Fike FIK-IM-10 User manual

BEFORE INSTALLING

If the modules will be installed in an existing operational system, inform the

operator and local authority that the system will be temporarily out of service.

Disconnect the power to the control panel before installing the modules. This

system contains static sensitive components. Always ground yourself with a

proper wrist strap before handling any circuits so that static charges are re-

moved from the body. The housing cabinet should be metallic and suitably

grounded.

NOTICE: This manual should be left with the owner/user of this equipment.

GENERAL DESCRIPTION

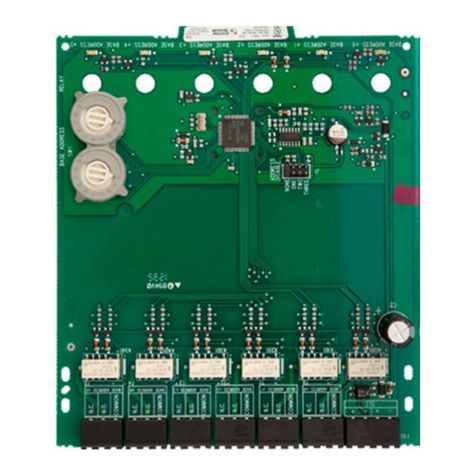

The FIK-IM-10 Ten Input Monitor Module is intended for use in an intelligent

alarm system. Each monitor module is intended to interface between a control

panel and normally open contact devices, such as pull stations. A common

SLC input is used for all modules, and the initiating device loops share a

common supervisory supply and ground. Otherwise, each monitor operates

independently from the others. Each module has its own unique address.

A pair of rotary code switches is used to set the address of the first mod-

ule from 01 to 150 (01 to 90 on panels that support up to 99 addresses).

The remaining modules are automatically assigned to the next nine higher

addresses. Provisions are included for disabling a maximum of two unused

modules to release the addresses to be used elsewhere. Each module also has

panel controlled green LED indicators. The panel can cause the LEDs to blink,

latch on, or latch off.

C0202-00

SHIPPED ON BOARD:

(1) Shunt in Class A/B position

(Shipped in Class B position, remove shunt for Class A)

COMPATIBILITY REQUIREMENTS

To ensure proper operation, this module shall be connected to a compatible

Fike system control panel.

