FASTERHOLT GT12 Installer manual

Irrigator

GT12 ENG

Telephone: +45 97 18 80 66

Telefax: +45 97 18 80 40

Email: [email protected]

Web: www.fasterholt.dk

(EN) 21-04-2021

User Manual &

Spare Parts Catalogue

Fasterholt Maskinfabrik A/S

Ejstrupvej 22

DK-7330 Brande

Denmark

2

Contents

Declaration of Conformity 3

General safety 4

Operating Instructions & Information 4

Product labelling 5

Symbols used in this product 5

Intended use 6

Nelson SR150 6

Operating instructions 7

Starting your irrigator 7

Setting up the Gun trailer 10

Start-up 11

Maintenance 12

Preparation for winter 12

Troubleshooting table 14

Spare parts 36

Hose drum 38

Chassis 40

Gearbox 50

Chassis 54

Pendulum Gun trailer 58

Standard Gun trailer 68

3

Declaration of Conformity

EEC Declaration of conformity

Fasterholt Maskinfabrik A/S

CVR:

58 83 28 12

TEL:

+45 97 18 80 66

FAX:

+45 97 18 80 40

E‑Mail:

mail@fasterholt.dk

Manufacture (name and

address):

Adresse: Ejstrupvej 22,

Fasterholt

Ort: 7330 Brande

Country: Denmark

Web: www.fasterholt.dk

Hereby is certified that the following

product:

Description, ID/mark, type:

Serial No. if any:

Notified body if any:

EEC-type certificate if any:

Harmonised standards if any:

EN 908:1999+A1:2009.

DS/EN/ISO 12100:2011.

DS/EN/ISO 14120:2015.

Is made according to the announcement no.693 of 10. Jun 2013 that implements the

DIRECTIV 2006/42/EC.

Name, title and signature of manufacture:

Date

Signature

Irrigator GT 12

4

IMPORTANT!

Read this manual carefully before using

your irrigator!

Your new Fasterholt irrigator is a high quality,

Danish built machine, but even the best

machines only deliver top results when they are

properly handled and maintained.

To ensure that the machine complies with the

EU Machinery Directive, only original spare

parts may be used. Otherwise, compliance will

be lost and safety will be entirely at your own

risk.

The irrigator is only suitable for irrigation

with clean water from a drilled well or a

watercourse.

We must point out that any damage caused

by incorrect operation and/or negligence

is not covered by the warranty. Fasterholt

Maskinfabrik A/S only guarantees new

machines sold through an authorised Fasterholt

dealer. Any modifi cations made to the design

of the irrigator shall exclude Fasterholt

Maskinfabrik A/S of any liability and shall void

the warranty.

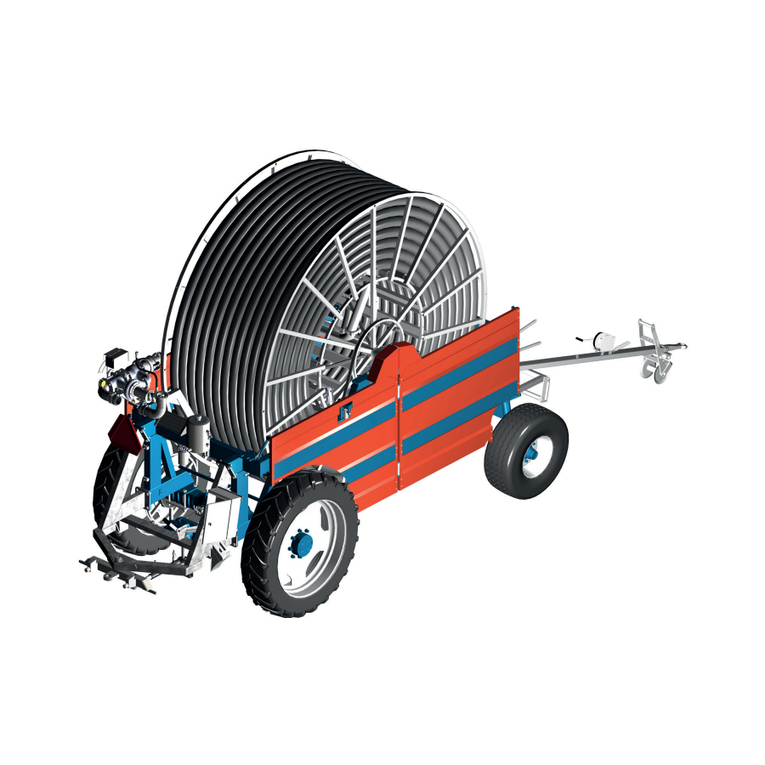

The Fasterholt FM GT12 is a stationary type

irrigator with a hose drum (rewind machine).

