AMA200 Rev150720

2

CONTENTS

Table of Contents

CONTENTS................................................................................................................ 2

INTRODUCTION ...................................................................................................... 3

Overview................................................................................................................ 3

Features.................................................................................................................. 3

Specications......................................................................................................... 3

GENERAL DESCRIPTION ....................................................................................... 4

Components ........................................................................................................... 4

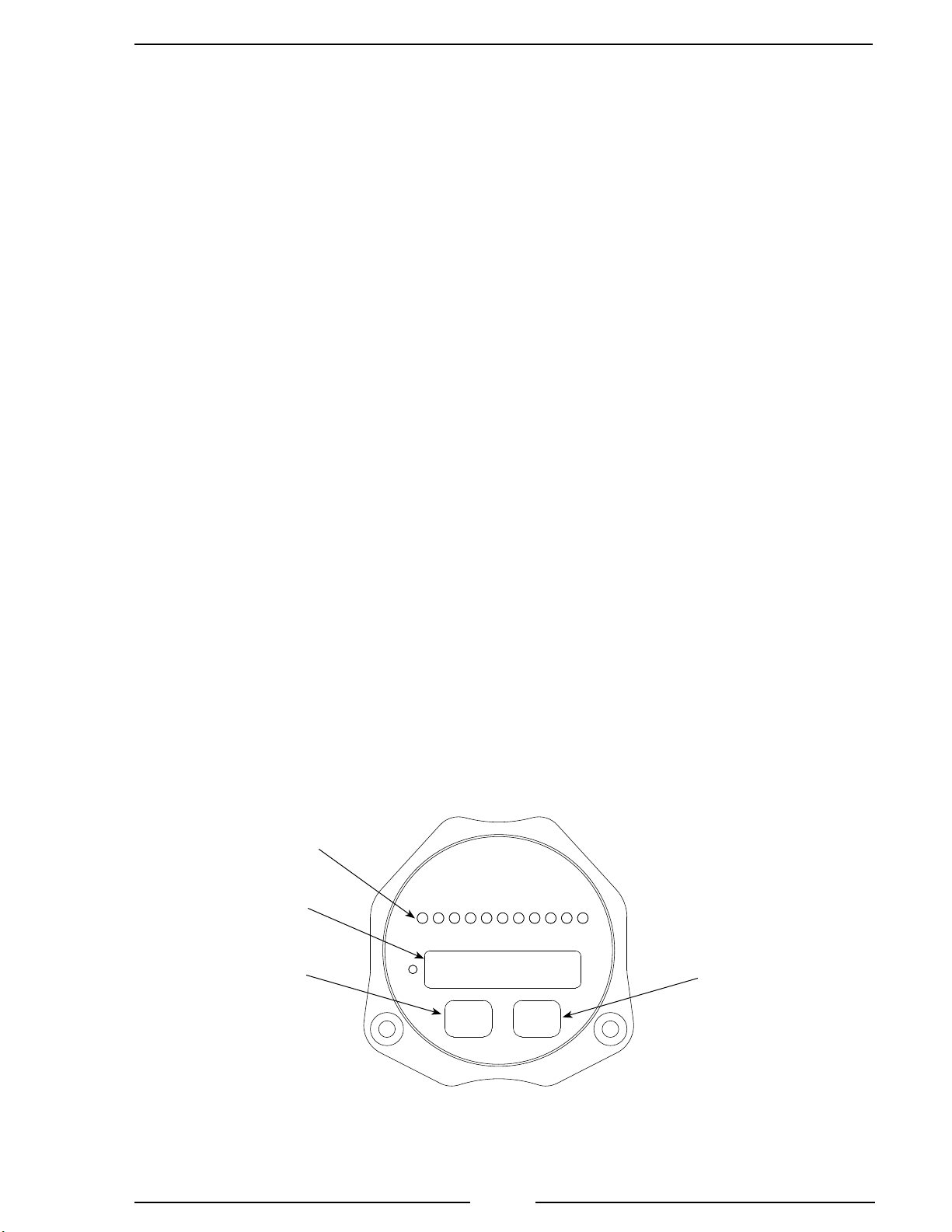

Controls and Indicators.......................................................................................... 5