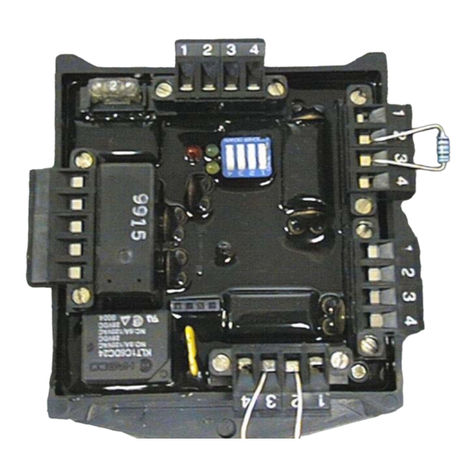

COMPONENTS

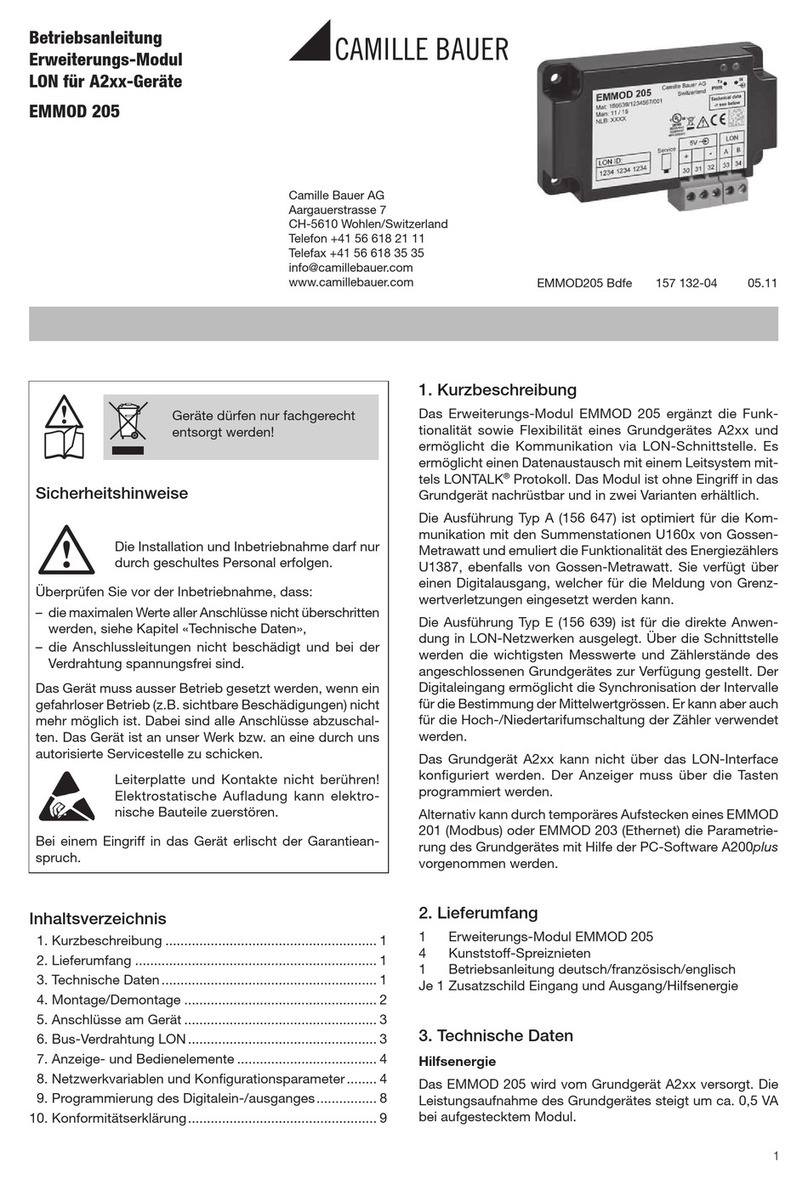

The following is a description of the FIK-IM-10 mounting framework:

• One or two FIK-IM-10 modules can be installed in an FIK-BB-2 cabinet.

The FIK-BB-2 cabinet has a built-in chassis that will accommodate one or two

FIK-IM-10 modules.

The front FIK-IM-10 module positions of each chassis are offset below the rear

0

1

2

3

4

56789

0

78

6

5

4

3

21

910

11

12

13

14

15

BASE ADDRESS

ADDRESS

DISABLE

NONE

ONE

TWO

THREE

0

1

2

3

4

56789

0

78

6

5

4

3

21

9

BASE ADDRESS

ADDRESS

DISABLE

NONE

ONE

TWO

THREE

10

11

12

13

14

15

C0234-05

FIGURE 1: FIK-BB-2 CABINET

FIK-IM-10 module positions so that all of the status indicators are visible. For

cabinet dimensions refer to the FIK-BB-2 instruction manual.

INCLUDED:

(6) 1 x 4 Terminal

Blocks

(2) 1¼" (32mm)

Stand offs

(3) Shunts (10) 47k Ohm End

of Line Resistors

(2) Nuts

(4) Machine Screws

SPECIFICATIONS

Normal Operating Voltage: 15-32 VDC

Stand-By Current: 3.75 mA @ 24V

Alarm Current: 55 mA (assumes all ten LEDs solid on)

Temperature Range: 32°F to 120°F (0°C to 49°C)

Humidity: 10 to 93% Non-condensing

Dimensions: 6.8" H x 5.8" W x 1.25" D

Accessories: FIK-BB-2 Cabinet and Chassis

Wire Gauge: 12-18 AWG

Maximum IDC

Wiring Resistance: 1500 Ohms

Maximum IDC Voltage: 10.2 VDC

Maximum IDC Current: 240 µA (each circuit)

I56-6893-000

INSTALLATION AND MAINTENANCE INSTRUCTIONS

R

704 SW 10th Street

Blue Springs, MO 64015

Phone: 816.229.3405; Fax: 816.228.9277

www.fike.com

FIK-IM-10

Ten Input Monitor Module

http://www.fike.com/06-912

Fo

r system/product documentation including

installation, operation, and maintenance,

scan QR code or enter URL provided.

