FibroLAN MCM1000S-LX1 Manual

MCM1000S/L

Module Converter/Extender

1000Base-SX/LX to 1000Base-LX

User and Installation Guide

Version: 2.4

FibroLAN Ltd.

2 Carmel St. P.O. Box 544 Yokneam-Illit, 20692 ISRAEL

Tel: 972-4-9591717 Fax: 972-4-9591718

MCM1000S/L GBE module

2

FEDERAL COMMUNICATIONS COMMISSION

AND

CANADIAN DEPARTMENT OF COMMUNICATIONS

RADIO FREQUENCY INTERFERENCE STATEMENTS

This equipment generates, uses, and can radiate radio frequency energy and if not

installed and used properly, that is, in strict accordance with the manufacturer’s

instructions, may cause interference to radio communication. It has been tested

and found to comply with the limits for a Class A computing device in accordance

with the specifications in Subpart B of Part 15 of FCC rules, which are designed to

provide reasonable protection against such interference when the equipment is

operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the user at his own

expense will be required to take whatever measures may be necessary to correct

the interference.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

This digital apparatus does not exceed the Class A limits for radio noise emission

from digital apparatus set out in the Radio Interference Regulation of the Canadian

Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Règlement sur le brouillage

radioélectrique publié par le ministère des Communications du Canada.

CE Mark

The CE mark symbolizes compliance with the European Community

required technical standards.

The product herewith complies with the requirements of the EMC Directive

89/336/EEC,the Low Voltage Directive 73/23/EEC and the R&TTE Directive

99/5/EC.

The product was tested in a typical configuration.

Levy Malkiely

Quality Manager

MCM1000S/L GBE module

3

Table of contents

General Description page 4

Features Summary page 4

Product list page 5

MetroStar Chassis Layout page 6

Module Front Panel page 7

Installation procedures page 8

F/O cabling connection page 9

F/O ports Specifications page 10

MA™ Concept and Functions page 11

MMM-4 Management module page 12

DIP switches setting page 13

LST (Link Segmentation Test page 14

SLE (Subscriber Link Emulation) page 16

Typical Configuration page 17

Troubleshooting page 18

Specifications page 19

Module default settings page 19

Warranty Limitation page 20

Thank you for purchasing the MCM1000S/L GBE

Module Converter/Extender from FibroLAN.

We hope that this guide will help you to obtain

the best results from the device while minimizing

installation time.

If you still need help installing or troubleshooting the MCM1000S/L

converter after reading the detailed information in this guide, please visit our

web site, contact your reseller, or call FibroLAN directly.

(Support @fibrolan.com; Tel: +972-4-9591717; Fax: +972-4-9591718)

TRADEMARKS

Any trademarks mentioned in this manual are acknowledged to be the property of the

trademark owners.

MCM1000S/L GBE module

4

1 –General Description

This module provides conversion from a fiber-optic multimode GBE link (1000Base-SX)

to a Single Mode Link (1000Base-LX) to allow extension of up to 80km. The

MCM1000S/L is based on a full digital technology: signals from one F/O port are

converted to digital electrical signals, fully retimed, then converted again to F/O and

transmitted from the second port. This design provides a resilient conversion, advanced

control and diagnostic features. In addition it facilitates special applications like daisy

chaining, back-to-back and management. Port 1 is 1000Base-SX or LX type. Port 2 is

defined as 1000Base-LX for link distances and is normally connected to a remote unit.

The module may act as an Extender Media Converter if Port 1 is 1000Base-LX type.

(Refer to section 3 for a complete list of available GbE modules)

Single Fiber Strand modules (SX/LX 20, 40Km) are also available.

Link Segmentation Test (LST) allows easy link test segmentation (LST ON=Test mode)

to locate a failed link segment and in LST OFF mode (Fault Propagation mode) the shut

down of the entire link if one of the F/O link is disrupted and Network Device notification

of the link failure. A front panel LED will show the LST setting for each F/O port.

A Loop-Back function (for each port) simplifies troubleshooting of link problems.

Incoming received data on the RX port is looped back and transmitted from the TX port.

Each port provides separate Link and Activity indications for enhanced diagnostics.

Like other MetroStar modules, the MCM1000S/L is fully SNMP managed. All MetroStar

modules are hot swappable. A special LED indicates that the module is well inserted in

its slot and “alive” even before links are established. The MCM1000S/L module is

managed via the MetroStar Management module. (MMM-01or MMM-04 module)

The embedded MA™ (Micro Agent) is an on chip management system enabling the

management of remote access devices eliminating the need of a SNMP agent and IP

address. When the MCM1000S/L module is connected through its F/O link to a remote

device, which is MA™ enabled, a comprehensive set of monitoring and control functions

can be implemented from the SNMP management module (located in the MetroStar) into

the attached remote MA devices.

The MCM1000S/L modules family supports another unique outstanding feature: SLE

(Subscriber Link Emulation) enabled through the system management (for a detailed

description, refer to section 11)

2 –Features Summary

Two fiber (1000Base-SX/LX to 1000Base-LX) ports

Conversion method: Direct Digital with LST capability

SNMP managed including Telnet

MMM-04 Management :SNMP, Web, CLI (Console, Telnet, SSH)

Remote MA devices management. Front panel MA Active LED

Covered distance: up to 120Km point to point, more if cascaded

Single Fiber Strand (SFS) modules (up to 20, 40Km)

LST: Link Segmentation Test for each port: allows to locate a failing segment

within a network

F/O Loop Back for each F/O port

Diagnostics LED indicators for Link and Activity monitoring each F/O port

On board DIP switches for LB (loop-back) and LST for each F/O port

Supports SLE (Subscriber Link Emulation) through system management

Supports OFC (Offline Configuration Facility)

MCM1000S/L GBE module

5

3 –Product List

The MCM1000S/L module is offered in the following preconfigured versions:

