070.655-IOM (FEB 22)

Page 2

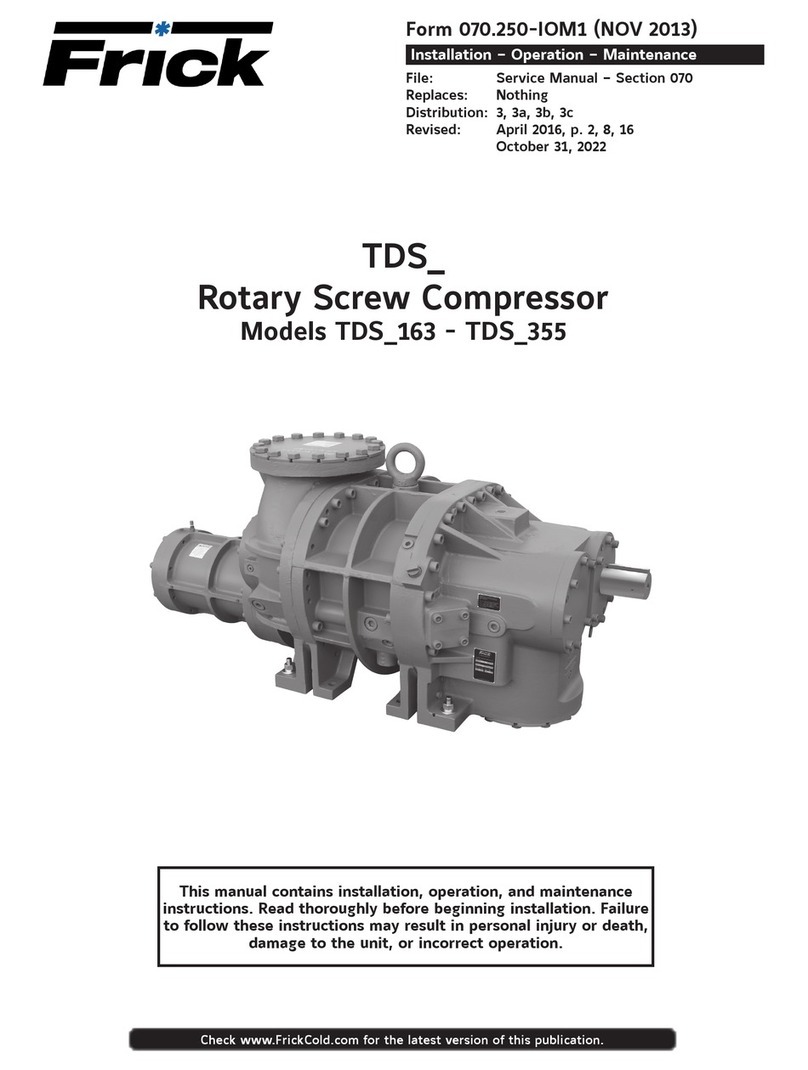

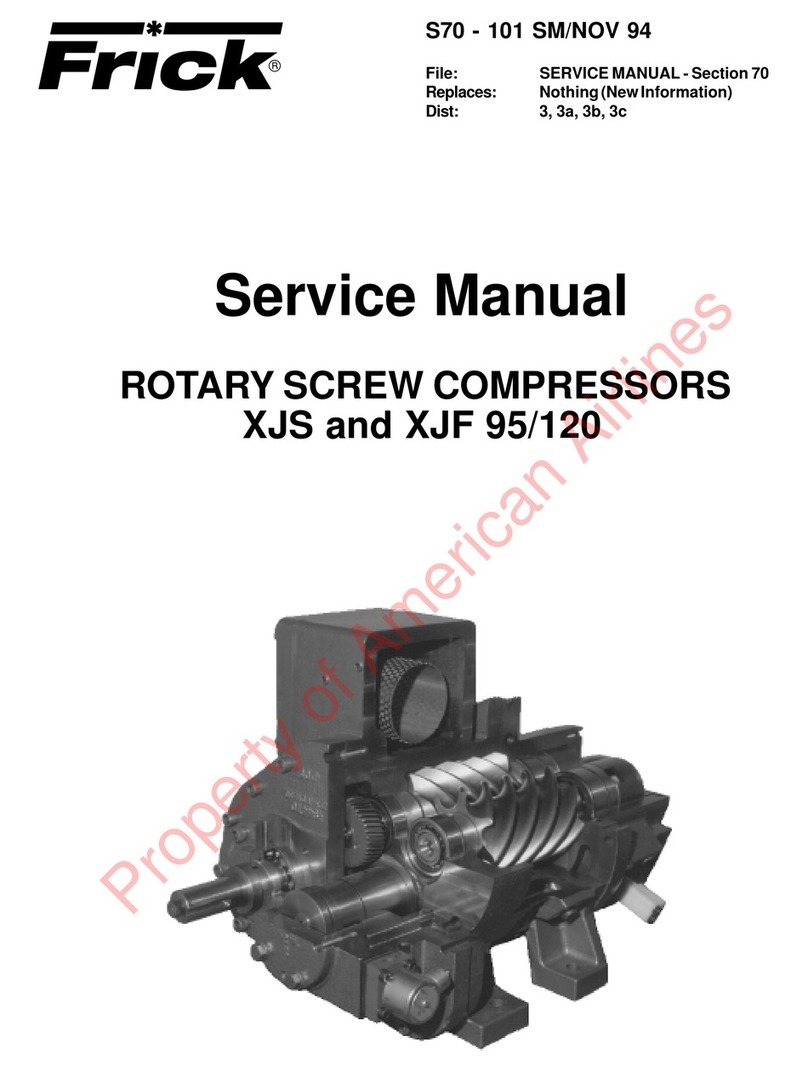

SBTP Rotary Screw Compressor

Installation - Operation - Maintenance

Table of Contents

General information

Design limitations ............................................................. 3

Job inspection .................................................................. 3

Standard bare compressor ............................................... 3

Transit damage claims ...................................................... 3

Compressor identification ................................................ 3

Description........................................................................ 4

Frick SBTP compressor ............................................... 4

Compressor lubrication system ................................... 4

Oil pump....................................................................... 5

Construction details...................................................... 5

Installation

Design limits ..................................................................... 7

Outline dimensions ........................................................... 7

Holding charge and storage ............................................ 15

Rigging and handling....................................................... 15

Foundation ..................................................................... 15

Customer connections .................................................... 16

Compressor oil ................................................................ 16

Oil pump ......................................................................... 16

Compressor..................................................................... 16