1 I56-6893-000

1/15/2021

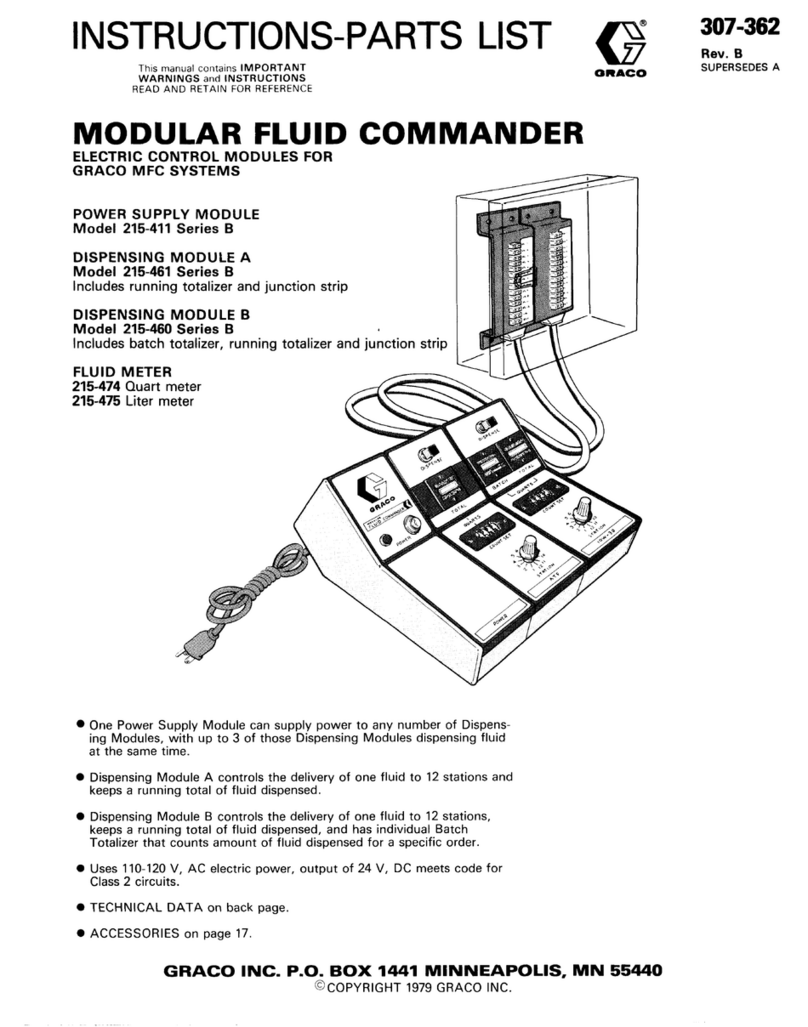

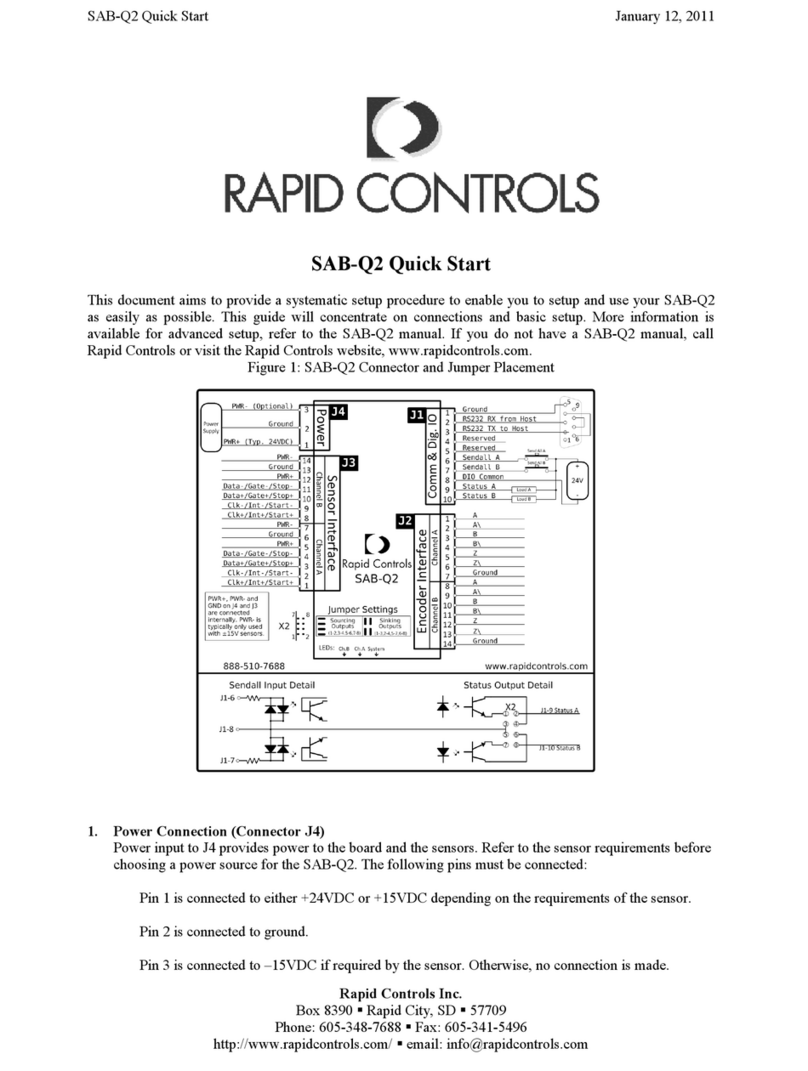

INSTALLATION STEPS

1. Cabinet Mounting

In a clean, dry area, mount the backbox using the four holes pro-

vided in the back surface of the cabinet. (See Figure 2.)

2. Module Installation

There are two methods for installing a module in the rear position

of a chassis. Method one is for installation of a rear module only,

when no module will be installed in front of it. Refer to Figure 3 for

instructions. Method two is for installation of a rear module when

another module will be installed in the chassis position in front of

it. Refer to Figures 4a and 4b for method two. All necessary screws

and standoffs are supplied with the modules.

C0237-00

FIGURE 3. INSTALLATION OF REAR MODULE ONLY, METHOD ONE

2

3

1

Step 1: Insert the bottom edge of the FIK-IM-10 module down into a rear slot

of the chassis.

Step 2: Carefully swing the upper edge of the board towards the back of the

chassis until it touches the short standoff attached to the chassis.

Step 3: Align the long standoff with the short stand off and tighten.

FIGURE 4A. INSTALLATION OF FIK-IM-10 MODULE IN A REAR CHASSIS

POSITION, METHOD TWO

1

2

3

1

FIGURE 4B. INSTALLATION OF FIK-IM-10 MODULE IN FRONT CHASSIS

POSITION

Step 1: Insert the bottom edge of the FIK-IM-10 module down into a front slot

of the chassis.

Step 2: Carefully swing the upper edge of the board towards the back of the

chassis until it touches the 11⁄4" (31.75mm) standoffs installed on the

rear module.

Step 3: Align two 4-40 screws with the two standoffs and tighten.

Step 4: Address and wire the modules according to the instructions in this manual.