MCM1000S-LX1

1000SX multi-mode 850nm, 220m, to 1000LX single mode 1310nm Conversion

Module, 10km, 2*Duplex SC, MA

MCM1000S-LX2

1000SX multi-mode 850nm, 220m, to 1000LX single mode 1310nm Conversion

Module, 20km (over G.652 fiber), 2*Duplex SC, MA

MCM1000S-LX3

1000SX multi-mode 850nm, 220m, to 1000LX single mode

1550nmDFBTx/1550nmRx, Conversion Module, 40km. 2*Duplex SC, MA

MCM1000S-LX4

1000SX multi-mode 850nm, 220m, to 1000LX single mode

1550nmDFBTx/1550nmRx, Conversion Module, 80km. 2*Duplex SC, MA

MCM1000S-LXF13

1000SX multi-mode 850nm, 220m, to 1000LX Single Fiber Strand,

1310nmTx/1550nmRx, Conversion Module, 20km (over G.652 fiber),

1xduplex/1xsimplex SC, MA

MCM1000S-LXF15

1000SX multi-mode 850nm, 220m, to 1000LX Single Fiber Strand,

1550nmDFBTx/1310nmRx, Conversion Module, 20km (over G.652 fiber),

1xduplex/1xsimplex SC, MA

MCM1000S-ZXF13

1000SX multi-mode 850nm, 220m, to 1000LX Single Fiber Strand,

1310nmTx/1550nmRx, Conversion Module, 40km (over G.652 fiber),

1xduplex/1xsimplex SC, MA

MCM1000S-ZXF15

1000SX multi-mode 850nm, 220m, to 1000LX Single Fiber Strand, 1550nmDFBTx/

1310nmRx, Conversion Module, 40km (over G.652 fiber), 1xduplex/1xsimplex SC,

MA

MCM1000L-LX1-2

1000LX single-mode 1310nm, 10Km to 1000LX single-mode 1310nm Extender

module 20Km (over G.652 fiber), 2*Duplex SC, MA

MCM1000L-LX1-3

1000LX single-mode 1310nm, 10Km to 1000LX single-mode 1550nm DFB Extender

module 40Km, 2*Duplex SC, MA

MCM1000L-LX1-4

1000LX single-mode 1310nm, 10Km to 1000LX single-mode 1550nm DFB Extender

module 80Km, 2*Duplex SC, MA

MCM1000L-LX3-3

1000LX single-mode, 1550nmDFBTx/1550nmRx, 40Km to 1000LX single-mode

1550nmDFBTx/1550nmRx, Extender module 40Km, 2*Duplex SC, MA

MCM1000L-LX4-4

1000LX single-mode, 1550nmDFBTx/1550nmRx, 80Km to 1000LX single-mode

1550nmDFBTx/1550nmRx, Extender module 80Km, 2*Duplex SC, MA

MCM1000L-LX4-5

1000LX single-mode 1550DFB, 80Km to 1000LX single-mode 1550nm DFB/APD

Extender module, 120Km, 2*Duplex SC, MA

All MCM1000S/L series modules have identical functionality. Therefore, any description

and features of one module refers to all other types.

The F/O ports supports GBE 1000Base-SX/LX transmissions, set to 1000Base-FX and

FDX (Full Duplex). Any network device which connects to the F/O ports of

MCM1000S/L module should be configured to Auto-Negotiation disabled mode

(forced to 1000Base-FX and FDX) to obtain the link connectivity.

The modules incorporate on board DIP switches (LST ON/OFF, Loop-Back ON/OFF)

per port to easily perform troubleshooting and maintenance functions.

Recall that Port 1 (normally 1000Base-SX type port) can be offered as 1000Base-LX

port (MCM1000L-LX Extender series).

Port 2 (1000Base-LX) is normally connected to a remote GBE device.

The MCM1000S modules, installed in the MetroStar System chassis, can be managed

locally through the serial connection (CLI) or a Telnet connection through a SNMP

Manager station. With MMM-04 module, Web management is also available Refer to

section 8 for more details.

The module is managed also by the FibroLAN MetroView Device Manager.

Note: the firmware or software update for the various MetroStar modules and

remote MA CPE devices is implemented by means of the TFTP routine.

MCM1000S/L GBE module

6

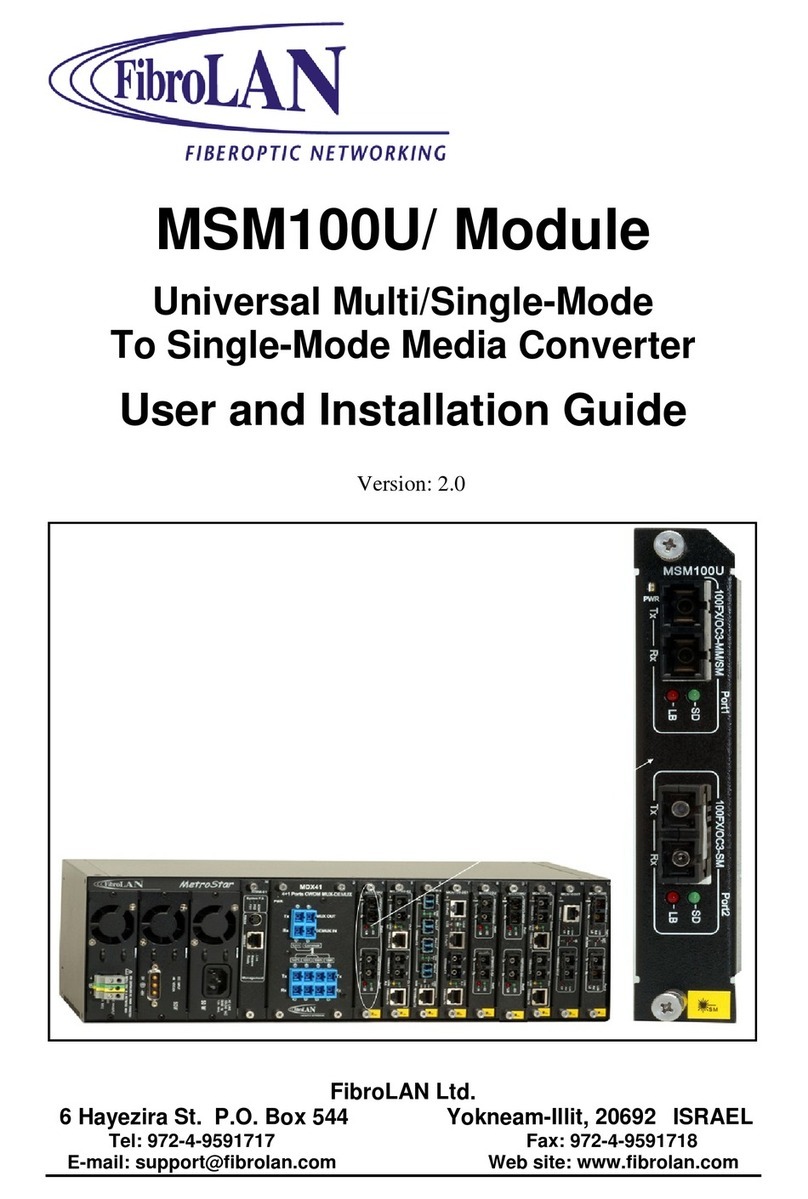

4 –MetroStar Chassis Layout

1 2 3 41512

In slot position # 3 (from the left), it is possible to install a additional redundant

Power Supply or the Blank panel BP-02.

Slot position # 4 is normally dedicated for the MetroStar™SNMP management

module (MMM-01or MMM-04) for standalone MetroStar™. The PMM module is

normally installed in slot # 4 in unmanaged MetroStar™System (optional module)

When the MetroStar™chassis is not fully populated with conversion modules, it is

mandatory to install the BP-01 Blank Panel in the vacant slots.

In slot position # 3 (from the left), it is possible to install an additional redundant

Power Supply or the Blank panel BP-02.

