2.2 Permitted uses

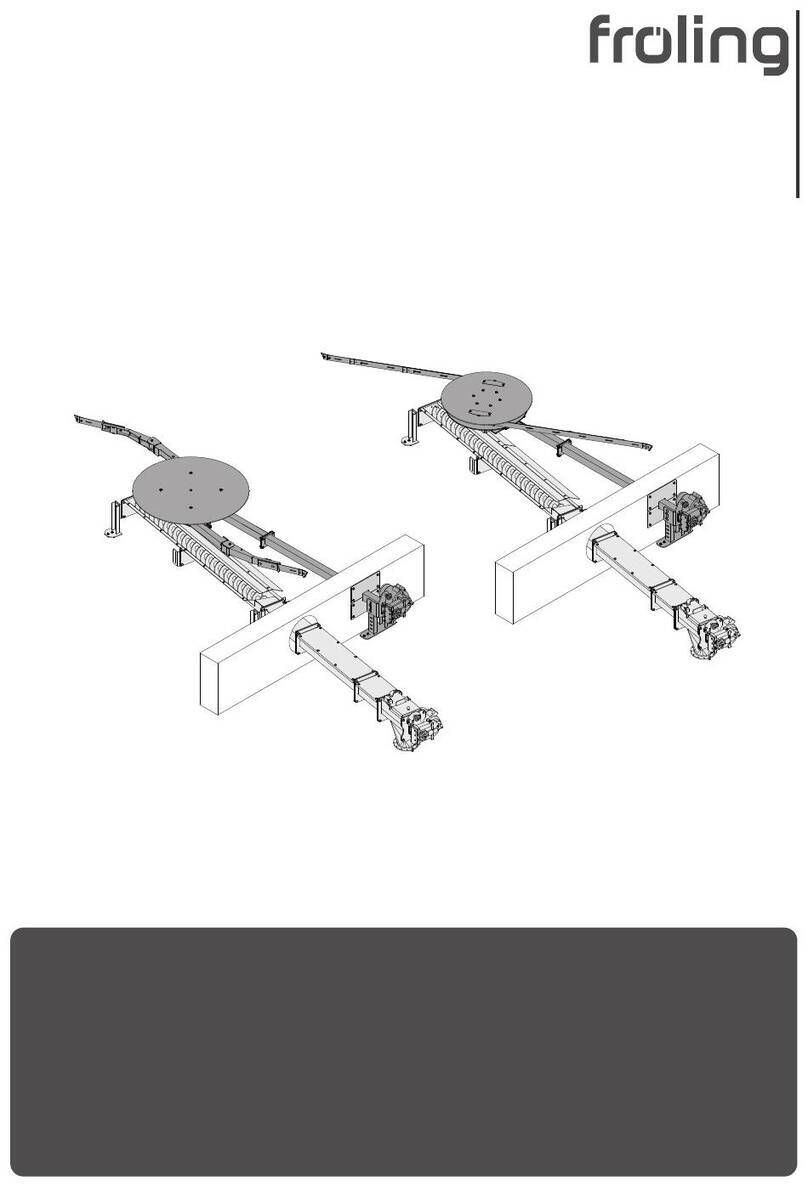

Froling’s “GAR articulated arm rotary agitator” discharge system is only designed to

discharge fuels from suitable stores. Only use fuels specified in the “Permitted fuels”

section.

The unit should only be operated when it is in full working order. It must be operated in

accordance with the instructions, observing safety precautions, and you should ensure

you are aware of the potential hazards. The inspection and cleaning intervals in the

operating instructions must be observed. Ensure that any faults which might impair

safety are rectified immediately.

The manufacturer or supplier is not liable for any damage resulting from non-permitted

uses.

Only original spare parts or specific alternative spare parts authorised by the

manufacturer may be used. Any kind of change or modification made to the product

will invalidate the manufacturer’s conformity with the applicable guideline(s). In such

cases, the product will need to undergo new hazard evaluation procedures by the

operator. The operator will then be fully responsible for the declaration of conformity

according to the valid guideline(s) for the product and will need to issue a

corresponding declaration for the device. This person will then assume all of the rights

and responsibilities of a manufacturer.

DANGER

If the device is used incorrectly:

Incorrect use of the system can cause severe injury and damage.

When operating the system:

❒Observe the instructions and information in the manuals

❒Observe the details on procedures for operation, maintenance and cleaning,

as well as troubleshooting in the respective manuals.

❒Any work above and beyond this (e.g. servicing) must be carried out by a

heating engineer approved by Fröling Heizkessel- und Behälterbau GesmbH

or by Froling customer services

Safety 2

Permitted uses

Installation and Operating Instructions GAR 110 / 150 | M2060120_en 7