Fike TWINFLEX SRM 100-0010 User manual

INSTALLATION AND MAINTENANCE INSTRUCTIONS

100-0010 Twinflex SRM Module

26-1369-01

1

TWINFLEX®SRM

Solenoid Releasing Module

100-0010

(Suitable for TWINFLEX®SRP control panels from V01.000)

Solenoid Releasing Module

Engineering and Commissioning

Manual

(TO BE RETAINED BY THE COMMISSIONING ENGINEER)

26-1369-01

2

Contents

General Description......................................................................................................3

Before Installation.........................................................................................................4

Positioning......................................................................................................................................4

Device Installation / Mounting ......................................................................................................4

Connections ..................................................................................................................6

Module Layout................................................................................................................................6

Zone Connections (J1)........................................................................................................7

Solenoid Connections (J2)..................................................................................................8

External Power for Solenoid (J3) ........................................................................................9

Input Connections (J4, J5, J6)..........................................................................................10

Discharge pressure circuit (J4) .........................................................................................11

Bottle pressure switch circuit (J5) .....................................................................................11

Solenoid Missing circuit (J6) .............................................................................................11

Acceptance Testing ....................................................................................................12

Hardware Connections ...............................................................................................13

Inspections & Testing.................................................................................................13

DIL Switch SW2 Settings............................................................................................14

LED Table.....................................................................................................................15

Operation.....................................................................................................................16

Technical Data.............................................................................................................17

Technical Support.......................................................................................................18

26-1369-01

3

General Description

The SRM (Solenoid Releasing Module) is a module that controls the

operation of the Solenoid valve(s) in a Suppression system. The typical

applications where the SRM can be implemented for are –Pre-action

sprinkler, Deluge, CO2, Water mist and Foam. The SRM can be used to

monitor a Discharge Pressure switch to provide feedback to the Control

Panel that the Releasing agent has been dumped into the protected space.

The SRM can also be used to monitor the Solenoid and container for any

fault conditions like low bottle pressure, wire connections, faulty actuator

coil, tamper valve etc.

The SRM is connected to the Twinflex SRP (Single Releasing Panel) via a

dedicated zone circuit.

The zone circuit is configured on the SRP as –Release SRM. A maximum of

2 SRMs can be connected on a Zone circuit. The communication between

the SRP and SRM(s) is established via the Twinflex signaling protocol.

26-1369-01

4

Before Installation

The Twinflex SRM must be installed in compliance with the SRP installation manual. The installation

must also meet the requirements of any local authority and BS7273 Pt1 : 2006.

Positioning

The module should be mounted securely and care should be taken to ensure the device is accessible for

future maintenance.

Device Installation / Mounting

All wiring must be installed in compliance with the recommendations laid out by BS7273 Pt1 : 2006

as well as any special recommendations documented in the control panel installation manual. The

cabling used should be of a 2-core 1.5mm2screened, fire resistant type (e.g. MICC or FP200 equivalent),

and is to be wired in the form of a screened 2-core radial circuit (with no spurs) from the control panel,

terminating at the last (“End of Line”) device. Note that ALL connections, including inputs, should be

made via screened FP cable.

Fix the back box in a suitable position using the screw holes provided on the back, remembering to allow

enough space for the correct termination of the appropriate fire resistant cable. See technical data on

page 15 for enclosure dimensions.

This equipment is only IP30 rated so must be mounted outside the area being protected.

There are six 20mm cable entry points provided on the top and one on each side of the enclosure.

These are not knockouts and should be removed either by running a sharp knife around their outer

groove or drilling out the cable entry points.

Site safety procedures should always be observed when using a knife to remove the cable entry points.

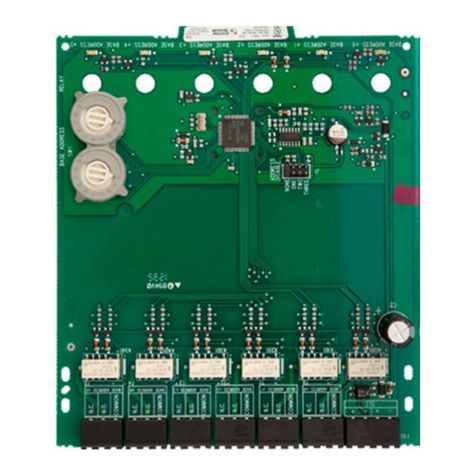

If cable entry points are drilled out the PCB should be removed from the enclosure before drilling