MCM1000S/L GBE module

7

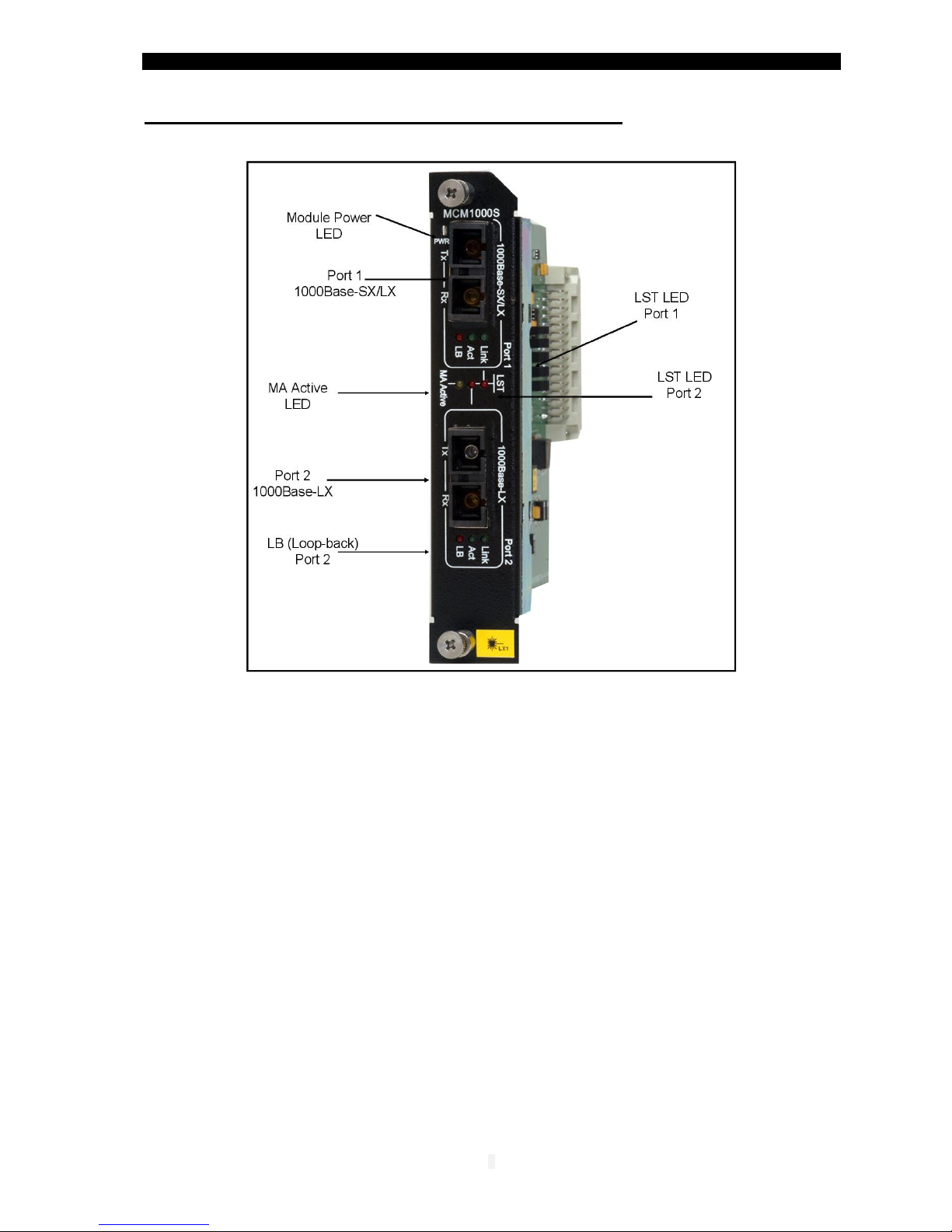

5 –Module front panel - Parts Identification

1. Port 1 LEDs:

Link: steady green lit: a F/O link has been established.

Act: port 1 activity. Blinking green (receive / transmit)

LB: lit red implies port 1 is in loop-back mode

2. Port 1 Duplex SC fiber optic connector: (left /Tx, right / Rx)

3. System LED indicators:

Port 1 LST: lit red implies that an idle signal is sent from port 1 (S4 UP, LST ON)

when data is not transmitted at the same time.

Port 2 LST: lit red implies that an idle signal is sent from port 2 (S3 UP, LST ON)

when data is not transmitted at the same time.

MA active: steady lit (amber): the MCM1000S module is connected to a remote

enabled MA and active device.

4. Port 2 Duplex SC fiber optic connector: (left /Tx, right / Rx)

5. Port 2 LEDs:

Link: steady green lit: a F/O link has been established.

Act: port 1 activity. Blinking green (receive / transmit)

LB: lit red implies port 2 is in loop-back mode

6. Power ON/OFF green LED indicator (PWR LED)

MCM1000S/L GBE module

8

6 –Installation procedures

Slot assignment

MCM1000S/L modules may be installed in any of the slots marked 1 to 12,however by

installing modules systematically next to each other (from left to right) it will make it

easier to install additional modules in the future allowing clear access to the slots.

Installation of Modules

All MetroStar™ modules are hot swappable however it is recommended – whenever

operationally acceptable, to install a module (or swap an already installed module) while

the system is powered OFF.

All modules are equipped with two self-clinching screws –always use BOTH of them for

safe insertion and removal of modules into/from the system.

To install a module in a vacant slot: remove the blank panel covering the slot using a

crosshead screwdriver. Hold the module vertically with one hand by the side facets of the

metal frame of the module. Do not touch the PCB (printed circuit board) or any of the

components with your hand. The frame is asymmetrical: its bottom end rectangular while

its other side has a diagonally “cut” edge – make sure this side is up. Align both upper

and lower edges of the PCB with the lower and upper Nylon guides of the slot and gently

glide the module into the slot, applying only a small pressure. If correctly positioned and

aligned, it should allow the module all the way in. At the final stage (2-3 mm short of full

insertion) you will experience a slightly higher resistance –apply a higher pressure with

your finger on the panel of the module till you feel it “clicks in” and its panel is flush with

the surface of the chassis. At this point, if the MetroStar™ is powered ON the PWR LED

(left-upper side of the module or any corresponding LEDs on the PMM) will light. If not lit,

ensure that unit is powered UP; if still not lit –remove the module and re-insert. Is

problem persists; troubleshoot by inserting same module in a different slot and/or

another module in the suspected slot. Fasten both self-clinching screws using your

fingers by turning them clockwise, while doing that an increasing resistance indicates

that the screw is well aligned with it’s nut. Finally, using a crosshead screwdriver fasten

both screws (normally no more than one full turn will be required). Make sure not to

apply excess power.

To Swap a module: Unfasten the 2 screws using a cross-head screwdriver then

continue by turning them with your fingers counter-clockwise till the head of the screw

“pops out”. Hold both screws with fingers of BOTH hands and pull the module out.

Ensure applying balanced force at both screws to maintain vertical position throughout

the process, although it might be necessary to slightly tilt the module at the very first mm.

Continue as above to insert the new module. If you choose to leave the slot vacant,

always close it with a blank panel.

Warning: Do not INSTALL a module into a slot with already attached TP/F/O cabling.

Connect the cables to the module ports only after having verified that the module is well

inserted and its Power LED is lit.

Conversely, DISCONNECT the TP/F/O cabling from the module ports before replacing it. Non-

compliance with the above procedure may cause module's malfunction.

General considerations for MetroStar MCM1000X modules

The MetroStar™ system is delivered by default equipped with 2 power supplies –either

AC or DC. A third - redundant power supply module is optional. Each P.S. provides 14A.

The PS modules (2 or 3 if the optional is installed) are operating in a load-sharing mode;

therefore even the first 2 PS modules may provide a redundancy effect. The MCM1000S

when loaded with 2 FO transceivers needs 1.3 amperes. If 12 such modules are installed,

then the third P.S should be added, if redundancy is needed. With Up to 10 MCM1000S

modules, two P.S provide redundancy.

MCM1000S/L GBE module

9

7 –Fiber Optic Connection

The MCM1000S/L modules are equipped with two SC-type connectors.

Do not remove the protective covers on the fiber connectors until you are ready to

connect the fiber optic cables. Power should be connected (install the module into a

MetroStar slot) before attaching the fiber optic cables. When dealing with fiber optic

cables, it is essential to ensure that the Tx at one end of the link is connected to the Rx

at the other end of the link. Some duplex fiber optic cables are color coded to help

monitor the direction of data transmission. If the fibers are not coded, special attention

must be paid to ensure a proper connection. If your distance is shorter than specified in

the table below (see next page) for your model or should you wish to perform a local test,

insert first in line (both receive and transmit) appropriate attenuators (5db should suffice).

