15

en

For your safety.

Read all safety warnings and all

instructions. Failure to follow the

warnings and instructions may result in electric shock,

fire and/or serious injury.

Save all warnings and instructions for future reference.

Do not use this pneumatic tool before you have

thoroughly read and completely understood this

Instruction Manual. The documents mentioned

should be kept for later use and enclosed with the pneu-

matic tool, should it be passed on or sold.

Please also observe the relevant national industrial safety

regulations.

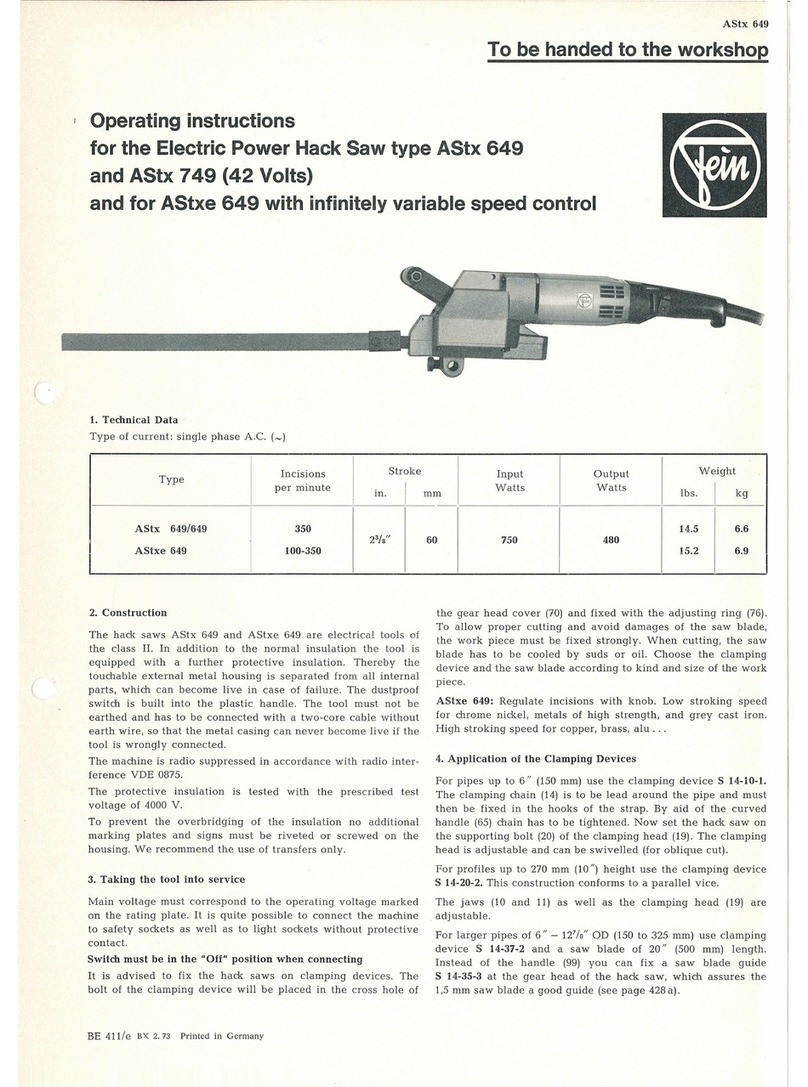

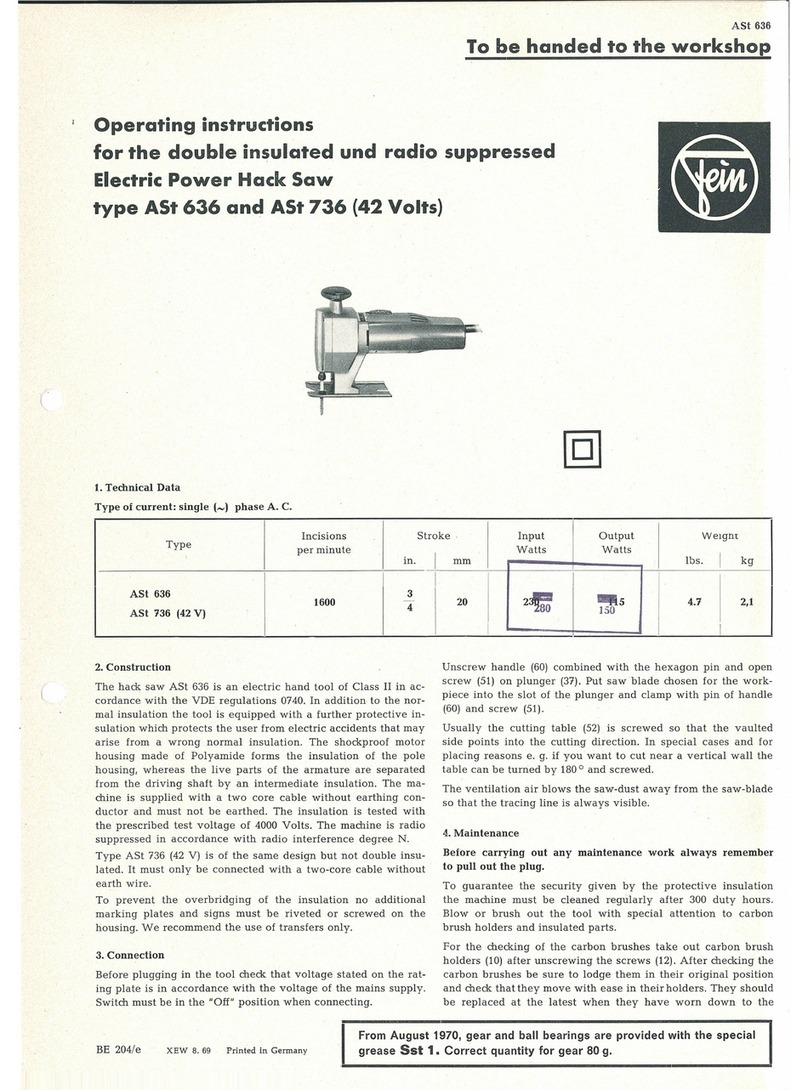

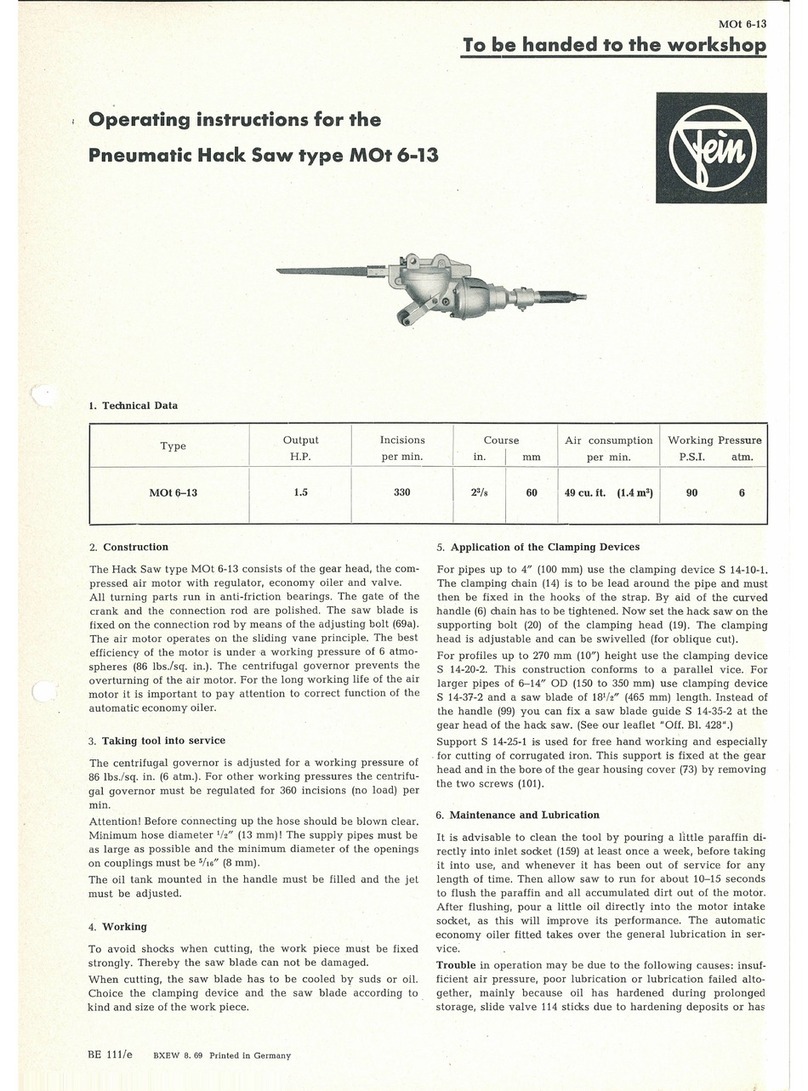

