2

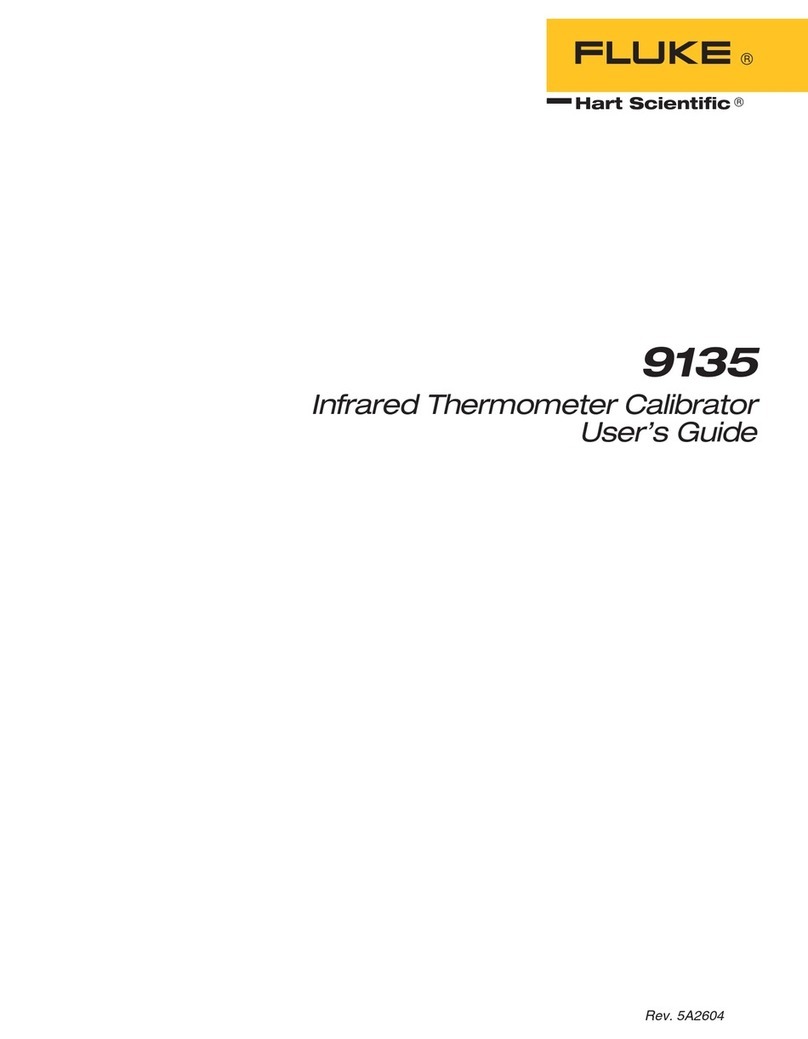

VIBCODE sensors of series VIB 8.660 are used in

industry to measure the following parameters:

– Vibration acceleration on rotating machines

– Cavitation in pumps

– Shock pulse signals in roller bearings

The VIBCODE sensor is operated together with

a compatible, portable measuring device. For

measurement, the VIBCODE sensor is connected

to a coded VIBCODE stud, which is permanently

installed on the machine.

VIBCODE sensors of series VIB 8.660 HEX are per-

mitted for use in the Ex-zone in accordance with

ATEX guidelines.

Safety instructions

•Read these operating instructions carefully and

keep them in a safe place.

•Observe the operating instructions of the devic-

es to be connected.

•Only use the sensors as intended and only for

the permitted purpose of application.

• Only use original accessories.

• Replace defective sensors and cables.

