Forematic F550 User manual

F550/F560 doc. B05

P1

doc. B05

iss V1.1

F550/F560 PICO installation manual

Description

The F550 & F560 sets are based around the PICO 24Vdc sliding

gate motors. The F550 is for domestic gates. The F560 is for

light industrial gate applications such as an office development.

A toothed rack fixed to the gate engages with a pinion on the

motor. Drive is delivered through a worm drive gearbox. The gate

cannot be moved while the gearbox is engaged. A key override

disengages the motor from the drive pinion. Used in exceptional

circumstances, like power failure.

Two double button rolling code remotes are included. Buttons can

be programmed to open fully for vehicles or partial opening for

pedestrians. The 2nd button can open another gate. Up to 16

remotes can be registered. A safety photo beam is included to

detect vehicles. Further safety devices may be added.

Operation

On an input from a remote or an external control, the gate will

open fully or partially. The closed and fully open positions are

determined by limit switches acting on ‘skis’ fitted to the rack. If

the remote is activated while the gate is running, it will stop. The

next remote activation will re-start in the other direction.

For safety, the gate slows at ends of travel. If the automatic

close function is enabled, the gate will re-close after a delay.

If the photo beam is interrupted during closing, the gate stops

then re-opens. The gate will stay open while the beam is

interrupted. The motor has a stall sensor to detect physical

blocks in the gates path. If an obstacle is detected in either

direction, the gate will stop and reverse direction.

Safety warnings

Automatic gates can be hazardous. It is the responsibility

of the home owner to be aware of the risks and provide,

adequate warning of hazards. Users should be given instruction on

the safe use of the automatic gate.

This manual is written for engineers aware of construction criteria for

automatic gates and accident prevention criteria in force in the

automation industry. Only qualified persons may do installation or

maintain work on this barrier that may change its risk assessment.

Turn off the power before working on the gate. We recommended

signage to warn users and members of the public of risk of injury to

pedestrians. Do not permit public access to the gate area. Do not use

remotes when out of sight of the gate. Do not let children or untrained

people use remotes. Do not let unsupervised children near the gate.

Specifications

Supply 220-240Vac 50Hz 2.5A

Pinion Mod.4 15 teeth

Speed 16mm/sec

Duty cycle 25% 20 times/hr

Gate size F550 –600kg

F560 –900kg

Motor power F550 –110W

F560 –150W

Temp O/L 120°C

Temp’ -20°C to 50°C

Protection IP44

Physical Protection

Gates must be of a robust construction to be automated without

attendance. Wheels on which the gate roll must be free running &

well maintained on clean level ground tracks. Support rollers must

be adjusted and maintained for smooth running. Gates must have

physical stops at both extremes to prevent derailment hazards.

Cables must be sufficiently protected against abrasion that could

lead to a hazard due to exposure of electrical conductors.

Electrical supplies must be protected by an earth leakage device.

There must a disconnect switch outside the gate area.

‘Automatic gate’ signs are required on both sides of the gate

warning against risk of contact injury. A pedestrian side gate is

preferred for regular pedestrian access.

User Instructions

It is the site owner or manager’s responsibility to ensure that only

trained people operate the gate, and ensure all operators are

aware of gate hazards. Operators must take responsibility for the

safety of any person within the hazard area. Never let children

play near gates in motion.

Keep the gate area clear of objects. Examine the gate for

imbalance or signs of wear. Have gate properly maintained and

repaired by qualified personnel when necessary.

Manufacturers are not responsible for injury resulting from failure

to meet the requirements in this manual. An adequate clearance

must be provided around the gate to prevent entrapment.

Photobeam

Remotes

Safety warnings

Automatic gates can be hazardous. It is the responsibility

of the home owner to be aware of the risks and provide,

adequate warning of hazards. Users should be given instruction on

the safe use of the automatic gate.

This manual is written for engineers aware of construction criteria for

automatic gates and accident prevention criteria in force in the

automation industry. Only qualified persons may do installation or

maintain work on this barrier that may change its risk assessment.

Turn off the power before working on the gate. We recommended

signage to warn users and members of the public of risk of injury to

pedestrians. Do not permit public access to the gate area. Do not use

remotes when out of sight of the gate. Do not let children or untrained

people use remotes. Do not let unsupervised children near the gate.

