Flott SB 18 Plus User manual

SB

18 Plus

TBZ 18

Plus

SB 20 Plus TBZ 20 Plus

SB 23 Plus TBZ 23 Plus

SB 25 Plus TBZ 25 Plus

TB 18 Plus

TB 20 Plus SB 20 FB Plus

TB 23 Plus

TB 25 Plus

Operating Manual

Contents

2

04/03/2020 218333

Important Notice!

This operating manual has been prepared in the German language, which is

the language of the original. All versions available in other languages are only

the translations of the German original operating manual.

Contents

218333 04/03/2020

3

Contents

Contents 3

1

Introduction 6

1.1 Pillar Drilling Machine.............................................................................................7

1.1.1 Technical Data........................................................................................7

1.1.1 Technical Data........................................................................................8

1.1.2 Rating Plate of the Pillar Drilling Machine ...............................................9

1.1.3 Intended Use ........................................................................................10

1.1.4 Improper Use........................................................................................10

1.2 Legal Provisions................................................................................................... 11

1.2.1 Liability.................................................................................................. 11

1.2.2 Warranty...............................................................................................12

1.2.3 Copyright..............................................................................................12

1.3 Operating Manual.................................................................................................13

1.3.1 Definition of Terms................................................................................13

1.3.2 Illustrations and Signs in this Text ......................................................... 15

1.3.3 Structure and Design of Safety Instructions...........................................16

2

Safety Instructions 18

2.1 General Safety Instructions .................................................................................. 18

2.1.1 The Operating Manual..........................................................................18

2.1.2 The Duties of the Operating Company.................................................. 19

2.1.3 The Safety of the Machine....................................................................19

2.1.4 The Working Staff .................................................................................20

2.1.5 The Workplace......................................................................................20

2.2 Safety Instructions for the Use of the Machine......................................................21

2.2.1 Transport to the Installation Site............................................................21

2.2.2 Commissioning, Operation, Decommissioning......................................22

2.2.3 Maintenance and Repair.......................................................................23

2.2.4 Disposal................................................................................................24

2.3 Safety Devices of the Machine.............................................................................25

Contents

4

04/03/2020 218333

3

Technical Description 26

3.1 Functional Description..........................................................................................26

3.2 Machine Overview................................................................................................27

4

Installation of the Machine 28

5

Before Using the Machine 30

5.1 Mounting Accessories and Options.......................................................................30

5.1.1 Mounting Drill Chuck.............................................................................30

5.1.2 Installing the Cutter...............................................................................31

5.1.3 Set Drill Guard and Press .....................................................................32

5.1.4 Installing Machine Vice .........................................................................34

5.2 Adjusting the Height of the Machine.....................................................................35

5.3 Connecting the Machine Electrically.....................................................................36

5.4 Checks Before Commissioning.............................................................................37

6

Operating the Machine 38

6.1 Control Elements of the Machine..........................................................................38

6.2 Drilling Through Hole............................................................................................42

6.3 Drilling Hole with Limiter.......................................................................................44

6.4 Bore with DepthAdjustment .................................................................................46

6.5 Tapping with Depth Adjustment ............................................................................49

6.6 Changing Drilling Parameters...............................................................................52

6.7 Calling up the Operator Menu of the Control System............................................ 54

7

Shutting Down the Machine 55

7.1 Switching the Machine Off....................................................................................55

7.2 Press Emergency Stop of the Machine.................................................................56

7.3 Measures Before Maintenance and Repair........................................................... 57

Contents

218333 04/03/2020

5

8

Troubleshooting 58

8.1 Error Messages on the Display.............................................................................58

8.2 Other Malfunctions and Remedies........................................................................59

8.3 Release of the MachineAfter a Fault....................................................................60

9

Maintenance of the Machine 61

9.1 Inspection and Maintenance Intervals ..................................................................61

9.2 Dismantling Drill Chuck ........................................................................................63

9.3 Installing/Removing the Protective Hood.............................................................. 65

9.3.1 Removing the Protective Hood..............................................................65

9.3.2 Installing the Protective Hood................................................................68

9.4 Tensioning or Replacing Ribbed V-belt................................................................. 72

9.5 Replacing Control Panels.....................................................................................75

9.6 Lubrication Schedule............................................................................................77

9.7 Repair ..................................................................................................................78

