V20240125 •Page 9 of 9Model: SS4 | SS4-MBS | SS4-FMH

To service your unit, refer to the service manual which includes:

• Troubleshooting procedures.

• Detailed parts breakdowns and illustrations.

• Part numbers of serviceable components and assemblies.

Maintenance

Servicing Your Unit

Scan this code for

service manual

To keep your unit operating properly, perform the following daily maintenance procedures:

• Inspect the stainless foot grate for debris and clean

when necessary.

• Collection basin should be emptied and cleaned

each time the chemical supply container is changed

or refilled. See Collection basin cleaning instructions

for more information.

Note: During heavy use, over-spray can fill up basin.

Be mindful of fluid levels not reaching above manifold,

this can cause the unit to operate improperly.

• Verify nozzle assembly is free of any debris or

blockage. Rinse with low pressure water if necessary.

• Check suction line and strainer for debris. Clean as

needed.

• Inspect all tubing for leaks or excessive wear. Make

sure all hose clamps and push fittings are in good

condition and properly secured.

For SS4, SS4-BSH, and SS4-MBS units:

• Remove brushes by lifting them out from the brush

bracket. Remove debris and clean. Brushes should be

replaced every 6 months depending on wear.

• Slide out debris tray. Empty debris and wipe clean.

• Base assembly of unit is fully stainless and can be

cleaned in place by method suitable for stainless steel.

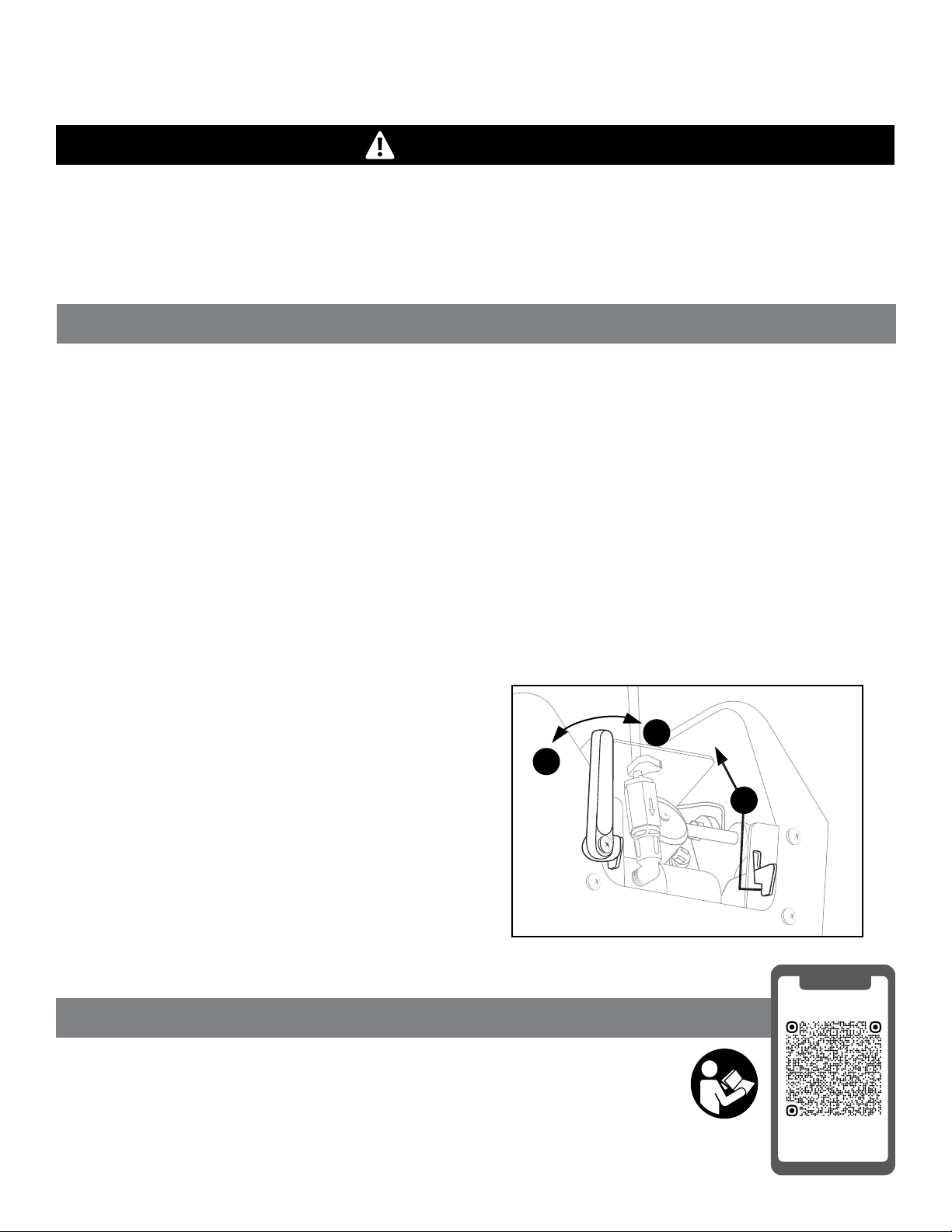

1. Turn Lock Lever to the unlock position

2. Holding the mechanism by its touch points, slide the

mechanism over to the right, lift up, and towards you

to disengage the hooks

3. Place mechanism aside, level with the floor.

4. Empty and clean the collection basin.

5. Re-insert the mechanism by repeating step 2 in

reverse order.

6. Slide the lock lever until it is upright and/or tab is

touching the mechanism, as shown below.

For SS4-MBS units only:

Collection basin cleaning instructions:

Performing any maintenance with the unit pressurized may result in serious injury. Before conducting any

maintenance, always ensure the unit has been depressurized by disconnecting the air line on the unit. Servicing

or modifying this unit with parts not listed in this manual may cause the unit to operate improperly. Do not use

unauthorized parts when servicing the unit. Remember to reconnect air line, and re-prime the unit according to the

priming instructions in the operation manual after performing any maintenance.

WARNING

Maintaining Your Unit

1

6

2