Valtek No. 10003460 15-1

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Valtek CavControl Trim

GENERAL INFORMATION

The following instructions are designed to assist in

assembling, disassembling and troubleshooting

Valtek® globe valves equipped with CavControl™ trim.

Product users should thoroughly review this bulletin in

conjunction with Installation, Operation, Maintenance

Instruction 1 (Mark One and Mark Two Control Valves)

and Installation, Operation, Maintenance Instruction 24

(Valtek Beta Positioner) before installing, operating or

performing any maintenance on the valve.

To avoid possible injury to personnel or dam-

age to valve parts, WARNING and CAUTION

notes must be strictly followed. Modifying this

product, substituting non-factory or inferior

parts, or using maintenance procedures other

than outlined could drastically affect perfor-

mance and be hazardous to personnel and

equipment.

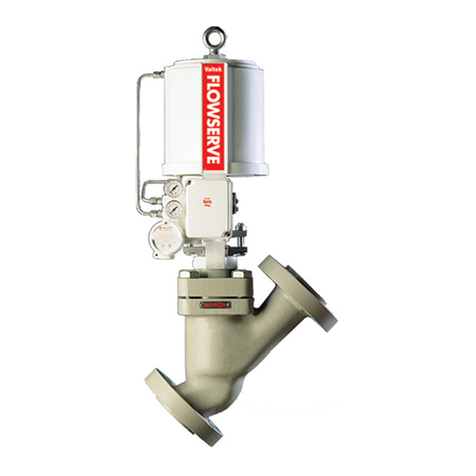

Installation

Standard unpacking and installation instructions are

outlined in Installation, Operation, Maintenance Instruc-

tion 1. Regardless of the air-action, valves equipped

with CavControl trim must be installed in the line with the

flow direction over the plug.

CAUTION: Improper installation will result in severe

cavitation damage to the valve.

NOTE: Flowserve recommends a strainer be installed

upstream of the valve prior to start-up. This will help

prevent debris build-up and trim fouling.

DISASSEMBLY AND REASSEMBLY

Disassembling CavControl Trim

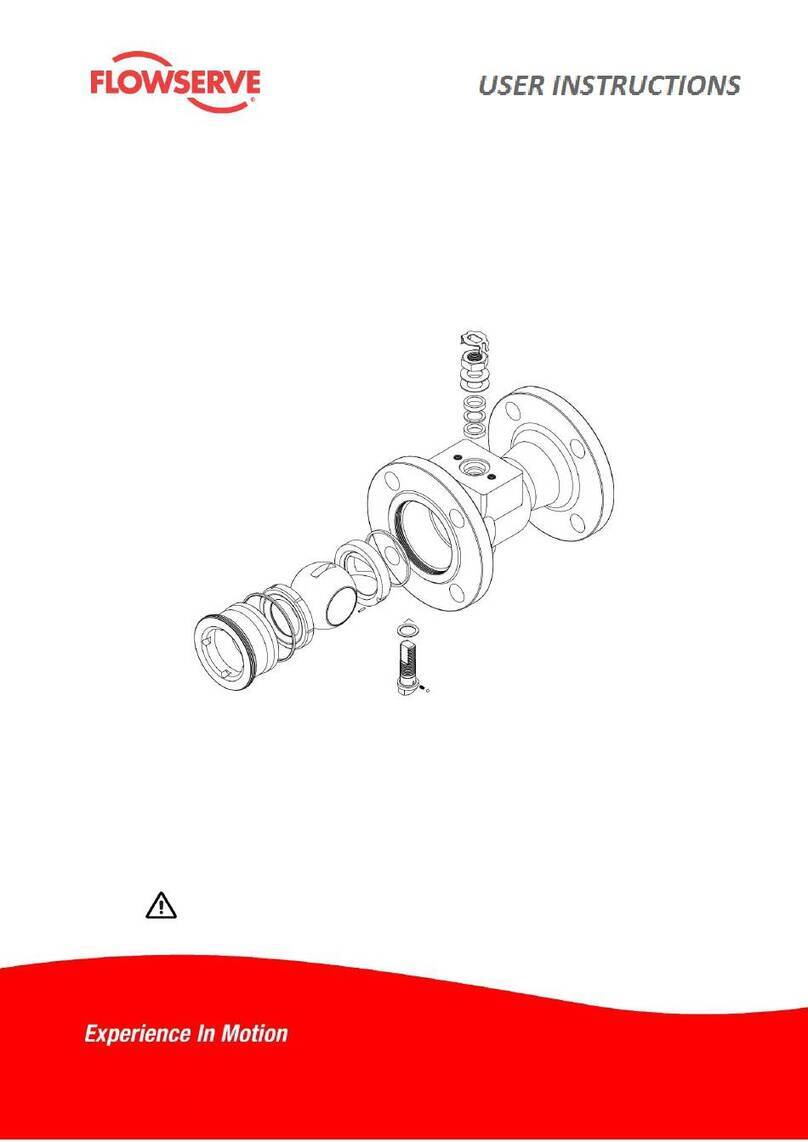

When disassembling valves with CavControl trim, refer

to either figure 1 or 2 and proceed as follows:

WARNING: Depressurize line to atmospheric pres-

sure or remove valve from line and drain all process

fluids and decontaminate the valve (if caustic or

hazardous materials are present). Failure to follow

this warning can cause serious injury.

1. Stroke the valve to the full open position by applying

air to the lower cylinder port.

2. Remove the bonnet flange bolting and lift the ac-

tuator/plug assembly out of the valve body.

CAUTION: Lift the actuator/plug assembly

straight out of the valve body to avoid damage

to the plug head, seat ring or trim. If the actuator

is not provided with a lifting ring, use lifting

straps around the yoke legs.

WARNING: With pressure-balanced trim,

danger exists in removing the actuator/plug

assembly out of the valve body, especially if

PTFE pressure seals are used on the plug. The

pressure-balanced sleeve could bind on the

plug, allowing the sleeve to be lifted out of the

body along with the actuator/plug assembly. If

the sleeve should loosen and fall, it could cause

personal injury and damage valve parts or

nearby equipment. Step 3 outlines the correct

procedure for removing the sleeve from the

plug.