FPA400 Rev0708

2

CONTENTS

Table of Contents

CONTENTS ................................................................................................................ 2

INTRODUCTION ...................................................................................................... 4

Overview ................................................................................................................ 4

Features .................................................................................................................. 4

Specifications ......................................................................................................... 5

GENERAL DESCRIPTION ....................................................................................... 6

Components ........................................................................................................... 6

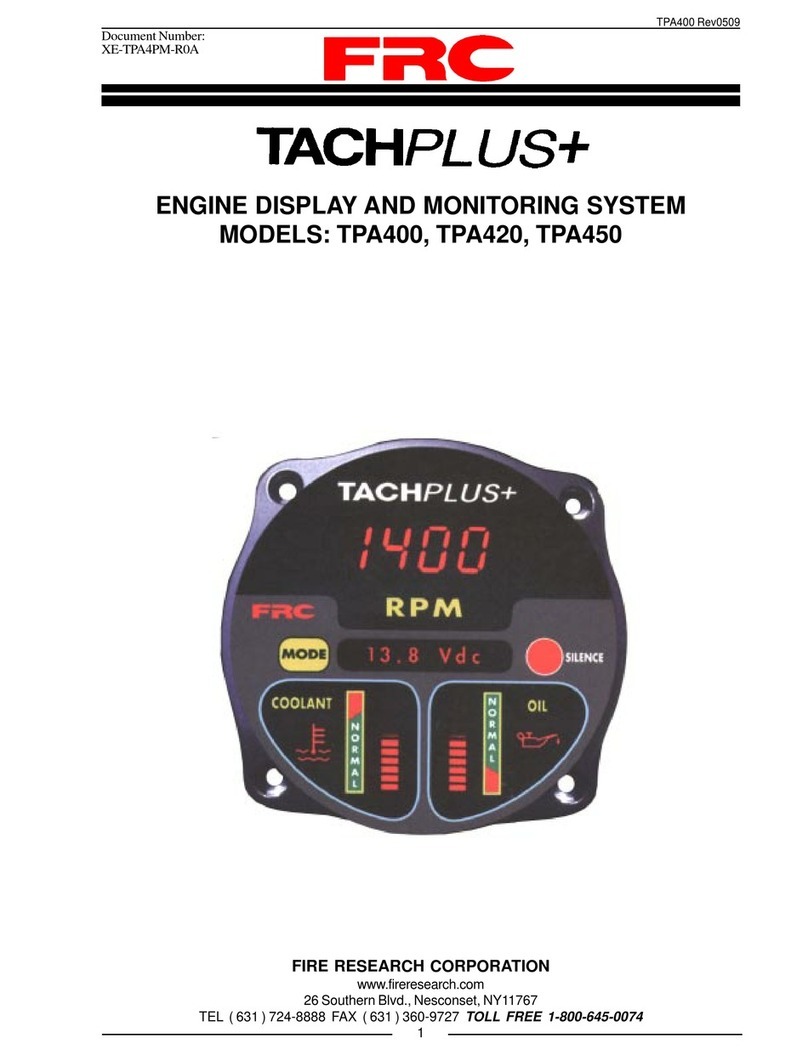

Controls and Indicators .......................................................................................... 7

INSTALLATION ........................................................................................................ 8

Install Display Module .......................................................................................... 8

Install Pressure Sensor ........................................................................................... 9

Install Flow Sensor .............................................................................................. 10

OPERATION ............................................................................................................ 16

Datalink Interface ................................................................................................ 16

Program Features ................................................................................................. 17

External Totalizing Button (Optional) ................................................................. 17

PROGRAMMING .................................................................................................... 18

Inputs ................................................................................................................... 18

Display Module Identification Mode ................................................................... 18

Program Access Mode ......................................................................................... 19

Program Code Descriptions ................................................................................. 22

CALIRBRATION ..................................................................................................... 26

Flow Calibration, Single Point (Code 321) ......................................................... 26

Flow Calibration, Multiple Point (Code 322) ...................................................... 27

Pressure Calibration (Code 323) .......................................................................... 28

WIRING .................................................................................................................... 30

External Totalizing Button Option ....................................................................... 30

Display Module ................................................................................................... 30

Pressure and Flow Sensor .................................................................................... 31