The hose drum is mounted on a turntable and

equipped with a gun trailer lift, so the unwind

direction can be changed without having to

move the machine. A turbine is used to power

the machine and rewind stops automatically

when the gun trailer reaches the machine.

The machine is available with an underpressure

stop or an overpressure stop. With the

overpressure stop function, make sure that the

pump is either switched off via a pressostat

or can dispose of water by other means

when the machine stops irrigation. With the

underpressure stop function, the pump must be

stopped via a pressostat.

The machine must be supplied with a maximum

pump pressure of 12 bar. The recommended

pressure 7-9 bar.

Safety instructions/warnings

If the machine is to be moved via a public

road, the machine must fi rst be emptied of

water.

As this machine is used for fi eld irrigation

involving high water pressure, there is

a risk of injury if the machine is used

inappropriately. The warnings and safety

instructions given here must therefore be

respected and followed precisely.

- It is forbidden to stand on the machine

during irrigation and transport. (risk of

fatal injury)

- The guards are fi tted for your own safety -

please leave them in place

- Remember to tighten the wheel bolts

- During transport on uneven roads/fi elds,

move VERY carefully according to the

conditions.

- DANGER! Avoid welding in the paint layer!

Before welding, remove all paint from the

welding area

- Only one person (the operator) should

be in the vicinity of the machine during

transport, setup and dismantling

WARNING: If the machine is

stopped during rewind, the hose is

in tension and the drum may run

backwards when the clutch lever is

released.

Operating Instructions & Information

General safety

5

The following symbols are used in this product and the following documentation.

WARNING Indicates a potentially dangerous situation which, if not

prevented, could result in death or serious injury.

LUBRICATION Indicates lubrication is required as per the service

description

SERVICE WARNING Indicates a service hazard

Symbols used in this product

SMØRING

Str: 100x45 mm

HUSK efterspænding

af hjulbolte

Str: 69x20 mm

Product labelling

6

1. Select the nozzle size that best suits your application and install it. Performance data

for the diff erent sizes are shown in the table below.

2. Adjust the stop on the part circle to obtain the desired irrigation angle.

Adjustment:

The only thing you can adjust is the counterweight on the drive arm. By moving the

counterweight forward, the gun will slowly irrigate from side to side. If you move the

counterweight back, the gun will irrigate quickly. If it does not irrigate quickly enough, you

can remove the brake springs in pairs. (Contact the service department).

WARNING: DO NOT ADJUST WHEN THE GUN IS IRRIGATING!

HIGH WATER PRESSURE – STAY CLEAR!

Nelson SR150

Intended use

7

1. Position the machine horizontally in line with the unwind direction.

2. The ground must be level for the fi rst 10 m of the unwind direction.

3. Connect the two hydraulic hoses to the tractor.

4. Rotate the drum in the desired direction.

Rear

support leg

Front

support leg

For hydraulic

turntable

It is important that the machine is level.

This can be adjusted with the support legs

at the front and rear.

Operating instructions

Starting your irrigator

8

5. Lower the two hydraulic support legs to the ground so they are fi rmly engaged. If

the ground is very hard, it may be necessary to move them up and down a few times.

(Warning!! The support legs must not raise the wheels of the machine from the

ground.)

6. The gun trailer lowers automatically when the support legs are lowered.

7. If the machine is equipped with a high pressure/low pressure function, ALWAYS REMEMBER

to press start before fl icking the toggle switch to the desired stop function.

Høj tryk Lav tryk

Lever in this position when

turning the machine.

Lock for fth wheel.

Used during transport

and irrigation.

Mark indicates

chassis position

for road transport.

9

Move the lever on the left hand side to unwind. See the photo below.

Open the slide valve on the gun trailer to allow the water to fl ow freely from the hose

during unwinding. It is important that the feed hose is not connected to the machine until

the hose is fully unwound.

For irrigation, move the lever

in the direction of the arrow.

To unwind, move the clutch release

lever in the direction of the arrow.

Gear selector

Before irrigation, move

the lever in the direction

of the arrow.

To unwind, press the

lever in the direction

of the arrow.

10

REMEMBER when unwinding the hose to ensure that the gun trailer lift is adjusted

correctly. And remember to make sure the machine is standing on fi rm ground, otherwise

damage may occur to the gun trailer lift and machine.

Connect the gun trailer to the tractor and start unwinding the hose. The unwinding speed

must not exceed 3 km/h.

If the water has not started to fl ow out of the machine after about 10 metres, it may be

benefi cial to stop unwinding for a moment and start again.

