10

The actual weight of the machine provides ad-

equate sanding pressure to produce good sanding

quality.

The expelled cooling air can be guided in the most

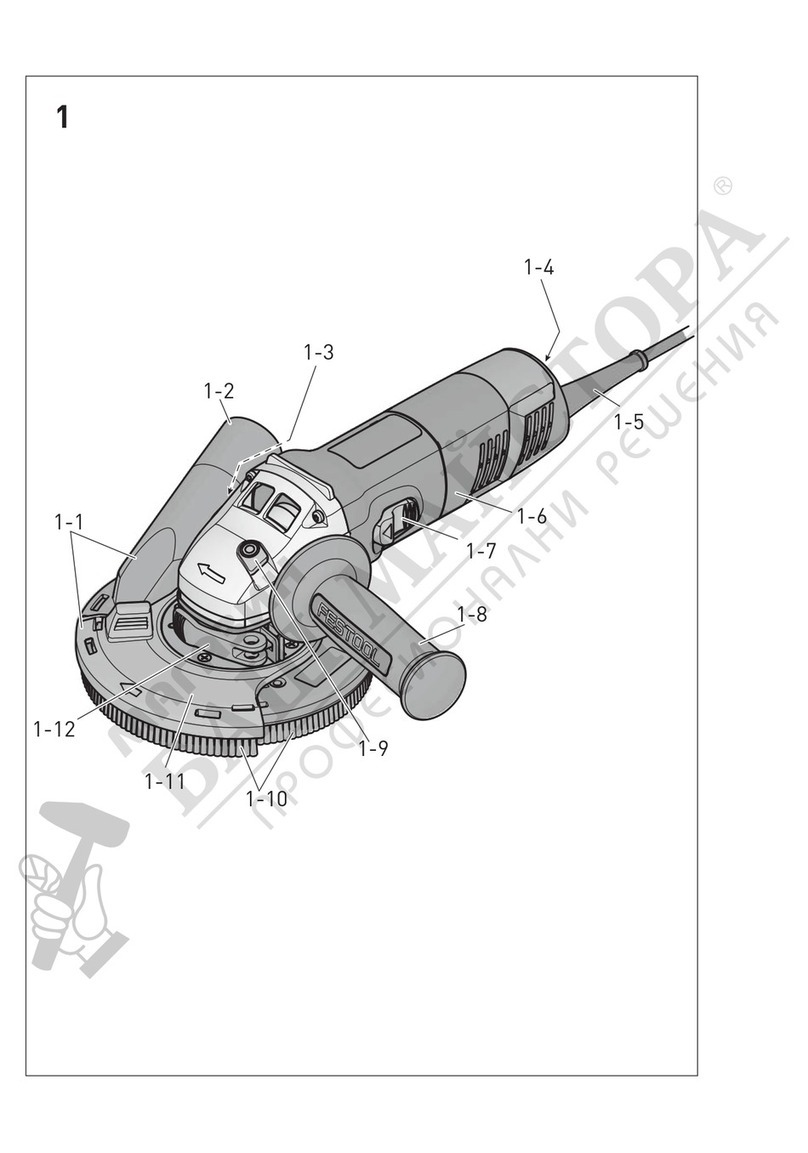

favourable direction by the ducting flap (1.1) .

4.1 Working with the sanding frame in the

case of type BS 75 E - Set

Set the machine with the knurled head screw (2.4),

so that when it is placed on the workpiece surface

the sanding belt does not engage.

The sanding belt is engaged by turning the knurled

head screw towards the plus symbol until the belt

makes contact.

Continue turning the knurled screw to achieve the

desired depth of stock removal (1 complete turn

corresponds to a height adjustment of 0.4 mm).

When interrupting or on completing work, the

sander is raised from the working position (2.3)

set to a position of rest (2.2) by means of an ec-

centric lever.

By swinging the eccentric lever back to working

position the depth of stock removal set previously

is again obtained.

4.2 Taking the sanding frame off

Press down the knurled head screw (2.4) until the

shank (2.5) springs out of the spring catch and the

machine can be withdrawn from the rear.

The sander and sanding frame are aligned

for optimum accuracy at the factory by

suitable adjustment of the guiding struts.

For this reason do not remove the guiding

struts.

4.3 Assembling the sanding frame

Make sure that the glide pins (2.6, 2.8) fixed to

the sanding frame engage front and back in the

grooves of the guide struts (2.7, 2.9).

Slide the sander downwards along the grooves

until the shank (2.5) engages.

4.4 Changing the sanding belt

Pull the lever (3.5) forward; the belt is now slack

and can be removed.

When inserting the sanding belt, make sure that

the running direction of the belt (usually indicated

by an arrow on the inside) matches the running

direction of the machine (3.4).

Tighten the belt again with the lever and align

when running.

4.5 Dust extraction

The dust produced while working can be

detrimental to health, combustible or

explosive. Suitable safety measures are

necessary.

The dust bag (4.1) with the adopter (4.3) is at-

tached to the exhaust duct (4.2) by means of a

bayonet catch by turning to the right.

The dust bag is removed for emptying by turning

it to the left.

At the time of fixing, ensure that the leaf spring

stud touches the belt housing.

The dust extraction system will continue to func-

tion effectively as long as the bag is emptied in

good time.

For working with the protection of the environ-

ment in mind it is advisable to use the Festool

dust extraction system.

The connecting socket from the suction hose can

be connected using the adapter (4.4) which is sup-

plied as standard.

4.6 Stationary use (partly accessories)

– Attach both feet (5.3) via the two threaded holes

(4.5). Important: the straight edges of the feet

must face inwards.

– Make sure that the machine is standing firmly:

use clamps to attach the feet to the base.

4.7 Longitudinal stop (partly accessories)

– Attach the longitudinal stop to the threaded hole

(5.2) using screw (5.1).

– Unscrew the screw (6.3) to adjust the position

of the longitudinal stop along the sanding belt.

– To sand sloping surfaces, unscrew the screw

(6.2) and adjust the longitudinal stop. The scale

(6.1) indicates the angle setting.

5 Maintenance and care

Always remove the power supply plug

from the socket before carrying out any

work on the machine.

All maintenance and repair work which

requires the motor casing to be opened

may only be carried out by an authorised

service centre.

Customer service and repair. Only

through manufacturer or service work-

shops: Please find the nearest address

at:: www.festool.com/Service

EKAT

1

235

4

Use only original Festool spare parts!

Order No. at: www.festool.com/Service