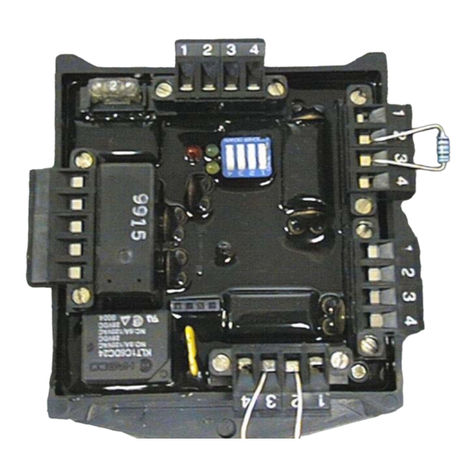

(see Figure 1).

26-1369-01

5

Figure 1 –The SRM Layout

Stuffing glands should be used on all cables to prevent stress being applied to the PCB mounted

terminals.

Care should be taken when terminating devices to ensure all cables are correctly sleeved and

connections are secure. Improper connections will prevent a system from responding correctly in the

event of a fire.

To prevent an inadvertent extinguishant discharge, the solenoid valve should not be connected to the

container while wiring the SRM circuits and setting up the DIL switches SW1 and SW2. The solenoid

should be connected to the container after all other installation has been completed and verified.

26-1369-01

6

Connections

In order to carry out high voltage testing and resistance measurements, temporarily connect the

incoming and outgoing zone cables to each other using a 3-way connector block. Once all testing has

been carried out on the cabling, and ‘continuity & integrity’ has been proven, the SRM may be

connected and assembled.

Please remember that all high voltage testing must be carried out before the installation of the SRM

otherwise the electronics will be damaged.

Remember that the device at the end of the line must have its EOL signal activated using the relevant

EOL switch (Refer to DIL switch settings table on page 12). Do not use a resistor or capacitor (or

another manufacturer’s End of Line device) as the end of line, as this may prevent correct operation of

the zone.

Module Layout

The following figure shows the SRM layout. Terminals J1 thru J6 are used for all the field wiring

connections. DIL switch SW1 is used to select between 1x24V or 2x12V solenoid(s) and

DIL switch SW2 is used to configure the SRM (Refer to DIL switch SW2 settings table on page 12).

Figure 2 –SRM Board Layout

26-1369-01

7

Zone Connections (J1)

Figure 3 shows how to make the zone positive, zone negative and screen connections between the SRP

panel and the SRM(s).

Figure 3 –Zone Connections

Please note that the “SCREEN” terminals on the SRM should only be connected to the zone cable screen

and NOT to the building earth or the back box earth terminal. The cable screen is connected to earth at

the panel end only, via the zone “SCRN” terminal. It is important to maintain the screen continuity in

order to protect against data corruption from interference.

Fault Monitoring –Zone connections are power limited and supervised. Open and Short faults cause a

loss of communication between the SRP panel and the SRMs. They are detected and annunciated by the

SRP panel.

26-1369-01

8

Solenoid Connections (J2)

Solenoid connections are power limited and supervised. The Solenoid connection (12 or 24 volt)

requires an EOL circuit supervision assembly (Part# 17-0144), provided by Fike, to be installed between

the SRM and the solenoid coil. The assembly provides a means to monitor the solenoid wiring for open

and short faults.

A single 24V solenoid must be connected as shown in Figure 4. DIL switch SW1 must be in ON position

and the solenoid needs to be connected between terminals 1 and 4 at the Solenoid Valve terminal block.

The maximum cable length between the Solenoid and the SRM must not exceed 3 meters.

Figure 4 –24 Volt Solenoid Connections

Two 12 V solenoids must be connected as shown in Figure 5.

DIL switch SW1 must be in OFF position. Solenoid #1 needs to be connected between terminals 1 and 2

and Solenoid #2 needs to be connected between terminals 3 and 4 at the Solenoid Valve terminal block

on the SRM. The maximum cable length between the solenoid and the SRM must not exceed 3 meters.

Figure 5 –12 Volt Solenoid Connections

26-1369-01

9

External Power for Solenoid (J3)

A 24V DC 2A External Battery Backed Up power supply is required to power the solenoid to dump the

Releasing agent. The 24V DC power can be supplied by the SRP panel AUX PWR 1 & AUX PWR 2

terminals.

