| 4 QS301905 Rev A

USING THE DISPLAY

The display module features a dot matrix LCD display with 4 push buttons on a

removable puck. Out of the box, the display indicates level in feet and depicts

the level within the 4-20mA span on a bar graph at the right side of the display.

The four buttons perform the following functions:

ESCAPE

o Exit configuration mode

o Return to a higher menu level

o Display Echo Curve

Up Arrow

o Modify parameter values

o Choose display mode

Right Arrow

o Choose configuration options

o Choose parameter digits to edit

o Display contents of parameters

ENTER

o Enter Menu and Options

o Confirm configuration options

o Confirm changes to parameters

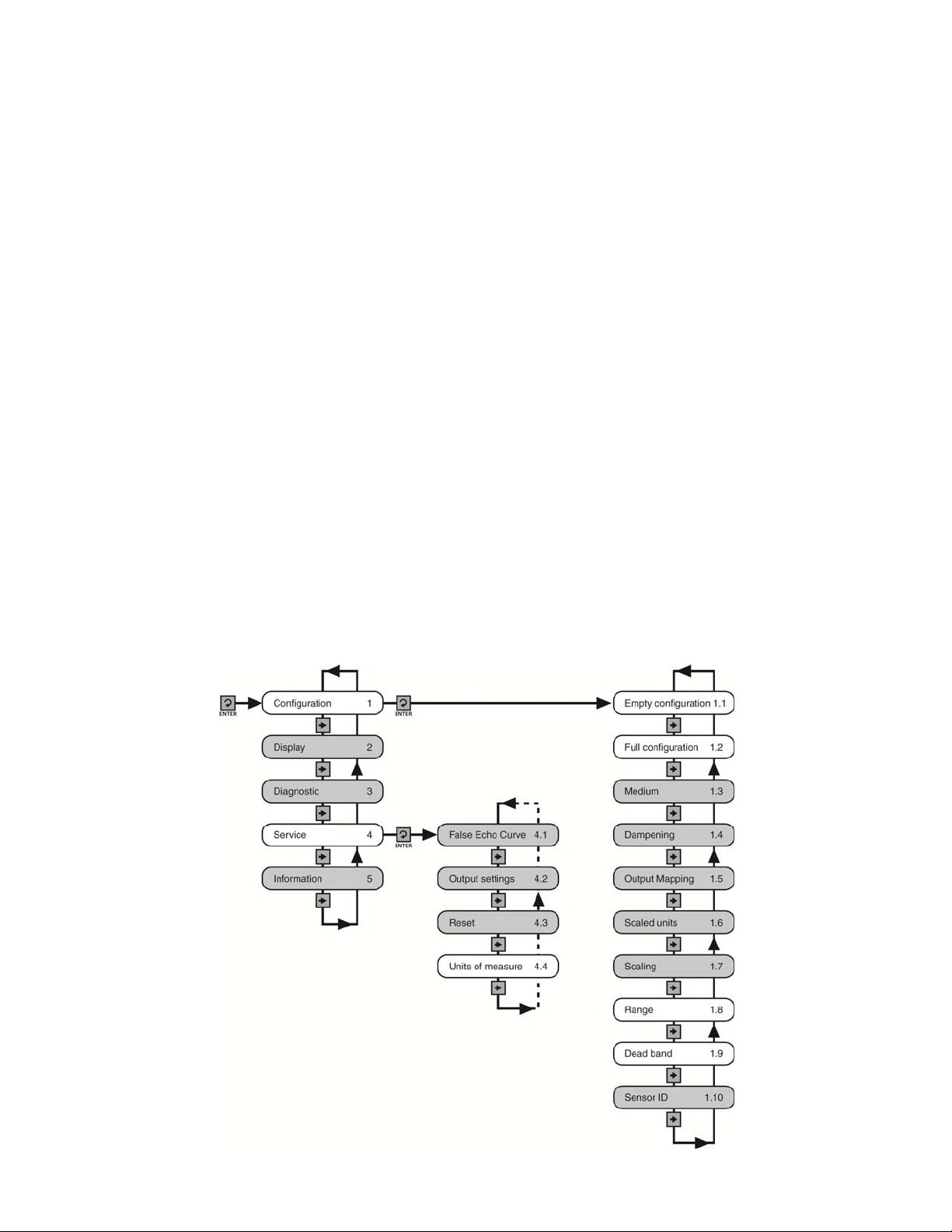

MENU INTRODUCTION

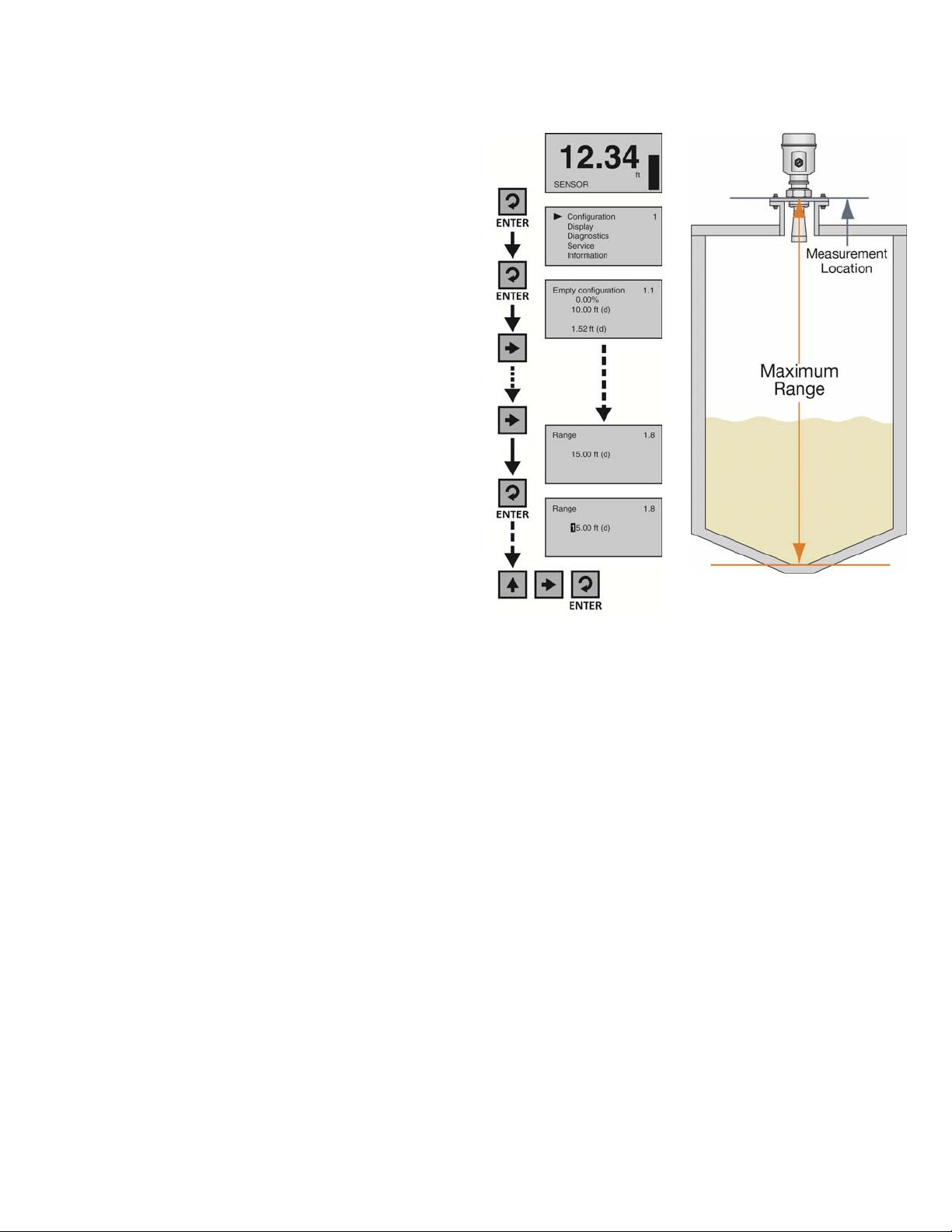

1) To enter the Main Menu (from the Main Screen), press the ENTER button.

2) Use the Right Arrow button to scroll through the Main Menu options.

a) Configuration - Below are the configuration menu functions:

i) Empty Configuration

ii) Full Configuration

iii) Medium

iv) Dampening

v) Output Mapping

vi) Scaled Units

vii) Scaling

viii) Range

ix) Dead Band

x) Sensor ID

b) Display - This menu function sets the display mode and contrast.

c) Diagnostics - Below are the diagnostic menu functions:

i) Measurement of Peak Values

ii) Measurement Status

iii) Echo Curve

iv) Simulation

d) Service - Within the service menu functions, you can store a False

Echo Curve, set units of measurement, change output settings, reset

configuration settings, set language or set a PIN for the sensor.

e) Info - This item provides information on the sensor’s type, serial

number, date of manufacture and software version.

3) To select one of the functions, press ENTER.

4) To exit the programming mode, press ESC.