Description 1

User notices

Safety warnings

Warranty

Site preparation 2

Alignment

Motor & rack

Ducts & Cabling

Setup 3

Quick setup

Connections

DIP switches

Adjustment

Remotes

Wiring 4

Universal wiring

Examples

Certificate of conformity

Warranty

F550/F560 doc. B05

P2

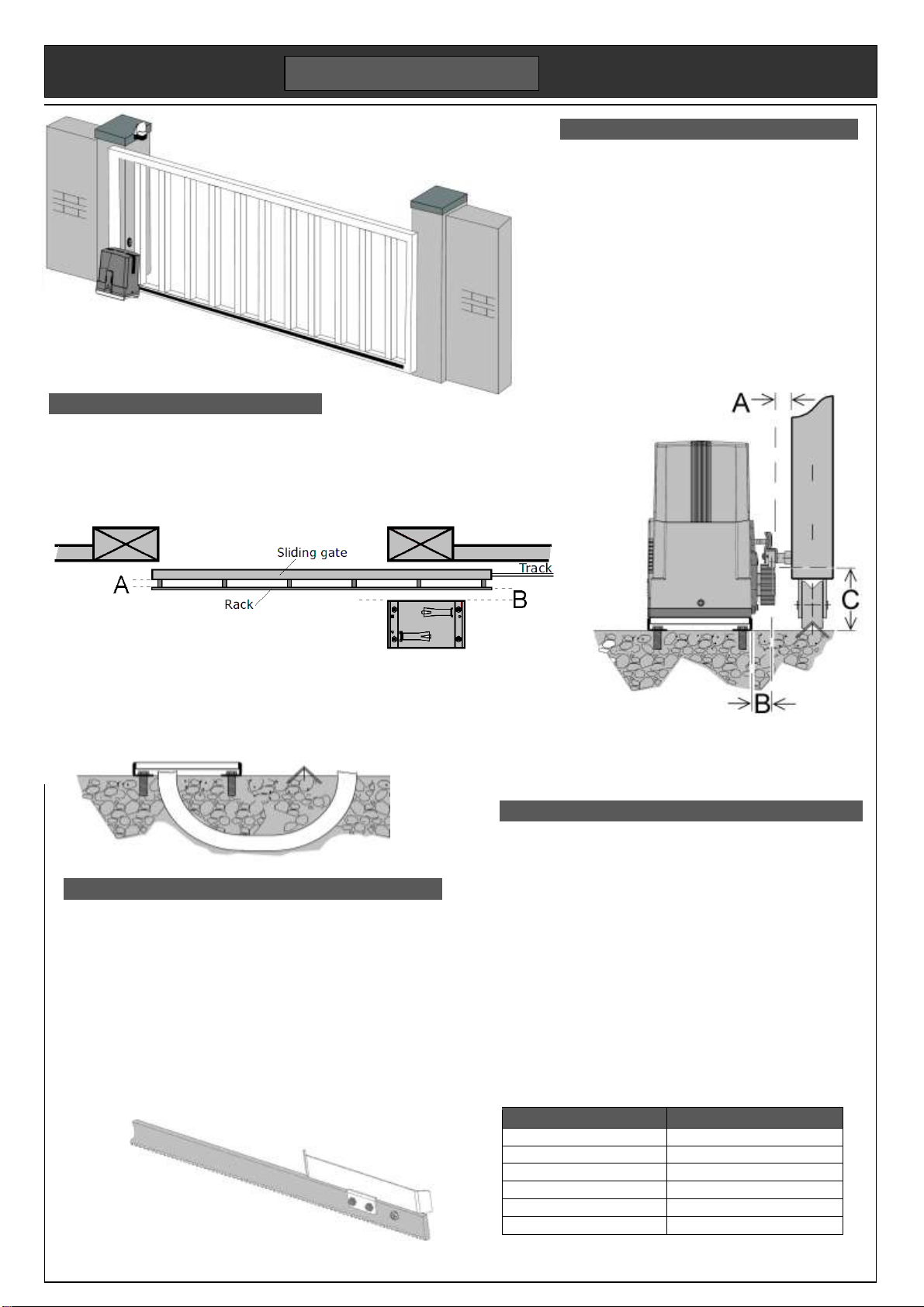

Left opening gate

Near post

Far post

Mechanical

Gates must be level and free running on a ground

track, or on cantilever gate bearings. It is usual to

support the gate at the top with nylon rollers. Two

gates mounted on the same track may slide from

each side of an opening to meet in the centre.