Mounting the motor: foot mounted only .................... 16

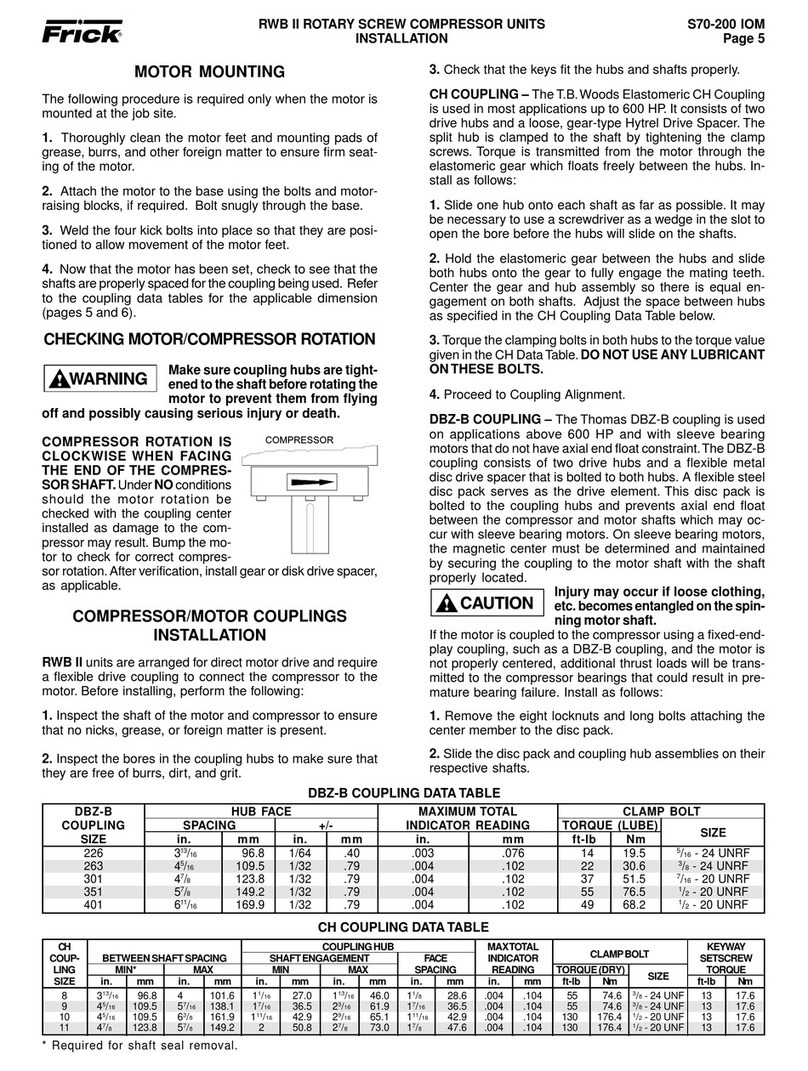

Connecting the compressor to the motor .................. 16

Aligning the coupling.................................................. 17

Oil heaters ...................................................................... 17

Oil filters ........................................................................ 17

Oil cooling requirements ................................................. 17

Natural gas applications ............................................. 17

Dehydration or evacuation test ....................................... 17

Installing electrical components...................................... 18

Slide stop transmitter................................................. 18

Capacity slide valve transmitter.................................. 18

Directional control valves .......................................... 18

Operation

Operation and start-up instructions ............................... 19

Compressor hydraulic system ........................................ 19

Volumizer volume ratio control ...................................... 20

Low ambient operation .................................................. 20

Initial start-up ................................................................ 20

Initial start-up procedure .......................................... 20

Normal start-up procedure ........................................ 20

Maintenance

General information ....................................................... 21

Normal maintenance operations .................................... 21

General maintenance ................................................ 21

Changing the oil ........................................................ 21

Maintenance program ............................................... 21

Maintenance schedule..................................................... 22

Vibration analysis............................................................ 22

Oil quality and analysis ................................................... 22

Operating log ................................................................. 22

Troubleshooting guide .................................................... 23

Abnormal operation analysis and correction ............. 23

Replacing the capacity linear transmitter: slide valve 23

Replacing the

volumizer transmitter: slide stop.............23

Replacing the bare compressor ...................................... 24

Long-term storage.......................................................... 24

Preparing the compressor for storage............................. 25

Maintaining the compressor............................................ 25

Shutdown due to incorrect oil pressure: high stage

and booster ............................................................ 25

Troubleshooting the SBTP compressor .......................... 26

Troubleshooting the oil pump and system....................... 26

Troubleshooting the hydraulic system ............................. 27

Forms

Compressor prestart checklist......................................... 28

Drive train alignment....................................................... 29

Operating log sheet ........................................................ 29

Vibration data sheet........................................................ 30

Indicates an imminently hazardous situation, which if not avoided, results in death or serious

injury.

Indicates a potentially hazardous situation or practice, which if not avoided, results in death or

serious injury.

Safety precaution denitions

Indicates a potentially hazardous situation or practice, which if not avoided, results in damage to

equipment and/or minor injury.

Indicates an operating procedure, practice, or portion thereof,which is essential to highlight.

WARNING

CAUTION

DANGER

NOTICE