Note: If the SRP Panel AUX PWR is used, each AUX PWR output can supply up to a maximum of 1A

which must not be exceeded.

If a separate external power supply is used it must be listed for use with Fire Alarm systems. It must be

connected to +24V and 0V terminals on J3.

Due to 24V DC input and solenoid isolation from the host control panel the connected power supply

must have the ability to indicate a ground fault on the 24V DC and also provide an on-board fault relay

that must be connected to a Monitored Input on the SRP to signal the fault.

26-1369-01

10

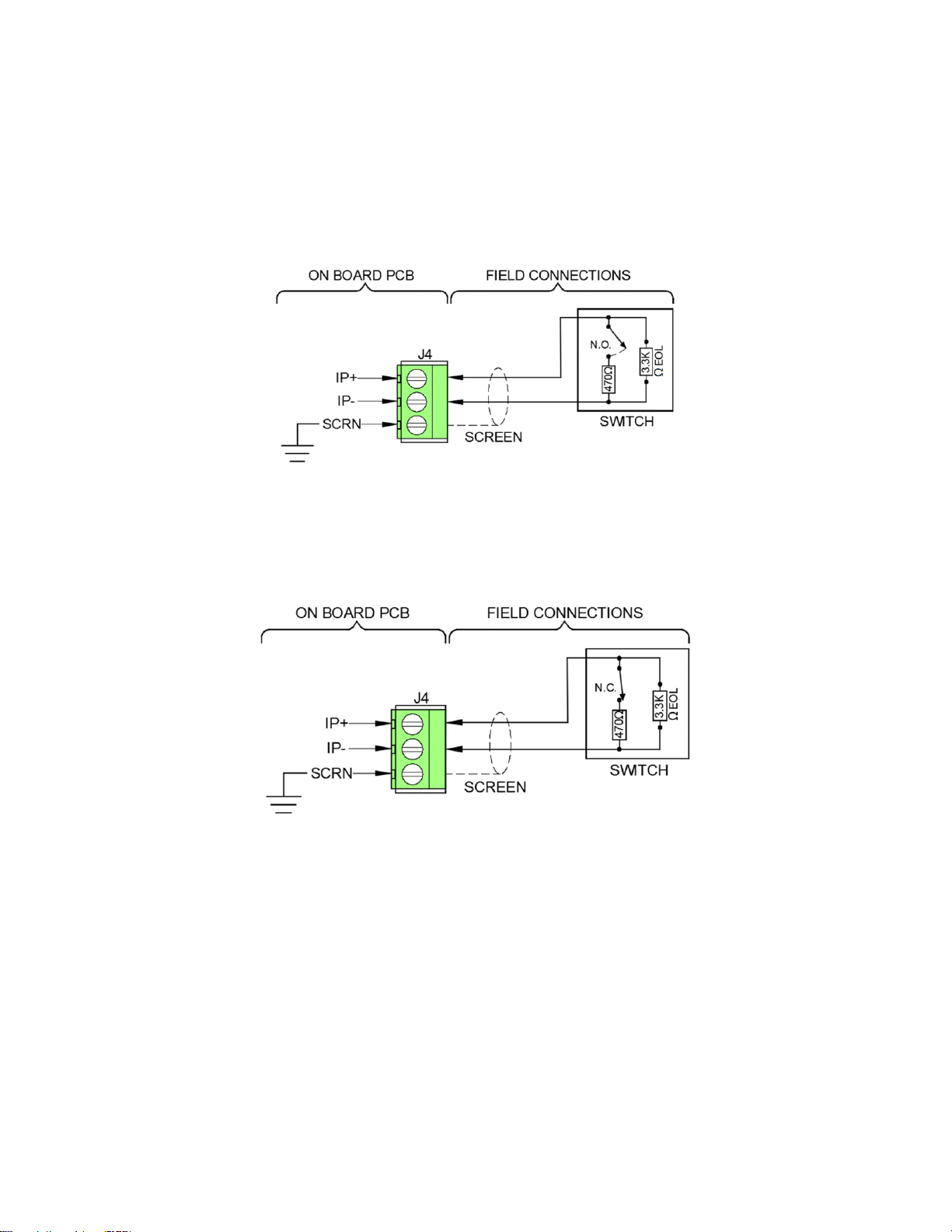

Input Connections (J4, J5, J6)

Input connections on Terminals J4, J5 and J6 are all contact closure inputs. The inputs can be individually

configured (via DIL switch SW2) to be normally open or normally closed. Figures 6 and 7 show how to

make input connections. All input connections are power limited and supervised.