The motor’s steel base plate is set in concrete at

the same time as the gate track. Their relative

height will depend on the size of the gate wheel

used, typically 80 –100mm diameter.

The motor can be packed higher to meet the rack

if required. The toothed rack normally has slotted

mounting holes to allow accurate adjustment.

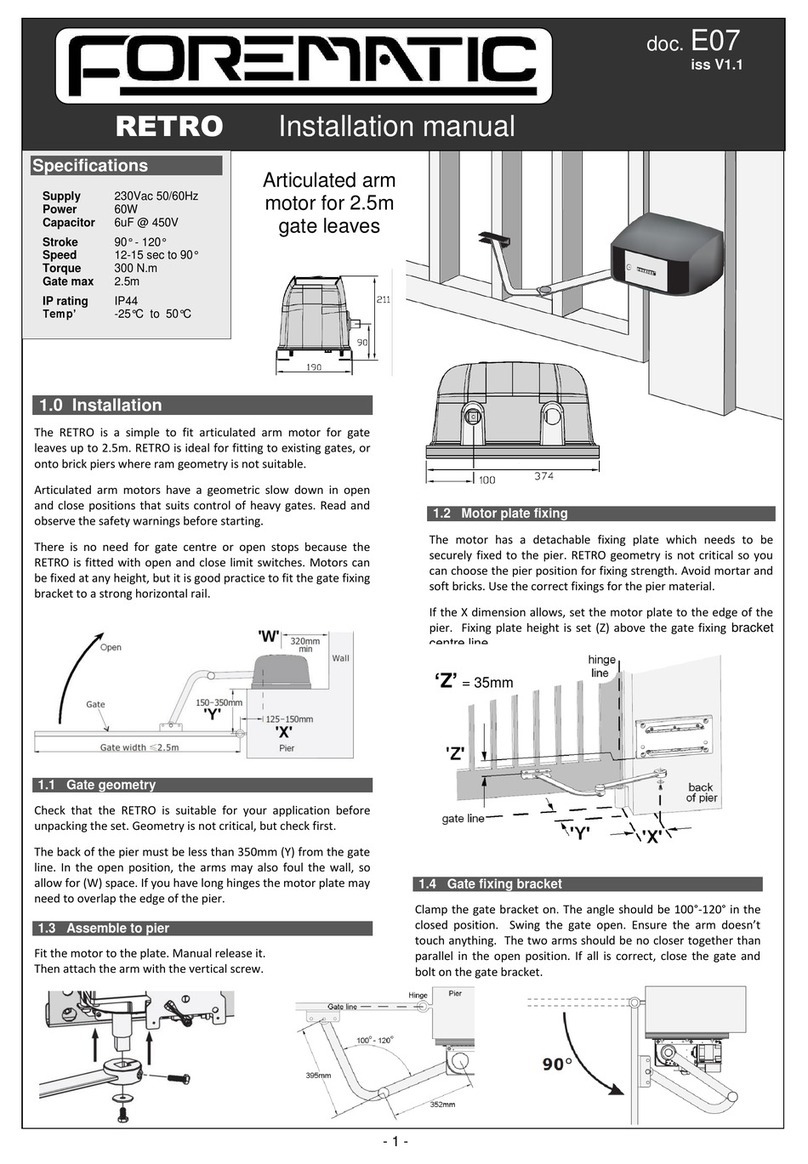

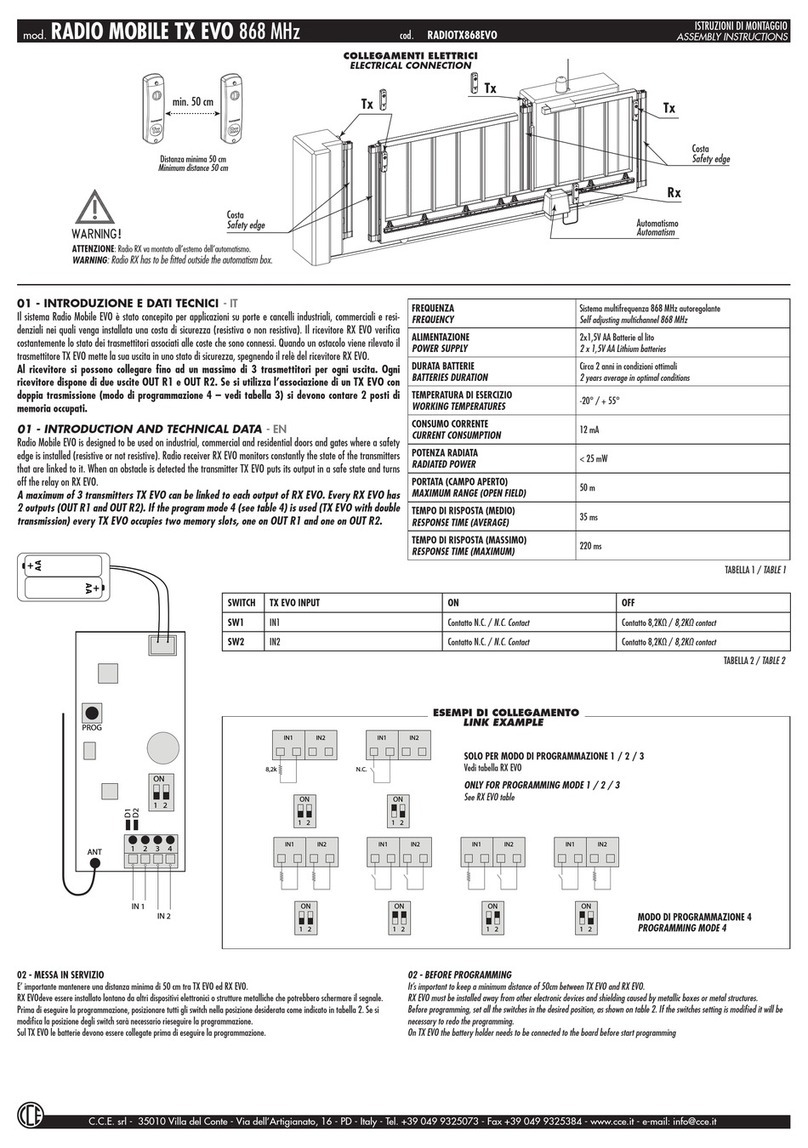

Mounting the motor and rack

Slotted holes in the motor base allow some adjustment. Mount

the motor square to the gate with the rack central to the pinion.

The toothed rack is best fitted using the motor pinion to set the

height. Make the fixing near the motor, then slide the gate along

to set next fixing height. Allow a 2mm gap between rack and

pinion to reduce drag and wear. This can be done by packing

the motor up by 2mm, then remove the packing later.

Skis are brackets bolted to the toothed rack to strike the motor

limit switches. Slide the gate to the open position. Set the ski so

that it bends the spring. Repeat for the closed position. Final

adjustment can be made when motor is running.

Alignment dimensions .

A Allow 25mm from the face of the gate to the back of the toothed rack.

B Allow 30mm from the centre the toothed rack to the edge of the base plate.

C Allow a min 92mm from underside of the base plate to bottom of toothed rack.

For wheels bigger than 100mm diameter, it may be necessary to cast the base plate into

a raised concrete plinth. If not, the base plate can be bolted to a ground level concrete

pad incorporating the ground track. We recommend fixing studding with resin because

the motor’s high shear force and vibration is inclined to loosen expansion bolts. Always

use washers and self locking nuts.

Ducts & Cabling

When casting the foundations, be sure to provide one or more

cable ducts to the underside of the motor base. It will not be

possible to run cables above the gate’s ground track. While

installing the ground track, it is useful to run another duct or

direct burial cable under the track to the opposite gate post.

Align the ducts with the fifth hole in the base plate. Cables

will be required for mains supply, photo beams and any

access control devices, for example an intercom. The motor

has two cable glands in the base for the cables.

At minimum, you will need a low voltage cable to each gate

post, and a mains supply to the motor base. The cable type

will depend on the duct standard. An eight core outdoor

grade alarm cable is adequate. More than one device at the

same location can be run from one cable using the universal

wiring scheme.