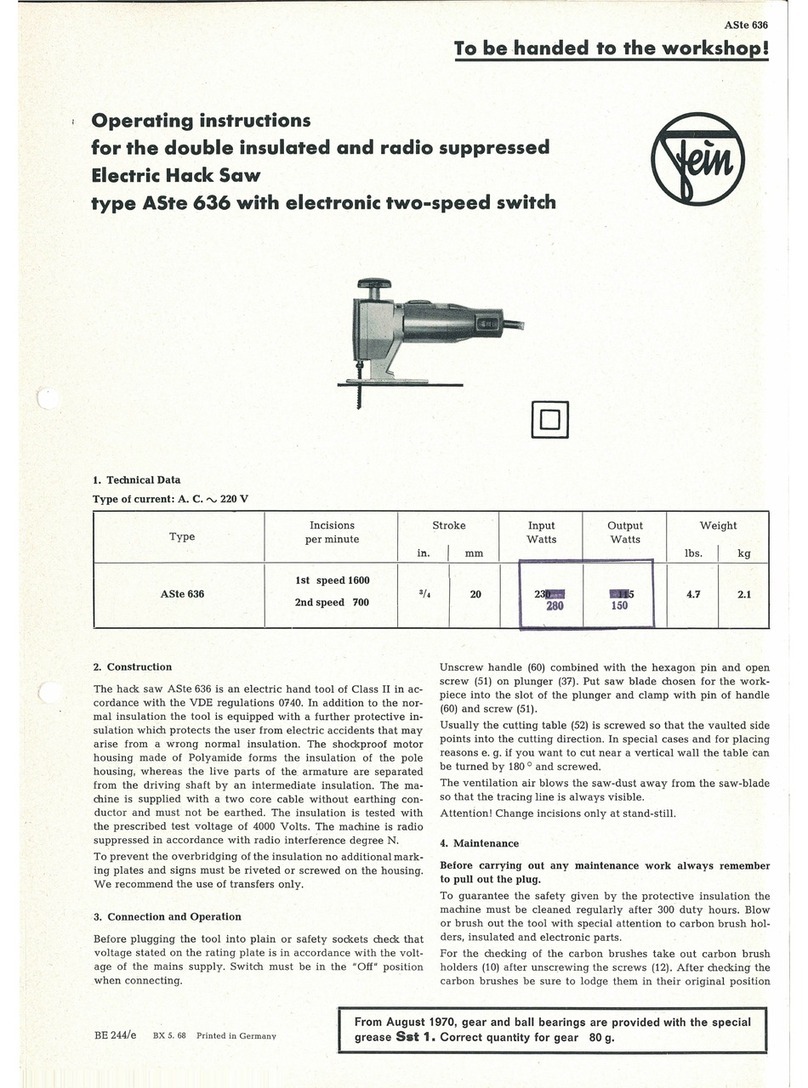

Intended use of the pneumatic tool:

Hand-guided compressed air hacksaw for commercial use

for cutting round and other shaped work pieces of metal,

plastic and cement in weather-protected environments

using the application tools and accessories recommended

by FEIN.