It is important that the gun trailer is unwound in line with the machine for the fi rst 10

metres of unwinding, as excessive movements may prevent the gun trailer from entering

the gun trailer lift.

WARNING: Never unwind the hose too far – always ensure that there are at

least 2 hose turns left on the drum, otherwise the hose coupling will be damaged

when the hose is rewound. Driving on hilly terrain may therefore require an

assistant or a warning lamp, which can be purchased separately.

WARNING: If the hose temperature exceeds 30 degrees, e.g. due to the machine

being in sunlight, cool it by ushing water through the hose before unwinding

it, to avoid damage to the hose. Unwind the machine 2-5 metres to activate the

limit stop sensor. This to stop water from passing through.

When unwinding the hose, it is important to avoid suddenly braking/stopping the tractor,

as the hose may tangle on the drum. Instead, slow down gently and stop.

If the hose becomes loose on the drum during unwinding, adjust the drum brake. If the

hose is loose on the drum when fully unwound, tighten it with the PTO crank handle.

REMEMBER to remove the PTO crank handle after tightening. Never place the crank

handle on the machine's PTO input during unwinding or operation. Never release/put the

clutch lever in neutral position when the crank handle is on the machine's PTO input and

the hose is in tension.

When the hose is fully unwound, close the slide valve of the gun trailer again.