CAUTION

Radiation emitted from a fiber optic connector may be

hazardous to human vision. Therefore, the following rules

must be strictly observed.

All single-mode (SM) models are CLASS I LASER PRODUCTS

and must be handled with special care

When not in use, keep the fiber optic connector closed using

its protective cover.

The fiber optic transmitter is a CLASS 1 Laser product that

may endanger your eyes

Never stare directly into the fiber optic connector of a powered

device or into the end of a fiber connected to it.

Do not look directly into the fiber optic cables or transmitter

Laser Safety

The emissions produced by the end products described in this guide are under Class 1 emission

level according to IEC 60825-1 and the FDA 21 CFR 1040.10 and 1040.1. These products shall not

be installed in an optical network handling above Class 1 level.

MCM1000S/L GBE module

01

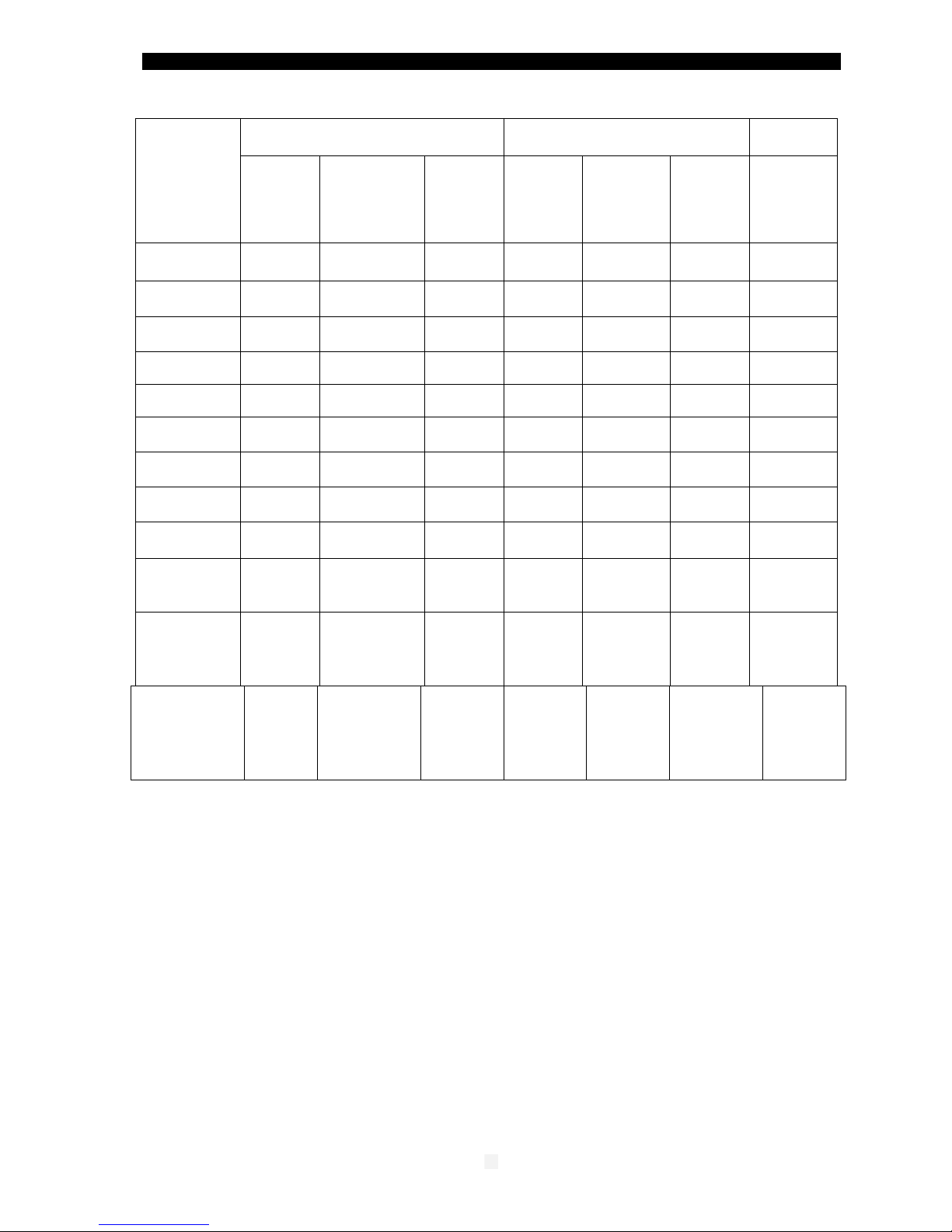

F/O ports specifications

Model

Port 1

Port 2

Minimal

Output

Power

dBm

Minimal

Receive

Sensitivity

dBm

WL

nm

Minimal

Output

Power

dBm

Minimal

Receive

Sensitivity

dBm

WL

nm

Suggested

DistanceKm

MCM1000S-LX1

-9.5

-19

850

-11

-20

1310

0,2/ 0-10

MCM1000S-LX2

-9.5

-19

850

-7

-20

1310

0,2 / 5-20

MCM1000S-LX3

-9.5

-19

850

-5

-23

1550/DFB

0,2 /10-40

MCM1000S-LX4

-9.5

-19

850

0

-24

1550/DFB

0,2 /25-80

MCM1000L-LX1-2

-11

-20

1310

-7

-20

1310

0-10/10-20

MCM1000L-LX1-3

-11

-20

1310

-5

-23

1550/DFB

0-10/10-40

MCM1000L-LX1-4

-11

-20

1310

-0

-24

1550/DFB

0-10/25-80

MCM1000L-LX3-3

-5

-23

1550DFB

-5

-23

1550/DFB

10-40/10-40

MCM1000L-LX4-4

0

-24

1550/DFB

0

-24

1550/DFB

25-80/25-80

MCM1000L-LX4-5

0

-24

1550/DFB

0

-32

1550/DFB/

APD

25-80/80-120

MCM1000SLXF13

MCM1000SLXF15

-9.5

-19

850/850

-9

-21

1310/1550

1550DFB /

1310

0,2/ 5-20

MCM1000SZXF13

MCM1000SZXF15

-9.5

-19

850/850

-3

-22

1310DFB/15

50

1550 DFB/

1310

0,2/ 10-40

MCM1000S/L GBE module

00

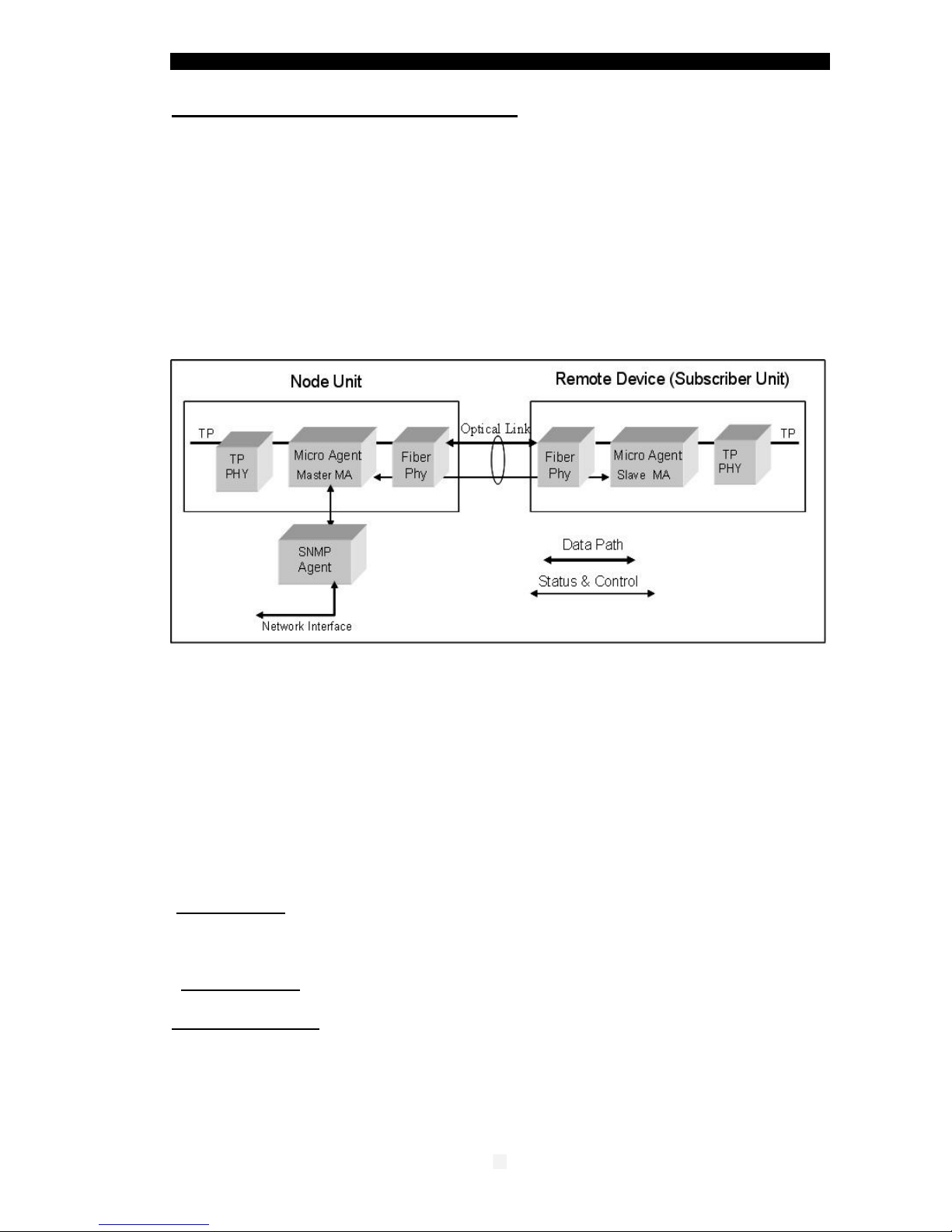

8 –MA Concept and Functions

The MA™ (Micro Agent) is an on-chip management system providing the monitoring

and management of remote access devices without the need of an expensive

SNMP agent module. The MA™ does not require an IP address

The chip is embedded in both the remote units, mostly referred to as a CPE, and in

the access concentrator device deployed in the access node. A unique secured in-

band management protocol allows the two devices communicating between

themselves over the fiber link bi-directionally, therefore both monitoring and

management commands can be remotely performed on the CPE. Control frames

are not forwarded to data ports

Micro Agent Basic System Block Diagram

When MA™ enabled devices are deployed at both ends of the fiber link, they

automatically learn about each other’s presence and begin providing full remote

management functions within 20 to 30m.seconds from the moment the link has

been established. However, if an MA™ enabled devices cannot complete such

handshake within that time, it concludes that the opposite end device is not MA™

enabled, subsequently it bypasses its special functions and operates like a

standard, straight forward access device. Therefore there are no interoperability

issues between network devices which have MA™ chips embedded in them and

those that have not.

The following management functions are available for the MCM1000S/L

module through an MA™ enabled and SNMP managed MetroStar:

Module status: display the MCM1000S/L ports basic status and configuration

settings Link status (SX and LX), Signal Detect status (SX and LX), Channel’s enable

(LX), LST modes, Loop-back (SX and LX), SLE modes, Remote MA device type and

Power status)

Module Control: provides the user with options to set the channel’s description,

LB/LST control, enable/disable channel, and to restore the module’s defaults setting.

Link management: related to the complete MA link including both ends,

