Types 3710, 3720, 3722

2

Contents

Introduction

2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope of Manual 2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type Number Description 3.

. . . . . . . . . . . . . . . . . . .

Positioner to Actuator Mountings List 3.

. . . . . . . . .

Specifications 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Type 3722 Converter

3.

. . . .

Mounting the Positioner

6.

. . . . . . . . . . . . . . . .

Connections

10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply Connection 11.

. . . . . . . . . . . . . . . . . . . . . . . .

Output Connections 12.

. . . . . . . . . . . . . . . . . . . . . . .

Instrument Connection 12.

. . . . . . . . . . . . . . . . . . . . .

Vent Opening, Purge Option, and Actuator

Vent Connection 12.

. . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Purge Tube 13.

. . . . . . . . . . . . . . .

Electrical Connection for the Type 3722

Positioner 14.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Connections 14.

. . . . . . . . . . . . . . . . . . . .

Calibration

16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Initial Cam Position 16.

. . . . . . . . . . . . . .

Zero and Span Adjustments 17.

. . . . . . . . . . . . . . . .

Standard or Beacon Indicator Alignment 18.

. . . . .

Changing Positioner Action

19.

. . . . . . . . . .

Single-Action/Double-Action 19

. . . . . . . . . . . . . . . . .

Direct-Action/Reverse-Action 19

. . . . . . . . . . . . . . . .

Split-Range Operation 20.

. . . . . . . . . . . . . . . . . . . . .

Changing the Spool Valve (To Increase Positioner

Output Capacity) 20.

. . . . . . . . . . . . . . . . . . . . . . .

Changing the Span Adjuster Assembly (To Change

Positioner Input Range) 21.

. . . . . . . . . . . . . . . . .

Principle of Operation

22.

. . . . . . . . . . . . . . . . .

Positioner Maintenance

23.

. . . . . . . . . . . . . . .

Replacing the Standard or Beacon Indicator 23.

. .

Removing the Type 3722 Converter 23.

. . . . . . . . .

Removing the Positioner 23.

. . . . . . . . . . . . . . . . . . .

Removing the Feedback Arm Assembly 25.

. . . . . .

Disassembling the Feedback Arm Assembly

and Span Adjuster Assembly 25.

. . . . . . . . . . . . .

Removing the Feedback Shaft (Cam Shaft) 26.

. . .

Disassembling the Spool Valve, Action Block,

and Gasket 26.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembling the Input Module and

Summing Beam Assembly 27.

. . . . . . . . . . . . . . .

Replacing the Input Module Diaphragm 27.

. . . . . .

Assembling the Input Module and Summing

Beam Assembly 28.

. . . . . . . . . . . . . . . . . . . . . . . .

Assembling the Spool Valve, Action Block, and

Gasket 29.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembling the Feedback Shaft (Cam Shaft) 29.

.

Replacing the Feedback Arm Assembly

and Span Adjuster Assembly 30.

. . . . . . . . . . . . .

Type 3722 Converter Maintenance

30.

. . .

Disassembling the Type 3722 Converter 30.

. . . . .

Assembling the Type 3722 Converter 30.

. . . . . . . .

Testing the Type 3722 Converter Module 31.

. . . .

Parts Ordering

31.

. . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Kits

31.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List

31.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioner Common Parts 31.

. . . . . . . . . . . . . . . . . .

Diagnostic Connections 35.

. . . . . . . . . . . . . . . . . . . .

Type 3722 Electro-Pneumatic Converter 36.

. . . . .

Positioner Mounting Parts 37.

. . . . . . . . . . . . . . . . . .

Introduction

Scope of Manual

This instruction manual includes installation, operation,

calibration, maintenance, and parts ordering informa-

tion for the Type 3710 pneumatic positioner and Type

3720 electro-pneumatic positioner. This manual also

provides field installation and maintenance information

for the Type 3722 electro-pneumatic converter. Refer

to separate instruction manuals for information on the

actuator, control valve, and other accessories.

Only personnel qualified through training or experience

should install, operate, or maintain the positioner. If

there are any questions concerning the instructions in

this manual, contact your Fisher sales office or sales

representative before proceeding.

