2

ASSEMBLY / DISASSEMBLY

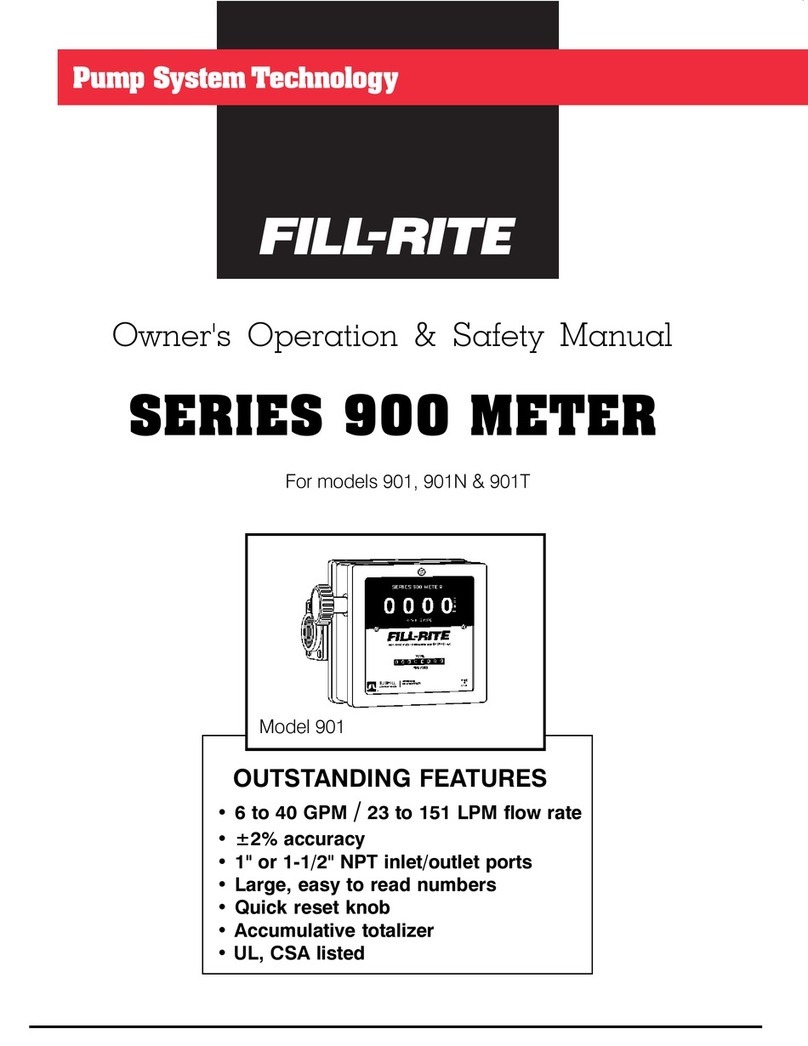

Meter consists of a chamber housing, measuring chamber,

gear train, counter assembly and cover. Meter can be

completely disassembled without disturbing piping.

Counter Assembly

For access to counter assembly, remove reset knob (item 3) by

grasping edges and pulling firmly. Remove two screws (item

29) and lift counterface (item 2) and cover (item 1) off. Remove

two screws (item 13) to extract counter (item 4). Reassemble

by reversing procedure.

Meter Chamber Assembly

To expose meter chamber assembly, tilt the meter at least

slightly face down, so that no parts fall out when removing meter

housing. Remove the four screws (item 20), then remove meter

housing (item 19). Meter chamber assembly consists of upper

and lower chambers, a nutating disc and seal gasket.

Reassemble by reversing procedure.

If replacement of any components of the meter chamber

assembly is required, the complete assembly must be

replaced due to the precise method of its construction. This

assures a proper fit and a correctly operating chamber.

Gear Train and Seal

To disassemble gear train and seal, remove gear frame (item

12) by prying slightly. Remove cluster gear (item 10) and

washer (item 11) from shaft (item 9). Remove drive gear (item

8) and washers (item 7) by rotating and pulling drive gear.

