HPS Rotary Screw Compressor Units070.700-IOM (MAR 21)

Page 2 Installation - Operation - Maintenance

Contents

General Information

Preface..............................................................................3

Design limitations.............................................................. 3

Job inspection...................................................................3

Transit damage claims.......................................................3

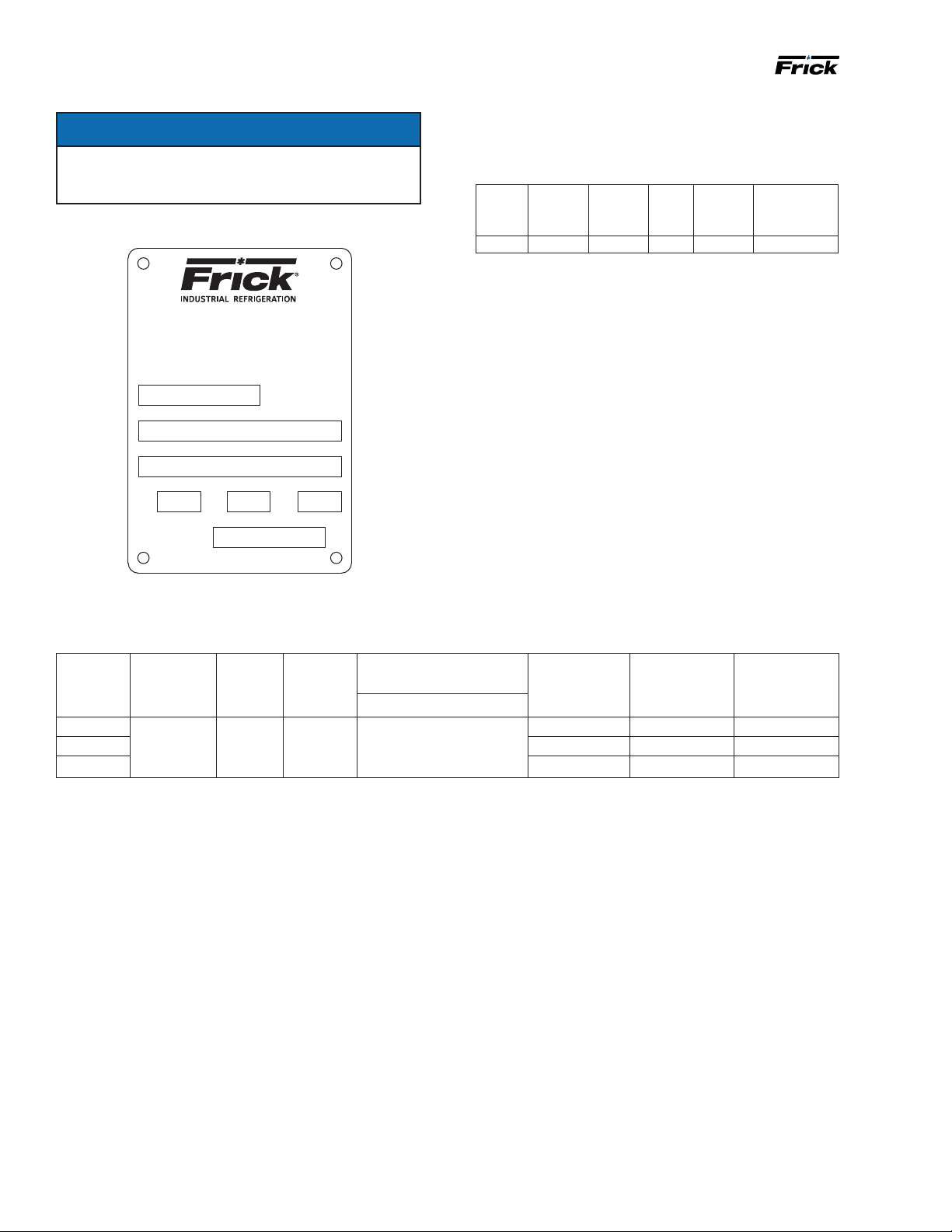

Compressor and unit identication....................................3

Installation

Foundation ........................................................................5