Setting up the Gun trailer

11

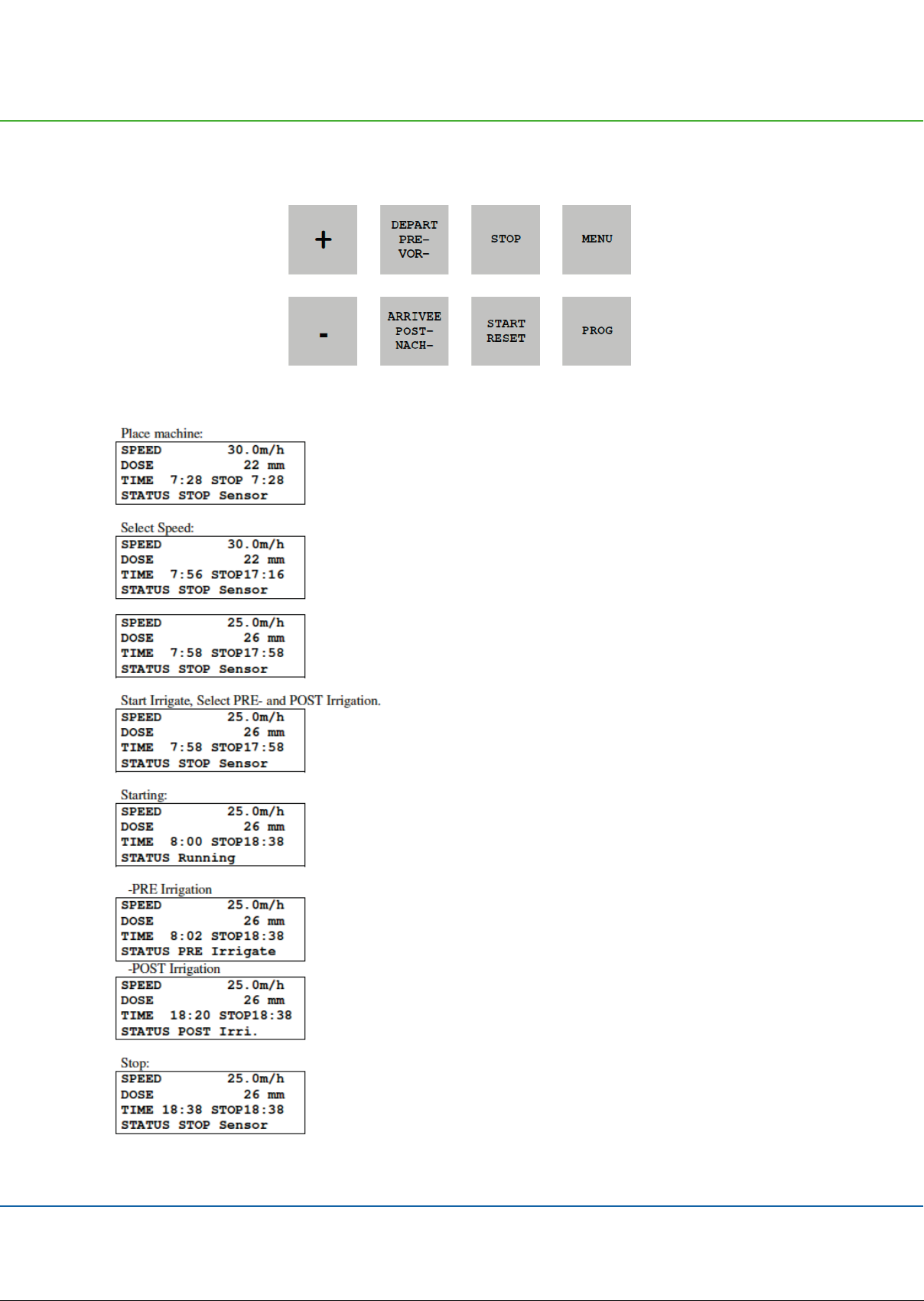

Gear Speed m/h

1 7 20

2 15 45

3 25 65

4 40 200

1. Enter the rewind speed on the computer using the arrow keys.

2. Select the gear according to the table below. (Table is also in the machine cabinet)

1. For pre-irrigation, press "PRE" (highlighted in display). For post-irrigation, press "POST"

(highlighted in display).

2. Connect the feed hose.

3. Press "START".

4. Open the hydrant and start the water supply pump. The water must not be fed too quickly

into the machine to prevent air in the machine, hose and pipe. This can cause pressure

surge and kickback in the system.

WARNING:

• If the hose is in tension when uncoupling, the drum can run back with great

force.

• All other adjustments to the machine, gun trailer and gun should only be made

when the machine is not in operation.

Automatic and manual stop

Rewind stops automatically when the gun trailer is wound back into the machine, thereby

aff ecting the stop bracket. The machine stops due to either overpressure or underpressure.

The machine can also be stopped either at the pump or by pressing "STOP" on the computer.

Emergency stop and safety stop

The safety cable ensures that the machine will stop in case of computer failure.

The machine is equipped with a rewind error bracket that stops rewind if the hose guide

should come out of alignment, causing the hose to tangle. The rewind error bracket will

activate the stop bracket when the reel comes off the edge of the drum.

REMEMBER when starting for the fi rst time, to check that the rewind error bracket and cable

are adjusted correctly.

Gun trailer and hose guide

The gun trailer can be adjusted with diff erent track widths. This is done by loosening the

locking bolts on the chassis and extending the legs to the desired track width.

If the gun trailer does not follow the same track during rewind as during unwind, loosen the

centre bolt on the steering wheel and move the wheel axle back and forth on one side by

turning the steering wheel.

The hose guide ensures that the hose is wound properly on the drum. If the hose does not

wind properly on the drum, the hose guide should be adjusted. The hose must be unwound

until there are two to three turns left on the drum. Remove the hose guide chains and adjust

the hose guide so the hose passing through the hose guide is against the hose already on the

drum. (Contact the service department at Fasterholt Maskinfabrik A/S)

Start-up

12

After winding for the fi rst time, you should:

1. Retighten the machine.

Weekly:

1. Lubricate the sliding bushing on the drum inlet pipe. Stop lubricating the sliding bushing in

the inlet bend of the hose drum when there is a slight increase in pressure in the grease

gun.

2. Lubricate the main bearing on the drum.

3. Lubricate the slide for the hose guide. The axle must never be dry.

4. Lubricate the fl oor reel for the hose guide.

5. Lubricate the wheels on the gun trailer.

6. Lubricate the turntable.

7. Grease the gear wheel on the drum.

Annually:

In addition to the above, the following should be performed annually:

1. Check the oil level in the reduction gear after every 200 hours of operation. If necessary,

top up with type 80/90 gear oil or equivalent.

2. Check the air pressure in the wheels.

On machine: 40psi (2.7 bar)

On gun trailer: 45psi (3.3 bar)

Before the frost sets in, prepare the machine for winter. Contact Fasterholt Maskinfabrik A/S

for a winter service inspection. This avoids unnecessary downtime during the season.

Preparation includes the following points:

1. Drain water from the machine and hose with compressed air. Open the slide valve on the

gun trailer. Note: Butterfl y valve MUST be open.