Device

Rating

Photo-beam on near post

1 core + Gnd

Photo-beam on far post

3 core + Gnd

Mains supply

2 core + Earth, typ. 1.5mm²

24V lamp output

2 core, typ. 0.5mm²

230Vac lamp

2 core + Earth, typ. 0.75mm²

Intercom

4 core + Gnd

Skis fixing viewed fromthe motor side

SITE PREPARATION

Right opening

F550/F560 doc. B05

P3

FZ500

4. Adjustments

Adjustments set the safe running of the gate. Follow the order

below. On completion additional controls and safety devices can

be wired in without the need to re-adjust.

DIP switches. Typical setting; DIP1,2,3 on, DIP4 off. Refer to

diagrams on previous page for DIP5. Pause times add

together. (eg DIP6&7 ON gives 50secs).

____________________________________

RV. Speed setting. It determines kinetic energy of the gate which

affects mid travel safety. Set heavy gates to run slower.

____________________________________

LV. Sets the speed in slow down zone. Set to close the gate

firmly against the post within force test limits.

____________________________________

Force. Regulates the maximum force applied by the motor before

obstacle detection kicks in. Set it high enough to move the

gate reliably, but not much more. The finer it is set, the more

sensitive to reversal.

____________________________________

Limit learning. Reset the skis after setting speed and force then re-

run the limit learning. Hold down ST button for 5 secs until

DL5 lights then let go. Press ST again. Gate opens and stops

at the limit. Run a cycle.

5. Remotes

Each remote button must be programmed individually. Buttons can

be set for full opening (stops at limit switch), or pedestrian opening

stops after 1.5m. To enable partial opening set DIP1 off, DIP2 on.

Up to 16 remotes can be programmed in. A programmed button

when pressed, will light DL6 brightly. An un-programmed button

flashes DL6 briefly, but shows the remote is functioning.

Full opening. Press CODE button for 2secs until DL6 lights. Press

the new remote button twice. DL6 switches off

Pedestrian opening. Set DIP1 off and DIP2 on. Press CODE for

2secs until DL6 lit. Press CODE again. DL6 flashes. Press

remote’s pedestrian button twice. DL6 switches off.

1. Quick setup

Motor must be engaged with the rack and skis set for short travel.

1. Connect Mains supply to L & N terminals on power board.

2. Connect together terminals IR, Stop & Gnd.

3. Set all DIP switches down. Set LV, RV, Force anti-clockwise

4. Hold down ST button for 5 secs until DL5 lights. Let go.

5. Press ST once. Gate opens and stops at left limit.

The gate will now open and close on the remote control. A test setup can be

done on the bench for familiarity. Limits will need to be reset.

2. Connections

Control connections are made at

the top of the PCB on an 11 way plug-in screw terminal connector.

Terminal

Function

Description

Stop

Stops in either direction. On

reconnection, pauses then

re-closes.

N/C contact, returns to Gnd

terminal.

Door

Control button input

N/O button input, return to

Gnd terminal

Sync

2 motor synchronising

Connect Sync and Gnd

terminals of two motors

Lamp

24V flashing lamp or

sounder output

Switches at 2Hz while the

motor runs. Return to +24V

terminal.

24V

Accessory supply

Constant DC supply. Up to

32Vdc

IR

Safety input re-opens while

closing. Also for hold open

N/C contact, returns to Gnd

terminal.

IR 24V

Photo beam power saving

supply.

24Vdc supply on when the

gate is in moving or open.

Gnd

Ground

Common to all I/O

The power board is on top of the transformer. Connect an RCD

protected mains supply run in external grade cable. Refer to example

wiring page for more information.

Terminal

Description

220V

Mains supply. Fused with T2.5A on the board

AC lamp

(type FA40)

The lampoutput ON while the motor is in

motion. Use a mains rated cable. Optional.

Batt

Backup batteries fitted below the transformer.

Optional. Use 1mm² wire.