Safety instructions.

Workplace

Keep work area clean and tidy. Cluttered or dark work

areas invite accidents.

Do not operate the pneumatic tool in explosive atmos-

pheres, such as in the presence of flammable liquids,

gases or dusts. Pneumatic tools create sparks which can

ignite the dust or fumes.

Keep children and bystanders away while operating the

pneumatic tool. Distractions can cause you to lose con-

trol over the pneumatic tool.

Safety when handling compressed air

Clean the compressed-air supply regularly. Protect the

hose from kinks, contraction, heat, and sharp edges.

Firmly tighten the hose clamps. Have damaged hoses and

couplings repaired immediately. In case of malfunctions

to the air supply, the compressed-air hose can be thrown

about and lead to injury. Raised dust or chips may cause

serious eye injury.

Personal safety

Stay alert, watch what you are doing, and use common

sense when operating a pneumatic tool. Do not use a

pneumatic tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inattention

while operating a pneumatic tool may result in personal

injury.

Use personal protective equipment. Always wear eye pro-

tection. Protective equipment such as dust mask, non-

skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

Prevent unintentional starting. Make sure that the switch

is in the “OFF” position before connecting the pneumatic

tool to the compressed-air supply. When your finger is

on the switch while carrying the pneumatic tool or when

connecting the pneumatic tool to the compressed-air

supply while it is switched on, accidents can occur.

Remove any adjustment tools or spanners before switch-

ing on the pneumatic tool. An adjustment tool or spanner

left attached to a rotating part of a pneumatic tool may

result in personal injury.

Do not overreach. Keep proper footing and balance at all

times. This enables better control of the pneumatic tool

in unexpected situations.

