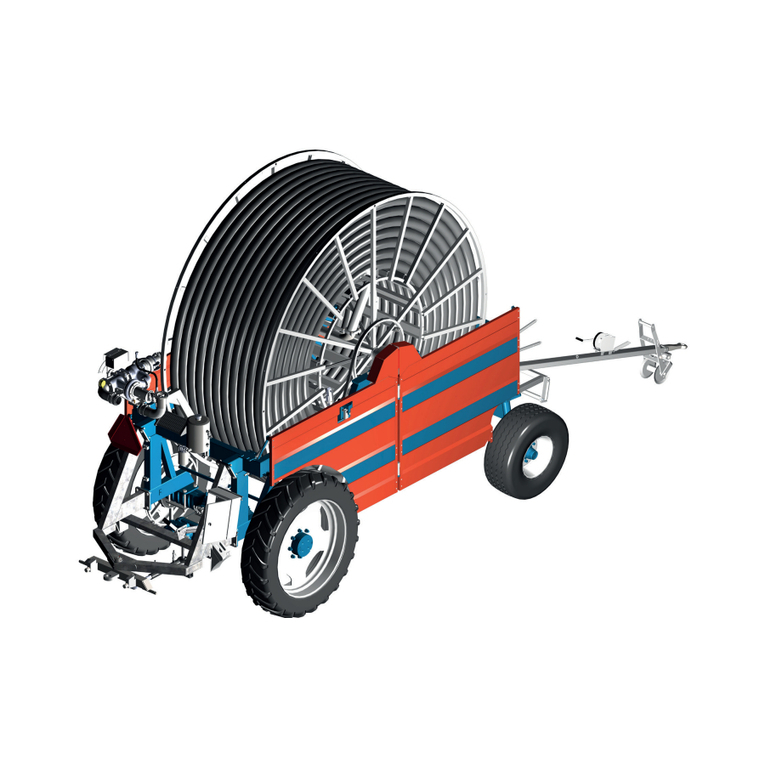

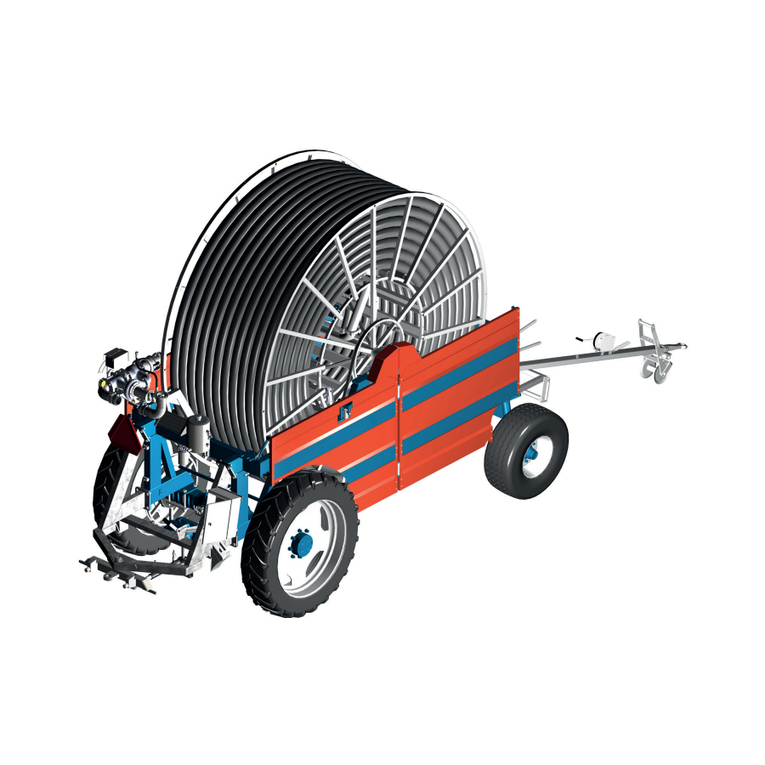

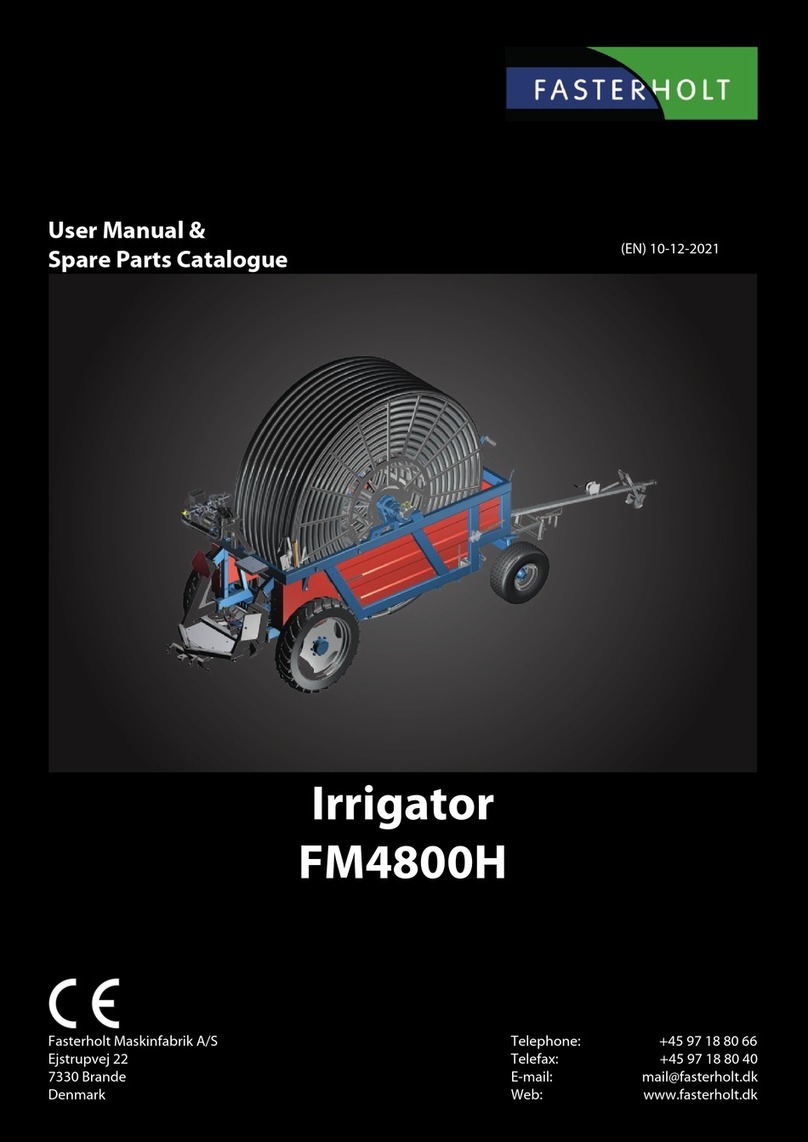

Irrigator

FM4550 EN

Telephone: +45 97 18 80 66

Telefax: +45 97 18 80 40

Email: [email protected]

Web: www.fasterholt.dk

(EN) 21-04-2021

User Manual &

Spare Parts Catalogue

Fasterholt Maskinfabrik A/S

Ejstrupvej 22

DK-7330 Brande

Denmark

2

Contents

Declaration of Conformity 3

General safety 4

Operating instructions for Fasterholt FM 4550 4

Product labelling 5

Symbols 5

Operating instructions 7

Starting your irrigator 7

Preparing the machine for irrigation 7

Preparing the machine after irrigation 8

Maintenance 8

Preparation for winter 8

Faults on the Irrigator 9

Setting the gun 9

Technical data 10

Nelson SR 150 11

Spare parts 32

Drum 32

Turbine installation 34

Turbine 36

Rear drawbar 44

Parts on rear drawbar 46

Hydraulics 48

Front axle and drawbar 50

Front axle 52

Cross track shaft 54

Rear axle assembly 58

Flat gear 62

Rear axle assembly parts 64

Shields 66

Parts on frames 68

Sensor 72

Turbine for drum 74

Stop bar 78

Gun 80

Optional equipment 85

3

Declaration of Conformity

EEC Declaration of conformity

Fasterholt Maskinfabrik A/S

CVR:

58 83 28 12

TEL:

+45 97 18 80 66

FAX:

+45 97 18 80 40

E‑Mail:

