Safety precautions

This section covers the basic

safety instructions when

working with this implement.

6

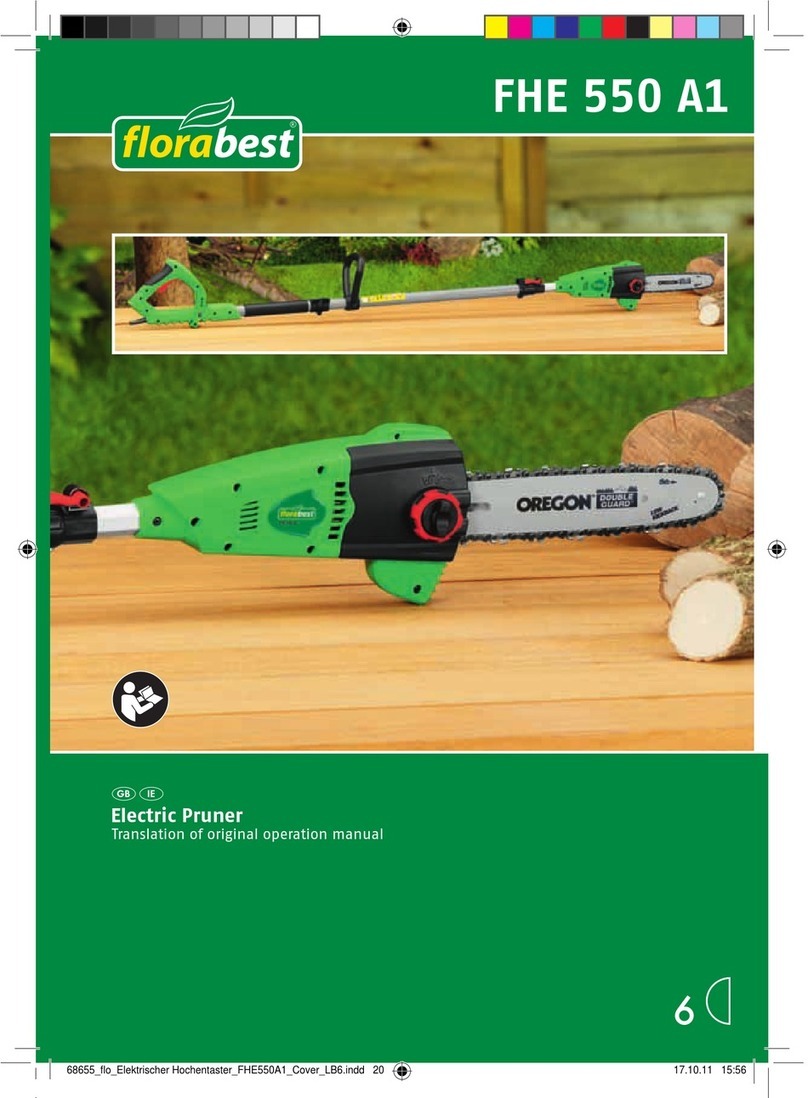

Functional description

The verticuttor and lawn aerator has two

easily exchangeable work cylinders:

An aerator cylinder made of hard plastic

with vertically rotating sprung tines, and a

verticutor cylinder with vertically mounted

high-grade steel knives.

The implement features a high-quality

plastic case with collection bag and a handle

bar with a folding function. Please refer to

the subsequent descriptions for the actual

functions of the individual control elements.

Technical data

Motor input ...............................1200 W

Rated voltage ............230-240 V~, 50 Hz

Protection Class ............................... II

Degree of protection........................ IPX4

Rotating speed of the tool

(no)...........................3600 min-1 (r.p.m)

Cylinder width...............................31 cm

Readjustment range for wear............9 mm

Volume collection bag .......................30 l

Weight ....................................... 9.9 kg

Acoustic pressure level

(LpA)..................84 dB (A); KpA= 3 dB(A)

Sound power level (LwA)

Measured ........99 dB (A); KwA= 4 dB (A)

Guaranteed ....................... 103 dB (A)

Vibration (an)............... 4 m/s2; K= 2 m/s2

The noise and vibration values were

established by the standards and stipulations

listed in the Conformity Declaration.

Technical and visual changes can be

completed in the course of further develop-

dimensions, references and details in these

Operating Instructions are without

guarantee. Consequently legal claims based

on these Operating Instructions cannot be

asserted.