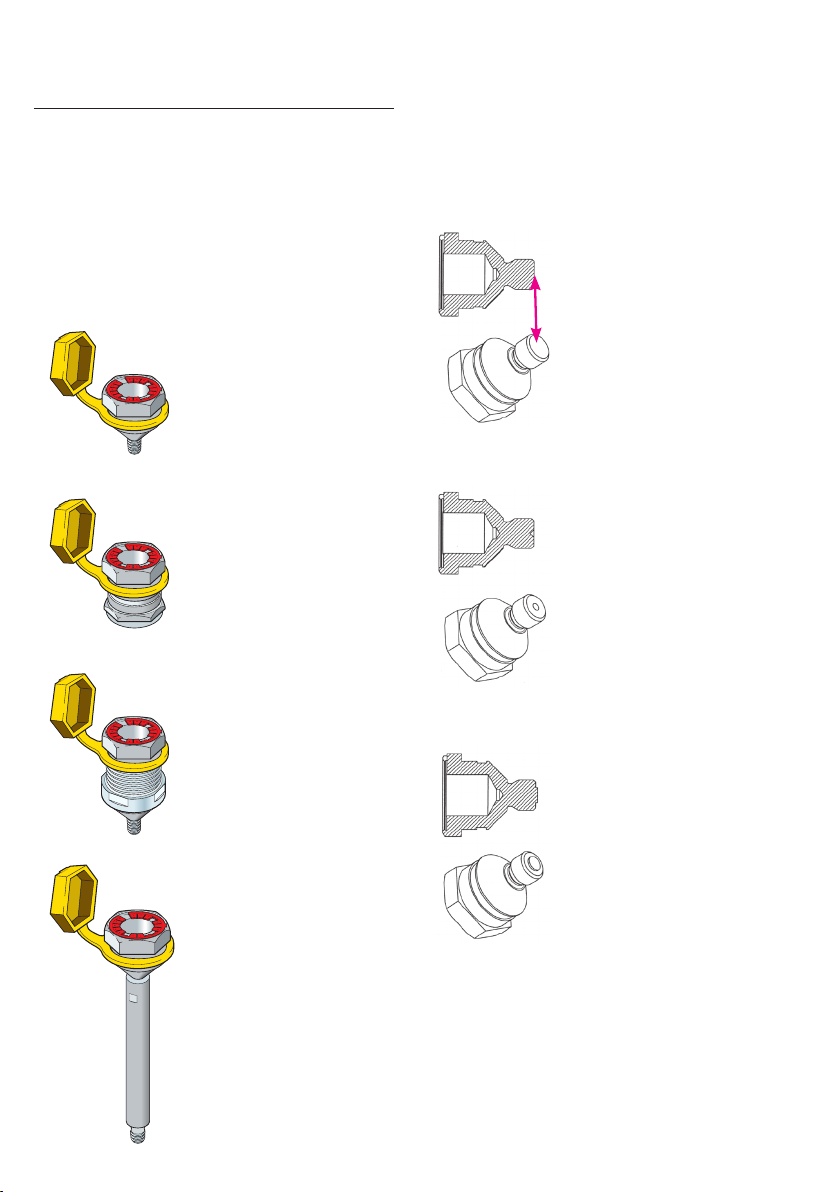

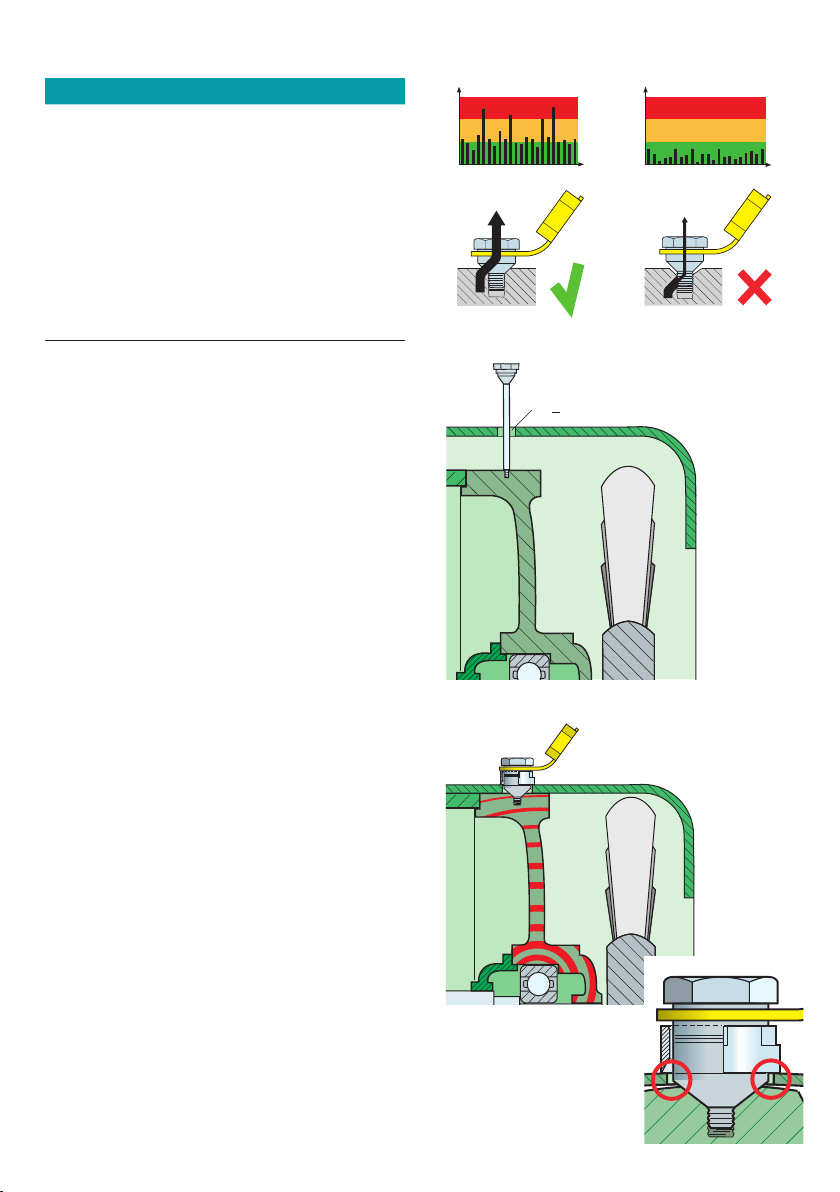

•Have installation of the VIBCODE studs carried

out by qualified personnel exclusively.

•Comply with the applicable safety regulations

when performing installation tasks on the ma-

chine in operation.

•Observe the technical specifications and permis-

sible operating conditions. If in doubt, contact

PRUFTECHNIK.

•VIBCODE sensors are compliant with the appli-

cable European directives. The complete Decla-

ration of Conformity is available under www.

pruftechnik.com/certificates.

Safety instructions for installation and operation

in the Ex-zone:

•Only VIBCODE sensors of series VIB 8.660 HEX

are permitted to be operated in the Ex-zone.

•Sensors of series VIB 8.660 HEX are only to be

connected to certified intrinsically safe circuits

giving due consideration to the following max-

imum values:

Ui= 30 V; Ii= 63 mA; Pi = 300 mW;

Ci = 347 nF; Li= negligibly small.

•The following devices may also be connected

to the VIBCODE VIB 8.660 HEX with their

intrinsically safe analogue output circuits. The

connection must take place via a cable with a

maximum length of 10 m an inductance per

unit length of L’ <1µH/m and a capacitance per

unit length of C’ < 120 pF/m.

– VIBSCANNER type VIB 5.400 EX / EC-Type Ex-