10

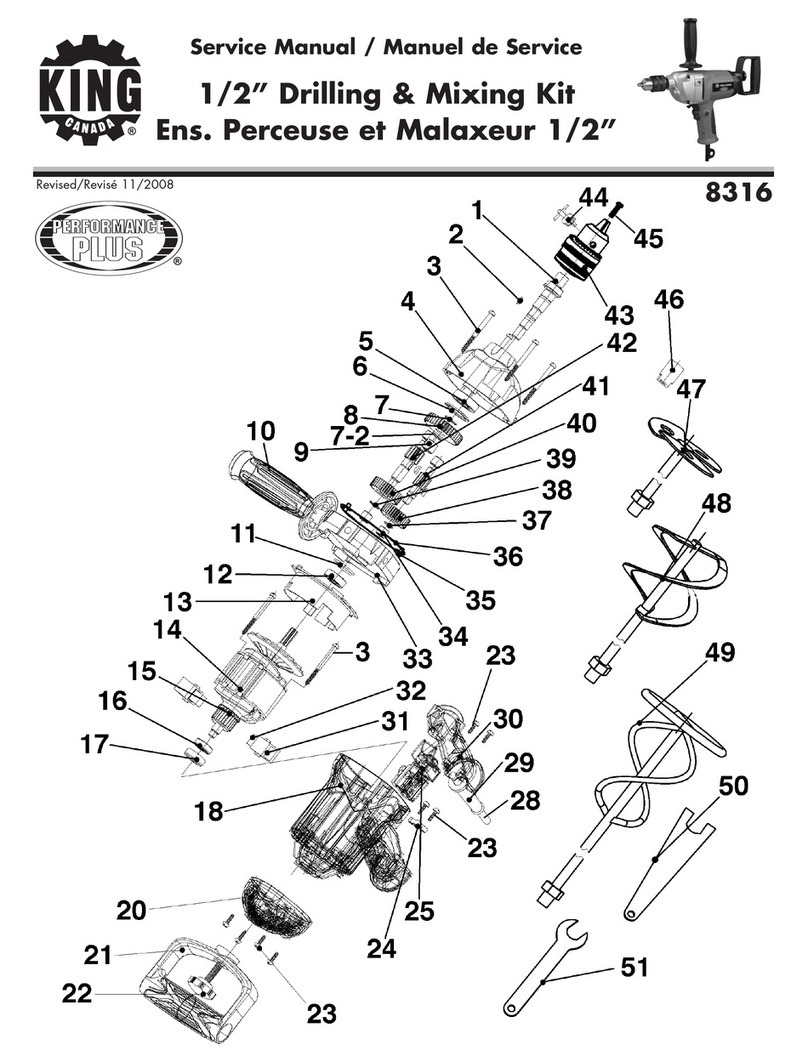

Spare Parts List and Drawings 79

11

Dimensional Drawings and Wiring Diagrams 92

12

EC Declaration of Conformity 97

Notes 98

Introduction

6

04/03/2020 218333

1 Introduction

Dear customer,

Thank you for choosing this quality FLOTT product! With the purchase of this

machine, you acquired a product that has an almost unique position in the

machine market due to its performance, design, user-friendliness and quality.

The outstanding FLOTT quality gives you the certainty of trouble-free and

highly efficient use of this machine for a long period of time. The machine is

thus inexpensive and gives you a provable increase in value for the benefit of

your company and your customers!

FLOTT – High Quality. Built on tradition...