The stated vibration emission value was

measured in accordance with a standard

testing procedure and may be used to

compare one power tool to another.

The stated vibration emission value may

also be used for a preliminary exposure

assessment.

Warning: The vibration emission

value may differ during actual use

of the power tool from the stated

value depending on the manner in

which the power tool is used.

Safety precautions aimed at

protecting the user should be based

on estimated exposure under actual

usage conditions (all parts of the

operating cycle are to be considered,

including, for example, times during

which the power tool is turned off

and times when the tool is turned on

but is running idle).

BG ERI

switched off.

Always disconnect the

plug from the mains

prior to maintenance

work or if the power

cable is damaged.

Noise level ratings LWA

in dB(A).

Protection Class II

Electrically powered

implements must not

be disposed of with

the domestic waste。

Caution with steps!

Turn off the power

when the implement

is to be carried

across steps.

Remove any soil residue

from the springs of the

impact protection cover

and/or the housing to

ensure that the cover closes

correctly. When operating

without the collection

basket, the impact

protection cover must be

completely closed.

Transport and

working

positions

General notes on

safety

This implement can

cause seriousinjuries if

it is not properly used.

Please read these

Operating Instructions

carefully and familiarize

yourself with all the

control elements

before operating this

implement.

switched off.

Always disconnect the

plug from the mains

prior to maintenance

work or if the power

cable is damaged.

Noise level ratings LWA

in dB(A).

Protection Class II

Electrically powered

implements must not

be disposed of with

the domestic waste。

Caution with steps!

Turn off the power

when the implement

is to be carried

across steps.

Remove any soil residue

from the springs of the

impact protection cover

and/or the housing to

ensure that the cover closes

correctly. When operating

without the collection

basket, the impact

protection cover must be

completely closed.

Transport and

working

positions

General notes on

safety

This implement can

cause serious injuries if

it is not properly used.

Please read these

Operating Instructions

carefully and familiarize

yourself with all the

control elements

before operating this

implement.

and firm shoes with

nonslip soles,strong long

trousers, ear defenders

and goggles. Never

operate theimplement

while bare footed or

when wearing open

sandals.

The protective devices

and your personal

protective equipment will

protect yourself and other

peopleand ensure that

the equipment can be

smoothly operated.

• Neveroperate the

implement if it is

damaged, incomplete or

has been modified

without theconsent of the

manufacturer. Never work

with damaged or missing

protective devices (e.g.

starting lever, unlocking

knob, impact protector).

Never disengage

protective devices (e.g. by

tying thestarting

lever).This ensures that the

equipment remains safe.

• Before starting the

equipment, ensure that no

objects or branches are

pushed into the blade

opening, that the

equipment is standing

stably and that the

workspace is tidy and not

blocked.

Check the condition of

your extension cable and

the connecting cable of

your equipment. Use the

necessary protective

equipment. There is a risk

of injury.

• If yourequipmentvibrates

or emits unusual noises

when switched on,

disconnect the plug from

thesocket and check the

cutting cylinder. Ensure

that no remains of

chopped matter are

blocking the cutting

cylinder or jammed

and firm shoes with

nonslip soles, strong long

trousers, ear defenders

and goggles. Never

operate the implement

while bare footed or

when wearingopen

sandals.

The protective devices

and yourpersonal

protective equipment will

protect yourself and other

people and ensure that

the equipmentcanbe

smoothly operated.

• Neveroperate the

implement if it is

damaged,incomplete or

hasbeen modified

without the consent of the

manufacturer. Never work

with damaged or missing

protective devices (e.g.

starting lever, unlocking

knob, impactprotector).

Neverdisengage

protective devices (e.g. by

tying the starting

lever).This ensures that the

equipment remains safe.

• Before starting the

equipment, ensure that no

objects or branches are

pushed into the blade

opening, that the

equipment is standing

stably and that the

workspace is tidy and not

blocked.

Check the conditionof

your extension cable and

the connecting cable of

your equipment. Use the

necessary protective

equipment. There is a risk

of injury.

• If yourequipmentvibrates

or emits unusual noises

when switched on,

disconnect the plug from

the socket and check the

cutting cylinder. Ensure

that no remains of

chopped matter are

blocking the cutting

cylinder or jammed