GSK928TE/TC CNC System User Manual

1

Content

Operation

1. Overview.....................................................................................................................1

2. Technical specification ............................................................................................. 2

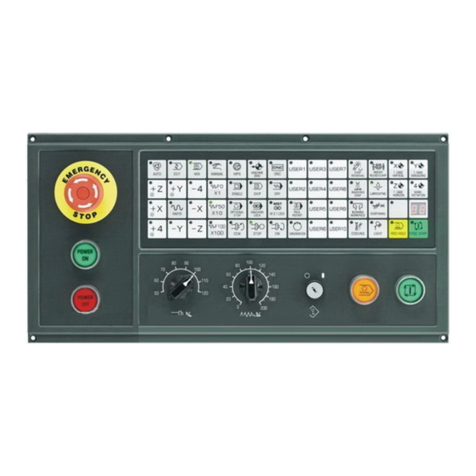

3. Operation panel ......................................................................................................... 3

4. Operation.................................................................................................................. 10

4.1 System power on/power off ................................................................................................10

4.2 CNC system operating mode.............................................................................................. 11

4.3 Edit mode............................................................................................................................13

4.4 Jog mode ............................................................................................................................29

4.5 Auto mode .....................................................................................................................53

4.6 Parameter setting................................................................................................................68

4.7 Tool offset setting mode......................................................................................................80

4.8 Diagnosis ............................................................................................................................84

4.9 Alarm of emergency stop and overtravel............................................................................88

4.10 LCD brightness adjust.......................................................................................................90

4.11 Driver switch control..........................................................................................................90

Programming

1. Overview................................................................................................................ 91

1.1 Coordinate axis and its direction.........................................................................................91

1.2 Machine zero.......................................................................................................................92

1.3 Programming coordinate.....................................................................................................92

1.4 Workpiece coordinate system.............................................................................................93

1.5 Reference point...................................................................................................................94

2. Program structure ................................................................................................ 94

2.1 Character ............................................................................................................................94

2.2 Word....................................................................................................................................96

2.3 Block number......................................................................................................................96

2.4 Block ...................................................................................................................................96

2.5 Program structure ...............................................................................................................97

3. Codes and their functions ................................................................................... 97

3.1 Gcodes — preparatory function ...............................................................................97

3.2 M function — auxiliary function ..............................................................................102

3.3 S function — spindle function ...................................................................................108

3.4 T function — tool function .........................................................................................109

3.5 F function — feedrate function.................................................................................. 110