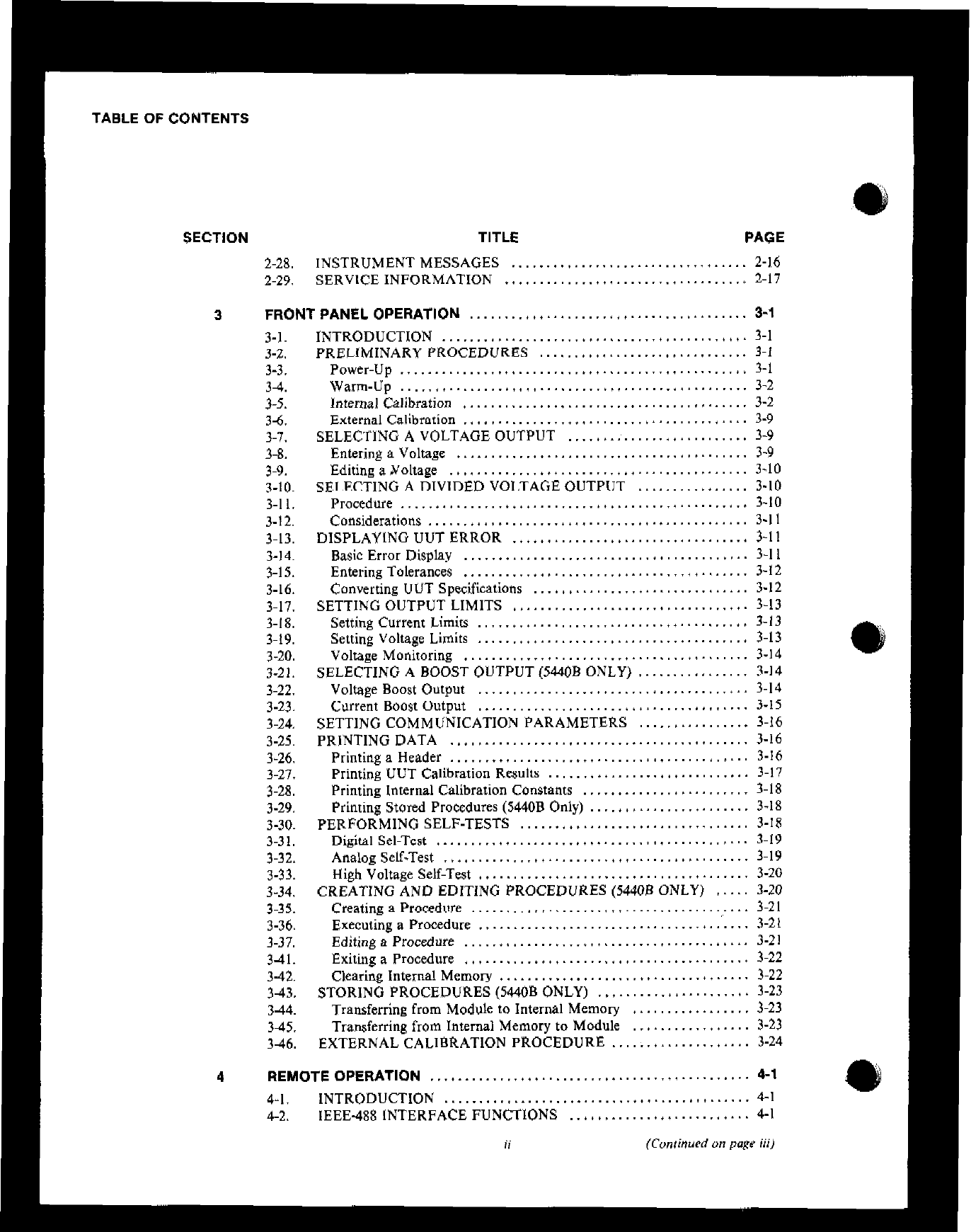

TABLE OF CONTENTS

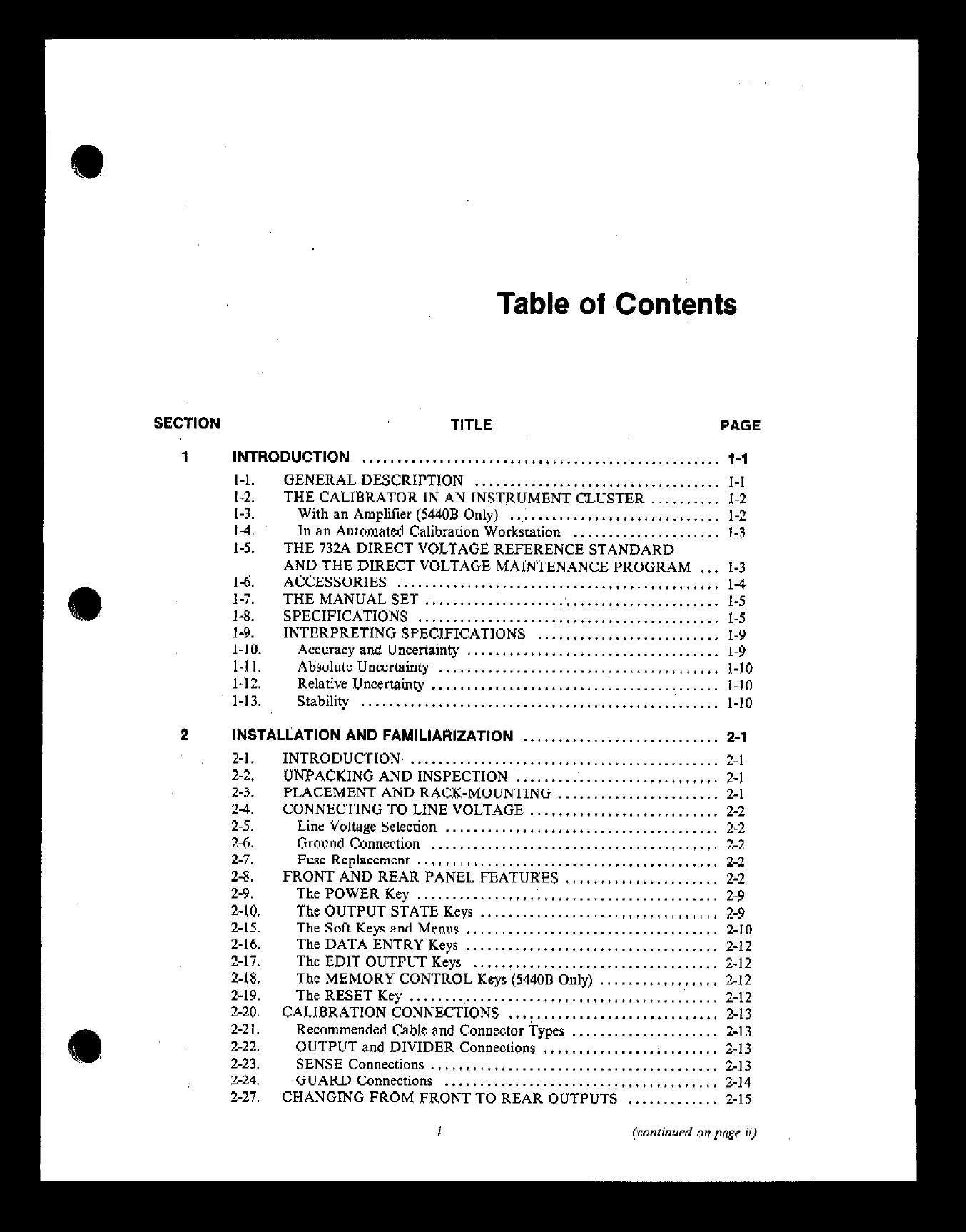

SECTION TITLE PAGE

2-28. INSTRUMENT MESSAGES .................................. 2-16

2-29. SERVICE INFORMATION ................................... 2-17

3 FRONTPANELOPERATION ........................................ 3-i

3-1. INTRODUCTION ............................................ 3-l

3-2. PRELIMINARY PROCEDURES .............................. 3-1

3-3. Power-Up ................ . ................................. 3-1

3-4. Warm-Up .................................................. 3-2

3-5. Internal Calibration ......................................... 3-2

34. External Calibration ......................................... 3-9

3-7. SELECTING A VOLTAGE OUTPUT ..... t.:. ................. 3-9

3-8. Entering a Voltage .......................................... 3-9

3-9. Editing a Y&age ........................................... 3-10

3-10. SELECTING A DIVIDED VOLTAGE OUTPUT ................ 3-10

3-11. Procedure .................................................. 3-10

3-l 2. Considerations .............................................. 3-l I

3.13. DISPLAYING UUT ERROR .................................. 3-l I

