Table of Contents

1 General 4

1.1 Functional description 5

2 Safety 6

2.1 Hazard levels of warnings 6

2.2 Permitted uses 7

2.2.1 Permitted fuels 8

Wood chips

8

Wood pellets

8

2.3 Qualification of staff 8

2.3.1 Qualification of assembly staff 8

2.3.2 Personal protective equipment for assembly staff 9

2.3.3 Qualification of operating staff 9

2.3.4 Protective equipment for operating staff 9

2.4 Design information 10

2.4.1 Standards 10

2.4.2 Requirements at the installation site 11

Information about the fuel store

11

2.5 Safety devices 12

2.6 Residual risks 13

3 Technology 15

3.1 Dimensions 15

3.2 Store sizes 16

3.3 Technical specifications 16

4 Assembly 17

4.1 Transport and handling 17

4.1.1 Temporary storage 17

4.2 Installation site 17

4.2.1 Wall penetration 18

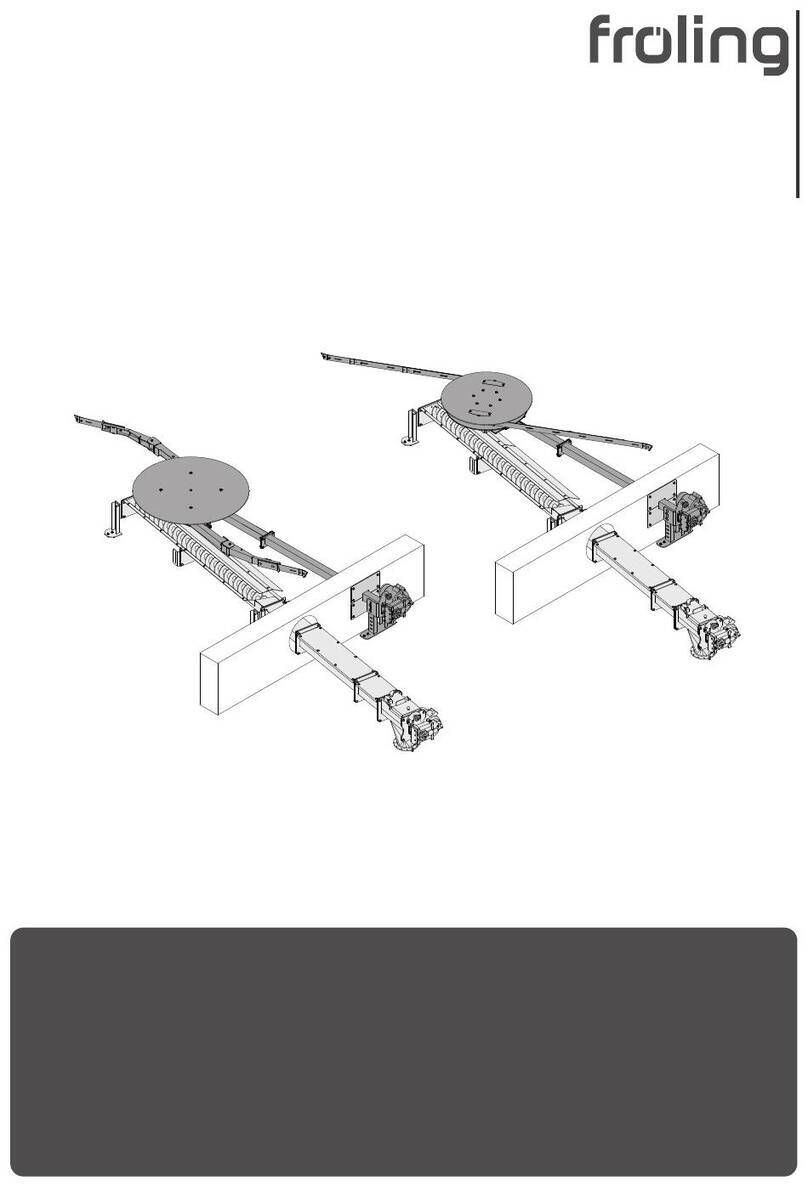

4.3 Assembling the torsion arm agitator 19

4.3.1 Materials supplied 19

4.3.2 Assembling the gears and feeder trough 20

4.3.3 Fitting the upper part of gravity shaft and drive unit 25

Assembly with screw Ø110

25

Assembly with screw Ø150 / Ø200

26

4.3.4 Fitting attachments 28

4.3.5 Setting the tension of the torsion springs 29

4.3.6 Fitting adjustable feet in boiler room (optional) 30

4.3.7 Closing the wall penetration 31

4.4 Connecting the system 31

4.4.1 Electrical connection 31

4.4.2 Connecting the sprinkler system 31

5 Operating the system 32

5.1 General information 32

Table of Contents

2 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com