mail@fasterholt.dk

Manufacture (name and

address):

Adresse: Ejstrupvej 22,

Fasterholt

Ort: 7330 Brande

Country: Denmark

Web: www.fasterholt.dk

Hereby is certified that the following

product:

Description, ID/mark, type:

Serial No. if any:

Notified body if any:

EEC-type certificate if any:

Harmonised standards if any:

EN 908:1999+A1:2009.

DS/EN/ISO 12100:2011.

DS/EN/ISO 14120:2015.

Is made according to the announcement no.693 of 10. Jun 2013 that implements the

DIRECTIV 2006/42/EC.

Name, title and signature of manufacture:

Date Signature

Irrigator FM 4550

4

General safety

!!! Important !!!!!! Important !!!

READ THIS MANUAL

BEFORE USING YOUR IRRIGATOR !!

Your new Fasterholt Irrigator is a Danish built machine, but even the

best machines only deliver top results when they are properly used

and maintained.

To ensure that the machine complies with the EU Machinery

well or a watercourse.

―It is forbidden to stand on the machine during irrigation

and transport

.

―The guards are fitted for your own safety - please leave

them in place

―Remember to tighten the wheel bolts

―When starting the machine on falling ground, you must

be VERY careful not to disconnect the tractor from

the machine until the machine has been put into gear,

otherwise the machine may run away.