In 1854 a small family-run company was founded in Remscheid, which devel-

oped braces and breast drilling machines and manufactured them for the

German market. With these products the company Arnz FLOTT Werkzeug-

maschinen made industrial history and is therefore often cited in industry cir-

cles as a "pioneer" in drilling technology. Thanks to its outstanding experience

and product quality, the company has become a powerful international player

a long time ago. Always close to its customers – "High Quality – made in Ger-

many". With its partners in Europe, FLOTT is not only rich in tradition but is al-

so one of the leading manufacturers of state-of-the-art, high-quality drilling,

sawing and grinding machines in Europe.

Traditionally committed to innovation.

FLOTT is the German antonym for stagnant. As a forward-looking and client-

oriented company, FLOTT continuously invests almost 5% of its annual turno-

ver in its own research and development projects. Permanent improvements

and, above all, intelligent, industry-specific innovations in drilling, sawing and

grinding technology – evidenced by numerous patents, industrial property

rights, customer and design awards – speak clearly for the company's innova-

tive strength and legendary pioneering spirit. For customers, this means the

certainty of having acquired a product, which is perfect in terms of technology

and suitability for drilling, sawing and grinding applications. The product al-

ways reflects the latest state of manufacturing technology, taking into account

the ergonomics for users. With an impressive guarantee and additional ser-

vices: traditionally the highest quality and service.

Service is the key to customer satisfaction…

With dedicated, modern training facilities for theory and practice offered by the

FLOTT drilling academy, as well as mobile training and demonstration units at

the FLOTT locations in Remscheid and the FLOTT commercial agencies we

satisfy all customer needs and interests highly efficiently. However, service al-

so means fast repairs to reduce machine downtimes to a minimum. With its

service partners across Germany and Europe, FLOTT offers a 24 hour repair

and spare parts service. These are just a few points of the FLOTT’s service

concept. Please read more at www.flott.de or use the consulting services from

our highly qualified dealers.

Introduction

218333 04/03/2020

7

1.1 Pillar Drilling Machine

1.1.1 Technical Data

Type SB 18 Plus TB 18 Plus TBZ 18 Plus

Order No. 218.308 218.303 218.309

Permanent/normal drilling perfor-

mance [mm] 18/20

Thread cutting performance [mm] max. M12

Spindle holder Type Mk2

Drilling depth [mm] 100

[mm] a = 240

[mm] b = 82

[mm] c = 340 x 280

Mains voltage [V] 230

Frequency [Hz] 50/60

Motor capacity [kW] 0.75

Stepless spindle speed [rpm] 30-3.000

Weight without packaging [kg] 195 170 155

Weight incl. packaging [kg] 225 200 185

permissible ambient temperature [°C] +10 to +40

Noise emission dB(A) 60

Type SB 20 Plus SB 20 Plus TBZ 20 Plus

Order No. 220.100 220.105 220.110

Order No. SB 20 FB Plus 220.115 --- ---

Permanent/normal drilling perfor-

mance [mm] 20/23

Thread cutting performance [mm] max. M12

Spindle holder Type Mk2

Drilling depth [mm] 100

[mm] a = 240

[mm] b = 82

[mm] c = 340 x 280

Mains voltage [V] 400

Frequency [Hz] 50/60

Motor capacity [kW] 1.5

Stepless spindle speed [rpm] 40-4.000

Weight without packaging [kg] 195 170 155

Weight incl. packaging [kg] 225 200 185

permissible ambient temperature [°C] +10 to +40

Noise emission dB(A) 60

Introduction

8

04/03/2020 218333

1.1.1 Technical Data

Type SB 23 Plus SB 23 Plus TBZ 23 Plus

Order no. R1

Order no. R2 223.020

223.025 223.021

223.026 223.022

223.027

Permanent/normal drilling

performance [mm] 23/25 (R1)

20/23 (R2)

Thread cutting performance [mm] max. M16 (R1)

max. M12 (R2)

Spindle holder Type Mk2

Drilling depth [mm] 100

[mm] a = 260

[mm] b = 110

[mm] c = 420 x 340

Mains voltage [V] 400

Frequency [Hz] 50/60

Motor capacity [kW] 1.5

Stepless spindle speed [rpm] 20-2.000 (R1)

