Press and hold the Power button for more than 2s, the battery light

will flash once, then the LED will light up in turn, and when the top most

running light flashes fast for about 10 times, it means that the system

parallel programming is successful and the battery is running normally.

6. System Start Up

STEP-1:

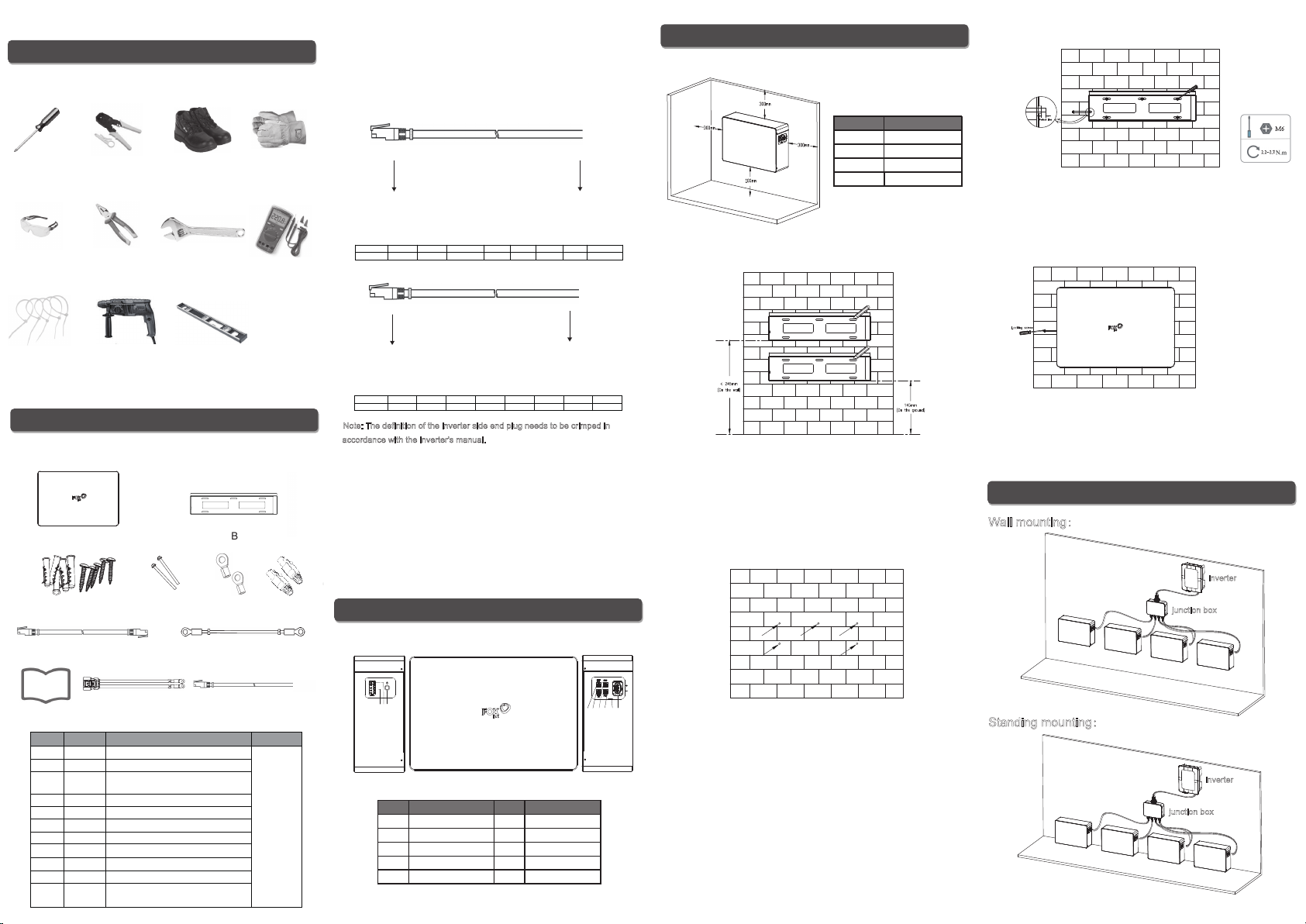

After installing the fixed battery, measure the voltage of the

STEP-2:

To connect the parallel communication cable between the

batteries, the link-in of the Master battery, i.e. the first machine,

needs to be plugged in with a plug (to short pin1 and pin6),

the link-out interface uses a parallel communication cable

V1.0.2

10-203-00311-01

replace the battery.

to determine whether there is a voltage output, and if so,

positive and negative terminals of the battery with a multimeter

STEP-3:

Connect the BAT+ and BAT- of the battery to the input of the

junction box (not included in the package), and then connect the

output of the junction box to the inverter; connect one of the

Note: the length of the power line needs to be the same when

(pin to pin network cable) to the link-in interface of the next battery,

and so on, and the last link-out interface is plugged in with a plug

(to short pin1 and pin6).

in parallel mode.

Stand-alone mode:

STEP-1:

After installing the fixed battery,

measure the voltage of the positive and negative terminals of

the battery with a multimeter to

determine whether there is a

voltage output, and if so,

STEP-2:

Plug the 2 plugs (to short pin1

and pin6) into the parallel

communication interface LINK-IN and LINK-OUT of the battery

respectively.

STEP-3:

Connect the BAT+ and BAT- of the battery to the corresponding

positive and negative terminals of the inverter; connect one of the

communication interface PCS of the battery to the interface of the

communication between the inverter and the battery; connect the

ground wire.

replace the battery.

Parallel mode:

Note: Different model of batteries cannot be mixed in one system,

any further questions related to the battery versions please

Connect the ground wire of each battery.

Lead-acid function:

Battery capacity: 104Ah

In the above two modes, when operating according to the

corresponding steps, the communication harness between the

battery and the inverter is not connected, and the battery enters

the lead-acid function by default; Both stand-alone mode and

parallel mode have lead-acid function.

When the battery uses the lead-acid function, the matching

inverter needs to be set to lead-acid mode as well, and the

following parameters need to be set on the inverter:

Charging voltage: 57.0V

Charging protection voltage: 57.6V

Float voltage: 53.0V

Maximum charging current: 50A

Discharge cut-off voltage: 48.0V

Maximum discharge current: 100A

Forced charging voltage: 48.0V

Battery internal resistance: 15mΩ

Note: Under the lead-acid function, the battery does not

communicate with the inverter, and the inverter will not display the

SOC information of the battery.

Note: Parallel mode supports up to 4 batteries in parallel.

Master battery Last battery

communication interface PCS of the Master battery to the interface

of the communication between the inverter and the battery;