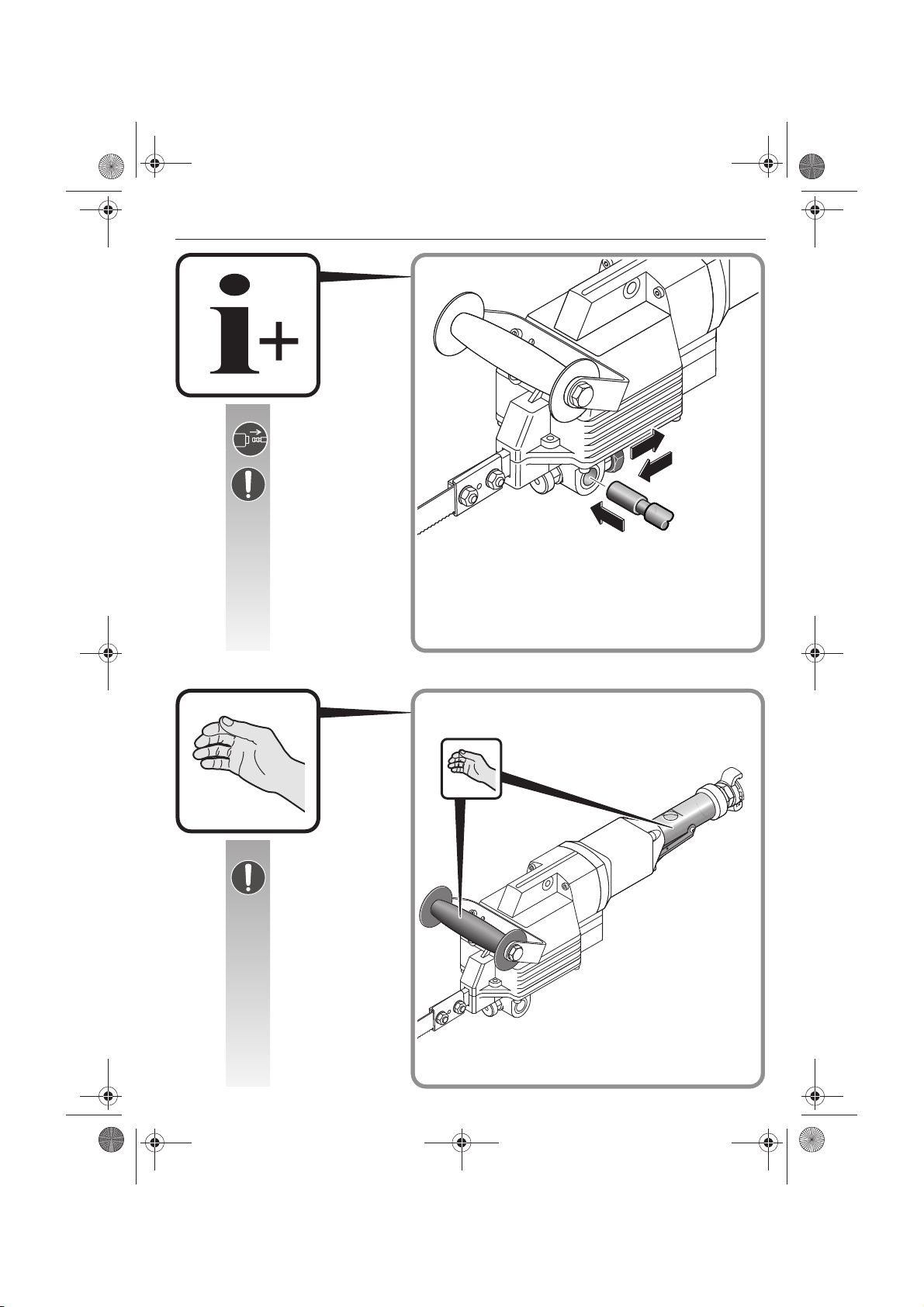

Dress properly. Do not wear loose clothing or jewellery.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair can be caught

in moving parts.

If devices are provided for the connection of dust extrac-

tion and collection facilities, ensure these are connected

and properly used. Use of dust collection can reduce

dust-related hazards.

Pneumatic tool use and care

Do not overload the pneumatic tool. Use the application

tool intended for your work. The correct pneumatic tool

will do the job better and safer at the rate for which it is

designed.

Do not use a pneumatic tool that has a defective switch.

A pneumatic tool that cannot be controlled with the

switch is dangerous and must be repaired.