Rigging and handling.........................................................5

Removing the skid.............................................................6

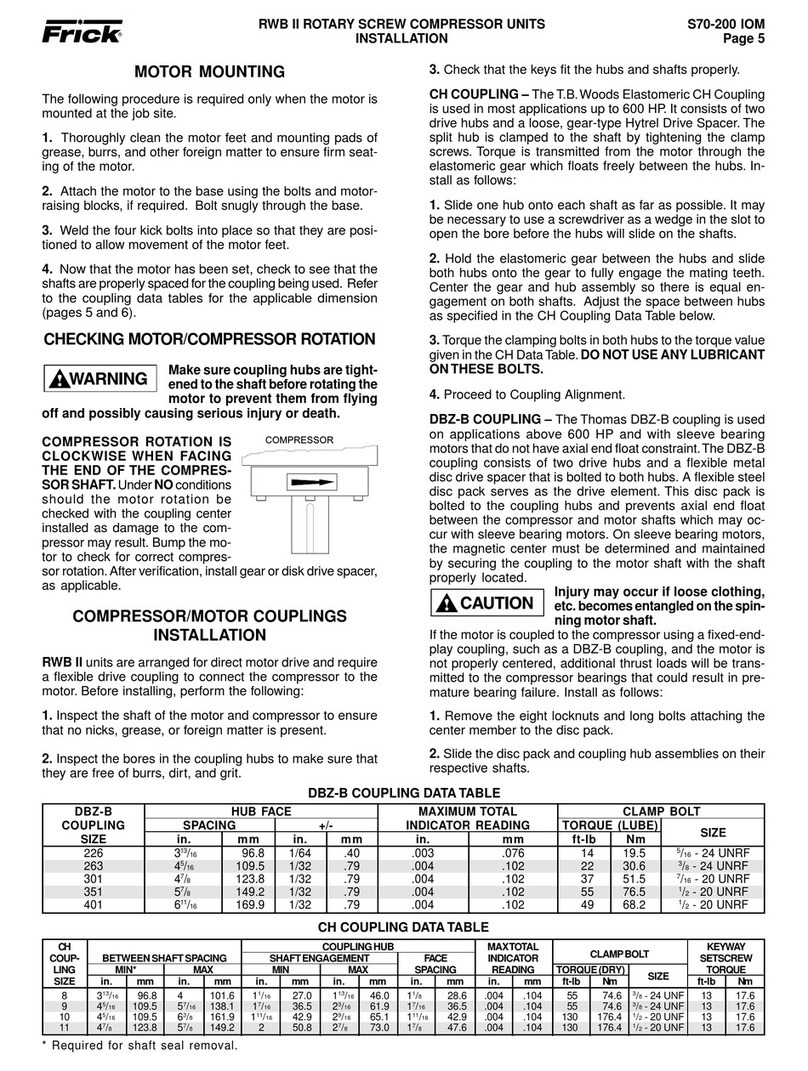

Checking the motor/compressor rotation ..........................6

Compressor/motor coupling installation............................6

Installing the coupling...................................................6

Holding charge and storage ..............................................7

Compressor unit oil...........................................................7

Oil charge..........................................................................7

Oil heater(s) ......................................................................8

Oil lter(s) ......................................................................... 8