2. Grease the slide shafts on the hose guide.

3. Clean the gun and inject acid-free oil.

4. Check the air pressure in the wheels.

5. Lubricate all moving parts with anti-corrosion oil.

6. Remove the battery and store it fully charged in a dry, frost-free environment.

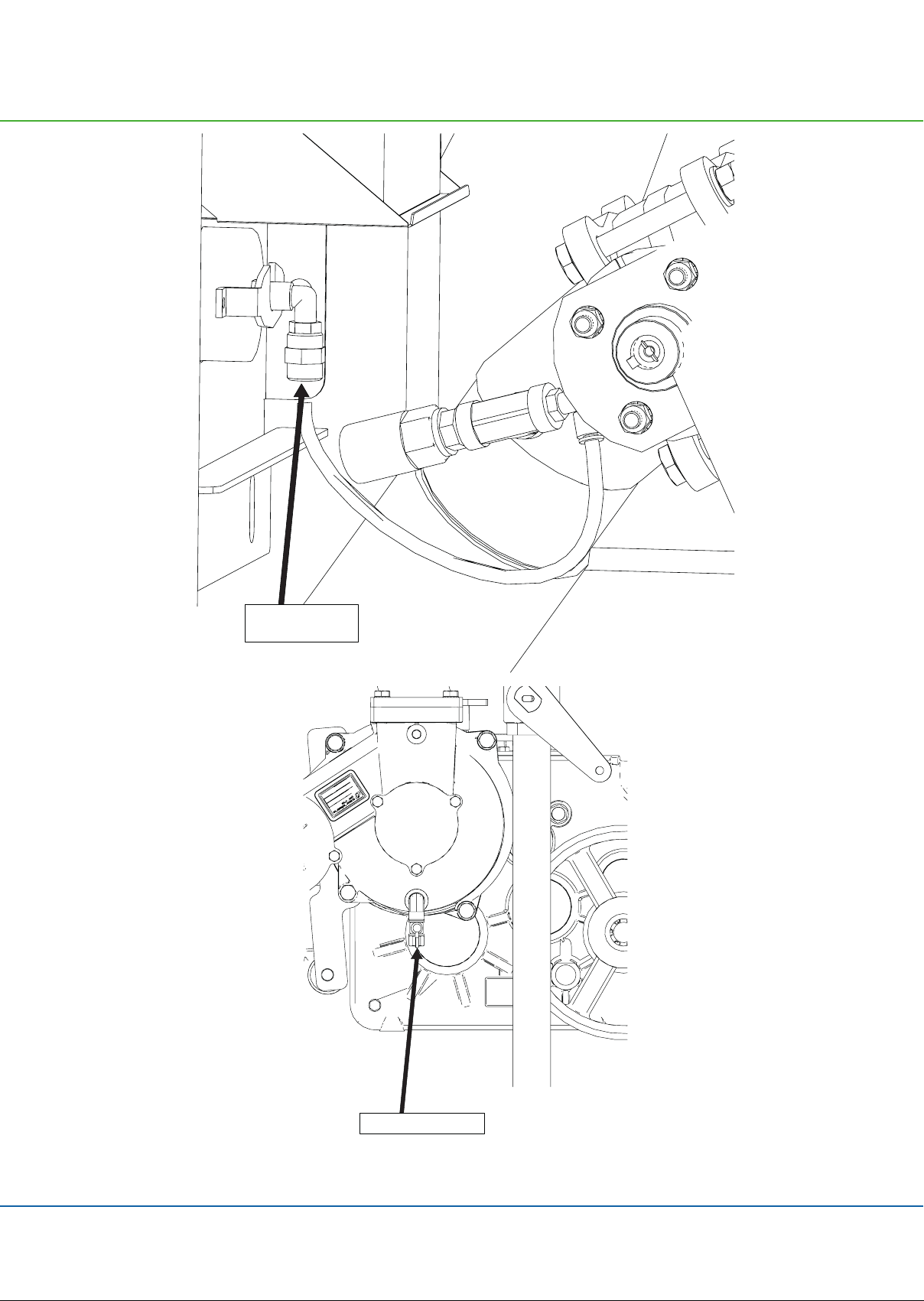

See the photos on the following page for frost protection.

Maintenance

Preparation for winter

13

Open the tap for frost protection.

Remove the hose for

frost protection.

14

Error Cause

Foreign object in turbine Remove front cover

and clean turbine.

