2.2 Permitted Uses

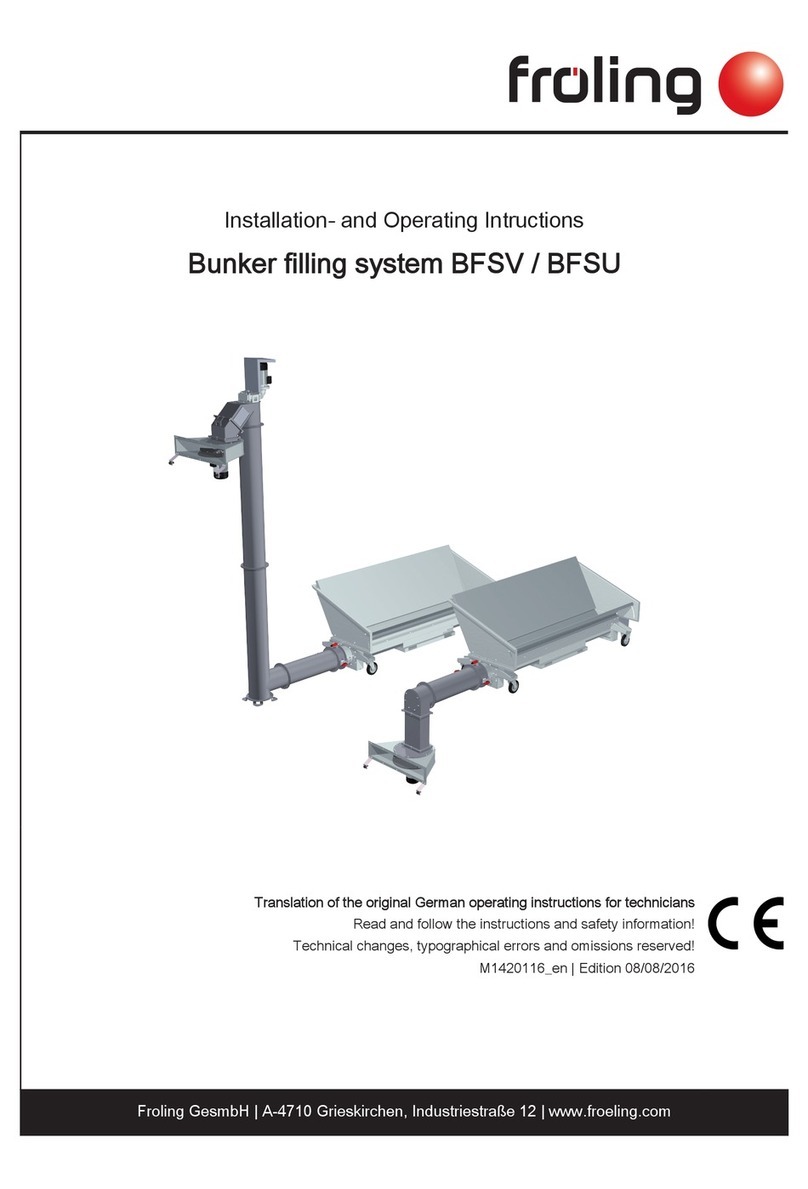

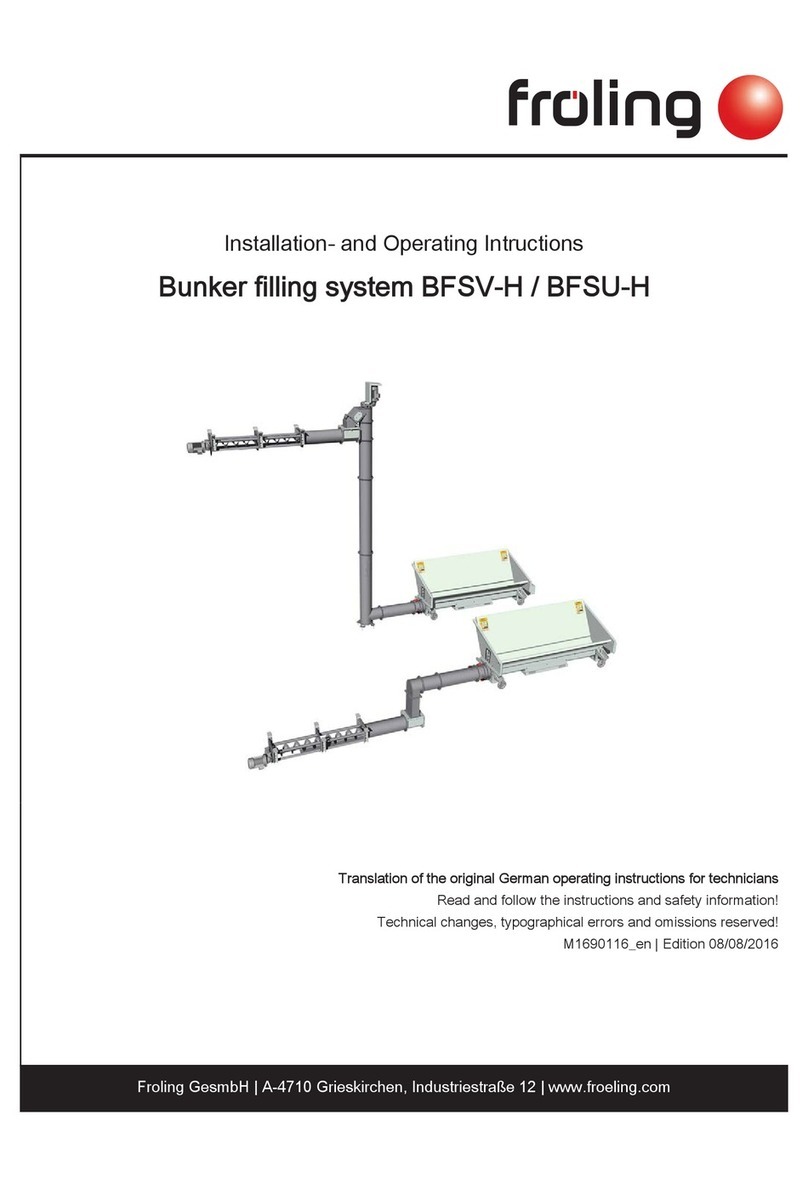

The Froling bunker filling system is solely designed for transporting fuels into suitable

store spaces. Only use fuels specified in the "Permitted fuels" section.

The unit should only be operated when it is in full working order. It must be operated in

accordance with the instructions, observing safety precautions, and you should ensure

you are aware of the potential hazards. The inspection and cleaning intervals in the

operating instructions must be observed. Ensure that any faults which might impair

safety are rectified immediately.

The manufacturer or supplier is not liable for any damage resulting from non-permitted

uses.

Only original spare parts or specific alternative spare parts authorised by the

manufacturer may be used. Any kind of change or modification made to the product

will invalidate the manufacturer’s conformity with the applicable guideline(s). In such

cases, the product will need to undergo new hazard evaluation procedures by the

operator. The operator will then be fully responsible for the declaration of conformity

according to the valid guideline(s) for the product and will need to issue a

corresponding declaration for the device. This person will then assume all of the rights

and responsibilities of a manufacturer.

2.2.1 Permitted fuels

Wood chips

Criterion Designation as per Description acc. to

ÖNORM M 7133

ÖNORM M 7133 EN ISO 17225

Water content W20 M20 air-dried

W30 M30 suitable for storage

W35 M35 limited suitability for

storage

Size G30 P16S Fine wood chip

G50 P31S Medium-sized wood

chip

EU: Fuel acc. to EN ISO 17225 - Part 4: Wood chips class A1 / P16S-P31S

Additional for

Germany:

Fuel class 4 (§3 of the First Federal Emissions Protection Ordinance

(BimSchV) - applicable version)

Note on standards

2Safety

Permitted Uses

8 Fröling Ges.m.b.H. | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com