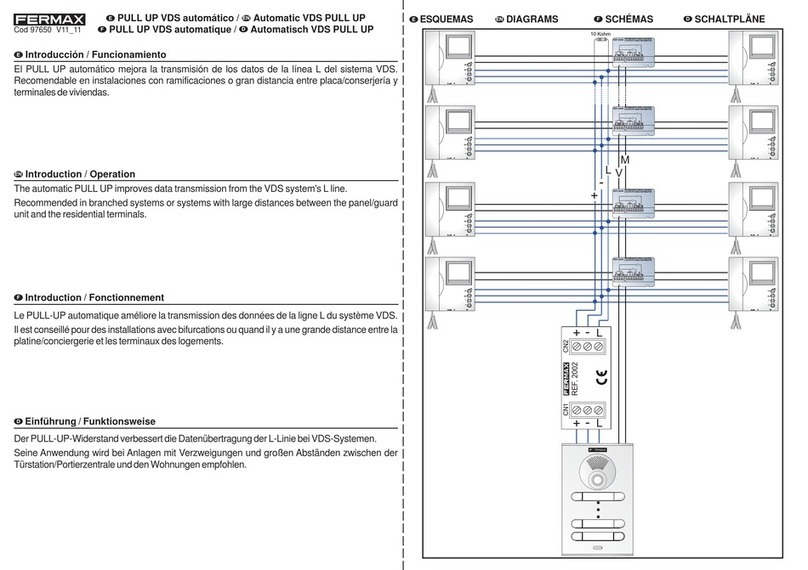

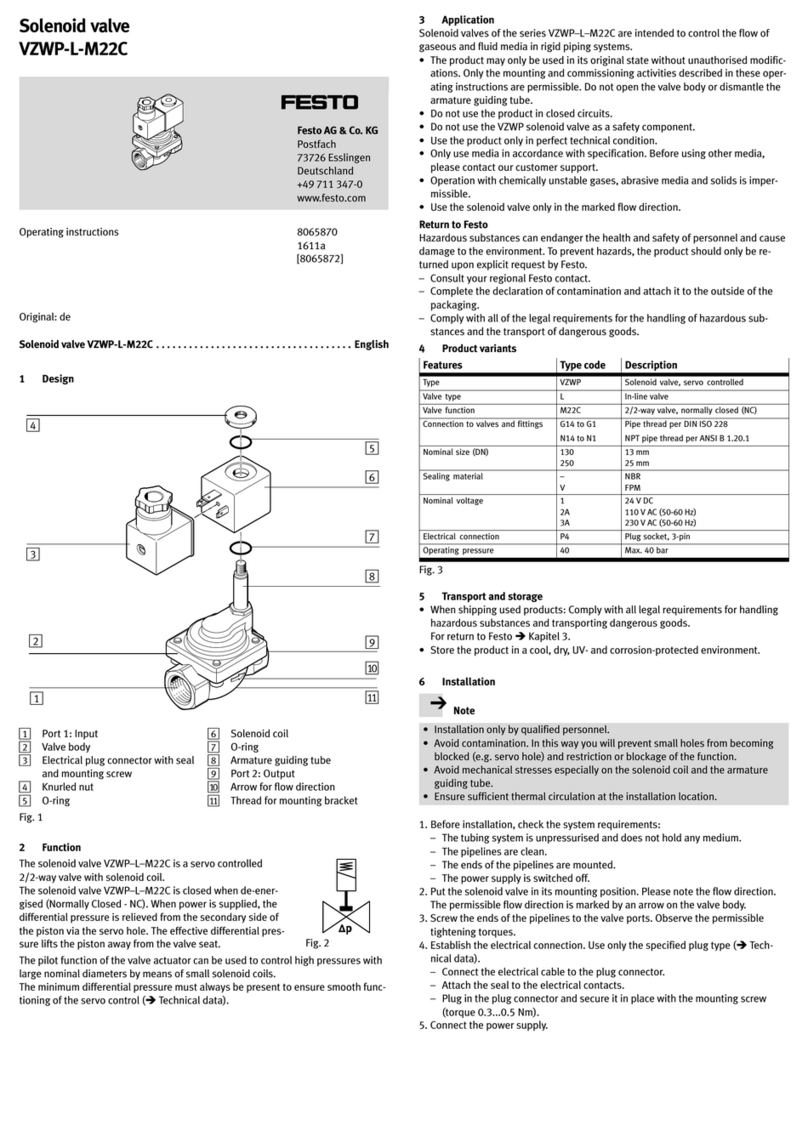

WIRING

NOTE: All wiring must conform to applicable local codes, ordinances, and

regulations.

