79-15167-00 REV. A www.fiberstars.com Page 4 of 10

FOR NEW INSTALLATIONS (FDS)

STEP 1. Ensure that incoming power is DISCONNECTED at the circuit breaker BEFORE any

electrical work is performed.

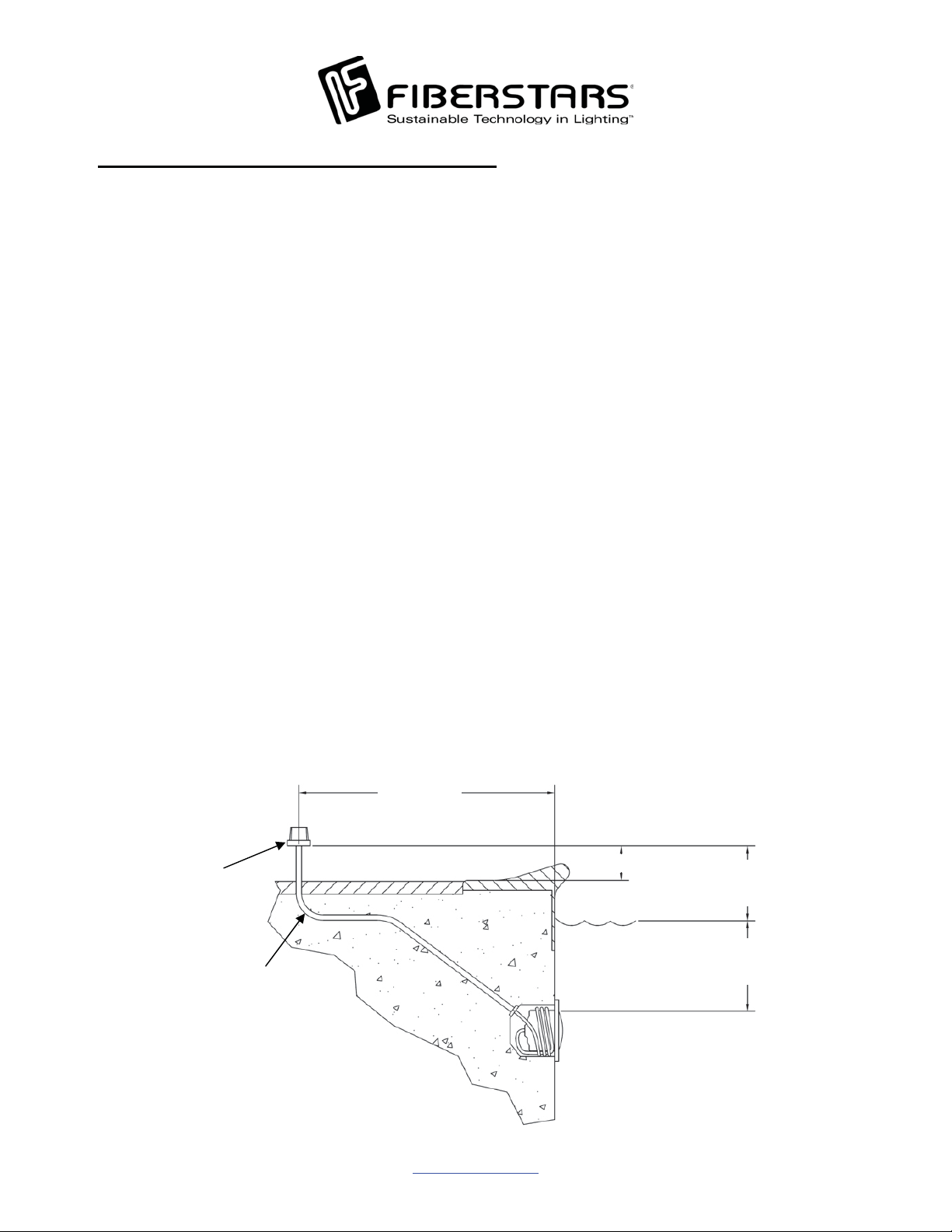

STEP 2. Place the supplied Brass base plate in accordance with National and Local electrical

codes and ordinances for junction box placement (see illustration below for proper

location and minimum spacing requirements).

STEP 3. The center conduit hub is equipped with a strain relief for a cord size of up to 10/3 AWG.

Only use with underwater lights equipped with water resistant cords.

STEP 4. Provisions for grounding terminals are provided for wires ranging from #16 AWG to #10

AWG. One equipment bonding terminal provision is provided and must be utilized for a

#8 AWG insulated copper bonding wire. Special considerations should be taken when

attaching stranded grounding and bonding conductors to the supplied grounding and

bonding screws, such as ring terminals rated for such applications.

STEP 5. Plug any unused conduit holes with the supplied conduit plugs.

STEP 6. Place the supplied rectangular gasket between the Brass base plate and the FDS adapter

(Important Note: For upgrade installations discussed on the next page, assure to replace

any existing gaskets with the supplied FDS gaskets).

STEP 7. There are three (3) wires in the FDS junction box for connection to underwater lights.

a. Connect the WHITE wire to the common from the house common and from the

common of the underwater light.

b. Connect the BLACK wire from the sub-panel connected to an appropriately rated

circuit breaker.

c. Connect the RED wire to the LOAD wire of the underwater light.

STEP 8. Place FDS cover and round gasket onto the FDS adapter and Brass base plate.

STEP 9. Using the supplied screws, finger-tighten the screws from the FDS to the Brass base

plate.

STEP 10. After all screws have been finger-tightened, completely tighten all screws in a cross

pattern so that the FDS will seal properly.

48” min.

4” min. 8” min. from bottom of J-Box

to Top of Water Line

18” min. from Water

Line to top of Lens

Rigid

Conduit

To GFCI, Circuit

Breaker, and

Power Source