Suction valve mounting.....................................................8

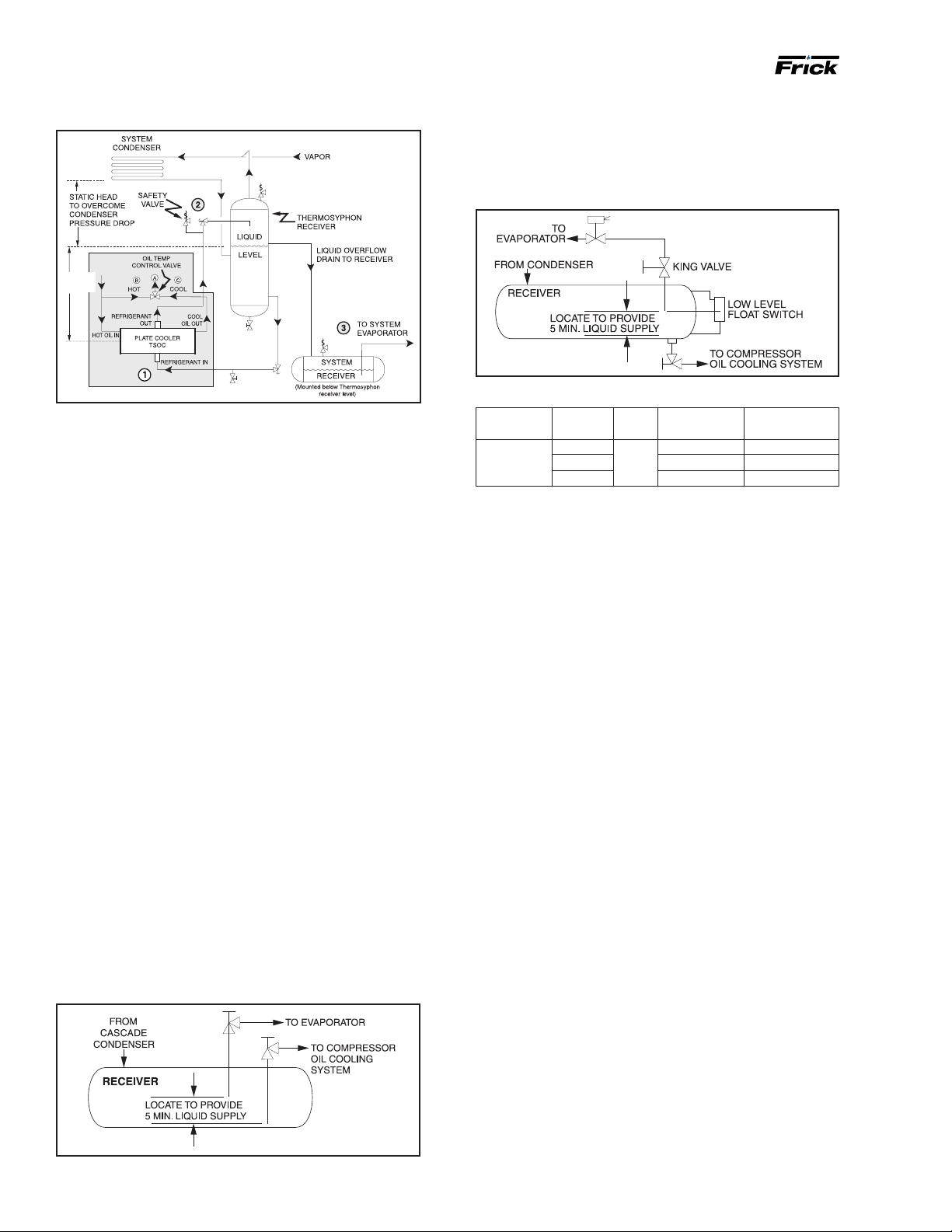

Thermosyphon oil cooling (TSOC)..................................... 9

Equipment ....................................................................9

System operation .........................................................9

Oil temperature control................................................ 9

Installation....................................................................9

Liquid injection oil cooling (optional)............................... 10

Water or glycol oil cooling (optional) ..............................10

Economizer (optional) .....................................................11

Economizer load balancing.............................................. 12

Economizing with VSDs...................................................12

Electrical .........................................................................12

Motor VSD package ........................................................12

Current transformer (CT) ratios.......................................13

Minimum burden ratings ................................................. 14

Control power regulator.................................................. 14

Installation of electronic equipment in an industrial

environment.............................................................15

Wire sizing ......................................................................15

Voltage source ................................................................15

Grounding .......................................................................16

Considerations ................................................................17

Conduit ...........................................................................17