The maximum cable length between the input device and the SRM must not exceed 3 metres.

Note: The triggering resistor used can be a 470Ωresistor (shown) or a 680Ω resistor.

Figure 6 –Normally Open Input Connection

Figure 7 –Normally Closed Input Connection

26-1369-01

11

Discharge pressure circuit (J4)

The following table shows state of the circuit based on connection type and switch position:

Switch Open

Switch Closed

Normally Open

Normal state

Active state

Normally Closed

Active state

Normal state

Normal state - Circuit is in Normal state.

Active state –The Discharge pressure switch is active which indicates that the extinguishing agent has

been released. The SRP Panel indicates this as a Released condition.

Bottle pressure switch circuit (J5)

The following table shows state of the circuit based on connection type and switch position:

Switch Open

Switch Closed

Normally Open

Normal state

Active state

Normally Closed

Active state

Normal state

Normal state - Circuit is in Normal state.

Active state –Bottle pressure switch is active which indicates that the pressurized container has a leak.

The SRP panel indicates this as a Fault condition.

Solenoid Missing circuit (J6)

The following table shows state of the circuit based on connection type and switch position:

Switch Open

Switch Closed

Normally Open

Normal state

Active state

Normally Closed

Active state

Normal state

Normal state - Circuit is in Normal state.

Active state –It indicates that the solenoid has been physically removed from the releasing agent

container for maintenance or testing. The SRP panel indicates this as a Fault condition.

26-1369-01

12

Acceptance Testing

Acceptance testing shall be performed in accordance with the requirements of BS7273 Pt1 : 2006,

requirements of the Local Authority Having Jurisdiction (AHJ), and the following requirements:

Note: before carrying out the following tests the Solenoid must not be connected to the suppression

container.

1. Temporarily disconnect the solenoid valve wires from the SRM and verify that a fault signal is

received by the SRP panel.

2. Temporarily switch off the end-of-line switch from the last SRM or disconnect the last SRM and

verify that a fault signal is received by the SRP panel.

3. Temporarily remove the end of line (EOL) resistor across the Solenoid Missing Input and verify

that a fault signal is received by the SRP panel. Repeat this for Bottle Pressure and Discharge

Pressure Inputs. These faults take approximately 60 seconds to be reported.

4. Temporarily trigger the Solenoid Missing Input by connecting a 470Ω or 680Ω resistor across IP+

and IP- terminals and verify that a fault signal is received by the SRP panel. Repeat this for the

Bottle Pressure Input. These faults take approximately 60 seconds to be reported.

5. Temporarily trigger the Discharge Pressure Input by connecting a 470Ω or 680Ω resistor across

IP+ and IP- terminals and verify that the system goes into a release state.

6. Verify the SRM Release LED illuminates and the solenoid valve operates.

7. Reset the SRP panel and verify that the SRM Release LED turns off.

8. Using either a manual release or the detection method of the panel, initiate the release mode.

9. Verify the SRM Release LED illuminates and the solenoid valve operates.

10. Reset the SRP panel and verify that the SRM Release LED turns off.

11. Verify that the SRM does not activate during any state other than Release for the programmed

Zone.

12. Secure the SRM front cover plate to the back box using the screws provided, as shown in

Figure 1 above. Make sure wiring is not pinched or excessive strain is not placed on the SRM

terminal block.

26-1369-01

13

Hardware Connections

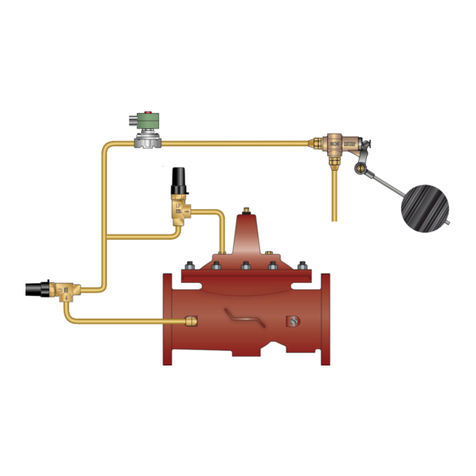

After the acceptance tests connect the solenoid valve (Figure 8) according to the valve manufacturer’s

instructions.