Remove O-ring seal (item 6).

When reassembling seal, lubricate O-ring liberally with oil or

petroleum jelly and replace in cover. Place washer on drive gear

shaft. Carefully rotate and push shaft through O-ring and cover

to prevent damage to O-ring. Shaft must then be guided into

pinion bevel (item 28) if counter has not been removed. Replace

remaining parts to complete assembly by reversing

disassembly procedure.

FLUID COMPATIBILITY

The 800C is compatible with the following fluids:

$Diesel Fuel, Gasoline, Kerosene, Mineral Spirits,

Heptane, and Hexane

The 800C is NOT compatible with the following fluids:

$Bleach, Hydrochloric Acid, Ink, Sulfuric Acid, and Salt

Water

If in doubt about compatibility of a specific fluid, contact supplier

of fluid to check for any adverse reactions to the following wetted

materials.

REPAIR

Meters needing repair should be taken to an authorized repair

shop for service. Meters must be thoroughly triple-rinsed before

being taken in for repair.

PRIORTOSERVICE,ADHERETOFOLLOWINGINSTRUCTIONS:

Meters must be triple-rinsed and accompanied by a note

indicating the chemicals which have been pumped through

the unit. Meters not adhering to these specifications may be

refused service.

1 800G1325 806C, 1%, U.S. Gallon 1

800G2727 806C, 1%, U.S. Gallon, Nickel Plated Opt.

800G1387 806C, 1%, U.S. Gallon, Teflon® Coated Opt.

800G1998 806C, 1% BSP, Liters Opt.

800G2705 806C, 1% BSP, Liters, Nickel Plated Opt.

800G1440 806C, 1% BSP, Liters, Teflon® Coated Opt.

2 800F4360 Cover 1

800F4362 Cover, Nickel Plated Opt.

800F4361 Cover, Teflon® Coated Opt.

3 800F4380 O-Ring (-131), Buna-N 1

800F4381 O-Ring (-131), Viton Opt.

4 800F4350 Screen 1

5 800F4320 5/16-18 x 7/8 SHCS 2

6 800F4340 Strainer Housing 1

800F4343 Strainer Housing, Nickel Plated Opt.

800F4342 Strainer Housing, Teflon® Coated Opt.

800F4337 Strainer Housing, BSP Threads Opt.

800F4339 Strainer Housing, BSP Threads, Teflon Opt.

800F4338 Strainer Housing, BSP Threads, Nickel Opt.

7 800F4390 1 x 2 Pipe Nipple 1

8 800F4400 1% Street Elbow 1

9 700F2800 O-Ring (-218) 1

700F2801 O-Ring (-218), Viton Opt.

TH18 Strainer Kit, 1%, U.S. (Includes items 2-6, 9)

TH18T Strainer Kit, 1%, U.S.,Teflon® Ctd. (items 2-9)

TH18X418 Strainer Kit, 1% BSP (Includes items 2-6, 9)

TH18TX418 Strainer Kit, 1% BSP,Teflon Ctd. (items 2-6, 9)

800C SERIES STRAINER KIT

ITM. PART

NO. NO. DESCRIPTION QTY.

* Item 1 not

included in kit.

PART

NO. DESCRIPTION

800KTG2540 Repair Kit, U.S. Gallon (Standard Seals)

(Includes items 6-12, 18, 22, 24-26, 28)

800KTG2541 Repair Kit, U.S. Gallon (Viton Seals)

(Includes items 6-12, 18, 22, 24-26, 28)

800KTG2542 Repair Kit, Liter (Standard Seals)

(Includes items 6-12, 18, 22, 24-26, 28)

800KTG2543 Repair Kit, Liter (Viton Seals)

(Includes items 6-12, 18, 22, 24-26, 28)

800KTG2579 Repair Kit, U.S. Gallon, (EPDM Seals)

(Includes items 6-12, 18, 22, 24-26, 28)

800B/800C SERIES REPAIR PARTS KITS

Ryton Aluminum Stainless Steel

EPDM Flourocarbon Buna N

Teflon® Nickel