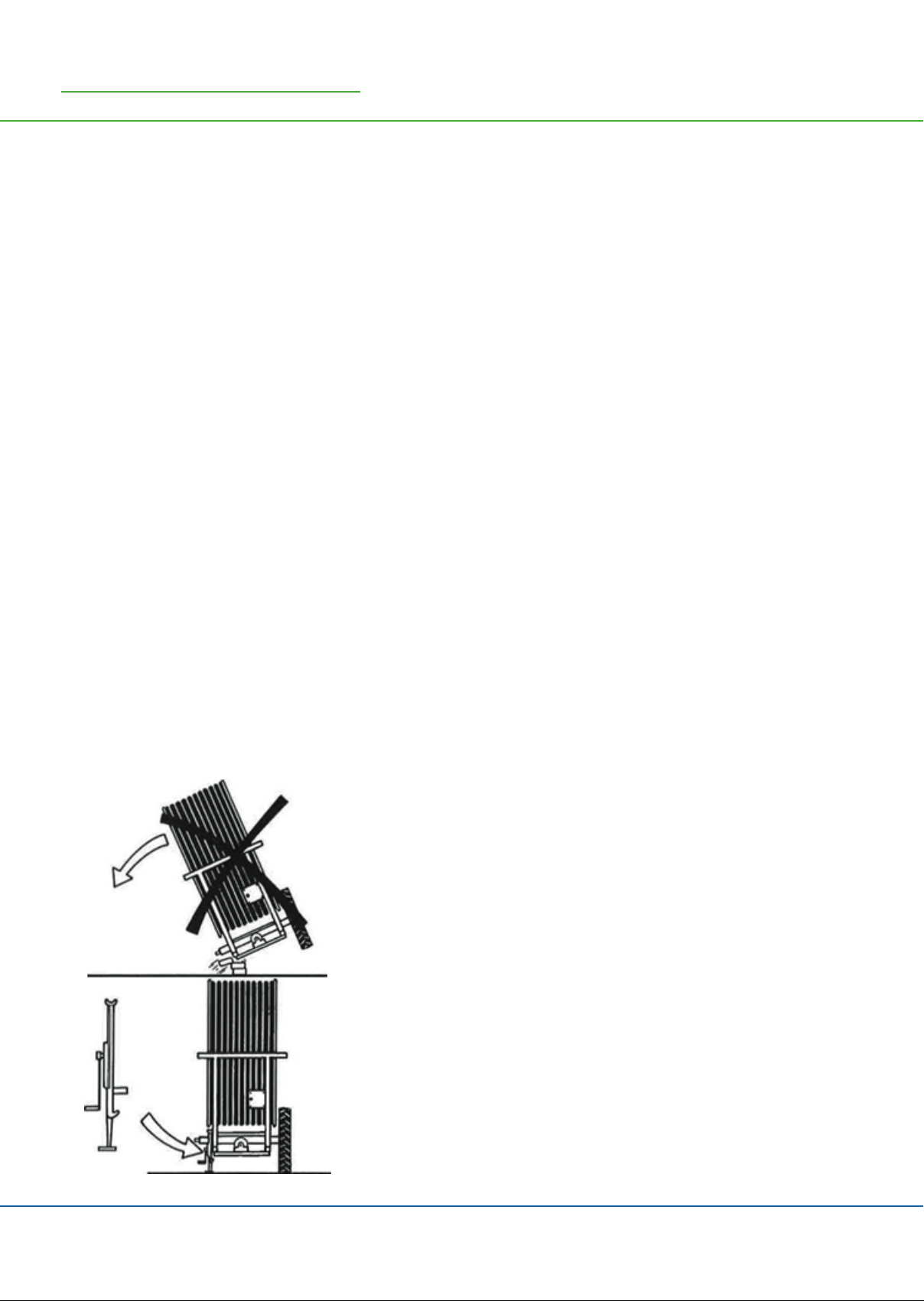

―If a rear wheel is removed, THE MACHINE MUST BE

JACKED UP AND VERY STABLE, because if it overturns,

it will fall completely on its side.

WARNING !!WARNING !!

―-

―

―The gun must face out to the side when unwinding the machine.

―

― against contact with overhead power lines with the

―

―

―mounted by

the rear wheels

― Avoid welding in the paint layer! Before welding,

remove all paint from the welding area

―

―Hydraulic oil can be harmful to health:

―

―

―

―

―

―

place indoors in a fully charged state.

―

―

―

―

immediately with water. If acid comes into contact with eyes,

-

ately.

―

-

diately.

―

―Disposal of oil spills:

―If oil spills are found, they should be cleaned up immediately

with rags or oil absorbent powder.

―Spilled products, as well as rags and powder used for oil spills,

must be stored in sealed metal containers and delivered to the

―

must be disposed of at an approved recycling site.

If the machine is to be moved via a public road, the machine must

5

Product labelling

Symbols

The following symbols are used in this product and the following documentation.

WARNING Indicates a potentially hazardous situation. Failure to avoid the situation may result in

death or serious injury.

