070.250-IOM1 (NOV 2013)

Page 2

TDS_ Rotary Screw Compressor

Installation - Operation - Maintenance

Table of Contents

General information

Preface .............................................................................3

Design limitations .............................................................3

Job inspection ..................................................................3

Standard bare compressor ...............................................3

Transit damage claims ...................................................... 3

Compressor identication ................................................3

Long-term storage............................................................4

Preparing compressor for storage................................ 5

Maintaining compressor ............................................... 5

Description........................................................................5

TDS_ compressor ........................................................5

Compressor lubrication system ...................................5

Oil pump.......................................................................6

Construction details ..........................................................6

Installation

Design limits .....................................................................7

Outline dimensions ...........................................................7

Holding charge and storage ............................................12

Rigging and handling.......................................................12

Lifting instructions......................................................12

Foundation .....................................................................12

Customer connections ....................................................13

Oil system requirements .................................................13

Oil selection ...............................................................13

Oil pressure ................................................................13

Oil cooling requirements ............................................13

Oil lters ....................................................................14

Oil pump .........................................................................14

Oil heaters ..................................................................... 14

Compressor oil ................................................................14

Compressor..................................................................... 14

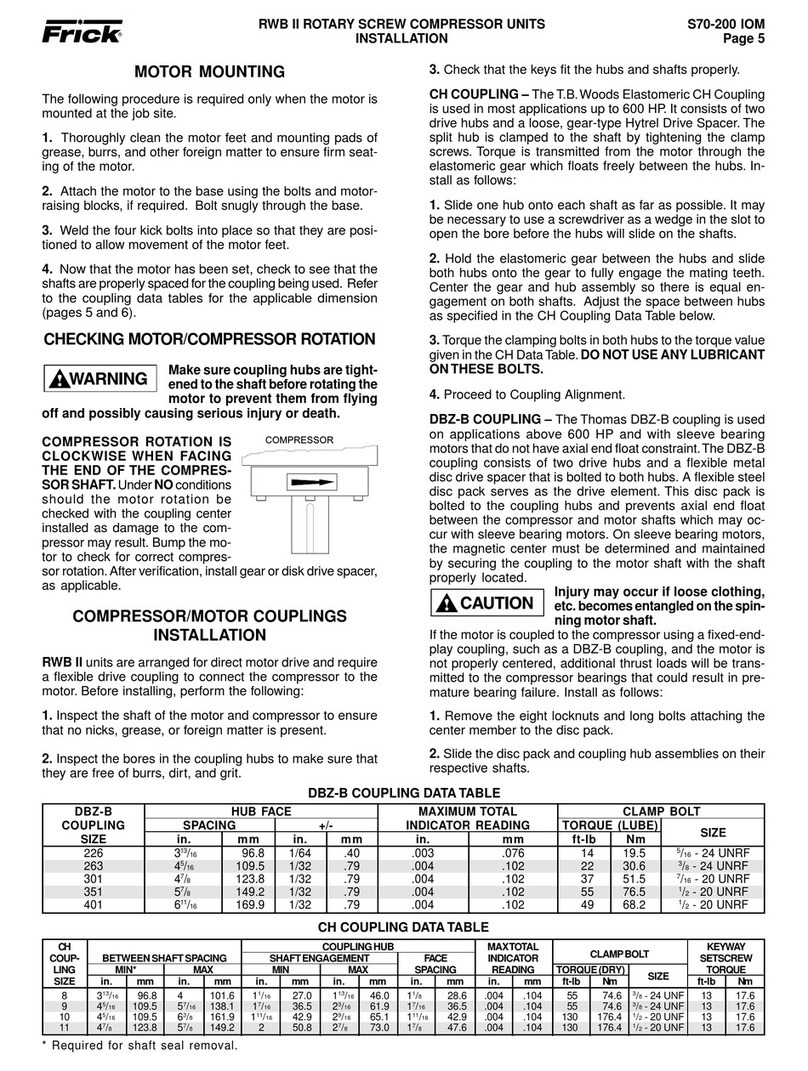

Motor mounting (foot mounted only) ......................... 14

Compressor/motor coupling requirements. ................14

Coupling alignment requirements...............................14

Coupling alignment procedure ........................................15

Hot alignment of compressor/motor ............................... 15

SV position potentiometer

replacement and adjustment....................................15

Volumizer potentiometer

replacement and adjustment....................................16

Compressor hydraulic system..........................................16

Volumizer volume ratio control ...................................... 17

Vi increase .................................................................17

Vi decrease ...............................................................17

Low ambient operation .................................................. 17

Balance piston pressure regulator

for TDSH 355 compressors ......................................17

Operation

Operation and start-up instructions ............................... 18

Initial start-up ........................................................... 18

Initial start-up procedure ..........................................18

Normal start-up procedure ........................................18

Maintenance

General information .......................................................19

Normal maintenance operations .................................... 19

General maintenance..................................................19

Changing oil ...............................................................19

Recommended maintenance program .......................20

Vibration analysis ...........................................................20

Oil quality and analysis ................................................... 20

Maintenance schedule..................................................... 20

Operating log ............................................................ 21

Troubleshooting guide .................................................... 21

Abnormal operation analysis and correction .............21

Bare compressor replacement ....................................... 21

Shutdown due to improper oil pressure (high-stage and

booster) ..................................................................22

Troubleshooting the TDS_ compressor (Frick RWB II

package) ..................................................................22

Troubleshooting the hydraulic system ............................. 22

Troubleshooting the oil pump and system ...................... 23

Read this rst: compressor prestart checklist ................. 24

Vibration data sheet........................................................ 26

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation or practice which, if not avoided, will result in death or

serious injury.

Safety precaution denitions

Indicates a potentially hazardous situation or practice which, if not avoided, will result in damage

to equipment and/or minor injury.

Indicates an operating procedure, practice, etc., or portion thereof which is essential to highlight.

Referenced manuals:

090.020-M: Quantum LX Maintenance

160.802-SPC: CompressorOilSpecications

090.022-O: Quantum HD Operation

WARNING

CAUTION

DANGER

NOTICE