30-3.000 (R2)

Weight without packaging [kg] 290 250 235

Weight incl. packaging [kg] 320 280 265

permissible ambient temper-

ature [°C] +10 to +40

Noise emission dB(A) 60

Type SB 25 Plus SB 25 Plus TBZ 25 Plus

Order no. R1 225.010 225.011 225.012

Permanent/normal drilling

performance [mm] 25/28

Thread cutting performance [mm] max. M16

Spindle holder Type Mk3

Drilling depth [mm] 120

[mm] a = 260

[mm] b = 110

[mm] c = 420 x 340

Mains voltage [V] 400

Frequency [Hz] 50/60

Motor capacity [kW] 1.5

Stepless spindle speed [rpm] 20-2.000

Weight without packaging [kg] 292 252 237

Weight incl. packaging [kg] 322 282 267

permissible ambient temper-

ature [°C] +10 to +40

Noise emission dB(A) 60

Introduction

218333 04/03/2020

9

1.1.2 Rating Plate of the Pillar Drilling Machine

The pillar drilling machine is identified by the type and type no. These and oth-

er data can be found on the rating plate, which is attached to the protective

hood of each machine.

Manufacturer:

Arnz FLOTT GmbH Werkzeugmaschinen

Vieringhausen 131

42857 Remscheid, Germany

Tel: +49 21 91 979-0

Fax: +49 21 91 979-222

Web: www.flott.de

Bohrmaschine

18 Plus, 20 Plus, 23 Plus, 25

Plus

xxx.xxx

V Hz

A kW

Introduction

10

04/03/2020 218333

1.1.3 Intended Use

The pillar drilling machine is designed exclusively for drilling, countersinking,

reaming and tapping metal, plastic and wood materials using suitable cutters.

The pillar drilling machine is intended to be operated by one person only.

Intended use also comprises

That the machine, depending on the type of machine, must be anchored to

the foundation or other suitable support

Compliance with the drilling performance stated in the technical data

That only appropriate cutters are used in their machine

That the cutters are properly fixed in the spindle

That the workpiece to be machined shall be secured against rotation on the

drilling table (e.g. by clamping or stop)

Compliance with inspection and maintenance schedules

That only FLOTT original spare parts are used and

Compliance with all instructions and information in this operating manual

and that of the cutter manufactures.

1.1.4 Improper Use

The pillar drilling machine must not be used for purposes other than as stated

in the section "Intended use".Any other use is considered improper.

Examples of improper use are

Drilling in other not suitable materials

The use of the machine without the necessary safety equipment

The use of unsuitable cutters and coolants

Unauthorized conversions or modifications to the machine.

Any improper use may result in:

Injury or killing of persons

Damage to the machine

Damage to other property.

Any improper use without exception is an action taken at the sole risk of the

user. Any resulting liability claims against Arnz FLOTT GmbH Werkzeug-

maschinen are excluded unless otherwise required by mandatory statutory

provisions.

Introduction

218333 04/03/2020

11

1.2 Legal Provisions

1.2.1 Liability

Arnz FLOTT GmbH Werkzeugmaschinen makes reference to the validity of its

general terms and conditions (see the Internet homepage

http://www.flott.de/de/flott/service/downloads/). These general terms and con-

ditions and the provisions contained therein for the limitation of the liability of

Arnz FLOTT GmbH Werkzeugmaschinen (especially the clauses 8.5, 8.8, 9.1

– 9.3 and 10.)

are part of this operating manual.

The information, data and notes given in the operating manual were up to date

at the time of printing. We reserve the right to technical changes as part of the

further development of the machines. Information, illustrations and descrip-

tions are non-binding. The information, illustrations and descriptions contained

in this operating manual are in particular not subject to any claims or rights for

previously delivered machines.