Stop Gnd

Gnd

Door

SW2

SW1

Sync

Gnd

IR

IR 24v

Lamp

+24v

o o o o o o o o o o o

SETUP

3. DIP switches

OFF (down)

ON (up)

DIP1

Buttons - one enabled

Both remote buttons

enabled to open

DIP2

Pedestrian - disabled

Pedestrian opening

enabled by remote

DIP3

Soft stop disabled

Enables the end of

travel slow down

DIP4

Limits –(N/O for Pico)

N/C (for other motors)

DIP5

Right to open

Left to open

DIP6

Pause time

(all off disables auto-close)

+ 10secs

DIP7

+ 20secs

DIP8

+ 40secs

ON

Remotes

Pedestrian

Soft stop

Limits

Direction

10 sec

20 sec

40 sec

ANT

LED3

LED4

LED5

LED6

LED7

Motor DC

DL6

DL5

RV

FORCE LV Code ST

ON

1

8

Radio receiver

2

3

4

Stop Gnd

Gnd

Door

SW2

SW1

Sync

Gnd

IR

IR 24

Lamp

24V

o o o o o o o o o o o

F550/F560 doc. B05

P4

Universal wiring scheme

Following a standard wiring scheme simplifies wiring while

allowing additions in the future. For PICO we recommend an

8 core alarm cable with the following allocation.

Core

Function

Terminal

Red

Accessory supply

24V

Black

Supply & input common

Gnd

Yellow

Safety input 1

IR

Orange

Safety input 2

STOP

White

Switched accessory supply

IR24

Green

Open button

DOOR

Blue

Audio2 or pedestrian input or safety link

Brown

Audio1 or lock or DC lamp

Run a cable to each location, or from one device to the next

in a chain. Connect to the device according to the table

below. The PICO also has the benefit of wireless devices.

FA31 Photo-beam (single set)

Make sure the link on the FA31 Rx is set to NC as shown.

PICO set wiring

Minimum wiring requires only

the FA31 photo-beam below.

Run an 8 core cable to each

side. For clarity, only the cores

used have been shown.

To left post To right post

Further devices can be

added to either cable.

E.g. vehicle sensor, exit

button, intercom, keypad.

WIRING

FA31

Tx

Black White

FA31

Rx

Yellow Black White

R200 Intercom

This 2 wire intercom follows the universal wiring scheme.

Wire the power supply to the house phone (P+ & P-).

FA31 Photo-beam (double set)

The wiring is different for two photo-beams. In this scheme

the two blue wires are joined together in the control panel.

Make sure the link on both FA31 Rx is set to NC as shown.

FA31

Tx

Black White

FA31

Rx

Yell Blu Blk White

FA31

Tx

Black White

FA31

Rx

Blue Black White

Forematic

9 Vanalloys Estate

Stoke Row

Henley RG9 5QW www.forematic.com QPB05-F550

WARRANTY

3 year return to base warranty covers defective manufacture and material. The warranty does not

cover accidental damage, misuse, or abnormal wear. Warranty is conditional on good installation,

maintenance and service recommended in this manual. Warranty is void if subject of unauthorised

modification or repair, or abnormal input voltage. This does not affect your statutory rights

C-202 panel

L+ L- Go Go D/O D/O

Brown Black Green

S-22 phone

L+ L- P+ P-

Brown Blk

N-P18 PSU

P- P+ 230Vac

Stop Gnd

Gnd

Door

SW2

SW1

Sync

Gnd

IR

IR 24

Lamp

24V

o o o o o o o o o o o

-Orange

-Black

-Green

-Black

-Yellow

-White

-Red

FA31

Tx

Gnd IR24

FA31

Rx

IR Gnd Gnd IR24

Declaration of Conformity

We hereby declare, that gate openers F-550 has been manufactured

in accordance with the following standards or normative documents

EN 60335-2-95: 2004

EN 60335-1/A13: 2008/A2: 2006

EN 62233: 2008

EN 61000-3-2: 2006, + A1: 2009 +A2: 2009

EN 61000-3-3: 2008

EN 55014-1: 2006 +A1: 2009 EN 55014-2: 1997 +A2: 2008

EN 50371: 2002

In accordance with the provisions of the following directives

98/37/EC Machinery Directive with amending directives

2006/95/EC LV Directive

2004/108/EEC EMC Directive

1999/5/EC R&TTE Directive

23.03.2011 –FOREMATIC

9 Vanalloys Estate, Stoke Row, Mr H WYNN JONES

Henley RG9 5QW, United Kingdom Director

Table of contents

Other Forematic Gate Opener manuals