the module channel on the local side and the remote CPE MA device:

Link Status, Set link bandwidth, Enable/Disable Up/Downstream SLE, invoke MA

remote device menu, Restore link default parameters.

Note: for a detailed description, please refer to the MMM-01 Management

Manual (version 1.6.2 and up).

MCM1000S/L GBE module

02

9 –MMM-04 enhanced management module

The MCM1000S/L module may also be managed via the MMM-04 management module.

The new module is aimed at replacing the MMM-01 module currently operating with the

MetroStar System.

The need to redesign and replace the MetroStar management module has emerged from

two main reasons:

Processor –a more powerful processor is used

Operating System - using a newer OS provides the foundation for a more flexible system,

with extended capabilities.

Features and Characteristics:

Linux operating system

SNMP V1, V2c, MIB II

(RFC1213/1215, RFC1514)

Web Management

IPv4

SSHv1/2

Telnet

FTP/TFTP client

RADIUS

Syslog and local logging

NTP V1-V4

Manages ALL line modules and

remote devices

Single slot, hot swappable

Remote S/W upgrade

2xRJ-45 for network

connection and for Console

Diagnostic LEDs

Alarms, programmable filtering

Comprehensive Statistics

MCM1000S/L GBE module

03

10 –DIP switches setting.

Each MCM1000S/L module is equipped with an array of 4 DIP switches that facilitate the

proper testing and setting of the F/O ports for optimal operation.

The DIP switches array is located on the motherboard. The module may contain either a

“piano” like array of DIP switches (blue color) or an array of slide switches (black color).

The following operations can be implemented on each F/O port:

Loop-back enable / disable

Link segmentation test: LST ON (Test mode), LST OFF (Link failure notification)

NOTE: The MA management overrides the DIP switches setting

UP –loop-back enable - port 1

UP –loop-back enable - port 2

Down –loop-back disable - port 1

Down –loop-back disable - port 2

UP –Test Mode - port 1 to port 2

Up –Test Mode - port 2 to port 1

Down - LST OFF - port 1 to port 2

Down - LST OFF - port 2 to port 1

LB=Loop-back

LST= Link Segmentation Test

Default DIP switches set-up:

S1,S2 in Down position (LB disabled)

S3,S4 in UP position ( LST ON=Test Mode)

Up

Down

TP F/O

Port Setup

LB LST

S1 S2 S3 S4

TP F/O

ON

OFF

Black Type DIP slide switches

1 2 1 2

Port Setup

LB LST

S1 S2 S3 S4

Blue Type DIP switches

Default DIP slide switches

set-up:

S1,S2 ON ( LB disabled)

S3,S4 OFF( LST ON=Test Mode)

The various settings are exactly

the same as those described

for the Blue Type DIP switches

Recall that UP position (in Blue

DIP switch) = OFF (in Black type

DIP switch) , Down=ON

UP –loop-back enable - port 1

UP –loop-back enable - port 2

Down –loop-back disable - port 1

Down –loop-back disable - port 2

UP –Test Mode - port 1 to port 2

Up –Test Mode - port 2 to port 1

Down - LST OFF - port 1 to port 2

Down - LST OFF - port 2 to port 1

LB=Loop-back

LST= Link Segmentation Test

Default DIP switches set-up:

S1,S2 in Down position (LB disabled)

S3,S4 in UP position ( LST ON=Test Mode)

Up

Down

TP F/O

Port Setup

LB LST

S1 S2 S3 S4

TP F/O

ON

OFF

Black Type DIP slide switches

1 2 1 2

Port Setup

LB LST

S1 S2 S3 S4

Blue Type DIP switches

Default DIP slide switches

set-up:

S1,S2 ON ( LB disabled)

S3,S4 OFF( LST ON=Test Mode)

The various settings are exactly

the same as those described

for the Blue Type DIP switches

Recall that UP position (in Blue

DIP switch) = OFF (in Black type

DIP switch) , Down=ON

Note: prior to power on the device, ensure that the DIP switches are in Default mode

LB (loop-back)

In normal operation, the LB DIP switches are in disable mode (DOWN position)

When it is necessary to perform a loop-back test in the selected port, then the

associated LB DIP switch should be enabled (UP position). The appropriate

LB LED will light to indicate that the selected MCM1000S port is in loop-back mode.