INSTALLATION ........................................................................................................ 6

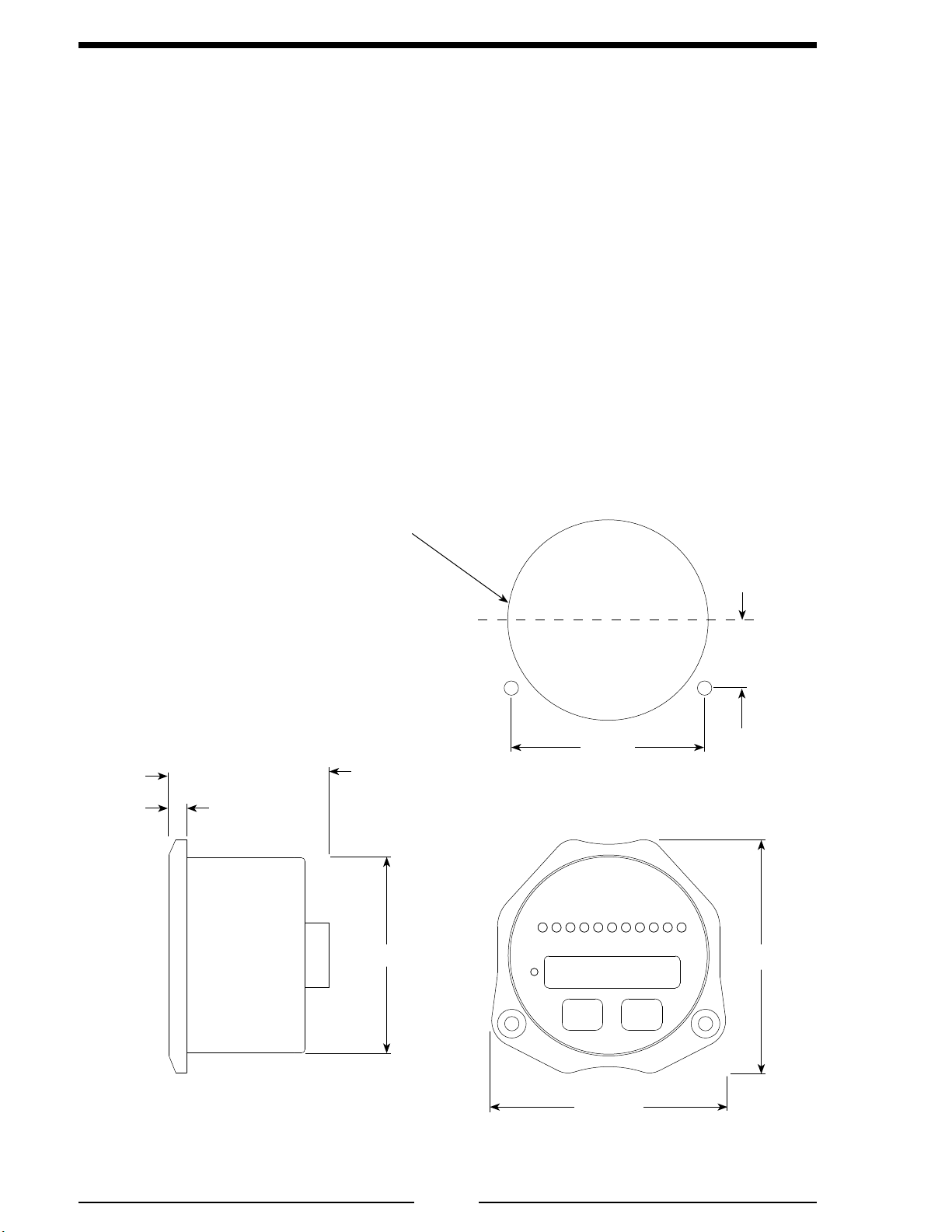

Install Display Module........................................................................................... 6

Install Pressure Sensor........................................................................................... 7

Install Buzzer ......................................................................................................... 8

OPERATION .............................................................................................................. 9

Datalink Interface .................................................................................................. 9

Test Mode ............................................................................................................ 10

PROGRAMMING .................................................................................................... 11

Inputs ................................................................................................................... 11

Program Access Mode ......................................................................................... 12

Table 1. Program Code Quick Reference ................................................................ 13

Program Code Descriptions................................................................................. 14

WIRING.................................................................................................................... 16

Display Module ................................................................................................... 16

Pressure Sensor.................................................................................................... 17

AMA210 .............................................................................................................. 18

List of Figures

Figure 1. Controls and Indicators............................................................................... 5

Figure 2. Display Module Mounting Dimensions ..................................................... 6

Figure 3. Pressure Sensor Dimensions....................................................................... 7

Figure 4. Display Module Wiring ............................................................................ 16

Figure 5. Pressure Sensor Wiring............................................................................. 17

Figure 6. AMA210 Wiring....................................................................................... 18