1. Install module wiring in accordance with the job drawings and appropri-

ate wiring diagrams.

2. All wiring to the FIK-IM-10 is done via terminal blocks. In order to prop-

erly make electrical connections strip approximately 1⁄4" of insulation

from the end of wire, sliding the bare end of the wire under the clamping

plate screw.

3. Set the address on the modules per the job drawing. Use the rotary code

switches to set the address of the first module between 01 and 90 (or 01

and 150 for panels that support 159 addresses).

In Class B operation, the remaining modules are automati

cally assigned to the next nine higher addresses. For example, if the base ad-

dress switch is set to 28, the next nine modules will be addressed to 29, 30, 31,

32, 33, 34, 35, 36, and 37.

The module is shipped in Class B position, remove shunt for Class A.

When operating in Class A, alternate modules are paired together (+0/+1,

+2/+3, +4/+5, +6/+7, +8/+9), resulting in a total of five modules. For

example, if the base address switch is set to 28, then 30, 32, 34 and 36 will be

automatically assigned to the modules while 29, 31, 33, 35 and 37 are avail-

able to be used for other modules on the SLC. For Class A and B operation,

DO NOT set the lowest address above 90 (or 150 for panels that support 159

addresses), as the other modules will be assigned to nonexistent addresses.

NOTE: The FIK-IM-10 must have power cycled for shunt changes to take ef-

fect.

4. A shunt is provided to disable a maximum of two unused modules in

Class B operation and one unused module in Class A operation. Modules

are disabled from the highest address and work downward. If two mod-

ules are disabled, the lowest eight addresses will be functional, while the

highest two will be disabled. For example, in Class B operation, if the

shunt for Address Disable is placed on “two” and the base switch is set

to 28, the modules will be assigned to 28, 29, 30, 31, 32, 33, 34 and 35

while disabling the highest two positions.

5. A communications loss feature is available on some panels. Upon a com-

munication loss, due to a microprocessor failure at the control panel, the

FIK-IM-10 will send a signal to the control panel to activate the notifica-

tion device circuits upon initiating of an alarm on the FIK-IM-10. A single

shunt is used to enable (shunt on) or disable (shunt off) this feature for

all modules on the board.

NOTE: All references to power limited represent “Power Limited (Class 2)”.

NOTE: Place unused shunts on single pin to store on board for future use.

WIRING NOTES

• Power-limited circuits must employ type FPL, FPLR, or FPLP cable as

required by Article 760 of the NEC.

PROGRAMMING

The modules are programmed as devices in each system according to the pro-

gramming instructions in the appropriate FACP manual.

C0225-00

C0226-00

BACKBOX

MOUNTING

HOLES

C0235-00

FIGURE 2: TYPICAL MOUNTING HOLE LOCATIONS

Step 1: Insert the bottom of the FIK-IM-10 module down into a rear slot on

the chassis.

Step 2: Carefully swing the upper edge of the board back towards the back of

the chassis until it touches the two standoffs.

Step 3: Align two 4-40 screws with the two standoffs and tighten.

Step 4: Address and wire the modules according to the instructions in this

manual.

The steps in Figures 4a and 4b describe and illustrate module in-

stallation when the rear chassis position and the position in front of

it will be filled. Front position installation is possible only if the rear

position is filled with a module.

2 I56-6893-000

1/15/2021

0

1

2

3

456789

BASE ADDRESS

TO NEXT

DEVICE

–

STATUS

INDICATORS

—

+

—

+

—

+

—

+

—

+

—

+

IDC

ADDRESS

+0

+1

+2

+3

+4

+5

+6

+7

+8

+9

IDC

ADDRESS

IDC

ADDRESS

IDC

ADDRESS

IDC

ADDRESS

—

+

—

+

SLC

—

+

—

+

+

–

+

FROM PANEL OR

PREVIOUS DEVICE

47K

EOL

RESISTOR

ELR-47K

CONNECT MODULES TO

LISTED COMPATIBLE

FIKE CONTROL PANELS ONLY

SIGNAL LINE CIRCUIT (SLC) 32 VDC MAX.