Before applying power to the module, ensure that the LB DIP switches are down.

LST (Link Segmentation Test)

The LST DIP switches have two positions per port. As long as no link failure is detected,

data is communicated normally.

When the DIP switches (S3 and S4) are in down position, this is the LST OFF mode of

operation. If a link failure occurs on one port, a signal is transmitted through the network;

the signal will turn off the link indicators on its way to the remote Network Device, which

is alerted and notified of the Link failure.

When the LST DIP switches are changed to Test Mode (UP position, LST ON) and there

is a link failure an idle signal is propagated in the network. This mode is used to identify a

failed link segment. In Test mode, the LST LED will lit (for each DIP switch S3 and S4)

Refer to next pages for a detailed explanation.

MCM1000S/L GBE module

04

11 –Link Segmentation Test (LST)

The MCM1000S is equipped with a powerful link status alert and link testing mechanism

-the “ Link Segmentation Test “, which allows the user to determine the behavior of the

MCM1000S media converter when a link failure is detected and notify the Network

Device on the integrity of the link. Thus the LST provides a view into what goes on

between two attached converters. It monitors the link status of a connection and forwards

this info to the Network Device. Network Devices are therefore aware of the link loss

on the “ other side “ of the converter and can select an alternate path.

In low cost GBE converters, a link failure at one port will cause the entire link to fail

without any notification and alertness of the link failure.

The MCM1000S module has two DIP switches for each direction where the LST function

is required as shown in figure-1.

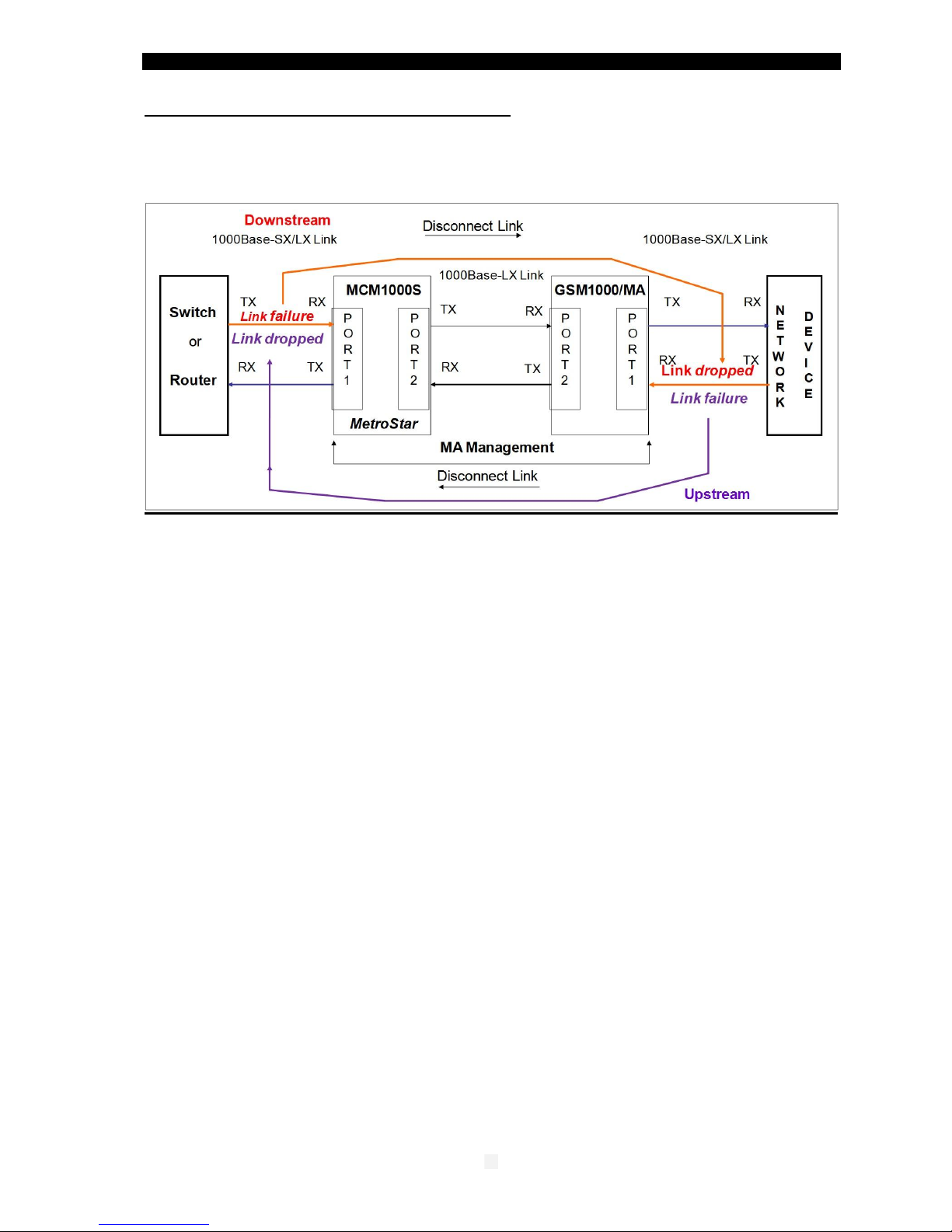

Figure –1 depicts the sequence of events when the LST DIP switches are in LST OFF

position and the link between Network Device B and the GSM1000/MA has failed.

Figure –1 LST OFF (Link failure notification)

1. The LST DIP switches (S3 and S4) in GSM1000/MA and MCM1000S module are in

LST OFF (Down position).

The active MA will override the setting of the DIP switches in GSM1000/MA

and the default values are established by the MMM-01 SNMP management

module installed in the MetroStar system. Therefore you have to setup the DIP

switches in GSM1000/MA from the remote management agent.

2. The LST in OFF mode will disconnect the entire link in the following events:

a. When a link failure takes place between Network Device B and GSM1000/MA,

the device GSM1000/MA detects a Link Down condition and transmits a signal to

MCM1000S module. This causes a Link Down condition at MCM1000S module

which will consequently disconnect the fiber link to Network Device A.?

Network Device A is thus alerted that a Link failure has occurred in the network.

b. Same events will take place (in opposite direction) in case that the link between

Network Device A and the MCM1000S module fails.

c. If both the fiber links (1000Base-LX) fail between the MCM1000S module

and the GSM1000/MA, appropriate signals are transmitted to both remote

Network Devices alerting them that there is a link failure.

A link down condition will thus occur between the MCM1000S and GSM1000/MA

and their attached Network Devices.

3. The LST in Test Mode (LST DIP switches in UP position) is used to isolate a failed

link segment. In Test mode an idle signal is transmitted which will turn on the

Link indicators of the intact link segments (provided that no data flow is taking

place at the same time.)