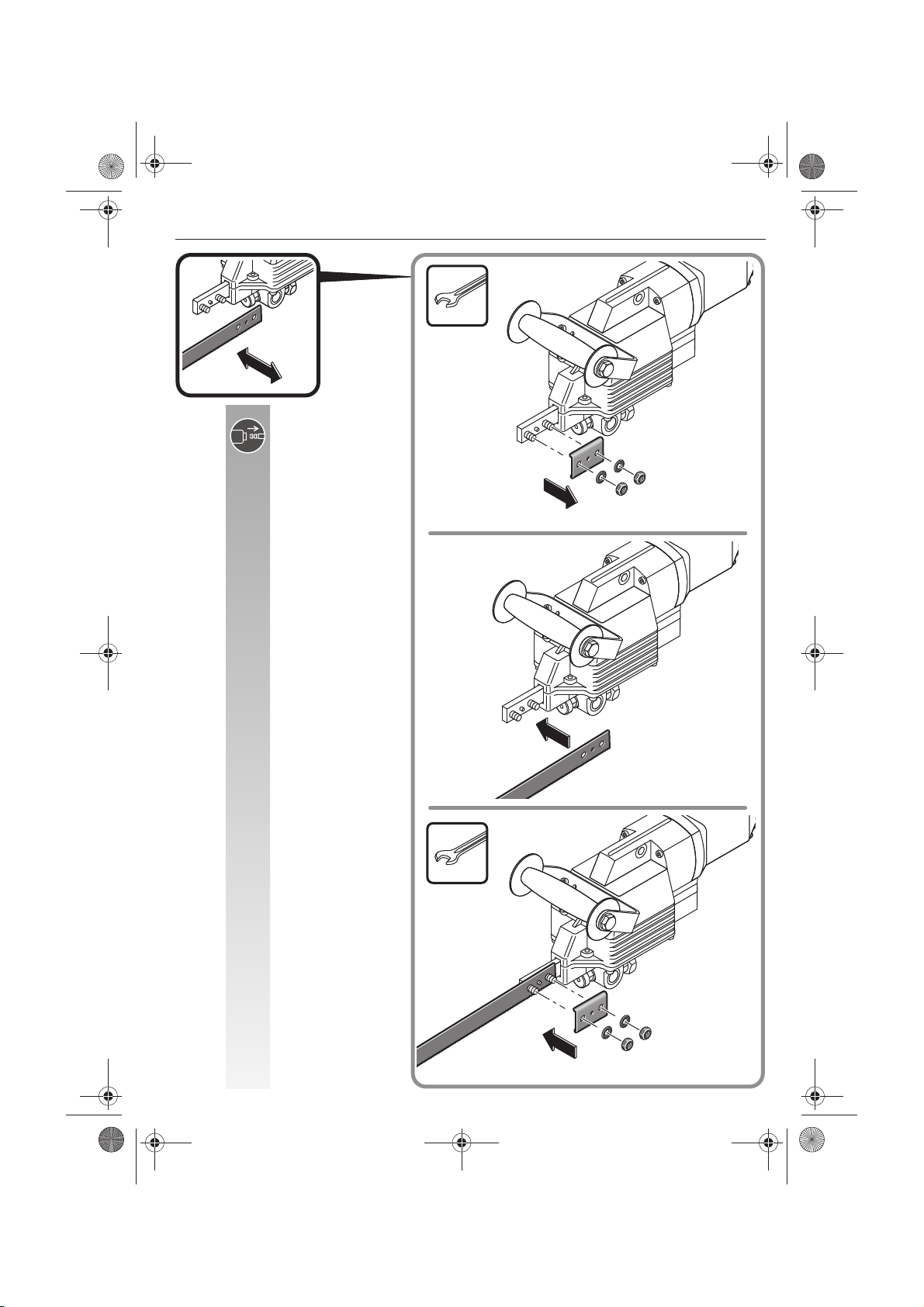

Disconnect the energy supply before making any pneu-

matic tool adjustments, changing accessories, or placing

the pneumatic tool aside. This safety measure prevents

accidental starting of the tool.

Store idle pneumatic tools out of the reach of children. Do

not allow persons unfamiliar with the pneumatic tool or

these instructions to operate the pneumatic tool. Pneu-

matic tools are dangerous in the hands of untrained users.

Maintain the pneumatic tool with care. Check for mis-

alignment or binding of moving pneumatic tool parts,

breakage of parts and any other condition that may affect

the pneumatic tool’s operation. Have damaged parts

repaired before using the pneumatic tool. Many accidents

are caused by poorly maintained pneumatic tools.

m/s2m/s2Vibrational emission value according

(vector sum of three directions)

h,D

m/s2m/s2Mean vibrational value for sawing

m, s, kg, A, mm, V,

W, Hz, N, °C, dB,

min, m/s2

m, s, kg, A, mm, V,

W, Hz, N, °C, dB,

min, m/s2

Basic and derived units of measurement from

the international system of units SI.

Character Unit of measurement,

international

Unit of measurement,

national

Explanation

OBJ_BUCH-0000000098-003.book Page 15 Thursday, October 20, 2016 4:52 PM