SBA1HM Rev120113

2

CONTENTS

Table of Contents

CONTENTS ................................................................................................................ 2

INTRODUCTION ...................................................................................................... 4

Overview ................................................................................................................ 4

Features .................................................................................................................. 5

Specications ......................................................................................................... 6

SYSTEM DESCRIPTION .......................................................................................... 8

Components ........................................................................................................... 8

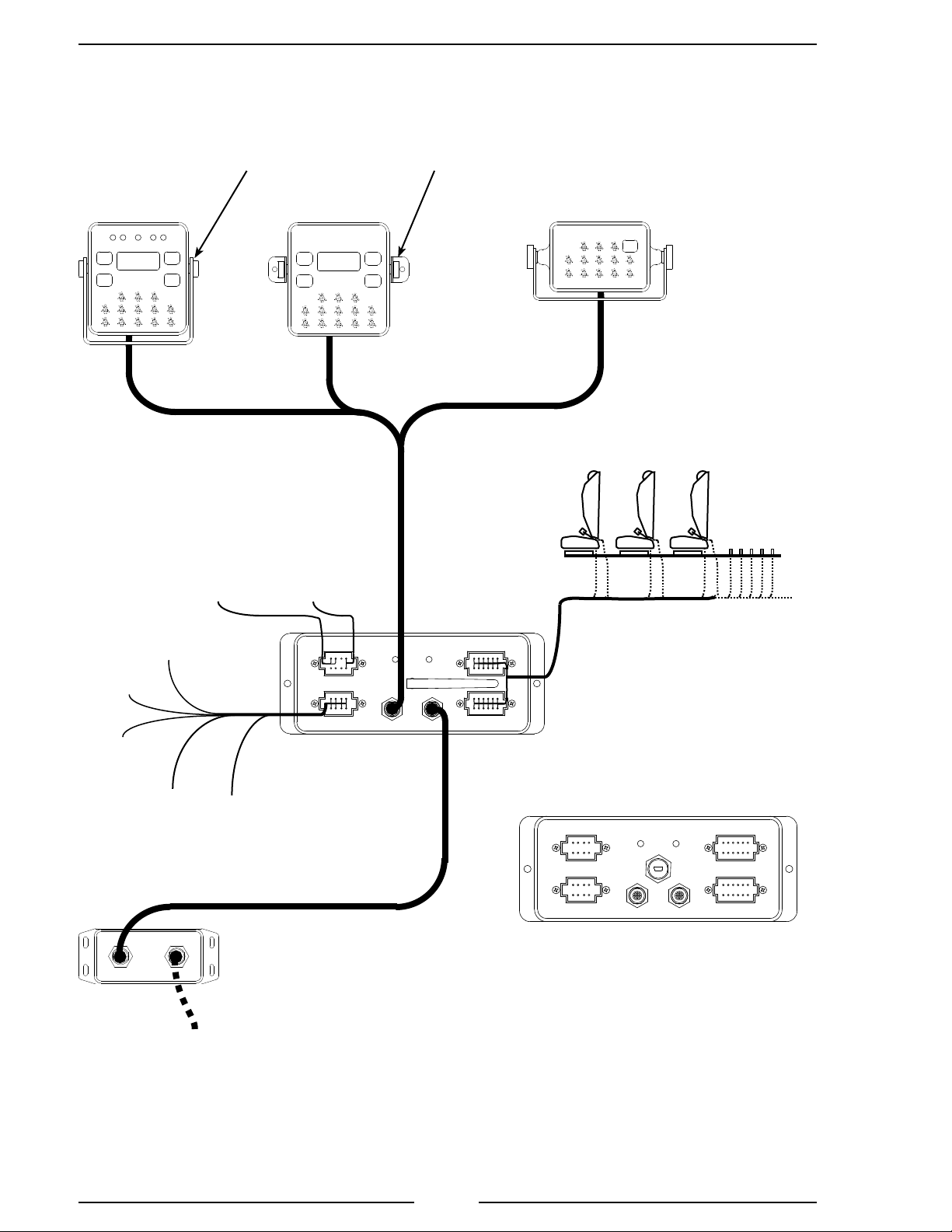

System Layout ..................................................................................................... 10

Display Module Controls and Indicators ............................................................. 12

Vehicle Data Recorder ......................................................................................... 14

Wireless Communications ................................................................................... 16

Data Collector ...................................................................................................... 16

Wireless Interface Module ................................................................................... 16

WatchDog PRO Module ...................................................................................... 17

INSTALLATION ...................................................................................................... 18

Install Seat Monitor Display Module................................................................... 18

Install 12-Seat Vehicle Data Recorder ................................................................. 20

Install 6-Seat Vehicle Data Recorder ................................................................... 22

Install Lateral G Sensor Module .......................................................................... 23

Data Collector ...................................................................................................... 24

Wireless Interface ................................................................................................ 25

SYSTEM POWER .................................................................................................... 26

SEAT MONITOR DISPLAY OPERATION ............................................................. 28

Message Display (SBA100, SBA200) ................................................................. 28

Set the Time (SBA100, SBA200) ........................................................................ 29

Set the Lateral G Indicator (SBA100) ................................................................. 29

Self-Test Mode ..................................................................................................... 30

Operational Check ............................................................................................... 31

WIRING .................................................................................................................... 32

Cables .................................................................................................................. 32

12-Seat Vehicle Data Recorder Connectors ......................................................... 34

6-Seat Vehicle Data Recorder Connectors ........................................................... 36

Vehicle Data Recorder Harness Connections ...................................................... 37

Seat Monitor Display Harness Connections ........................................................ 38

Ford Vehicle Data Recorder and Harness Connections ....................................... 39

Lateral G Sensor Module Harness Connections .................................................. 40

WatchDog PRO Modules ..................................................................................... 41