OVEM

6Festo – OVEM – 1702e English

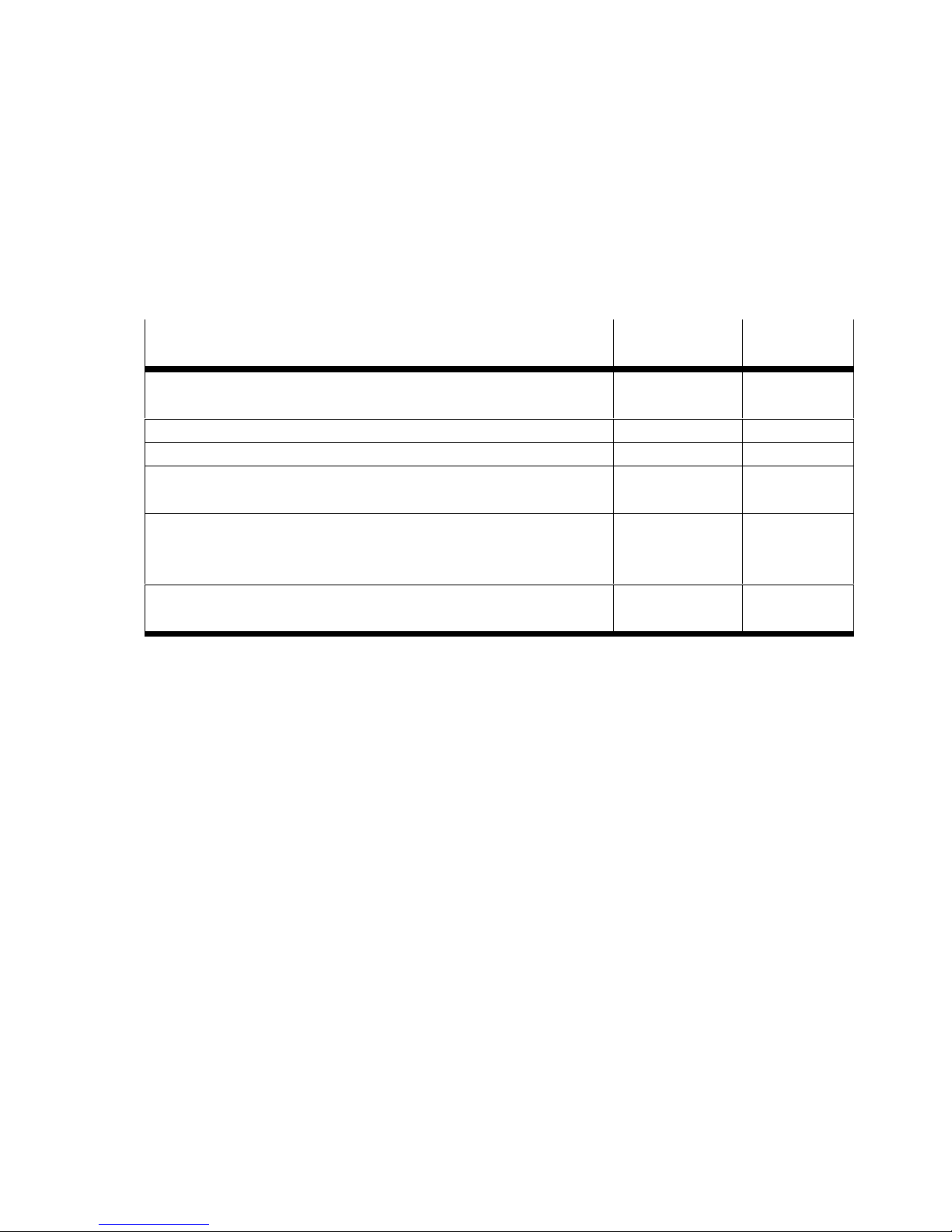

1.2 Characteristics

Characteristic Code Meaning

Vacuum suction nozzle OVEM Vacuum suction nozzle with vacuum solenoid valve ON/OFF

and electric manual override

Nominal width of laval

nozzle

-05 0.45 mm

-07 0.7 mm

-10 0.95 mm

-14 1.4 mm

-20 2.0 mm

Vacuum type -H high vacuum

-L high suction volume

Housing size / width -B 20 mm wide, ISO standard

-BN 20 mm wide, NPT

Pneumatic ports -QS all ports with QS push-in fittings (-B-QS)

all ports with QS push-in fittings inch (-BN-QS)

-QO Supply / vacuum port with QS push-in fittings, exhaust port

with open silencer (-B-QO)

Supply / vacuum port with QS push-in fittings inch, exhaust

port with open silencer (-BN-QO)

-GN all ports with female G thread (-B-GN)

all ports with female NPT thread (-BN-GN)