No liability is accepted for damage or malfunctions that occur as described be-

low:

Failure to comply with the operating manual

Operational errors

Improper working on and with the machine

Use of non-genuine spare parts and accessories of other origin than Arnz

FLOTT GmbH Werkzeugmaschinen

Unauthorized modifications and changes to the machine by the own or its

staff.

The following documents are relevant to the assessment of liability of Arnz

FLOTT GmbH Werkzeugmaschinen towards the user of the machine

With regard to the technical handling of the machine, only the requirements

of this operating manual

In all other cases, the individual contract concluded between the operating

company and Arnz FLOTT GmbH Werkzeugmaschinen in conjunction with

the relevant general terms and conditions of Arnz FLOTT GmbH

Werkzeugmaschinen

The general legal provisions.

In the event that the user themselves or via a third party operates or commis-

sions the machine outside the contract concluded with Arnz FLOTT GmbH

Werkzeugmaschinen or as a buyer after a reselling original purchaser, the lia-

bility of Arnz FLOTT GmbH Werkzeugmaschinen is limited to the liability under

the Product Liability Act and under the general statutory provisions provided

this operating manual has been adhered to.

Introduction

12

04/03/2020 218333

1.2.2 Warranty

Warranty claims shall be submitted to Arnz FLOTT GmbH Werkzeugmaschi-

nen immediately after the error or defect has been identified, stating the ma-

chine number, the machine type and the serial number.

Wear parts are not subject to warranty. The warranty is null and void in case

of:

Improper use of the machine

Improper working on and with the machine

Use of improper cutters and equipment and

Use of non-genuine spare parts and accessories of other origin than Arnz

FLOTT GmbH Werkzeugmaschinen.

1.2.3 Copyright

This operating manual and all documents contained therein are protected by

copyright. Any (even partial) duplication and disclosure to third parties, com-

munication and utilization of its contents are not permitted or require the ex-

press consent of Arnz FLOTT GmbH Werkzeugmaschinen.

Violations are liable to prosecution and oblige the offender to compensation for

damages. All rights for the exercise of intellectual property rights are reserved.

© Copyright 2018 by Arnz FLOTT GmbH Werkzeugmaschinen

Introduction

218333 04/03/2020

13

1.3 Operating Manual

This operating manual contains information and instructions which shall en-

sure that the operating personnel can work safely, properly and economically

on and with the machine. Only if the contents of the operating manual are un-

derstood and observed, can

Help to avoid hazards

Reduce repair costs and downtime and

Increase the reliability and service life of the machine.

To help you in the use of the operating manual, the sections below provide ex-

planations of systematics and rules used, as well as content and design speci-

fications, and, in some cases, illustrations with an example.

1.3.1 Definition of Terms

This operating manual uses some important terms, which are defined below.

Pillar drilling machine (machine)

The term pillar drilling machine means in this manual the complete machine.

For the sake of simplicity, only the term machine will be used in the following.

Spindle

The term spindle means the rotating component in which the drill chuck with

the cutter can be clamped directly.

Workpiece

The term workpiece means the material in the form of a component to be pro-

cessed.

Cutter

The term Cutter means in this operating manual the machining cutter (drill,

countersink, reamer and tap) used in the machine with which the workpiece is

machined.

Operating company

The operating company is any natural or legal person using the machine or on

whose behalf the machine is used.

Target group

The target group is a specific group of persons for whom specific information

in this operating manual is destined.

Introduction

14

04/03/2020 218333

Operating personnel

Operating personnel is who has been tasked and instructed to operate the

machine. The operating personnel is entitled to perform simple maintenance

such as cleaning the machine.

Authorized personnel

Authorized personnel are those who have been commissioned by the operat-

ing company to operate the machine as intended.

Trained personnel

Trained personnel who

Was informed about the tasks entrusted to them and, if necessary, trained

Was informed about the possible dangers of improper conduct and

Was informed about the necessary safety equipment, protective measures,

accident prevention regulations, relevant regulations and operating condi-

tions.