LUBRICATION Indicates lubrication is required as per the service description

SERVICE WARNING Indicates a service hazard

SMØRING

Str: 100x45 mm

HUSK efterspænding

af hjulbolte

Str: 69x20 mm

6

7

Operating instructions

Starting your irrigator

machine is at the crop to be irrigated, disconnect the tractor from the

front drawbar. Connect the tractor to the rear drawbar. -

-

connector in the female connector for the tractor lights. The machine

then winds up in the crop and stops.

-

-

bar over the hose and release the safety stop so the hose reel runs on

the hose .

During transport

Ground spike

If you do not lay the hose straight out, be to ensure that

.

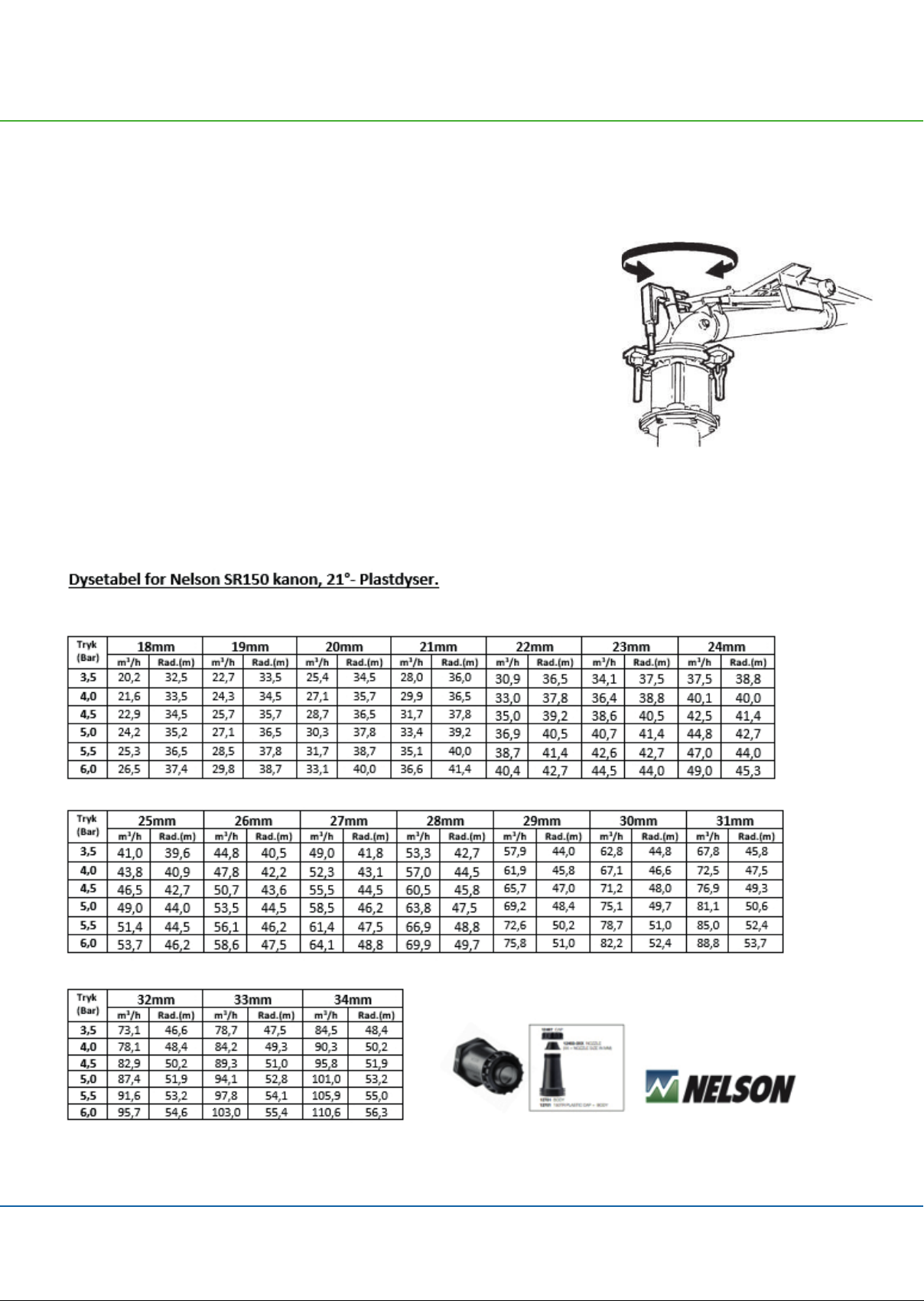

Preparing the machine for irrigation

Engage the pawl.

-

8

-

disengage the gear and raise the drawbar at the front before

Remember to close the decoupling valve

REMEMBER to connect machines with coupling levers

to move at is set in Program Rain. You do not have to select a

Preparing the machine after irrigation

Maintenance

Lubricate the steering, roller chain for hose guides, roller chain for forward

the machine by the front control cylinder. This is how to adjust the drawbars

full power and extend its useful life.