-GO Supply / vacuum port with female G threads, exhaust port

with open silencer (-B-GO)

Supply / vacuum port with female NPT threads, exhaust port

with open silencer (-BN-GO)

-PL prepared for manifold rail, vacuum and exhaust port with QS

push-in fittings (-B-PL)

prepared for manifold rail, vacuum and exhaust port with QS

push-in fittings inch (-B-PL)

-PO prepared for manifold rail, vacuum port with QS push-in

fittings, exhaust port with open silencer (-B-PO)

prepared for manifold rail, vacuum port with QS push-in

fittings inch, exhaust port with open silencer (-BN-PO)

Normal position of the va

cuum generator

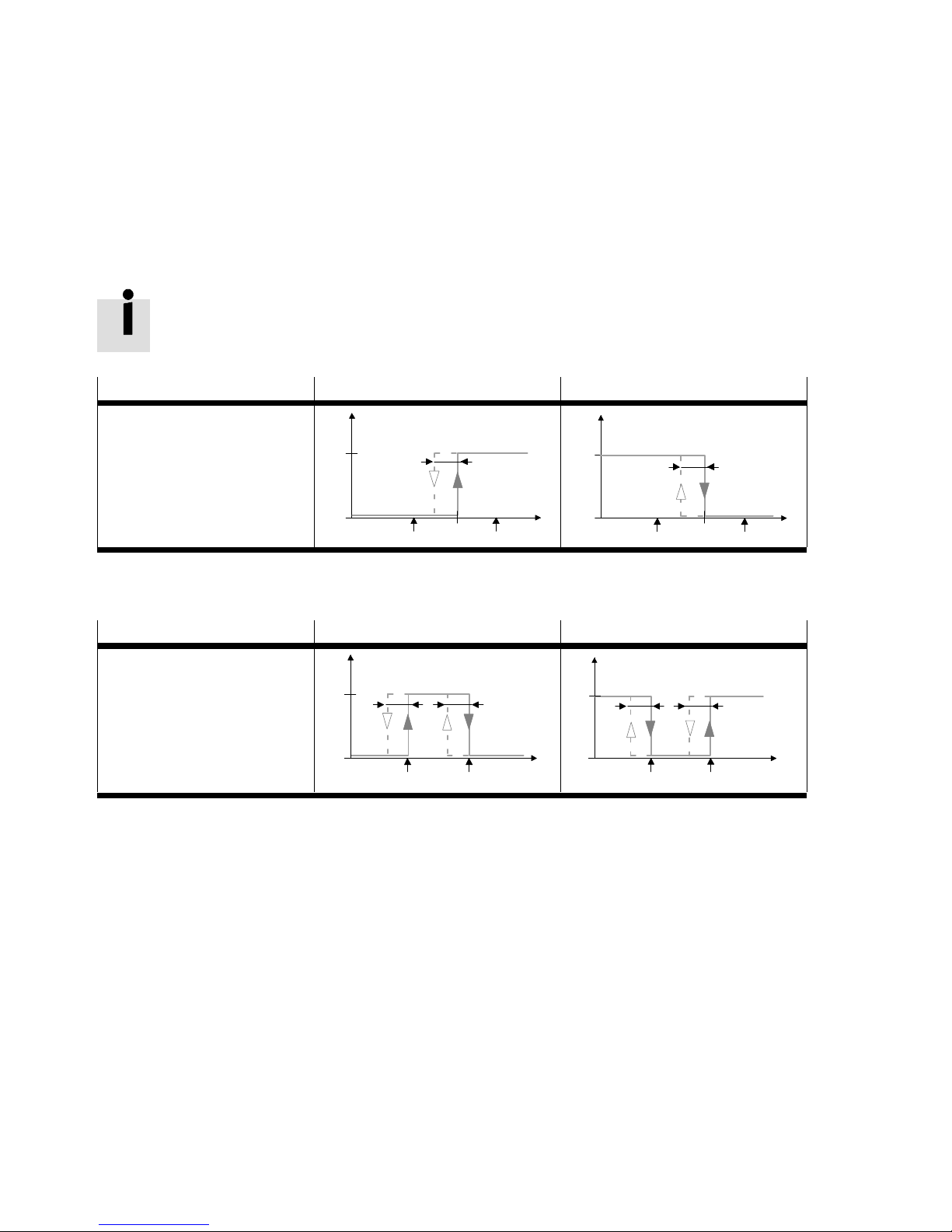

-ON NO, normally open (vacuum generation)

-OE NO, normally open (vacuum generation) with ejector pulse

-CN NC, normally closed (no vacuum generation)

-CE NC, normally closed (no vacuum generation) with ejector pulse

Electrical connection -N Plug M12 (5-pin)