Technical staff

Technical staff are those who, due to their professional training, knowledge

and experience, can assess and professionally carry out the work assigned to

them. The technical staff are familiar with the accident prevention regulations,

the relevant regulations and the operating conditions.

Personnel of Arnz FLOTT GmbH Werkzeugmaschinen

Personnel of Arnz FLOTT GmbH Werkzeugmaschinen is who is technical staff

and employee of Arnz FLOTT GmbH Werkzeugmaschinen.

Residual risks

Residual risks are not obvious risks that are given during the operation of the

machine.

Example:

Risk of burns from hot machinery and components after the machine has

been shut down.

Protective clothing

Protective clothing is a personal protective equipment that protects the body

against hazards from the work process. The protective clothing must comply

with the Occupational Safety Act.

When protective clothing must and should be used is defined by the applicable

accident prevention regulations.

Introduction

218333 04/03/2020

15

1.3.2 Illustrations and Signs in this Text

To emphasize important information, this manual uses the following picto-

grams, symbols and typographical signs.

Pictograms

General danger

Indicates safety instructions which must be observed and which cannot be

identified with a specific pictogram (e.g. one of the following pictograms).

High electrical voltage

Indicates the risk of electric shock.

Hot parts

Indicates the risk of burns when touching hot machinery and components.

Hand injuries

Indicates the danger of being pulled in, crushed or otherwise injured

Environmentally hazardous substances

Indicates the risk posed by chemical substances if these substances are not

disposed of in accordance with applicable environmental protection laws.

Safety note

Indicates instructions for safe working on and with the machine.

Use ear protection

Use safety goggles

Use safety shoes

Use protective clothing

Introduction

16

04/03/2020 218333

Symbols

The operating manual uses three different symbols:

This symbol indicates a single handling instruction. If there are more than

one instruction, they are numbered consecutively.

This symbol indicates lists that consist of equal content.

This symbol identifies subitem lists that are subordinate to the lists and

also consist of equal content.

Typographical signs

These safety instructions contain note of the type of danger in italics (see page

17, section Examples for safety instructions).

1.3.3 Structure and Design of Safety Instructions

All safety instructions contained in this operating manual have a uniform struc-

ture.

Components of a safety instructions

A safety instruction consists of several components:

A pictogram

A signal word that indicates the degree of danger

A note on the nature of the danger and

A note on the prevention of the danger.

The following signal words indicate the degree of danger:

Danger

Indicates an imminent danger to persons.

Possible consequences: Death or serious injuries

Warning

Indicates a potential hazard to persons.

Possible consequences: Death or serious injuries

Attention

Indicates a possible hazard to persons or property.

Possible consequences: Minor personal injury or damage to property

Note

Indicates a potentially harmful situation for property or the environment.

Possible consequences:

Damage to machine itself

Damage to property in the environment of the machine

Damage to the environment

Introduction

218333 04/03/2020

17

Examples of safety instructions

Warning

Danger by improper use of the machine.

The machine may only be operated by authorized and trained personnel.

The machine may only be operated when it is in flawless condition. All safety

devices must be present and fully functional.

Note

Check all screw connections before commissioning the machine

Tight fit

Externally visible damage.

Safety Instructions

18

04/03/2020 218333

2 Safety Instructions

2.1 General Safety Instructions

The machine corresponds to the state of the art at the time of placing the order

and is generally considered to be operationally reliable.

The machine can still be dangerous if

Unauthorized and untrained personnel operates the machine and

The machine is used improperly.

Then there is danger for

People

The machine and

Other property of the operating company.

2.1.1 The Operating Manual

The prerequisite for safe handling and trouble-free operation is knowledge of

the specific safety instructions and safety regulations, e.g.

DGUV Regulation 1 – Principles of Prevention

DGUV Rule 100–500 – Operation of Work Equipment

This operating manual shall be used in particular for safe working on and with

the machine. It contains safety instructions that must be observed.

In addition to the basic safety instructions in this section, you must also ob-

serve the special safety instructions in the other sections. They contain specif-

ic safety instructions for specific instructions that warn you of an impending

danger.