Wiring practices .............................................................18

Communications .............................................................19

UPS power and Quantum™ HD panels.............................. 19

Operation

Operation and Start‑Up instructions ............................... 21

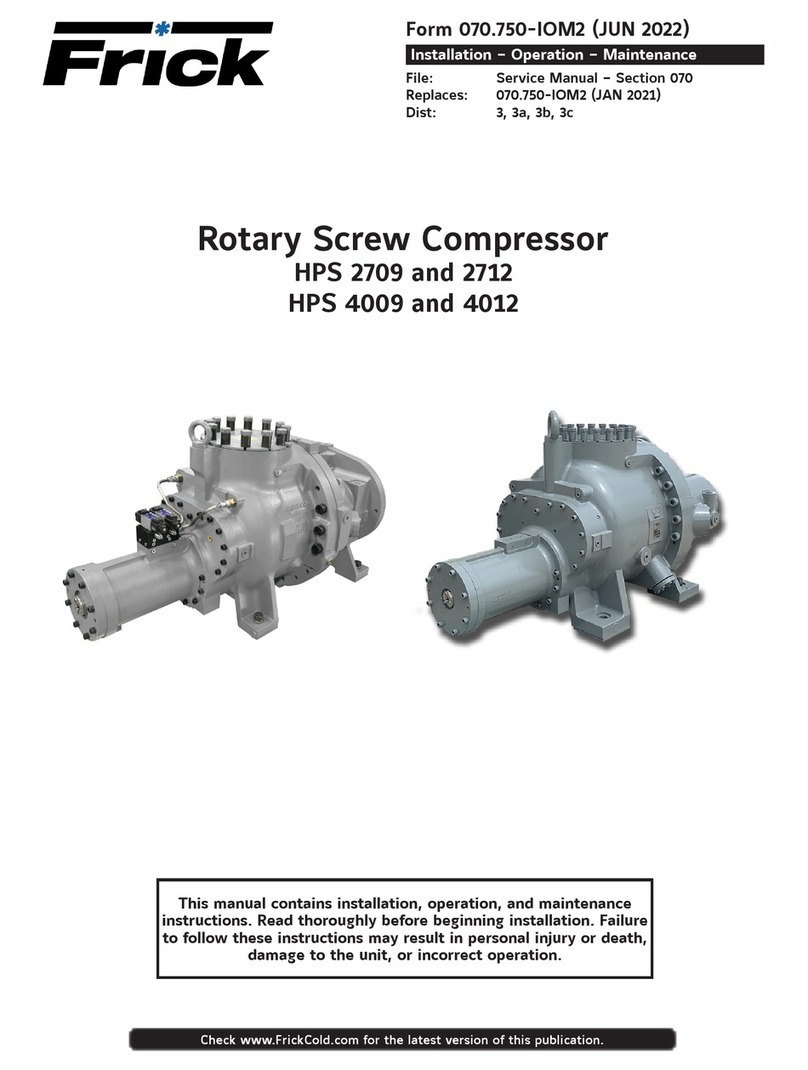

HPS compressor.............................................................. 21

Compressor lubrication system .......................................21

No pump oil system ........................................................ 21

Compressor oil separation system ..................................22

Cold‑start system (580 psig DWP) .................................. 22

Capacity regulation and xed volume ratio Vi.................23

Compressor oil cooling systems...................................... 23

Single‑port liquid injection..............................................23

Suction check valve bypass.............................................23

Low ambient operation ...................................................24

Initial start‑up .................................................................24

Initial start‑up procedure ................................................ 24

Quantum™HD EZ‑COOL™liquid injection adjustment

procedure ................................................................ 25

Solenoid control .........................................................25

EZ Cool status ............................................................25

EZ cool PI control.......................................................25

Operation of Danfoss liquid injection valve ..................... 26

Reset to factory setting:............................................. 27

VFD skip frequencies.......................................................27

Normal start‑up procedure .............................................27

Restarting the compressor unit after control power

interruption (plant power failure) ............................... 27

Maintenance

General information ........................................................29

Normal maintenance operations ..................................... 29

General maintenance ...................................................... 29

Compressor shutdown and start‑up................................ 29

General instructions for replacing

compressor unit components................................... 29

Oil lter (OF‑1) cartridge style........................................ 30

Strainer ‑ Liquid injection ...............................................30

Coalescer lter element(s) .............................................. 31

Changing oil .................................................................... 31

Maintenance schedule..................................................... 32

Maintenance program .....................................................33

Vibration analysis............................................................ 33

Oil quality and analysis.................................................... 33

Oil sampling procedure ................................................... 33

Operating log .................................................................. 33

Motor bearings................................................................ 35

Grease compatibility........................................................35

Troubleshooting guide..................................................... 35

Abnormal operation

analysis and correction ............................................35

Servicing the cold‑start valve

(580 psig DWP only) ................................................ 36

Testing pressure transducers...........................................36

Replacing pressure transducers....................................... 37

Temperature sensor ........................................................38

Troubleshooting.......................................................... 38

Replacement ..............................................................38

Oil level switch................................................................38

Replacement ..............................................................39

Troubleshooting the HPS Compressor unit......................39

Troubleshooting the oil separation system...................... 39

Troubleshooting the liquid injection oil cooling system...40

Motor and bare compressor replacement .......................40

SAE straight thread O-ring ttings assembly procedure . 40

Operating log sheet ........................................................ 44

Forms

HPS Compressor prestart checklist .................................45

Start‑up report................................................................ 46

Vibration data sheet........................................................ 50