9 10

B.- Cleaning and maintenance

Duetotheunfavourableconditions(swarth,coolants,highpressure,etc.)withwhichthese

viceshavetoworkinsidethemachiningcentres,itisimportantthattheviceiscleanedregularily.

Asimplecleaningoperationisusuallysucientbyusingthesidevents.

Werecommendasuctionpumpsystemasopposedtocompressedairwhichcouldcause

injury.Acompletecleaningoperationshouldbecarriedoutevery1000workinghours.Todoso,

the4ange-clampscrews(4026-090;4051-125)mustbeloosened,thecentraljawremoved,

andtheassemblyofthe2boltsandthespindlewiththeprotectorplatestakenoutofthevicebody

takingcaretoavoidtheboltsfromrotatinginthespindle.

Thenextstepistocleanthevicebodyandtheswarthinthespindlesandintheinteriorof

bothbolts.

Werecommendthatallslidingsurfacesshouldbegreased.

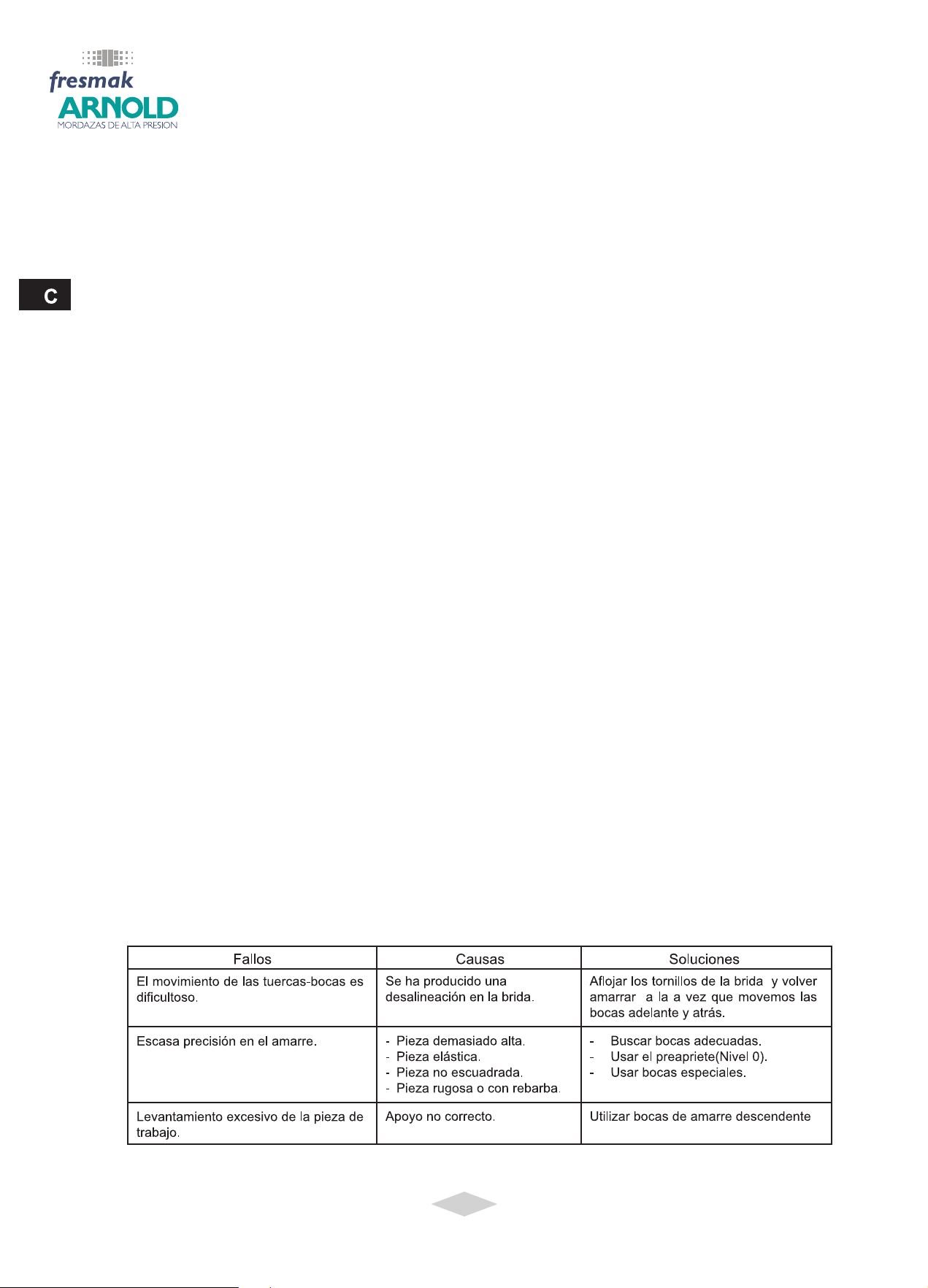

C.- Instructions for Changing and Replacing the Spindles

1) Loosenthecentralxedjaw(4106) or (4131),bodydowelpins(4122-090;9111-125)andthe

4angescrews.Thentakeoutthewholeassembly(bolts,spindlesandsidejaws).

2) UnscrewtheAllensetscrew(0004)anddetachtheange-regulatorassemblyfromthehy-

draulicunit.Themainspindle(4009)hastwoatsurfacesoneitherendtosimplifythisope-

ration.Thebolt(4007)isnowunscrewedfromthemainspindle.

3) Toreleasetheotherbolt(4102),unscrewthesetscrew(0215)locatedonthenutofthepiston

(4035)andthenunscrewthispiston.Thiswayonecantakeoutthenut(5-090;3-125)andthe

mainrightspindle(4102)loosennut(4003).

4) Ifthespindlerotateswhentakenout,thenutsmayhavecomeo-centre.Whenthisoccurs

