Table of contents

ii M1510021_en | Installation and operating instructions Sliding floor discharge unit

1 General information .................................................................................................................................... 4

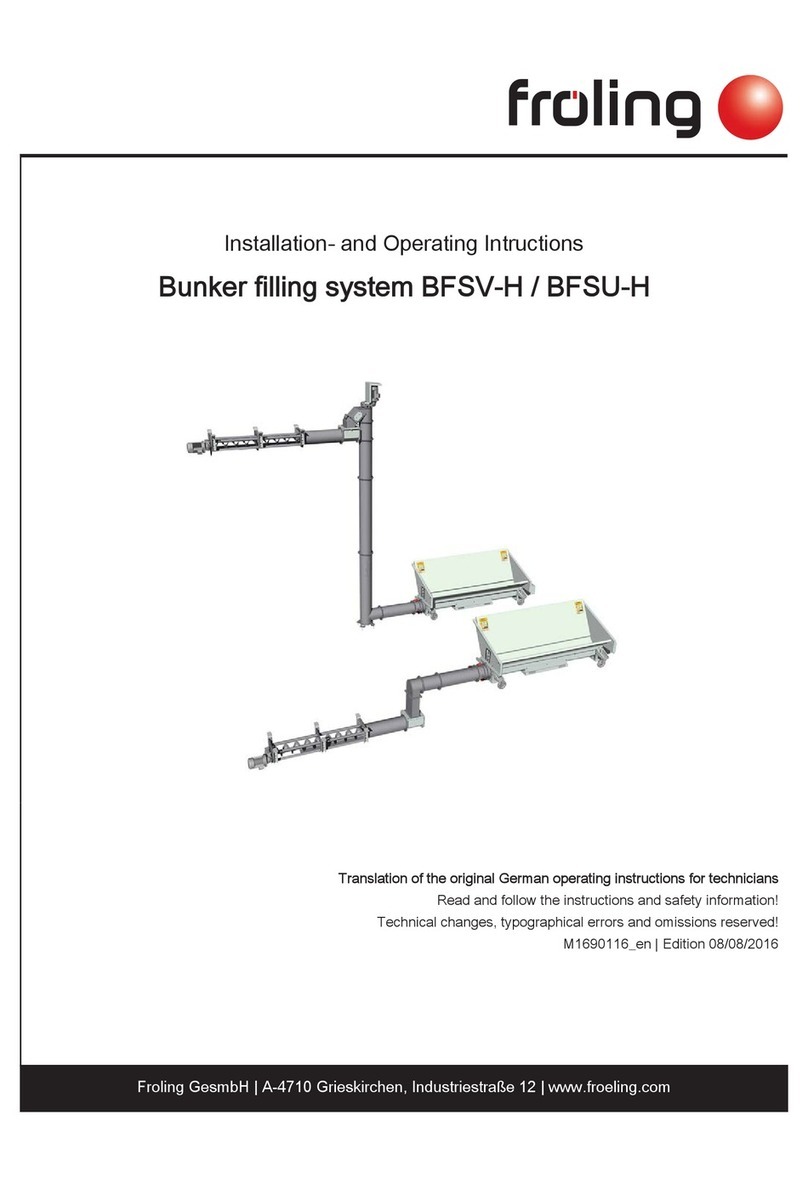

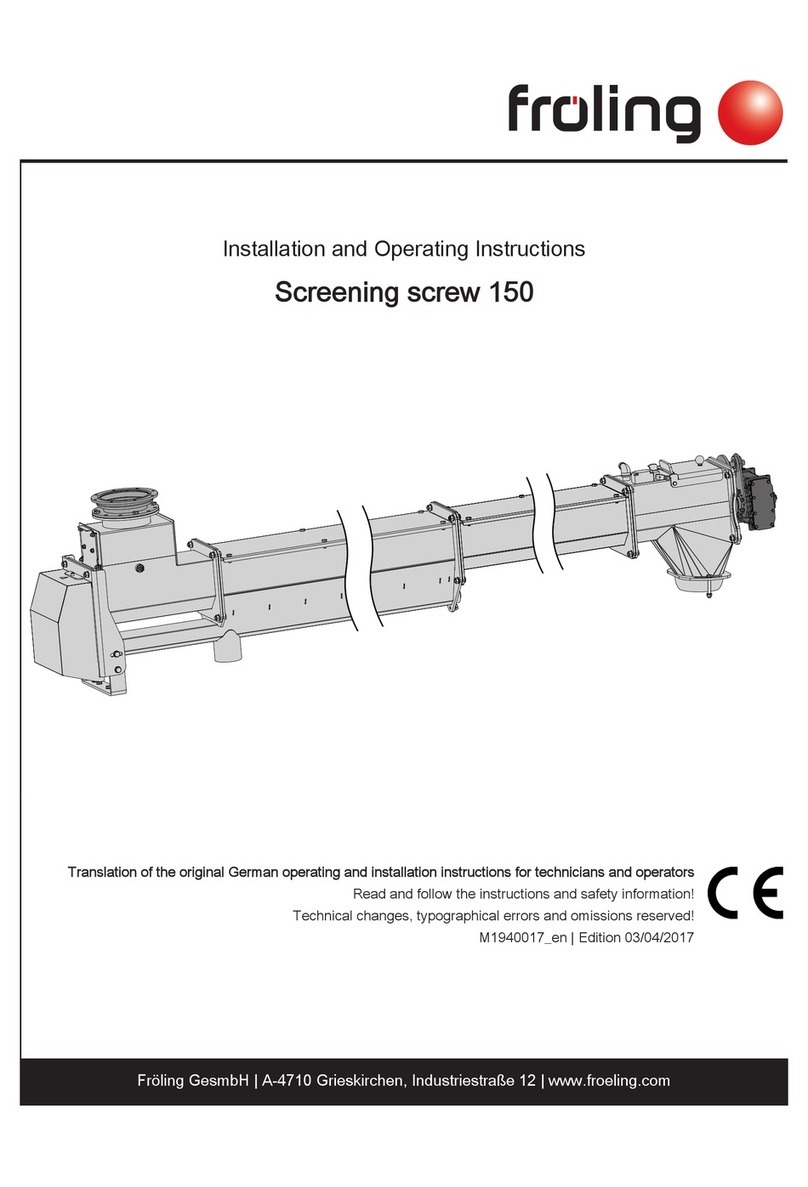

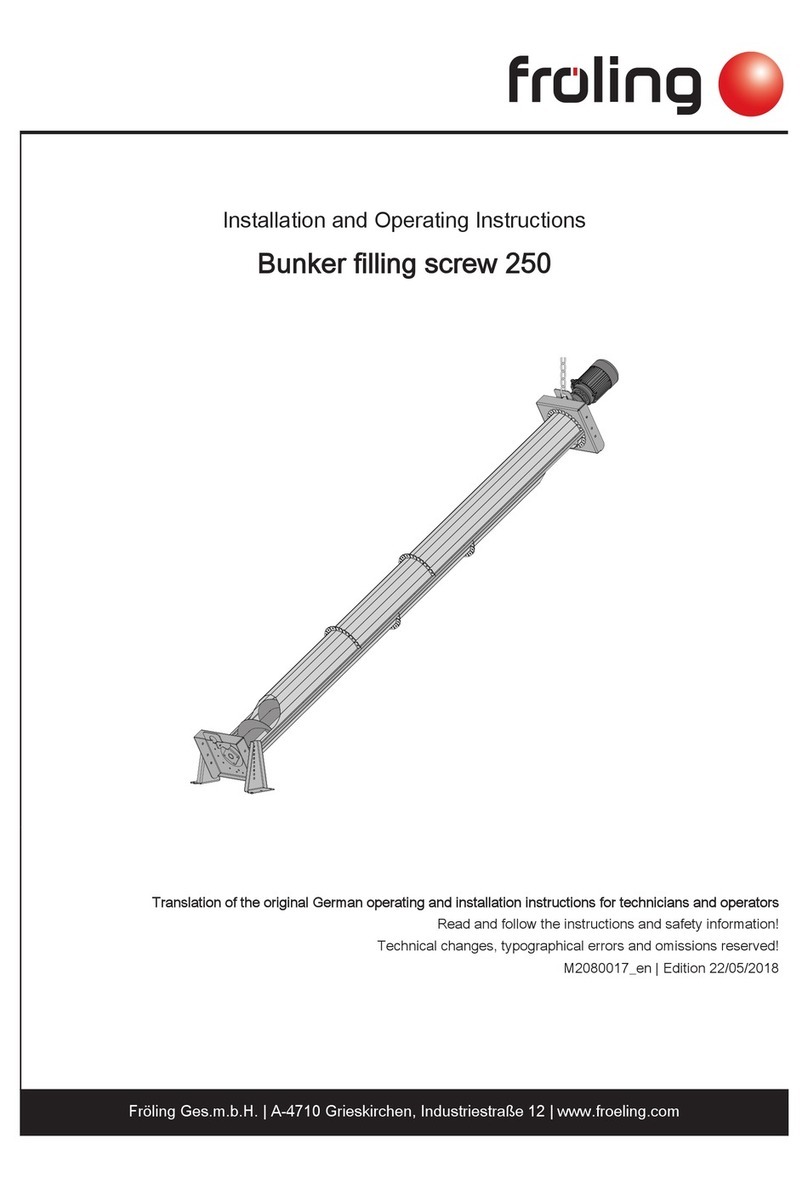

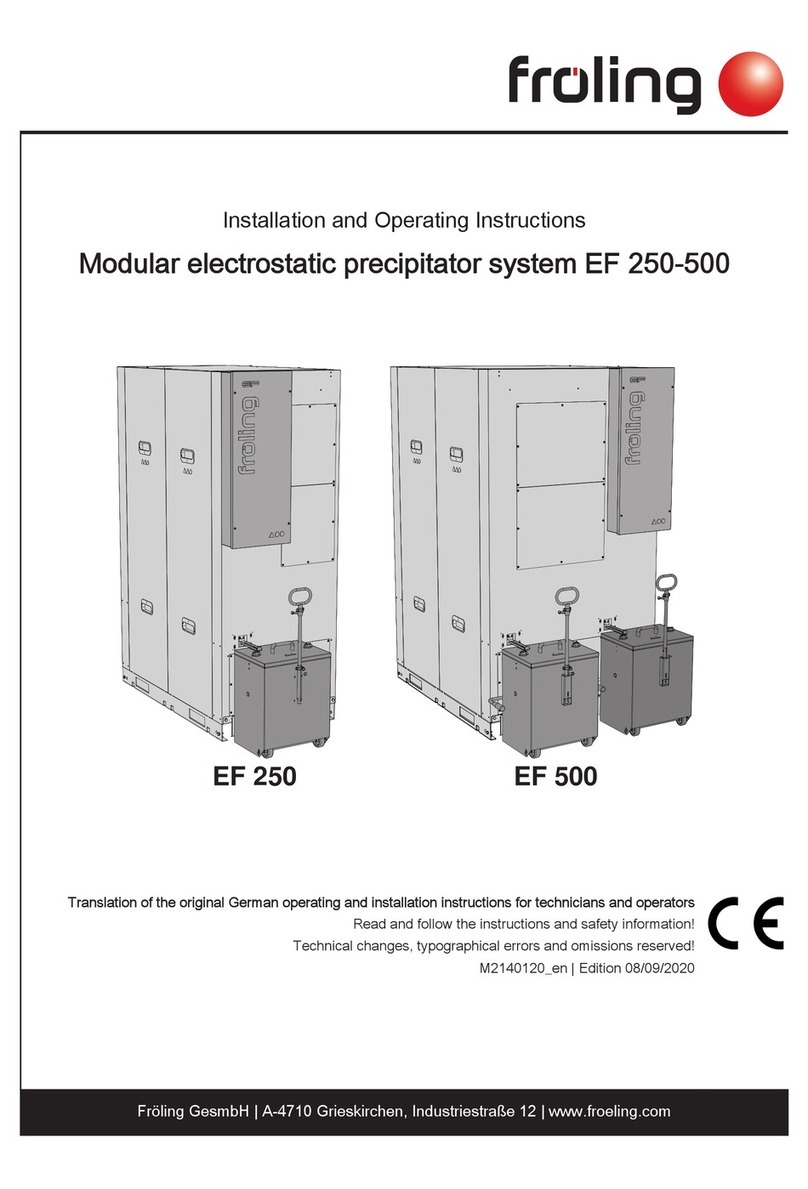

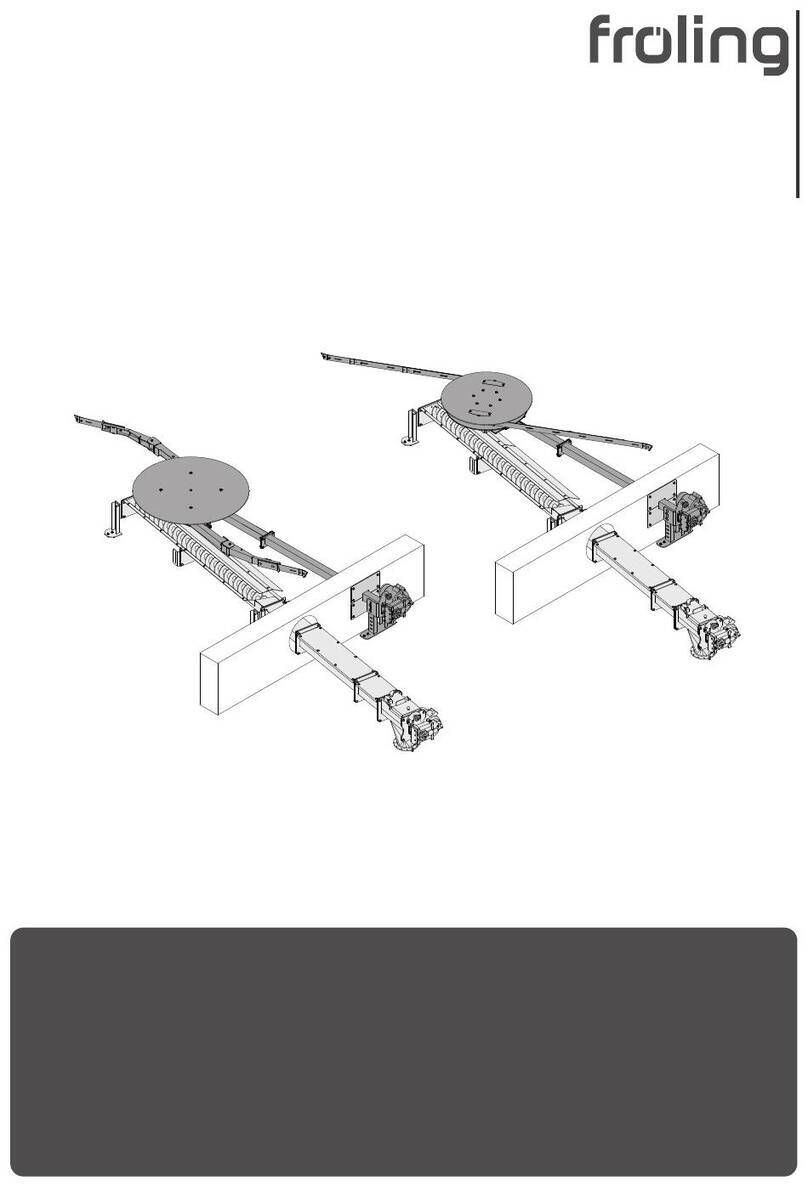

1.1 Functional description ........................................................................................................................... 5

2 Safety............................................................................................................................................................ 6

2.1 Hazard levels of warnings ..................................................................................................................... 6

2.2 Permitted uses ...................................................................................................................................... 7

2.2.1 Permitted fuels ........................................................................................................................... 8

2.3 Qualification of staff............................................................................................................................... 8

2.3.1 Qualification of assembly staff ................................................................................................... 8

2.3.2 Personal protective equipment for assembly staff ..................................................................... 9

2.3.3 Qualification of operating staff ................................................................................................... 9

2.3.4 Protective equipment for operating staff .................................................................................... 9