The operating manual must

Be read and understood by all persons who work on and with the machine

before beginning their work

Be available at the place of use of the machine at a designated place and

Be always complete and in perfectly readable state.

If you do not understand this operating manual or individual paragraphs, you

should not start your activity. Ask the technical staff

of the operating company or

of Arnz FLOTT GmbH Werkzeugmaschinen

before you get into a potentially dangerous situation.

Safety Instructions

218333 04/03/2020

19

2.1.2 The Duties of the Operating Company

The operating company must take into account a number of obligations with

respect to its staff.

The operating company is obliged to

Supplement the operating manual by instructions based on national regula-

tions for accident prevention and environmental protection

Inform the staff of all relevant regulations, instructions and laws, where re-

quired

Control all relevant regulations, notes and laws that will be complied with

Instruct the staff how to work on and with the machine

Clearly define the responsibilities for operation, maintenance and repair of

the machine

Check that the specified responsibilities are complied with

Verify at regular intervals whether its staff is aware of potential hazards and

operates the machine in accordance with the safety standards laid down in

the operating manual and

Ensure that the staff has read and understood the operating manual, espe-

cially the section on safety. If necessary, the operating company should

have the staff confirmed this in writing.

2.1.3 The Safety of the Machine

The following must be observed during all work on and with the machine:

The applicable regulations

The applicable professional association regulations (DGUV)

The relevant provisions and applicable environmental laws

Only use the machine in a technically perfect condition. This means that all

safety equipment of the machine is present and functional. In case of malfunc-

tions or errors, you must immediately shut down the machine and notify the

person in charge of the operating company of this condition.

You may take the machine into operation after restoring the proper functioning

of the machine.

Do not dismantle or put out of operation any safety devices. If you still need to

dismantle the safety devices, e.g. during maintenance or servicing work, you

must install them again immediately after the work has been completed.

Check all safety devices for proper operation before operating the machine.

Note

Modifications, extensions and conversions of the machine that impair safety

are strictly prohibited. They require the written approval of Arnz FLOTT GmbH

Werkzeugmaschinen.

Safety Instructions

20

04/03/2020 218333

Only use original spare parts if you need to replace components of the ma-

chine. Operation and safety of the machine are preserved only with original

spare parts.

2.1.4 The Working Staff

Only authorized and trained personnel may work on and with the machine.

Unauthorized persons are prohibited from using the machine. Personnel un-

dergoing training or instruction or who are undertaking a general programme

of education may only work on the machine under the continuous supervision

of an experienced person.

Young people under 18 years are only allowed to work on the machine

As part of their education

After successful detailed instruction and

Under the guidance and supervision of an authorized person.

Works on the electrical equipment or operating materials of the machine may

only be carried out by authorized personnel.

The responsible supervisor must instruct the operating staff at regular inter-

vals, at least once a year, on safe working practices. The instructions must be

appropriately recorded and be signed by the trained staff.

The operating personnel must promptly inform their supervisor of any changes

in the performance of the machine. This applies especially if the safety of the

machine is no longer guaranteed.

Personnel is not permitted to have loose hair, loose clothing or jewellery, in-

cluding rings, when standing near the machine.

The personnel must wear personal protective equipment as required or pro-

vided by a regulation.

2.1.5 The Workplace

Only occupy workplaces which of intended for the operation or maintenance of

the machine. The workplaces must always be dry, clean and unobstructed.

The machine must always be accessible from all sides. Do not store flamma-

ble or explosive substances near workplaces. The working area must be venti-

lated so that no hazardous or highly flammable mixtures or gases can accu-

mulate in dangerous quantities. If necessary, a suitable ventilation system

must be installed. To provide for the possibility of immediate and proper action

in the event of accidents and breakdowns, you must always have at hand at

your workplace:

Officially approved fire extinguisher

First aid kit

This manual suits for next models

28

Table of contents

Other Flott Drill manuals