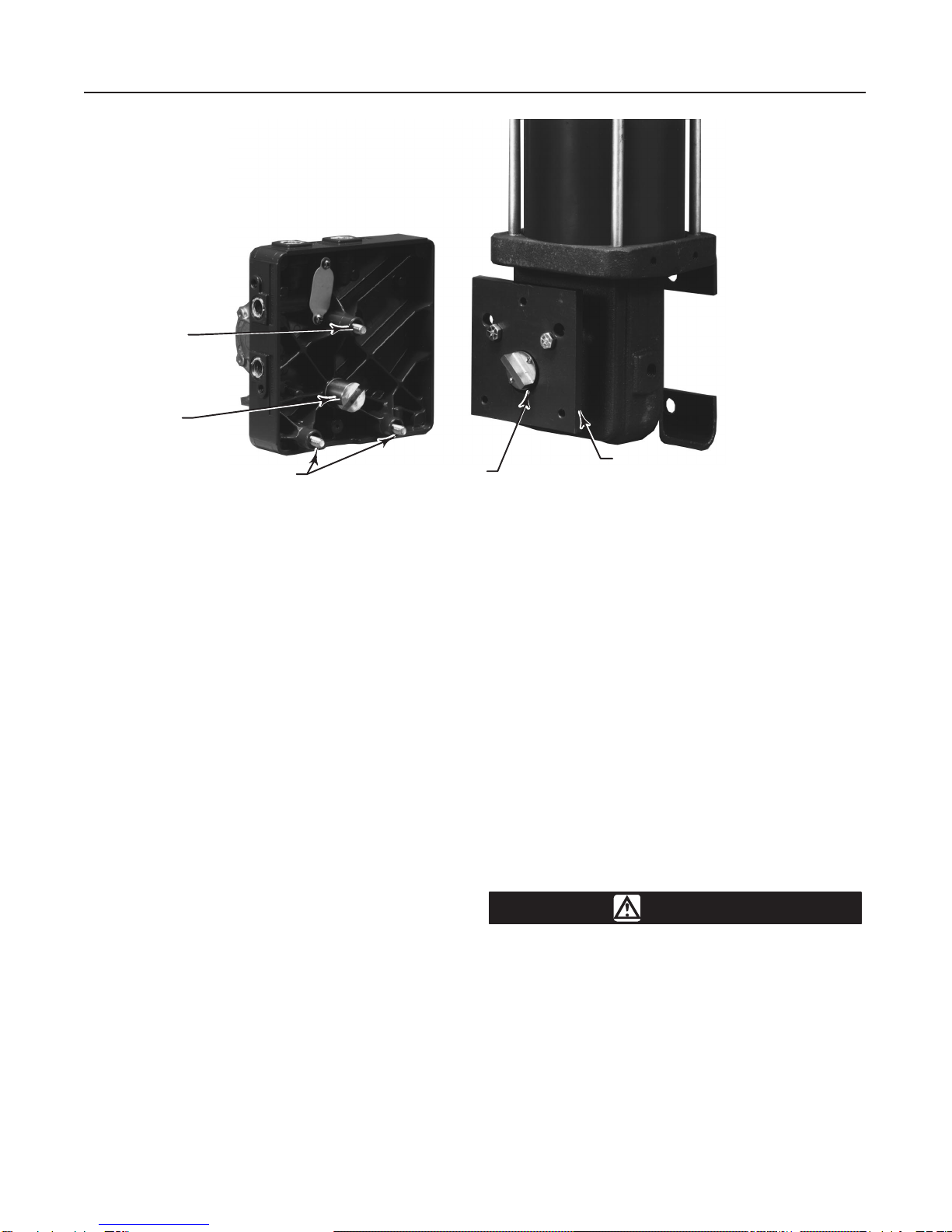

Description

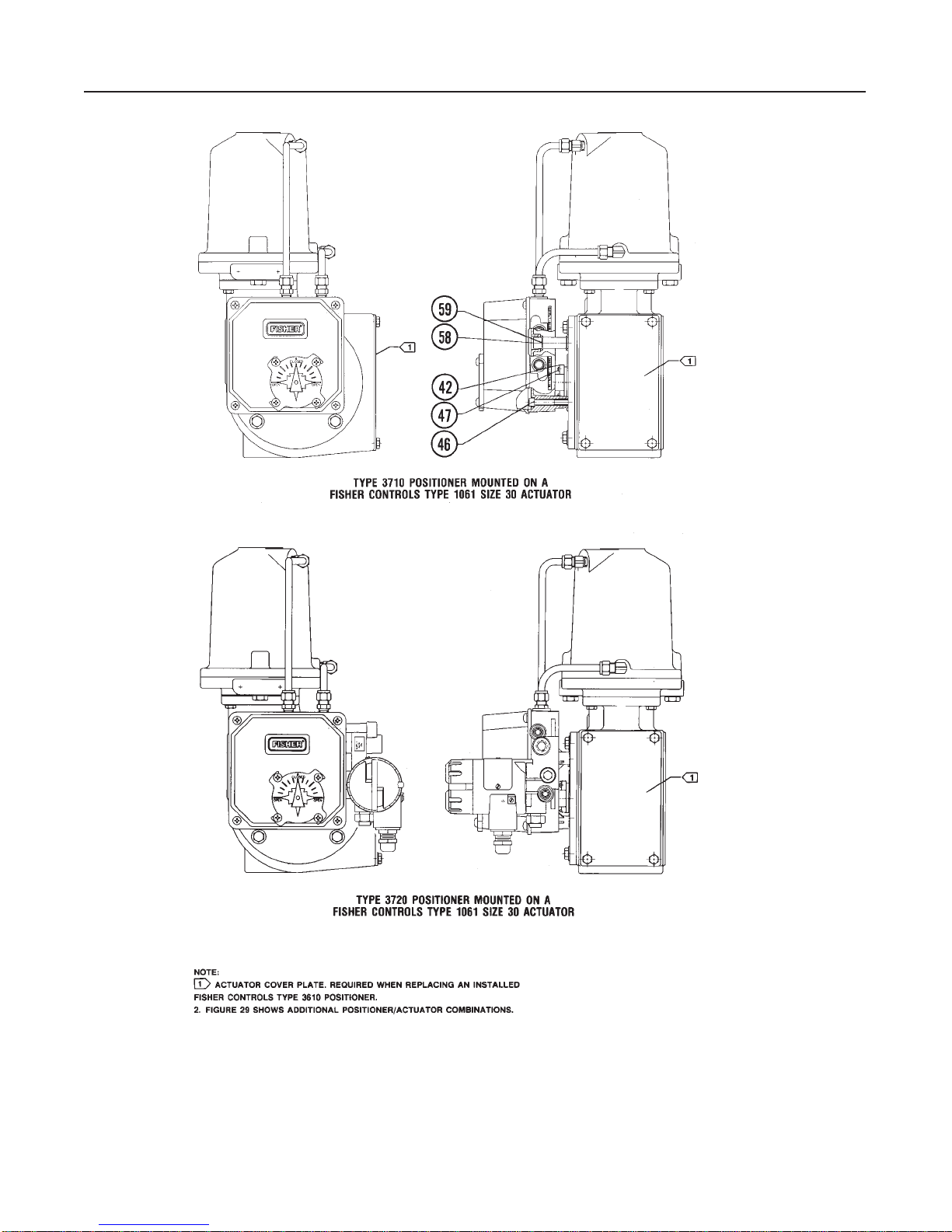

The Fisher Controls Type 3710 pneumatic positioner

and the Type 3720 electro-pneumatic positioner are

used with either diaphragm actuators (spring return) or

piston rotary actuators (spring return or double-action)

as shown in figure 1. These positioners provide a

valve ball or disk position for a specific input signal.

These positioners can easily be configured to provide

single- or double-action output for Fisher Controls

rotary actuators.

The Type 3710 pneumatic positioner accepts a pneu-

matic input signal. The Type 3720 electro-pneumatic

positioner accepts a milliampere (mA), direct current