3-14. Basic Error Display ......................................... 3-l I

3-15. Entering Tolerances ......................................... 3-12

3-16. Converting UUT Specifications ............................... 3-12

3-17. SETTING OUTPUT LIMITS .................................. 3-13

3-18. Setting Current Llmlts

......................................... 3-13

3-19. Setting Voltage Limits ....................................... 3-13

3-20. Voltage Monitoring ......................................... 3-14

3-21. SELECTING A BOOST OUTPUT (544OB ONLY) ................ 3-14

3-22. Voltage Boost Output ....................................... 3-14

3-23. Current Boost Output ....................................... 3-15

3.24. SETTING COMMUNICATION PARAMETERS ................ 3-16

3-25. PRINTING DATA ........................................... 3-16

3-26. Printinga Header ........................................... 3-16

3-27. Printing UUT Calibration Results ............................. 3-17

3-28. Printing Internal Calibration Constants ........................ 3-18

3-29. Printing Stored Procedures (54408 Only) ....................... 3-18

3-30. PERFORMING SELF-TESTS ................................. 3-18

3-31. Digital S&Test ............................................. 3-19

3-32. Analog Self-Test ............................................ 3-19

3-33. High Voltage Self-Test ....................................... 3-20

3-34. CREATING AND EDITING PROCEDURES (544OB ONLY) ..... 3-20

3-35. Creating a Procedure ................... $,, ............. .,~... 3-21

3-36. Executing a Procedure ....................................... 3-21

3-37. Editing a Procedure ......................................... 3-21

341. Exiting a Procedure ......................................... 3-22

3-42. Clearing Internal Memory .................................... 3-22

343. STORING PROCEDURES (54$OB ONLY) ...................... 3-23

3-44. Transferring from Module to Internal Memory ................. 3-23

345. Transferring from Internal Memory to Module ................. 3-23

346. EXTERNAL CALlEtRATION PROCEDURE .... ;. .............. 3-24

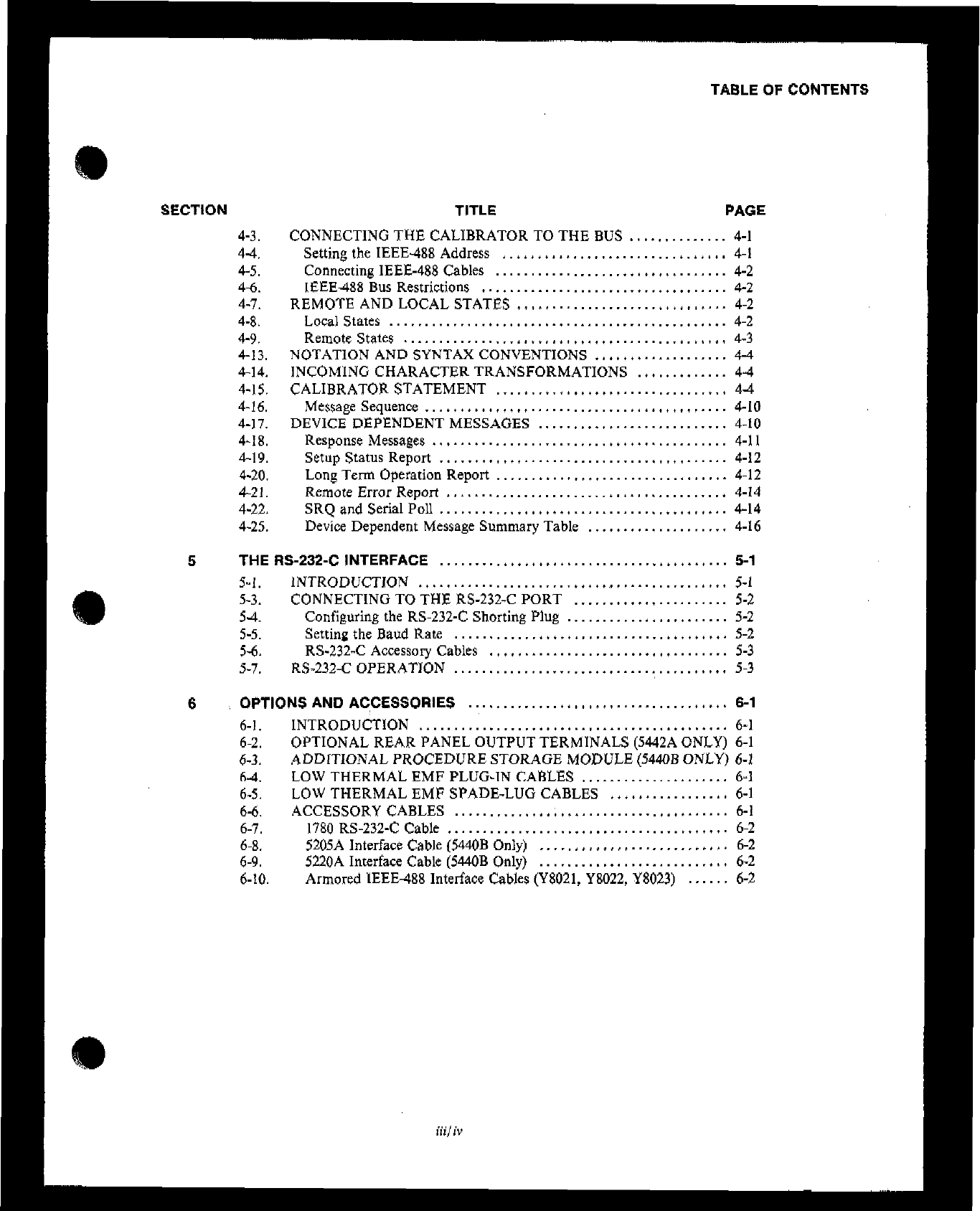

4 REMOTE OPERATION .............................................. 4-l

4-l. INTRODUCTION ............................................ 4-l

4-2. IEEE-488 INTERFACE FUNCTIONS .......................... 4-l

ii

(CorMwrri on puge iii)