Preparation for winter

9

-

Front wheel hubs, front spindle, hose guides, bearings on hose

guides, wheels.

years.

Lubricate the steering, roller chain for hose guides, roller chain for

-

lent grease.

Guide pins should be replaced every year.

Faults on the Irrigator

a.

b.

c.

d.

e.

f.

g.

h.

a. The hose guide needs to be adjusted:

To adjust the guide, remove the chain from the hose guide to the cross

hose again.

b. The guide pin is worn and needs to be replaced.

c.

move the hole plate at the end of the cable. If it cannot be moved

any further, the cable needs to be shortened.

3. Forced steering is not lined up and seems springy.

a.

out, leaving air in the system.

b.

Setting the gun

on the type of gun and the water volume. For high water volumes, the

pressure should be higher.

10

Technical data

Capacity up to 55m

11

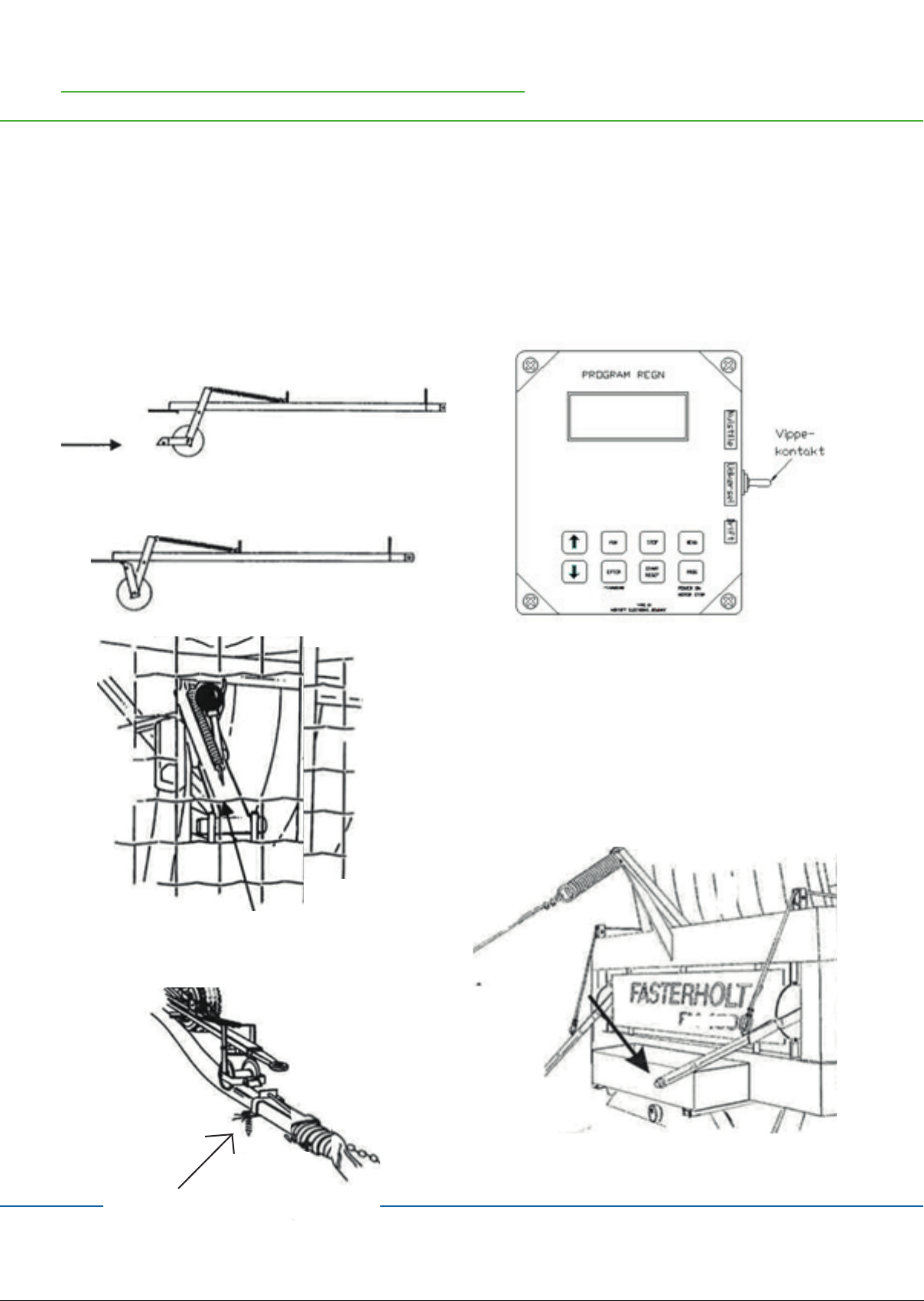

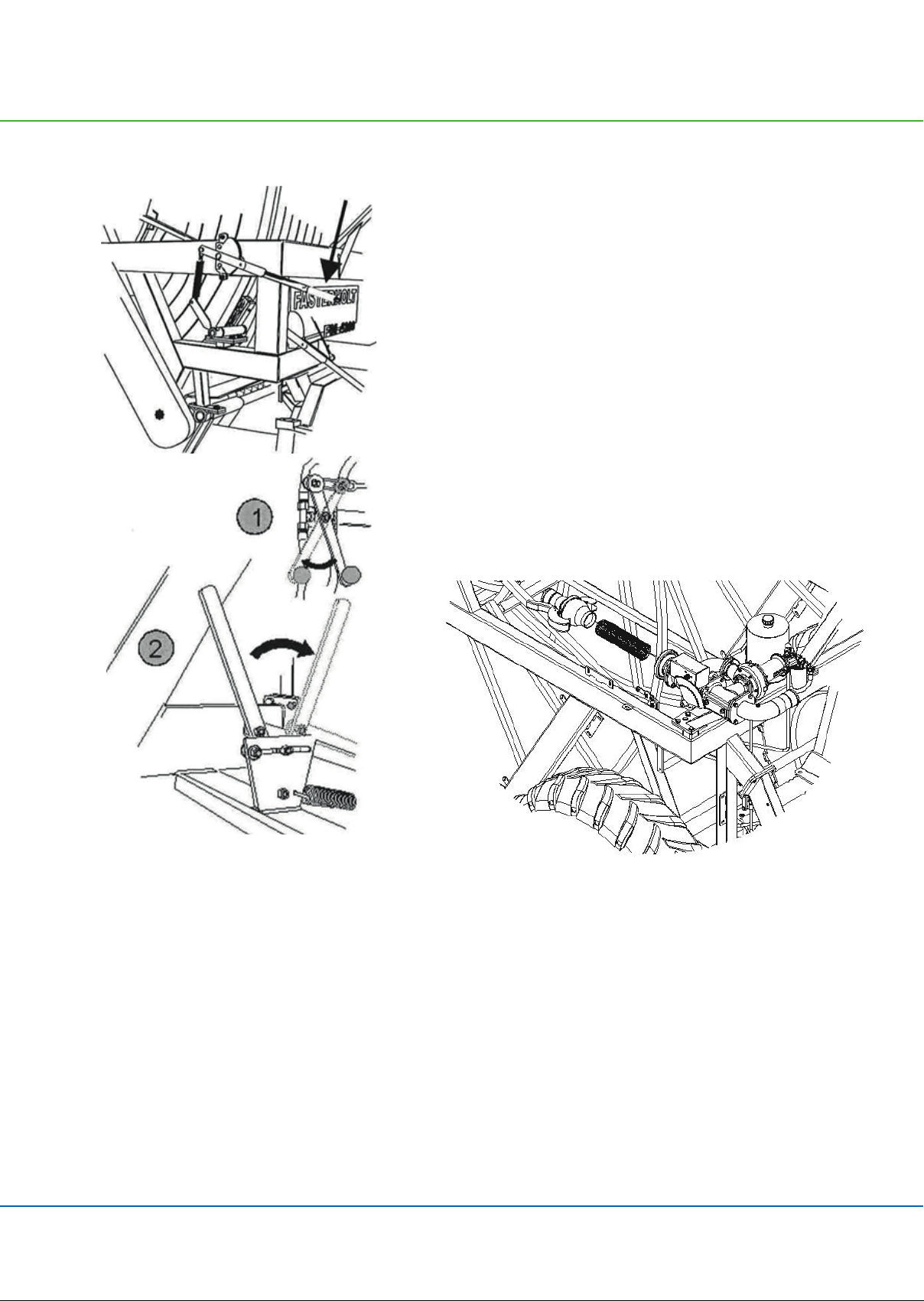

Nelson SR 150

Factory-adjusted to Danish conditions and ready to use after the following three steps:

1.

shown in the table below.

3.

ADJUSTMENTADJUSTMENT

The only thing you can adjust is the counterweight on the drive arm. By moving

the counterweight forward, the gun will slowly irrigate from side to side. If you

WARNING: DO NOT ADJUST WHEN THE GUN IS IRRIGATING !! DANGER........: HIGH WATER

PRESSURE – STAY CLEAR !!

12

13

-

ready to be moved to a new lane.