Figure 8 –Solenoid Valve

Note: A discharge pressure switch (P/N 02-12534) must be installed on the discharge piping for

each container equipped with a manual release actuator (required as per

EN12094-1 Section 4.18 option with requirements).

Inspections & Testing

The suppression system(s) shall be inspected and tested in accordance with the requirements of

BS7273 Pt1 : 2006 and the Local Authority Having Jurisdiction (AHJ). Inspection and testing shall be

performed by the system installer or an approved maintenance company who has been trained on the

correct operation and testing of the system. Any defects should be recorded and reported to the person

responsible for routine testing.

A Supervision Assembly must be

used between the solenoid and

the SRM, see Figures 4 & 5.

The maximum cable length

between the solenoid and the

SRM must not exceed 3 metres.

26-1369-01

14

DIL Switch SW2 Settings

The SRM can be configured via an on board DIL switch SW2 as per the table below. The last device on

the zone circuit must have the EOL signal enabled (switch number 1 in the ‘ON’ position).

Switch

position

Configuration

1

OFF (Default) –Not an EOL device.

ON –EOL device.

2

OFF (Default) –The SRM indicates Released State only when a Discharge pressure switch

activates.

* ON –The SRM indicates Released State when a Solenoid coil is energized OR

a Discharge pressure switch activates.

NOTE: Only one SRM per zone circuit shall be set to activate the Discharge Pressure

Switch input.

3

OFF (Default) –Discharge pressure contact is Normally Open.

ON –Discharge pressure contact is Normally Closed.

4

OFF (Default) –Bottle pressure contact is Normally Open.

ON –Bottle pressure contact is Normally Closed.

5

OFF (Default) –Solenoid presence contact is Normally Open.

ON –Solenoid presence contact is Normally Closed.

6

Always OFF.

Unused.

7

Always OFF.

Used for Factory Test mode.

8

Always OFF.

Used for Factory Test mode.

* This option can be used when a Discharge pressure switch is not installed for Releasing pressure

confirmation. In that case the SRM can indicate a Released state as soon as the Solenoid coil is

energized.

26-1369-01

15

LED Table

LED Label

Pattern

Indication

State

Disabled

Fast Blink

SRM Disabled.

Disabled

Off

SRM Enabled.

Normal

Release

Fast Blink

Agent Released.

Released

Off

Agent not Released.

Normal

Discharge

Pressure

Fast Blink

Discharge pressure is high.

Release in process

Slow Blink

Discharge pressure switch wire short fault.

Fault

Very Slow Blink

Discharge pressure switch wire open fault.

Fault

Off

Discharge pressure is normal and wiring is good.

Normal

Bottle

Pressure

Fast Blink

Bottle pressure is low.

Fault

Slow Blink

Bottle pressure switch wire short fault.

Fault

Very Slow Blink

Bottle pressure switch wire open fault.

Fault

Off

Bottle pressure is normal and wiring is good.

Normal

Solenoid

Missing

Fast Blink

Release Tamper input activated

Fault

Slow Blink

Release Tamper input wire short fault.

Fault

Very Slow Blink

Release Tamper input wire open fault.

Fault

Very Slow Double

Blink

Solenoid coil open fault.

Fault

On Continuous

Solenoid coil short fault.

Fault

Off

No faults on Solenoid coil and Release Tamper

input is in Normal state.

Normal

Power

Fault

Fast Blink

External power is low.

Fault

Off

External Power is good.

Normal

Fault

Fast Blink

A Fault condition is present on the SRM.

Check other LEDs to determine the Fault type.

Fault

Off

No Fault present on the SRM.

Normal

Comms

Off

The SRM is not functional.

Fault

Momentary Blink

every 5 seconds

The SRM is functional and communicating with the

SRP panel.

Normal

Fast Blink –LED blinks once every ¼ second.

Slow Blink –LED Blinks once every 2 seconds.

Very Slow Blink –LED Blinks once every 5 seconds.

Very Slow Double Blink –LED Blinks twice every 5 seconds.