thenutsmustbecentredbeforesettingthejaws.

D.- Disassembling the Hydraulic Unit

1) Loosenthesetscrew(0215)locatedinthecylinder(4004),unscrewthemainspindle(4009)

thusdetachingitfromthecylinder.

2) Removethebellevillesprings(0213-090;0007-125),andtakeoutthesmallpiston(4029-090;

0012-125).

3) Removethecylinder(4004),thelargepiston(4034),thewasher(4005),andthesmalland

largeseals.Withthe125modelremovethecover(4037)andtheseal(0011).

E.- Hydraulic Oil Relling

1) Placethesmallseal(0009)facingupinitssettinginthecylinder.Thenintroducethecylinder

(4005)washerdownintheoppositedirection.

2) Theseal(4006-090;0011-125)andcap(4037)(The090modelhasnocap)areattachedto

thepistonwhichisthenintroducedintothecylinder.Inordertoasurethecorrectpositionof

theseals,onemustblowairfromoneoftheendsofthepiston.

3) Placingtheassemblyinaverticalposition,thepistonisthenlledwithhydraulicoiltomaxi-

mumcapacitymakingsurethatthereisnoairtrappedintheoil.Thiscanbedonebystiringa

thinrodandthusremovinganyvisiblebubbles.

4) Werecommendhydraulicoilwitha6,5E/50ºviscosity(forexample,RenolinMR20–Fuchs).

5) Thesmallpiston(4029-090;0012-125)isslowlyintroducedintothelargepiston(4034),sea-

lingthechamber.Thepistonmustbeperfectlycleansoasnottodamagetheinterior.

6) Holding the main spindle (4009), introduce the belleville springs (0213-090; 0007-125).

Threadthedeposit(4004)tothespindleuntilthespringsarecompressed.Thehydraulicunit

isnowassembled.

7) Introducethepiston(4028)insidethespindle(4009).

8) Threadthemainspindleintheangeassembly.