MCM1000S/L GBE module

05

In Test mode, as long as no link failure is detected, data is communicated normally.

In case of a link failure in LST OFF mode, the Test Mode will provide a visual

indication of the active and operative links and indicate the failing link segment.

Figure- 2 (below) depicts the sequence of events when the LST DIP switches are

changed to Test Mode, following a link failure occurred in LST OFF mode.

S3

S4

S4

N

E

T

W

O

R

K

D

E

V

I

C

E

N

E

T

W

O

R

K

D

E

V

I

C

E

MCM1000S GSM1000/MA

TX TX TX

TXRX

RX

TX RX

RX

RX

AB

P

O

R

T

1

P

O

R

T

2

P

O

R

T

2

P

O

R

T

1

S3

Idle signal

TX

RX

Link On

Idle signal

Link On

Link Segment OK Link Segment OK Failed Link

1000Base-LX

1000Base-SX 1000Base-SX

MetroStar

S3

S4

S4

N

E

T

W

O

R

K

D

E

V

I

C

E

N

E

T

W

O

R

K

D

E

V

I

C

E

MCM1000S GSM1000/MA

TX TX TX

TXRX

RX

TX RX

RX

RX

AB

P

O

R

T

1

P

O

R

T

2

P

O

R

T

2

P

O

R

T

1

S3

Idle signal

TX

RX

Link On

Idle signal

Link On

Link Segment OK Link Segment OK Failed Link

1000Base-LX

1000Base-SX 1000Base-SX

S3

S4

S4

N

E

T

W

O

R

K

D

E

V

I

C

E

N

E

T

W

O

R

K

D

E

V

I

C

E

MCM1000S GSM1000/MA

TX TX TX

TXRX

RX

TX RX

RX

RX

AB

P

O

R

T

1

P

O

R

T

1

P

O

R

T

2

P

O

R

T

2

P

O

R

T

2

P

O

R

T

2

P

O

R

T

1

P

O

R

T

1

S3

Idle signal

TX

RX

Link On

Idle signal

Link On

Link Segment OK Link Segment OK Failed Link

1000Base-LX

1000Base-SX 1000Base-SX

MetroStar

Figure –2 LST ON - Test Mode

4. Isolation of a failed link segment:

a. To isolate the failed link segment (between the GSM1000/MA and the Network

Device B, the LST DIP switch S4 in MCM1000S module is turned ON

(Test mode) via the remote management

This action generates an idle signal to be transmitted from MCM1000S to

Network Device A turning On the Link at Network Device A. This indicates

that the link segment between the MCM1000S module and Network Device

A is operative.

b. The DIP switch S3 (port1>port2) at the GSM1000/MA device must be physically

set to Test Mode which in this case will cause the F/O Link LED at

MCM1000S/L (port2) to lit (Link ON)

This indicates that the link segment between the MCM1000S and GSM1000/MA

is intact and operative.

c. The above tests are an absolute indication that the failure is in the link segment

between the Network Device B and the GSM1000/MA port 1

d. After having located and repaired the failing segment, it is advisable to turn the

MCM1000S LST DIP switches to their default setting.

Notes (when GSM1010/MA or GSM1000/MA acts as a remote device ):

To preserve the link integrity for the MA inband management, the DIP switch S3

and S4 (in GSM1000/MA or GSM1010/MA) are by default set to Test Mode (LST ON)

Similar default setting applies to the MCM1000S module.

5. The correct deployment of the LST mode of operations in the FibroLAN MA managed

devices depends primarily on the network topology.

If the attached Network Devices (switches, routers) can provide an alternate path in case

of a link failure, then it is advisable and recommended to deploy the LST OFF mode (in

this case the Network Device is alerted of a link failure).

In case of a link failure, it is necessary to switch to Test mode in order to locate the failed

link segment. (via DIP switches or appropriate MA management commands)

6. On the other hand, if the attached Network Devices are dumb units and are unable to

provide an alternate path, then it is recommended to deploy the LST DIP switches in

Test mode (LST ON) which is the default setting.

MCM1000S/L GBE module

06

12 –SLE (Subscriber Link Emulation)

If the remote device is a FibroLAN MA™ device (GSM1000/MA or GSM1010/MA) and

the MetroStar system is managed, the most powerful SLE feature may be deployed to

further enhancing the network resilience.

SLE Operations

FibroLAN’s Subscriber Link Emulation virtually emulates the subscriber’s device or

network connected to the TP (or F/O) port of the remote device (GSM1010/MA or

GSM1000/MA) onto the F/O link of the MCM1000S/L port module (connected usually to

a switch/router). When activated (controllable via the management system only) it

senses the loss of the TP link (or F/O link) connected to the remote MA device, notifies

the MCM1000S/L and cuts off the port 1 F/O link of the MCM1000S module, alerting in

real time the switch/router of the subscriber’s failure. All this is performed without

disrupting the main F/O link, thus ensuring on-going control of the remote device (CPE)

via MA.

It should be noted that if the F/O link of port 1 of the MCM1000S/L module

(normally connected to a switch/router port) has failed, the SLE will cut-off the TP

port (or F/O) link of the remote GSM1000/MA device, providing in this manner an

optimal bidirectional safe operation.

Thus SLE has in effect two modes of operation:

Downstream SLE mode: link failure of the MCM1000S/L module F/O input port

(port 1) will cause the disconnect of the link input port of the remote GSM1000/MA

device

Upstream SLE mode: remote MA device link input port failure will cause the

disconnect of the MCM1000S module link port

Again it must be emphasized that this extensive set of features is obtained only if MA

enabled devices are installed at both ends of the link.

Note: When the SLE mechanism is enabled, it will override the LST mechanism.

During normal network operation, it is recommended to activate the SLE mechanism.

(Enable Downstream and Upstream modes through the management).

Use and stay in the LST ON (TEST mode) if link failure alertness is not needed.

In this case a link failure is indicated by its LED link OFF.

MCM1000S/L GBE module

07

13 –Typical Configuration

The MMM-01 Management module installed in the MetroStar System will monitor and

control and manage the modules installed in the MetroStar chassis and the remote MA devices.

It will report alerts and traps to the SNMP Manager located in the Central Node.

MetroStar™ equipped with a management module can be monitored and managed

from any SNMP management station running popular management platforms

(e.g. FibroLAN’s MetroView, HP OpenView, SNMPc, etc)

When the remote MA enabled devices are connected through their F/O link to a remote

Access Concentrator like the MetroStar which is MA™ enabled and SNMP managed, a

comprehensive set of monitoring and control functions can be implemented (through the

MCM1000S MA enabled module) into GSM1000 MA enabled remote devices.

When the remote device is not an MA device the MCM1000S/L module will act/perform as

a normal GBE media converter in respect to the attached remote device.

MCM1000S/L GBE module

08

14 –Troubleshooting

Prior to performing the following procedures, verify that the LB DIP switches are in DOWN

position (loop-back disable). Verify that the LST DIP switches are in Test Mode. Perform

the same setup at the remote MA device, including the disabling of SLE.

Problem

Indication

Corrective Action

No power

LED PWR:

Main power not

lit

Ascertain that the module is well inserted into its

slot and that its screws are firmly fastened.

Check that the power supplies LEDs in the PMM or

Management module are lit

Fiber link not working

(port 1 or port 2)

Link LED not lit

Verify that the correct fiber optic cables are being

used, i.e. multi-mode or single mode. Check that

the receive fiber is properly connected to the

transmit port of the remote fiber device AND the

transmit port to the receive port of the remote

device.