amination Certificate No. TÜV 01 ATEX 1699

– VIBXPERT type VIB 5.300 EX - xx / EC-Type Ex-

amination Cert. No. ZELM 07 ATEX 0355 X

•The permissible ambient temperature range is

between -20°C and +80°C [-4°F ... + 176°F].

•

•

The European installation regulations are to be

observed (EN 60079-14).

The information in the type-examination cer-

tificate is to be observed: TÜV 02 ATEX 1890,

incl. 1st supplement, issued october 6th, 2008.

Available on www.pruftechnik.com.

• Labeling of the sensors:

II 2G Ex ib IIC T4

Compatibility

• VIBCODE - VIB 8.660 HEX, S.N. > 00101

Device:

– VIBSCANNER EX, firmware > 1.66

– VIBXPERT EX, all versions

• VIBCODE - VIB 8.660, S.N. > 2362

Device:

– VIBSCANNER, firmware > 1.66

– VIBXPERT, all versions

Maintenance and repair work

Operation of the sensors does not require any

maintenance. Repair work by the user is not

possible.

Storage

•Store the VIBCODE sensor in the case of the

device.

• Conditions at the storage location:

– Dry and free of dust

– Temperatures are within the permissible range

– Vibration-free

– No high electromagnetic fields

– No corrosive materials

Disposal

After use, dispose of the sensor in an environ-

mentally friendly manner and in accordance with

national provisions.

S.N.