SEE PANEL INSTRUCTION MANUAL

FOR WIRE REQUIREMENTS.

CLASS B IDC (TYPICAL)

—

+

—

+

A/B SLCT

COM LOSS

DISABLE 1

DISABLE 2

0

1

2

3

45678910

11

12

13

14

15

POWER LIMITED

AND SUPERVISED

NOTE: Any number of UL listed contact closure devices may be used.

DO NOT mix fire alarm initiating and supervisory devices on the same initiat-

ing device circuit. Install contact closure devices per manufacturer’s installa-

tion instructions.

C0810-04

FIGURE 5. TYPICAL INITIATING DEVICE CIRCUIT CONFIGURATION – CLASS B

BASE ADDRESS

TO NEXT

DEVICE

–

STATUS

INDICATORS

—

+

—

+

—

+

—

+

—

+

—

+

IDC

ADDRESS

+0

+1

+2

+3

+4

+5

+6

+7

+8

+9

IDC

ADDRESS

IDC

ADDRESS

IDC

ADDRESS

IDC

ADDRESS

—

+

—

+

SLC

—

+

—

+

+

–

+

FROM PANEL OR

PREVIOUS DEVICE

CONNECT MODULES TO

LISTED COMPATIBLE

FIKE CONTROL PANELS ONLY

SIGNAL LINE CIRCUIT (SLC) 32 VDC MAX.

SEE PANEL INSTRUCTION MANUAL

FOR WIRE REQUIREMENTS.

CLASS A IDC (TYPICAL)

—

+

—

+

A/B SLCT

COM LOSS

DISABLE 1

DISABLE 2

IDC 2

IDC 3

IDC 4

IDC 5

0

1

2

3

456789

0

1

2

3

45678910

11

12

13

14

15

POWER LIMITED

AND SUPERVISED

REMOVE SHUNT FOR CLASS A.

FIGURE 6. TYPICAL FAULT TOLERANT INITIATING DEVICE CIRCUIT CONFIGURATION – CLASS A

NOTE: Any number of UL listed contact closure devices may be used. DO NOT

mix fire alarm initiating and supervisory devices on the same initiating device cir-

cuit. Install contact closure devices per manufacturer’s installation instructions.

C0811-04

DEVICE AND SYSTEM SECURITY

Before installing this product ensure that the tamper

seal on the packaging is present and unbroken and

the product has not been tampered with since leaving

the factory. Do not install this product if there are

any indications of tampering. If there are any signs

of tampering the product should be returned to the

point of purchase.

It is the responsibility of the system owner to ensure

that all system components, i.e. devices, panels, wir-

ing etc., are adequately protected to avoid tampering

of the system that could result in information disclo-

sure, spoofing, and integrity violation.

FCC STATEMENT

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

Fike®is a registered trademark of Fike Corporation.

3 I56-6893-000

©2021. 1/15/2021

This manual suits for next models

1

Other Fike Control Unit manuals

Fike

Fike Lantronix XPort 10-2627 Operating instructions

Fike

Fike FIK-RVM User manual

Fike

Fike FIK-M500M User manual

Fike

Fike EIV User manual

Fike

Fike P Service manual

Fike

Fike 55-043 User manual

Fike

Fike FIK-CR-6 User manual

Fike

Fike TWINFLEX IRM 100-0011 User manual

Fike

Fike FIK-FML Technical manual

Fike

Fike TWINFLEX SRM 100-0010 User manual

Popular Control Unit manuals by other brands

BENDIX

BENDIX R-12DC DBL CHECK RELAY VALVE manual

Altronix

Altronix LINQ2 Installation and programming manual

Camille Bauer

Camille Bauer EMMOD 205 operating instructions

Rapid Controls

Rapid Controls SAB-Q2 quick start

Kessel

Kessel FKA Instructions for installation, operation and maintenance

Festo

Festo VZWP-L-M22C Series operating instructions