2.4 Design information ................................................................................................................................ 10

2.4.1 Standards................................................................................................................................... 10

2.4.2 Requirements at the installation site .......................................................................................... 11

2.5 Safety devices....................................................................................................................................... 12

2.5.1 External safety devices .............................................................................................................. 12

2.6 Residual risks........................................................................................................................................ 13

3 Technology .................................................................................................................................................. 14

3.1 Technical data....................................................................................................................................... 14

3.2 Store layout and construction................................................................................................................ 15

3.2.1 Design data for the sliding floor discharge unit .......................................................................... 16

4 Installation ................................................................................................................................................... 17

4.1 Transport and positioning...................................................................................................................... 17

4.1.1 Temporary storage..................................................................................................................... 17

4.1.2 Positioning ................................................................................................................................. 18

4.2 Installation site ...................................................................................................................................... 19

4.2.1 Wall penetration ......................................................................................................................... 20

4.3 Installation of the sliding floor discharge unit ........................................................................................ 21

4.3.1 Masonry and concreting work .................................................................................................... 21

4.3.2 Installing the substructure .......................................................................................................... 23

4.3.3 Installing the transverse conveyor unit....................................................................................... 25

4.3.4 Finishing work on the substructure ............................................................................................ 27

4.3.5 Installing the upper structure...................................................................................................... 28

4.3.6 Installing the hydraulic unit and cylinder .................................................................................... 30

4.3.7 Fitting the upper part of the gravity shaft and drive unit............................................................. 32

4.3.8 Installing the sensors ................................................................................................................. 34

4.3.9 Closing the wall penetration....................................................................................................... 34

4.3.10 Temperature monitoring device in the fuel store (TMD): ........................................................... 35

4.3.11 Installing the bulkhead ............................................................................................................... 36

4.4 Connecting the system.......................................................................................................................... 38

4.4.1 Electrical connection .................................................................................................................. 38

4.4.2 Connecting the sprinkler system................................................................................................ 38

5 Operating the System ................................................................................................................................. 39

5.1 General information............................................................................................................................... 39

5.2 Initial start-up......................................................................................................................................... 39

5.3 Filling the store with fuel........................................................................................................................ 40

5.4 During operation.................................................................................................................................... 41

5.5 Decommissioning.................................................................................................................................. 43

5.5.1 Disassembly............................................................................................................................... 43

5.5.2 Disposal ..................................................................................................................................... 43

6 Servicing the system .................................................................................................................................. 44