joint out of a mismatched

combination.

The through dovetail can also

be a confusing joint to cut

because when you look at the

work piece with the female

recesses you can either see the

recesses, or you may instead

see the uncut portion between

two recesses that are called the

“pins”. If those uncut portions

are between one side of the

outboard most recess and the

edge of the work piece, they

are called “half pins”. It is

hard, especially at first, to keep

straight which work piece is

the male (most often called the

“tail board”) and which is the

female (most often called the

“pin” board).

I’ll try to take a bit of the

confusion out of this when we

talk about how to cut perfect

through dovetails using the

Festool VS-600. The Festool

manual talks about the male

fan shaped portion as the

“dovetail” and the female

recess or pin board as the

“tenons”, terminology I find

confusing myself.

Fortunately, it is easy to see

the difference by looking at the

template used for these two

portions of the joint.

The male

portion is cut using a template

where the sides of the guide

fingers are straight while the

female portion is cut using a

template where the sides of the

guide fingers are angled.

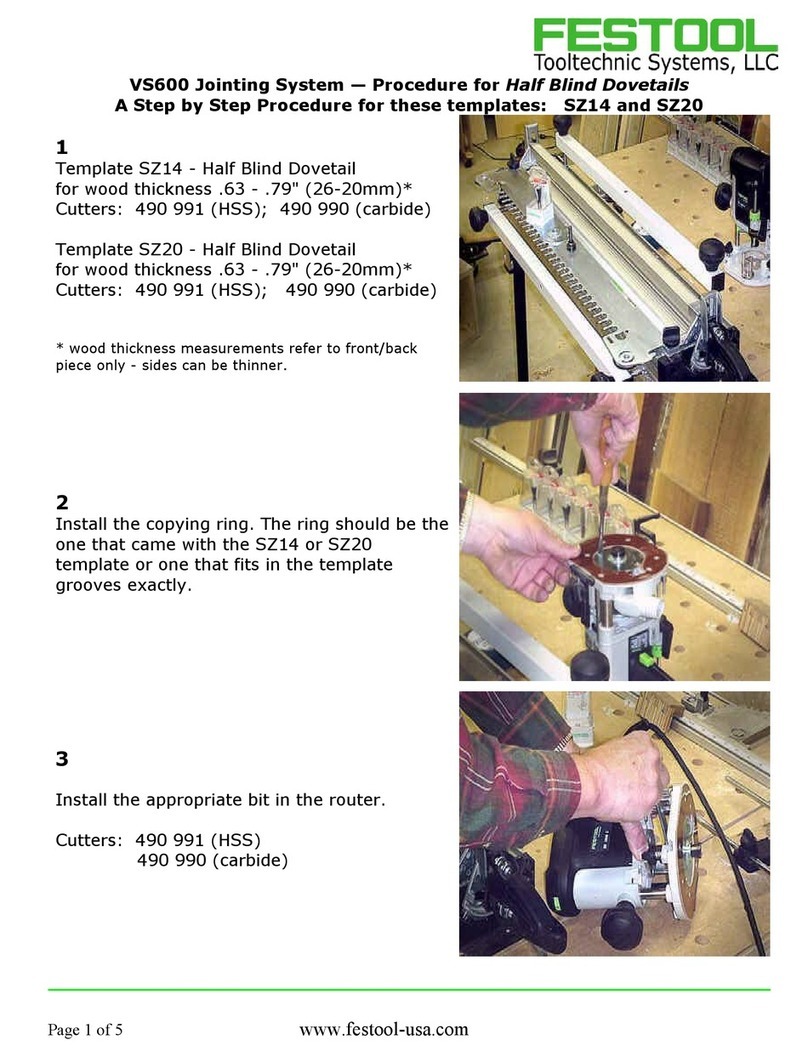

In Festool speak, the template

for cutting the male fan shape

is labeled as an SZO-14-S or

SZO-20-S, while the template

with the angled fingers for

cutting the female recesses is

labeled as an SZO-14-Z or an

SZO-20-Z.

It really doesn’t matter what

you call these two as long as

you are clear that you will use

the S for cutting the fan

shaped male “tails,” as shown

in the picture above right, and

the Z for cutting the female

recesses separated by “pins.”

Throughout this manual I will

refer to the male and female

parts of the joint trying to

avoid the confusing tail and

pin descriptions.

Other joints also called

“dovetail” joints – There

are a few other joints that also

trap one work piece to another

by a male with angled sides

mating with a female recess

with the same angled sides. If

the male and female portions

are cut in the ends of two work

pieces they can be joined flat,

end to end and are usually

called a “flat dovetail” joint. If

the female portion is cut into

the ends of both work pieces

and a separate male piece is

machined with the fan shape

at each end, that joint is

usually called a “butterfly”

dovetail joint. We will not be

discussing these flat or

butterfly dovetail joints in this

manual.

Advantages - Besides the

inherent strength of any of

these kinds of dovetail joints,

another great advantage of a

well machined dovetail joint is

that they are inherently self-

aligning. The bottom of the

fan shaped male protrusion

ends in flats which are exactly

the same level as the surface

into which the female grove or

socket is cut in the mating side

of the joint. The flat on one

7