FP4000 Rev0204

4

INTRODUCTION

Overview

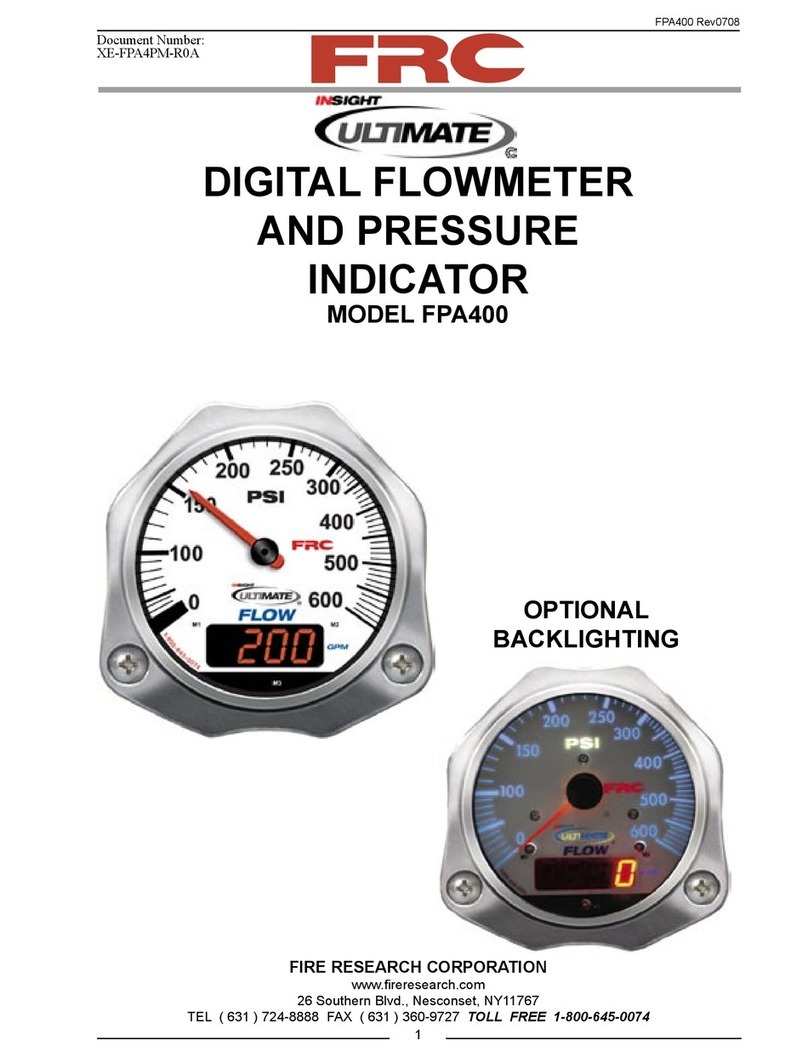

The INSIGHT ULTIMATE pressure gauge and digital flowmeter combines a

traditional style electronic pressure gauge and a digital LED flow display into one

practical display module. The pressure gauge/flowmeter is able to communicate with

other display modules over the FRC datalink. This technology allows for remote

displays, the display of flow for multiple discharges (summing), and the totalization of

flow for multiple discharges (accumulation).

The pressure gauge is an electronically controlled analog display. During normal

operation pressure information is provided from a solid state pressure transducer or the

datalink interface. The pressure transducer provides an electrical signal to the input of

the display module. A microprocessor controls the needle movement to provide an

accurate and steady pressure display. Leakage and freeze-up problems common in

mechanical pressure gauges are eliminated.

The digital flowmeter is a 4-digit LED display. During normal operation flow rate

information is provided from a paddlewheel flow sensor or the datalink interface. This

information is processed and and shown on the digital display as flow rate.

There are two operator selectable modes; display module identification and program

access. The digital display is used to show stored data or operator inputs when a

selectable mode is accessed. In the display module identification mode the digital display

will show the module serial number, manufactured date, software revision, module

function, and ID number. In the program access mode the digital display will show

operator inputs, program options, and error codes. The operator selected modes are

accessed and inputs are made by using the three magnet sensors on the front of the

display module.

All controls and indicators are located on the front of the display module.

Features

Display Module Identification and Program Access Modes

Datalink Interface

Multiple Flow Rate Calibration Points

Pressure Scale Expands Between 100 and 250 PSI

High and Low Flow Warnings

NFPA Color Coded Bezel (Optional)

External Totalizing Button (Optional)

Flow Conditioner (Optional)