3570 Series

4

Installation,

Mounting, and

Connections

Installation

The positioner is usually mounted on the actuator at

the Fisher Controls’ factory. However, if the positioner

and actuator are ordered separately, it is necessary to

mount the positioner on the actuator. Before mounting

the positioner, be certain the O-ring (key 33, figure 11)

is in place in the cylinder (top connection) in the base

of the positioner.

For appropriate actuator/positioner combinations, refer

to the positioner type number descriptions given earli-

er in this instruction manual.

DFor Type 3570, 3570C, 3572, and 3573 posi-

tioners, mount the positioner with two cap screws

(key 32, figure 11). If the range and bias springs are

not installed in the positioner, refer to the range spring

and bias spring procedures in the Maintenance sec-

tion.

Insert the threaded end of the spring retainer (key 19,

figure 3) into the center of the range spring (see figure

3). Then, insert a screwdriver into the center of the

range spring and extend the spring until the spring re-

tainer can be screwed into the top of the actuator pis-

ton rod extension. Tighten the spring retainer into the

top of the actuator piston rod extension. If the range

spring and/or bias spring is not installed in the posi-

tioner, refer to the procedures for either spring in the

Maintenance section.

DFor Type 3570P and 3570PC positioners, at-

tach the positioner extension and positioner to the cyl-

inder mounting plate with the two cap screws (key

100, figure 13). Make the required pressure connec-

tions as described in the following procedure. Go to

the initial range spring extension procedures for Type

3570P and 3570PC positioners.

DFor Type 3571, 3576, and 3577 positioners,

insert two cap screws through the holes in the mount-

ing bracket (key 55, figure 14) to attach the positioner

to the actuator mounting boss. Attach the hex drive

stud to the actuator-valve stem connection. Attach the

end bearing (key 56E, figure 14) to the hex drive stud.

Diagnostic Test Connectors (Optional)

Diagnostic test connectors are available from the fac-

tory, when the unit is ordered, or they can be installed

on an existing control valve assembly in the field.

These connectors are especially useful for ‘‘quick’’

connections when using the FlowScannert. The

FlowScannertis a portable, microprocessor-based

diagnostic and calibration system specifically designed

for use with pneumatically-operated control valves.

To support diagnostic testing of the control valve as-

sembly, the connectors, piping, and other hardware

can be installed between the 3570 Series positioner

and the actuator. A typical connector installation is

shown in figure 4. For connectors, please refer to the

FlowScannertDiagnostic Connection kit listing in the

parts list.

The hardware used includes 3/4-inch NPT pipe nipple,

pipe tee, and pipe bushings with a 1/8-inch NPT pipe

bushing for the connector. The connector consists of

1/8-inch NPT body and body protector (see figure 4).

1. Before assembling the pipe nipple, pipe tee, pipe

bushings, actuator piping, and connector body, apply

sealant to all threads.

2. Position the pipe tee, connector body, and body

protector for easy access when doing diagnostic test-

ing.