26-1369-01

16

Operation

Fault Monitoring –The SRM monitors all field wiring circuits for open and short faults. A fault is

indicated via on-board LEDs at the SRM. Fault type can be determined by observing the blink pattern of

active LEDs as listed in the LED table. Fault status is communicated to the SRP panel for indication at the

panel.

Disablement –The SRM can be disabled by disabling all releasing circuits at the SRP panel. The

disablement is indicated via the Disabled LED at the SRM. During disablement, the SRM does not

activate the solenoid automatically but it can still be activated manually via manual release actuator.

The SRM can be re-enabled by enabling all releasing circuits at the SRP panel.

Automatic Activation –The SRP panel signals the SRM to activate whenever the activation condition is

established. The SRM utilizes the external 24 volt power for solenoid activation. Based on the

DIL switch SW2 configuration setting, either the SRM waits for confirmation from the Discharge pressure

switch or it indicates a Released state as soon as the solenoid coil is energized.

Manual Activation –Manual activation is done by triggering the manual release actuator. A Discharge

pressure switch is required to indicate a Released state after a manual activation.

26-1369-01

17

Technical Data

Dimensions:

Overall Weight…………………………………………………

364g

Overall Size (W x H x D)……………………………………

189mm x 120mm x 56mm

Operating Temperature:

…………………………………………………………………………

-5oC to 40oC

Voltage Ranges:

Ext Supply………………………….…………………………….

24V to 28.5V DC

Zone Voltage……………….....................................

21.1V to 32V DC

Zone Operating Current

(Typical):

Quiescent………………………………………………………..

2.29mA

End of line ON (if applicable)……………………………

(in addition to Quiescent current)

0.07mA

Active……………………………………………………………….

5.58mA

Device Loading Units (DLUs)

…………………………………………………………………………

80

Number of devices per zone

…………………………………………………………………………

2

Solenoid:

…………………………………………………………………………

12V or 24V (see Solenoid

Connections on p6)

External Power Supply:

(for Solenoid)

…………………………………………………………………………

24V to 28.5V, 2A Max.

Max Cable Length to Inputs:

…………………………………………………………………………

3 Metres

Max Cable Length to Solenoid

…………………………………………………………………………

3 Metres

Flammability:

………………………………………………………………………..

UL94-V2

IP Rating:

…………………………………………………………………………

IP 30

Part Code:

…………………………………………………………………….….

100-0010

26-1369-01

18

Technical Support

Contact your supplier for technical support on this product.

Due to the complexity and inherent importance of a life risk type

system, training on this equipment is essential, and commissioning

should only be carried out by competent persons. Fike cannot

guarantee the operation of any equipment unless all documented

instructions are complied with, without variation. This unit

complies with the EMC directive.

Fike’s policy is one of continual improvement and the right to

change a specification at any time without notice is reserved.

Whilst every care has been taken to ensure that the contents of

this document are correct at time of publication, Fike shall be

under no liability whatsoever in respect of such contents. E&OE.

15

0843

Fike Safety Technology Ltd

Unit 31, Springvale Ind. Est.

Torfaen, NP44 5BD

15

DoP-100-0010

0843-CPR- 0222

Input/Output Device per EN54-18 ZA.3.

EN54-18:2005

100-0010

Intended for use in the fire detection and

fire alarm - Fixed fire fighting and gas

extinguishing systems in and around

buildings

Table of contents

Other Fike Control Unit manuals

Fike

Fike FIK-RVM User manual

Fike

Fike 55-043 User manual

Fike

Fike 55-046 User manual

Fike

Fike FAV User manual

Fike

Fike EIV User manual

Fike

Fike TWINFLEX IRM 100-0011 User manual

Fike

Fike P Service manual

Fike

Fike FIK-CR-6 User manual

Fike

Fike Lantronix XPort 10-2627 Operating instructions

Fike

Fike FIK-IM-10 User manual

Popular Control Unit manuals by other brands

Blonder tongue

Blonder tongue DAP Series instruction manual

Siemens

Siemens SITRANS F M MAG 8000 operating instructions

IBM

IBM BladeCenter Management Module installation guide

Eltek

Eltek flatpack2 user guide

unGer

unGer nLite HydroPower XXL manual

Pfeiffer Vacuum

Pfeiffer Vacuum HISCROLL operating instructions