14

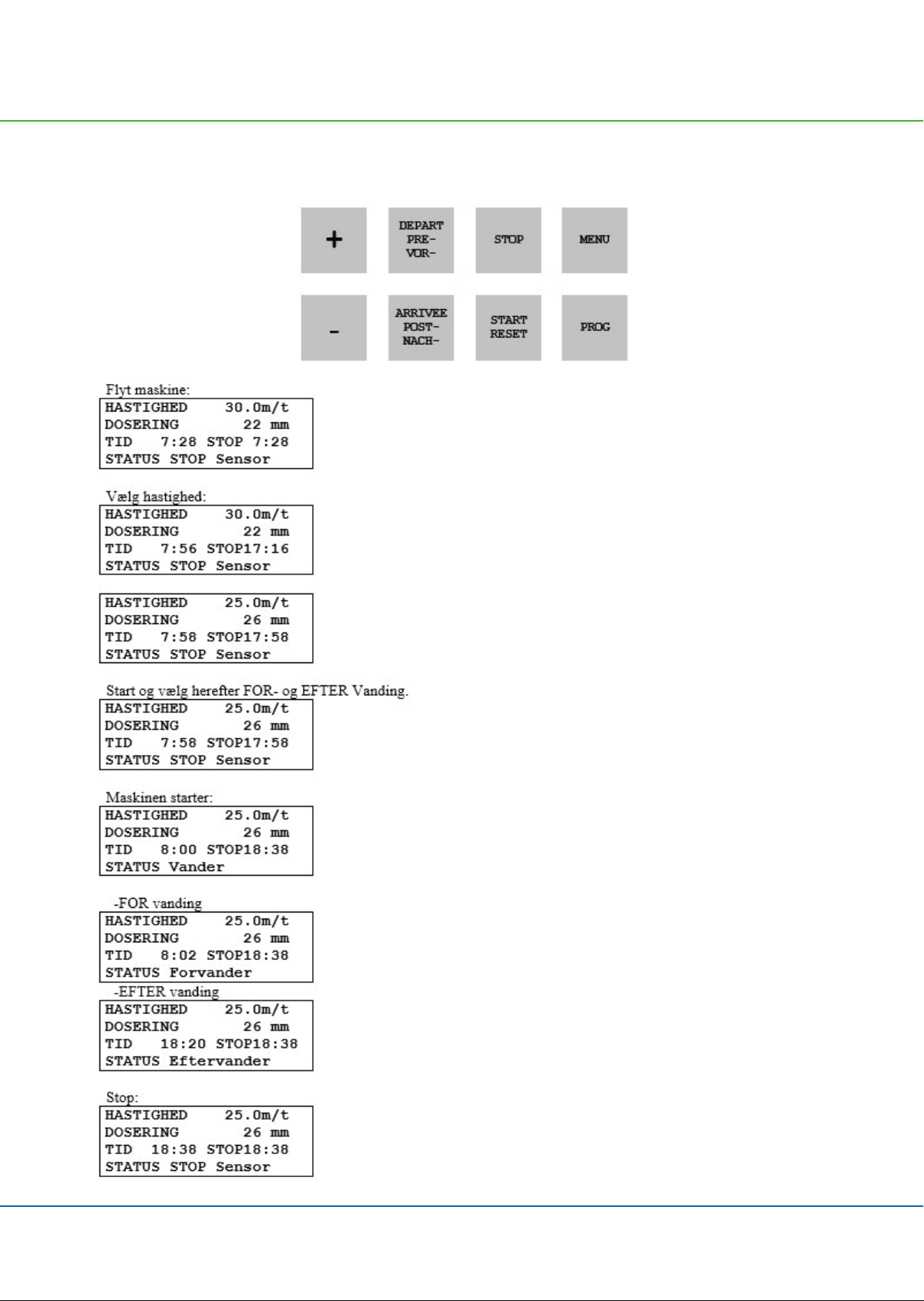

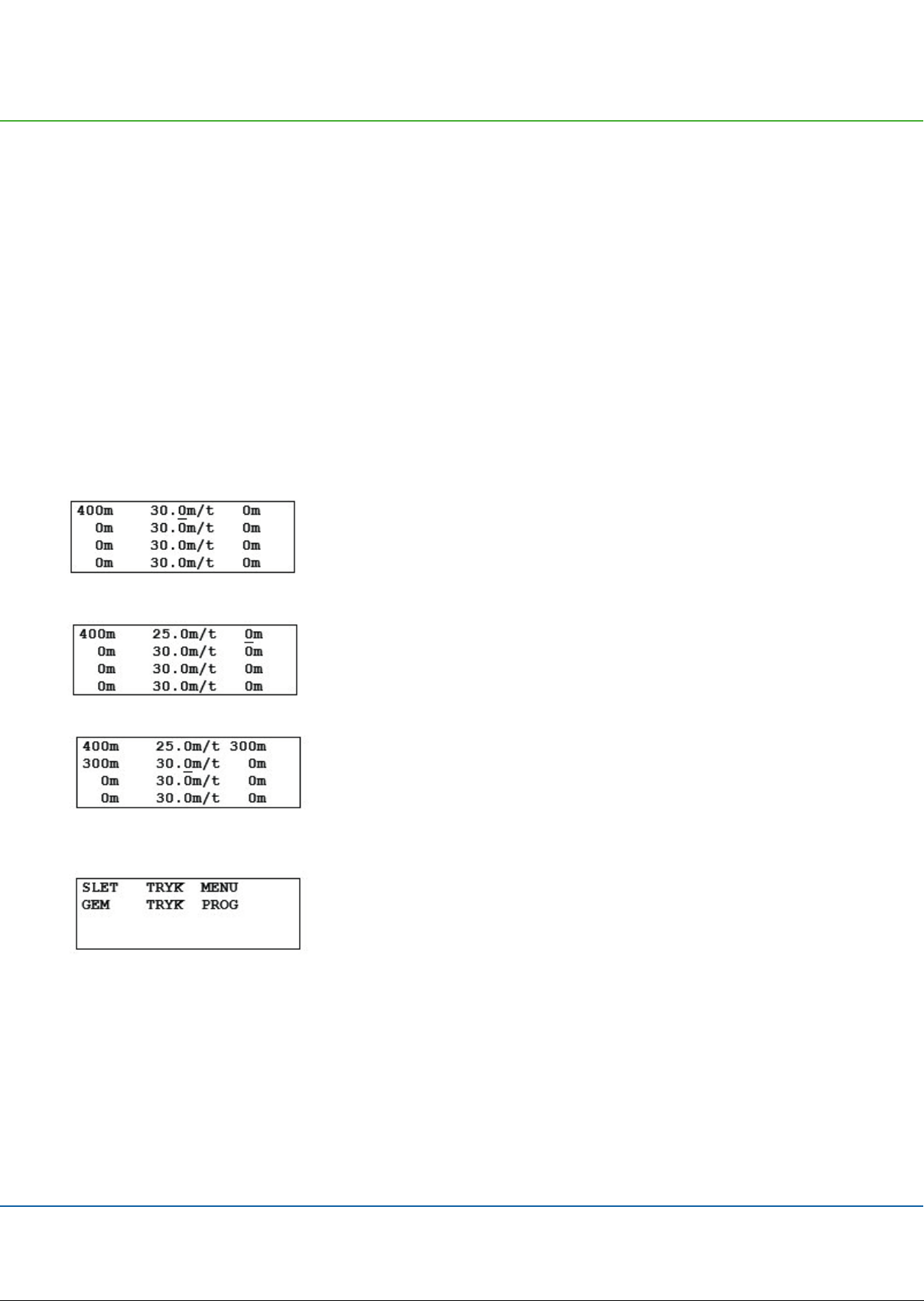

Standard display

Press the

Press the

Press the

Press the

Press the

When characters

15

Standard display

SPEED

ZONE

DOSE

TIME

STOP

STATUS

<Stop sensor >

< >

< >

< >

< >

If the display shows:

DISTANCE

BATTERY

PRE

volts.

or

16

except for pressure display, are the same as for digital pressure sensors. There are constants for the pressure sensor type. Similarly, set point

and hysteresis can be selected for each machine.

is lit.

1. Reset distance.

3. Stop pulses to the regulator motor.

For the

17

CURR. SPEED

START

Press the

See later chapter for details.

18

SIGNAL GSM signal strength.

A: First number on

See GSM chapter for details.

.

Press the -

sor is not in place, only the main valve can be opened, which then immediately closes again. Used to relieve pressure before removing charge

hose from hydrant.

First press the

-

elapsed, the main valve closes. When the -

Program Rain has

immediately based on the new speed.

19

The

will stop when it reaches the selected distance.

press the

If

If

20

STATUS

EMERGENCY:

RUNNING:

LOW PRESSURE:

STARTING:

START REMOTE:

START DELAY:

START PRESSURE:

START DENIED:

STOP USER:

STOP REMOTE:

STOP SENSOR:

STOP DISTANCE:

STOP DELAY:

STOP DENIED:

SUPERVISION TIME:

FORCE LOW PRES:

PRE IRRIGATION:

POST IRRIGATION:

Status messages in display

Machine has not been started, anyway speed pulses is received and it is trying to maintain

the speed requested.

The machine is irrigating, and everything is working properly.

Water pressure is below pressure switch treshold. Machine acts depending on Machine

data.

Operator has pressed START key, and start sequens is in process.

Machine is starting due to an SMS.

Machine is waiting for start delay to elapse. (See menu 4).

Machine has started due to pressure rise. Machine is using pressure level, to start 2’nd

machine on string.

Operator is holding STOP key to prevent PRESSURE and REMOTE start.

Machine has stopped due to operator STOP.

Machine has stopped due to an SMS.

Machine has reached end and is stopped by STOP SENSOR.

Machine has reached distance for stop. (See constant for early stop).

Machine has reached stop but waits nn Seconds to proceed stop sequence.

Operator is pressing START key, preventing REMOTE stop.

Machine has stopped due to supervision time is elapsed. Machine has not moved in nn

minutes. (See constant for supervision time).

Machine opens valve, to force pressure drop, to stop main pumpe. After 2 minutes, valve

closes to prevent draining of pipes.

Machine is performing pre irrigation

Machine is performing post irrigation

Table of contents

Other FASTERHOLT Farm Equipment manuals