Connections

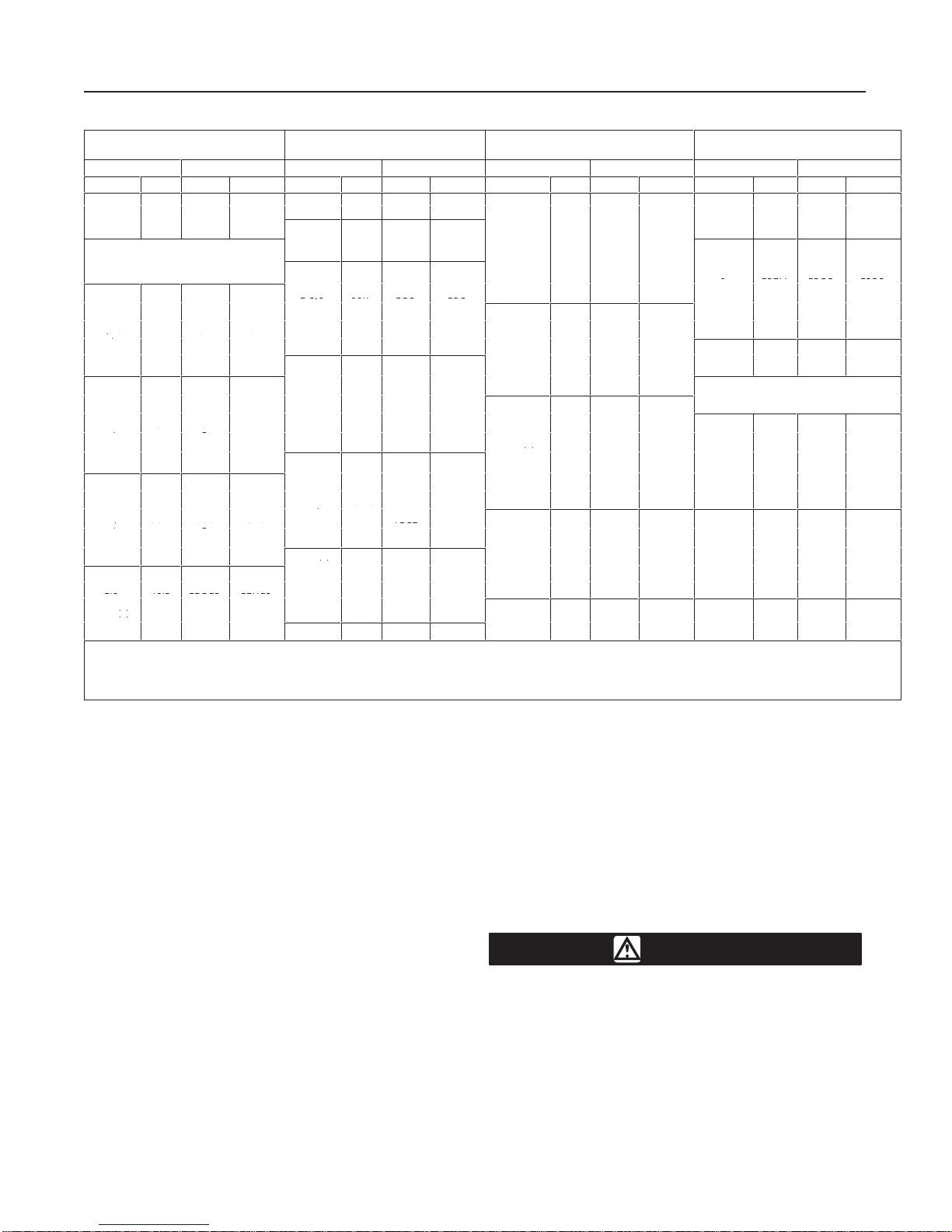

Piping Sizes

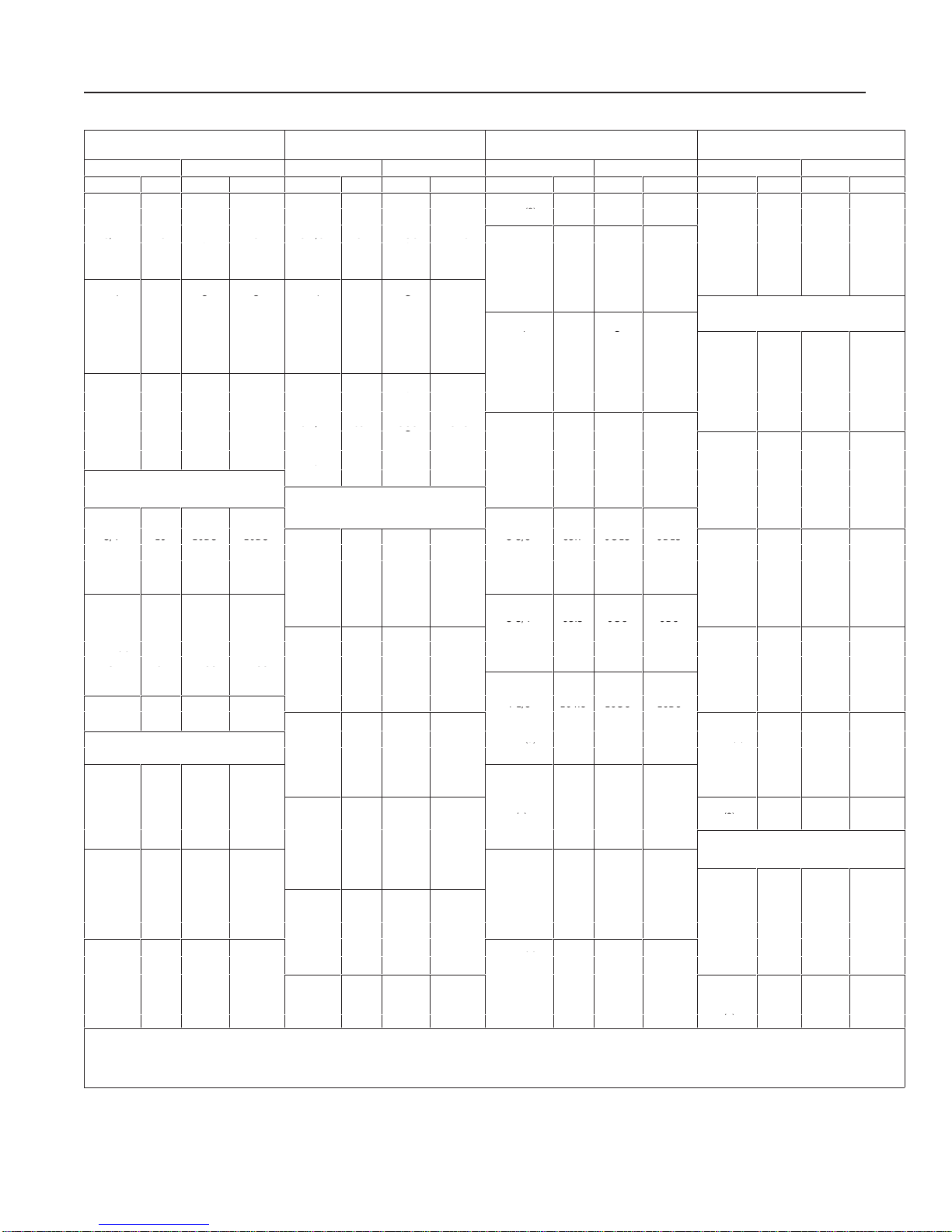

All pressure connections on the 3570 Series position-

ers are 1/4-inch NPT (female). Use 3/8-inch pipe or

tubing for supply, cylinder (bottom connection), and

instrument (input signal) connections. For the remote

vent pipe, if one is required, use 3/4-inch (19 mm)

(minimum inside diameter) pipe for runs up to 20 feet

(6.09 meters). For vent piping runs from 20 to 100 feet

(6.09 to 30.5 meters), use 1-inch (25.4 mm) (minimum

inside diameter) pipe. Refer to figure 2 for the loca-

tions and sizes of connections.

Vent

WARNING

If a flammable, toxic, corrosive, or reac-

tive gas is to be used as the supply

pressure medium, personal injury or

property damage could result from fire

or explosion of accumulated gas or

from contact with toxic, corrosive, or

reactive gas. The positioner/actuator as-

sembly does not form a gas-tight seal,

and when the assembly is enclosed, a

remote vent line, adequate ventilation,

and necessary safety measures should

be used. A remote vent pipe alone can-

not be relied upon to remove all hazard-

ous gas. Vent line piping should comply

with local and regional codes and

should be as short as possible with ade-

quate inside diameter and few bends to

reduce case pressure buildup.

FlowScanner is a mark owned by Fisher Controls International, Inc.