Perform a loop-back test to verify F/O port

integrity.

If LB test fails, verify that the output power of the

fiber optic port (s) is within manufacturer’s

specifications. Verify that the dB loss of the fiber

cable you are connecting to plus additional losses

(connectors losses, normally 1,5dB per mated pair;

Splice loss 0.3db max and 3db loss for safety

margin) is within the allowed dB budget. You may

deploy the LST ON to locate the failing segment

(Refer to section 11 for more details).

No transmit/receive on

F/O port

LED Act not lit

Check the status of the various LEDs indications

and F/O Links. Ensure that the equipment attached

to the MCM1000S module is properly configured

and operating.

Recall that the MCM1000S module does NOT

support Auto-Neg. on its F/O ports. Thus any

network device that is connected to the

MCM1000S F/O ports should be configured to

A/N disabled mode (i.e. forced to 1000Mbps and

FDX.

MA is not working

MA Active LED

not lit

Verify that the MCM1000S module is properly

connected to the remote MA device

Check that the Link LED is lit at both ends.

At the MetroStar management station perform the

following MCM1000S module checks:

a. Link status

b. Signal Detect status

If necessary, you may perform the “ Restore link

default parameters “ command

Check also the status of the remote attached

device.

MCM1000S/L GBE module

09

If the problem persists after carrying out the above procedure, do the following: exchange

suspected MCM1000S module with another similar module, and check connectivity

and mode of operation. If that has solved the problem, send your MCM1000S for repair. If

the problem still persists, there is probably some sort of general network failure. Call your

Make sure to provide the following information:

Date and place of purchase, from whom, original invoice

The serial number of the MCM1000S module and its Firmware revision

The serial # of the MetroStar™ including type of the installed modules.

The configuration of the equipment that is connected to the MetroStar™and the

sequence of events leading to the problem.

Actions already taken and status files.

Software revision levels of the installed equipment.

15 –Specifications

Standard Compliance

IEE 802.3 2000 edition, 1000Base-SX 1000Base-LX, IEEE802.3z

Conversion Method: Digital Conversion

Management:

SNMP management via MetroStar management module –MMM-01

F/O ports

Port 2: Duplex SC, S/M fiber, 1310/1550nm, 1000Base-LX (10/20/40/80/120 Km)

Port 1: Duplex SC, M/M fiber, 850nm, 1000Base-SX, (220m)

For Fiber optic specifications for each MCM1000S model, refer to “ section 7 “ Fiber Optic

Connections

Diagnostic LEDs:

Link, Activity (Tx or Rx), LB (loop-back), LST LEDs for F/O port 1

Link, Activity (Tx or Rx), LB (loop-back), LST LEDs for F/O port 2

MA Active (indicating MCM1000S connected to a remote MA active device) Common

LED

Power: power on / off (PWR LED)

DIP switches (mother board) per port

LST (Link Segmentation Test) Normal / Test mode (Down/Up)

LB (loop-back) enable / disable (Up/ Down)

The active Ma™ Management overrides the DIP switches setting

Management of Remote Devices: via MA™ Technology

SLE mechanism enabled/disabled thru MMM-01 management module

Specifications are subject to change without prior notice

Module default settings

Downstream bandwidth 1000Mbps

Channel enabled

LST enabled both ways (LST ON)

LB disabled both ways

SLE disabled both ways

No channel description

MCM1000S/L GBE module

21

16 –Warranty Limitation

FibroLAN warrants the equipment to be free from defects in material and workmanship, under

normal and proper use and in its unmodified condition for 24 months (unless

otherwise agreed upon) starting on the date of delivery from FibroLAN to its distributor.

FibroLAN’s sole obligation under this warranty shall be to furnish parts and labor for the repair or

replacement of products found by FibroLAN to be defective in material or workmanship during

the warranty period. Warranty repairs will be performed at the point of manufacture.

Following an authorized repair, the device shall be under warranty throughout its original period

but not less than 3 months.

Warranty shall be void in case where unauthorized attempts to repair or disassemble

/modify the device are evident.

You must claim repairs or replacements under this warranty only from the reseller from which you

have purchased the device, however you may refer directly to FibroLAN Ltd. to claim the

warranty providing reasonable proof that the reseller ceased operation and/or unreasonably

refused to provide you with the service. In such case you provide to FibroLAN the serial number

of the device, date purchased, full details of reseller from whom the device was purchase and a

copy of an invoice or another proof of the purchase.

This document and the information contained herein are proprietary to the manufacturer

and are furnished to the recipient for use in operating, maintaining and repairing

manufacturer equipment.

The information within may not be utilized for any purpose except as stated herein, and

may not be disclosed to third parties without the written permission from the

manufacturer. The manufacturer reserves the right to make changes to any technical

specifications in order to improve reliability, function and design.

This manual is applicable for Firmware revision v 2.3 and up

©COPYRIGHT 2003 –FibroLAN Ltd. All rights reserved

June 2011 –Version 2.4

This manual suits for next models

13

Table of contents

Other FibroLAN Media Converter manuals

Popular Media Converter manuals by other brands

Baumer

Baumer Hubner DeviceNet HMG10 operating manual

ADF Web

ADF Web HD67E05-IP-A1 user manual

Aventura

Aventura FBR-1FE1FX-SFP-MINI instruction manual

Adaptec

Adaptec VideOh! CD AVC-1100 Getting started

FOLSOM

FOLSOM 2100DE Installation and operator's manual

Shenzhen 3onedata Technology

Shenzhen 3onedata Technology 3012 user manual

Transition Networks

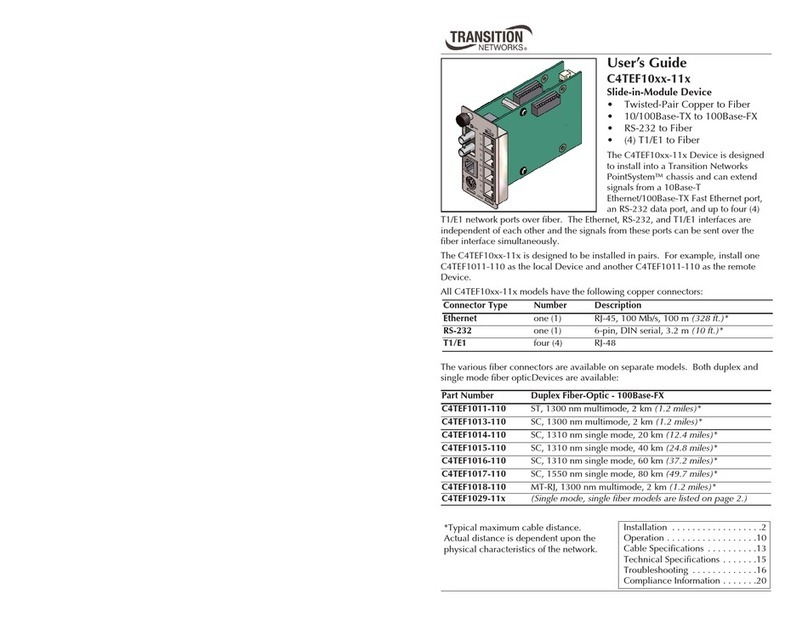

Transition Networks C4TEF1011-110 user guide

Cypress

Cypress HTCP-255DN Operation manual

NXP Semiconductors

NXP Semiconductors SSL2101 user manual

Treasure Cove

Treasure Cove Vibra-Phone 280 manual

Hama

Hama 00039960 operating instructions

Taiden

Taiden HCS-8316 series Installation and operation manual