Clutch lever not engaged Engage lever

Computer failure Check computer

3-way valve is stuck Check 3-way valve

Charge or replace

Stop sensor on stop

Adjust or replace

Fuse in computer Replace fuse

Control error Contact dealer or

Fasterholt Maskinfabrik A/S

Hose guide out of alignment Adjust the hose guide

Too much hose on drum Check hose length

Brake loose Adjust brake

Stops too quickly

when unwinding

Reduce speed

over a longer distance

Pressure too low Increase pressure or

switch to smaller nozzle

Sector guide damaged Replace/Repair stop trigger

Troubleshooting table

15

16

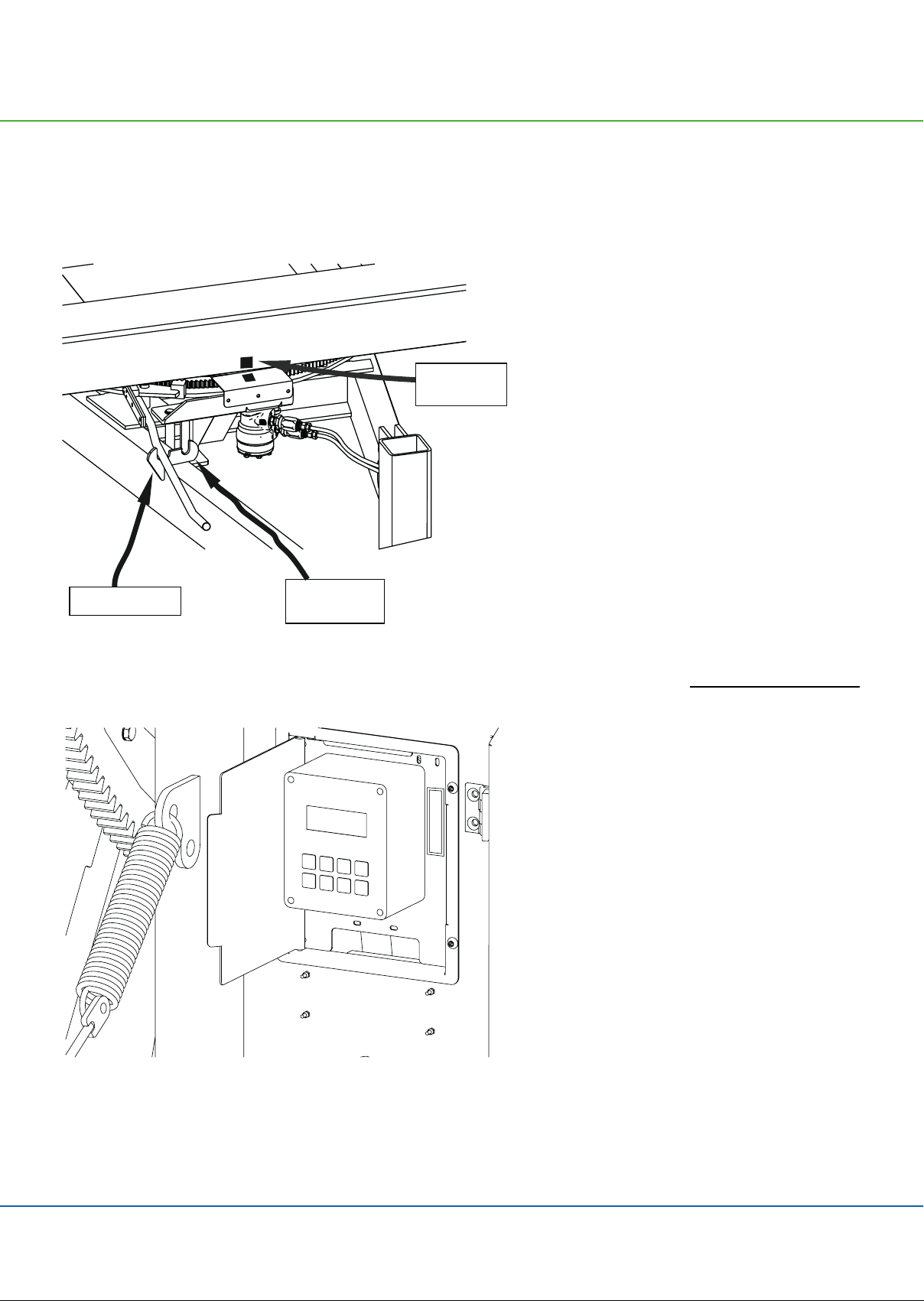

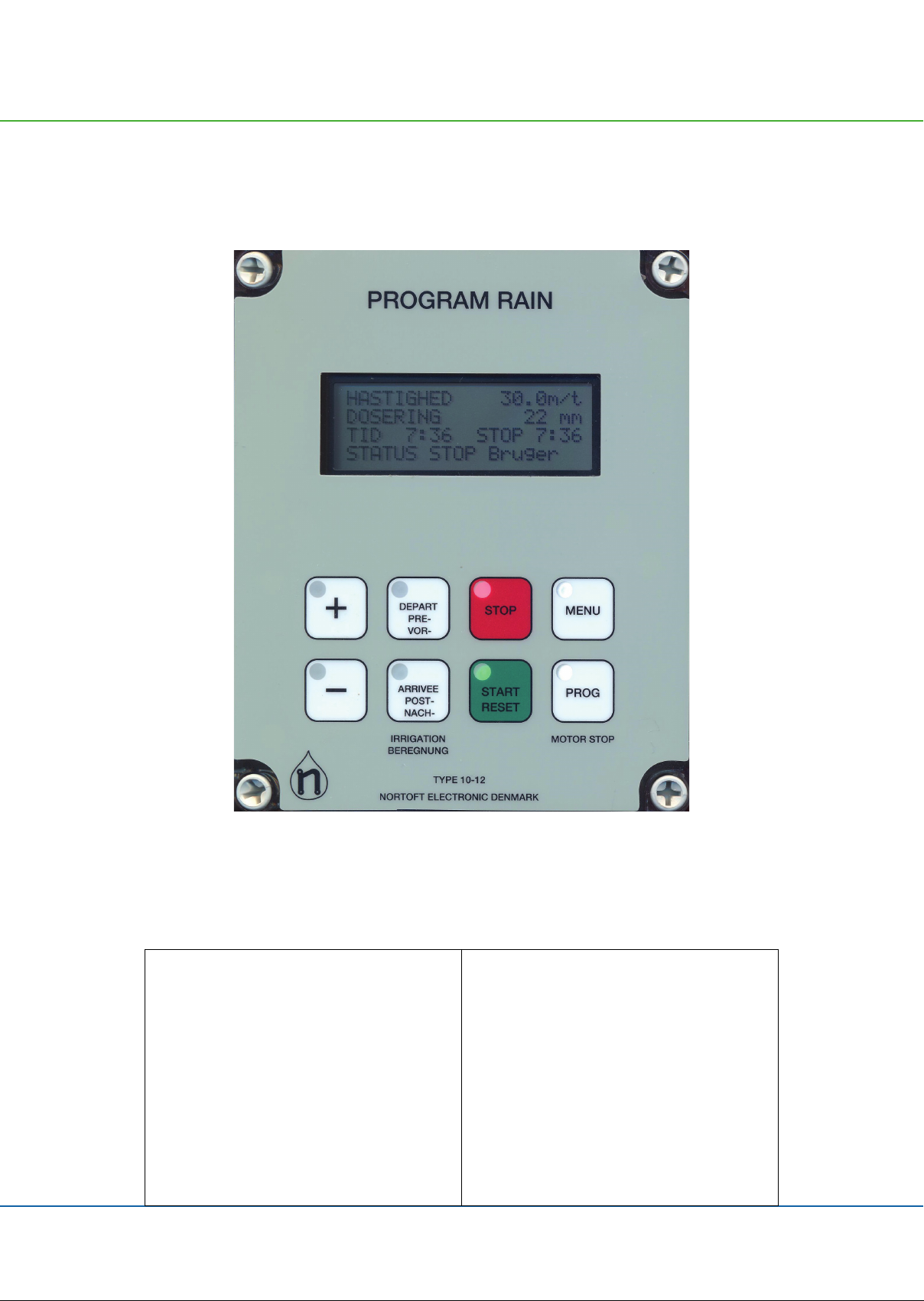

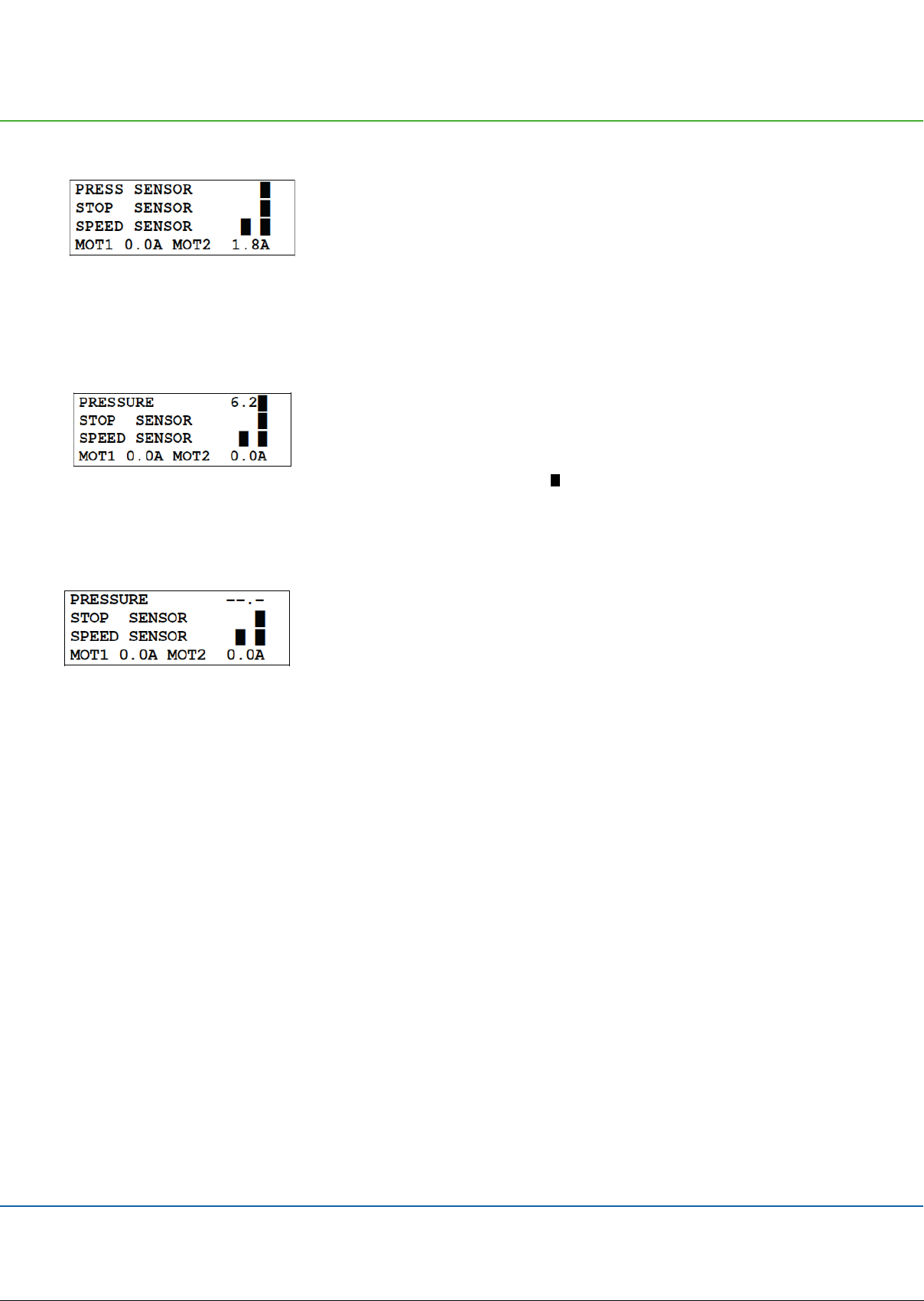

Speed regulator

Clock

Length of hose

Current speed

Charge regulator

Pressure sensor

Stop sensor

Speed sensor

Motor 2, stop motor

Slow start of turbine

Slow closing of inlet

Water volume + spreading width

GSM, SMS messages for remote control.

Analogue pressure sensor.

17

Pull hose out to end of the lane. ( ex 250 m )

later.

Press START to start. Press PRE and POST for pre- and post-

