| 2 MN301905 Rev A

Introduction / Table of Contents Step One

TABLE OF CONTENTS Page

Section One | Introduction: ............................................................................................................................... 2

Table of Contents: .................................................................................................................................... 2

Sensor Models: ........................................................................................................................................ 5

Operating Principle: ................................................................................................................................. 6

Features: .................................................................................................................................................. 6

Benefits: ................................................................................................................................................... 6

Limitations: ............................................................................................................................................... 6

Specifications: .......................................................................................................................................... 7

Intrinsically Safe Control Drawing: .......................................................................................................... 11

Labels for Intrinsic Safety: ....................................................................................................................... 12

Dimensions: ........................................................................................................................................... 13

Safety Precautions: ................................................................................................................................ 15

Section Two | Getting Started: ........................................................................................................................ 16

Setup Overview: ..................................................................................................................................... 16

Part Number: .......................................................................................................................................... 18

Section Three | Install Sensor: ....................................................................................................................... 20

Installation Requirements: ..................................................................................................................... 20

FCC Conformity: ..................................................................................................................................... 21

LR36 & LR41 Antenna Preparation: ...................................................................................................... 22

LR46 Antenna Preparation: .................................................................................................................... 23

Flange Riser Installation: ....................................................................................................................... 23

Beam Angle: .......................................................................................................................................... 24

Gimbal Mounts (for Solids): .................................................................................................................... 25

Solids Installation Tips: ........................................................................................................................... 25

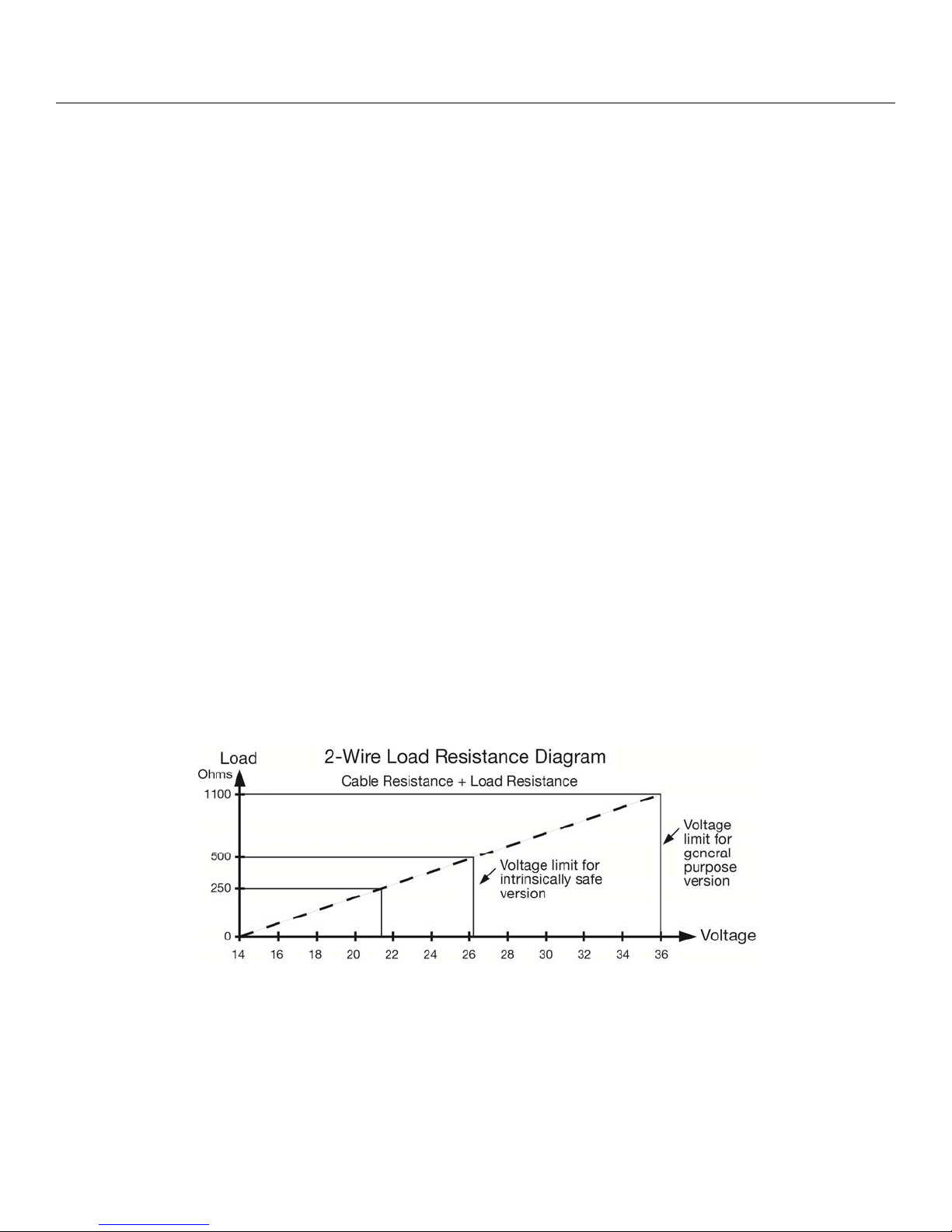

Section Four | Wire Sensor: ............................................................................................................................ 27

Terminal Wiring: ..................................................................................................................................... 27

Wiring to Displays, Controllers & PLCs: ................................................................................................. 28

Section Five | Configuration: .......................................................................................................................... 30

Basic Configuration Overview: ............................................................................................................... 30

Using the Display: .................................................................................................................................. 31

Changing Display Values: ...................................................................................................................... 32

Step 1 - Measure the Tank: ................................................................................................................... 33

Step 2 - Set the Units of Measurement: ................................................................................................. 34

Step 3 - Set the Empty Configuration (4mA): ......................................................................................... 35

Step 4 - Set the Full Configuration (20mA): ........................................................................................... 36

Step 5 - Set the Range (Maximum Range): ........................................................................................... 37

Step 6 - Set the Dead Band: .................................................................................................................. 38

Step 7 - Check the Echo Curve: ............................................................................................................ 39