starts.

machine is now ready to be moved to a new lane.

18

Standard display

Press the

Press the

Press the

Press the

Press the

(Only if GSM is selected)

(Only if GSM is selected)

When

19

Standard display

SPEED

ZONE

DOSE

TIME

STOP

STATUS

The dose is calculated from the speed and constants and shows the current number of mm

PROG

PROG

<

<

<

<

<

LOW BATTERY

LOW BATTERY

be charged.

be charged.

BATTERY

PRE

POST

PROG

PROG

voltage is below 14.0 volts.

PRE-

PRE-

or

or

POST-

POST-

20

Shows that the pressure is high when block is lit.

The machine can only move when the pressure is high.

The machine can only move when the pressure is high.

If no

If no

�

�

�Shows that the magnet is aligned with the stop sensor when block is lit.

�

�

The machine can only start when the magnet is aligned with the stop sensor.

The machine can only start when the magnet is aligned with the stop sensor.

�

�

1.

1.

Reset distance.

Reset distance.

2.

2.

3.

3.

Stop pulses to the regulator motor.

Stop pulses to the regulator motor.

�For the speed sensor test, block is only lit when the magnet passes the sensor.

MOT1, MOT2

�Displays the current motor current. When the current exceeds 4.5 A, the motor stops.

�

�

�Shows pressure in [BAR] (00.0) or [PSI] (000). Pressure is high when is lit.

�

�

The machine can only move when the pressure is high.

The machine can only move when the pressure is high.

�

�

Table of contents

Other FASTERHOLT Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Horst

Horst Contour SHCF36 Operator's manual

HME

HME HM-W0061 Operator's manual

M K Martin Enterprise

M K Martin Enterprise Skid Steer Thirfty Cutter manual

HARRISTON INDUSTRIES

HARRISTON INDUSTRIES 93066 Operator's manual

Sumo

Sumo Seeder quick start guide

Spearhead

Spearhead TWIGA MINI Operator's instruction manual

Toro

Toro Z Master TURBO FORCE Z453 Operator's manual

SteelMax

SteelMax TLB6000 Operator's manual

Harvest TEC

Harvest TEC 493 Installation kit

MacDon

MacDon D65 installation instructions

MacDon

MacDon NEW HOLLAND D2 Series Operator's manual

Xeda International

Xeda International CEDAX ELECTROFOG EWV8 instruction manual