070-450 IOM (NOV 13)

Page 5

XJF ROTARY SCREW COMPRESSOR

INSTALLATION - OPERATION - MAINTENANCE

Bare Compressors\General\Warranties\Screw Compressor

Purchased for Long Term Storage).

The following guidelines must be followed to maintain the

SCREW COMPRESSOR WARRANTY.

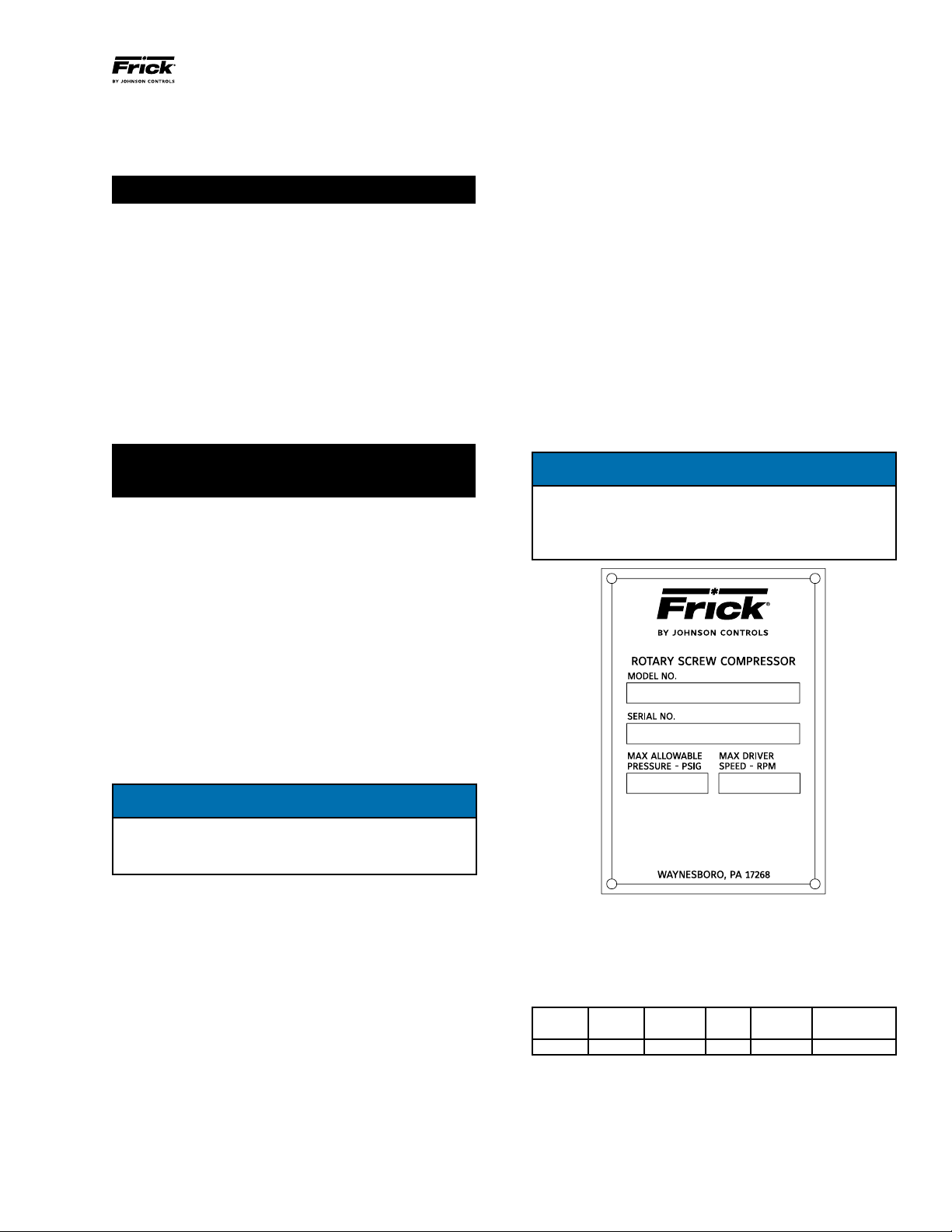

PREPARING COMPRESSOR FOR STORAGE

Evacuate compressor to remove moisture. Evacuation lines

are to be connected to port SM1. Evacuation lines are to be

connected to the three Schrader valves provided with the

compressor. One valve is connected to compressor suction.

The other two valves are located at the block on the cylinder.

Break vacuum with dry nitrogen and bring pressure to 0 psig.

Pump oil into the same ports mentioned in step 1. Johnson

Controls-Frick recommends break-in oil P/N 111Q0831809

for storage purposes. The amounts of oil needed per

compressor are:

95mm - 2Gal

120mm - 3Gal

151mm - 8Gal

After compressor is oil charged, pressurize compressor to

15 psig with nitrogen.

MAINTAINING COMPRESSOR

Ensure that the 5-15 psig nitrogen charge is maintained

with 15 psig preferred.

Rotate the male rotor shaft every two weeks. Mark the

shaft to ensure the rotor does not return to the original

position.

The compressor must be stored inside a dry building

environment.

Grease the male rotor shaft to prevent rust.

Record all information in a “Compressor Long Term Storage

Log.” See bottom of page 4.

Contact Johnson Controls-Frick Service with any

questions regarding long term storage.

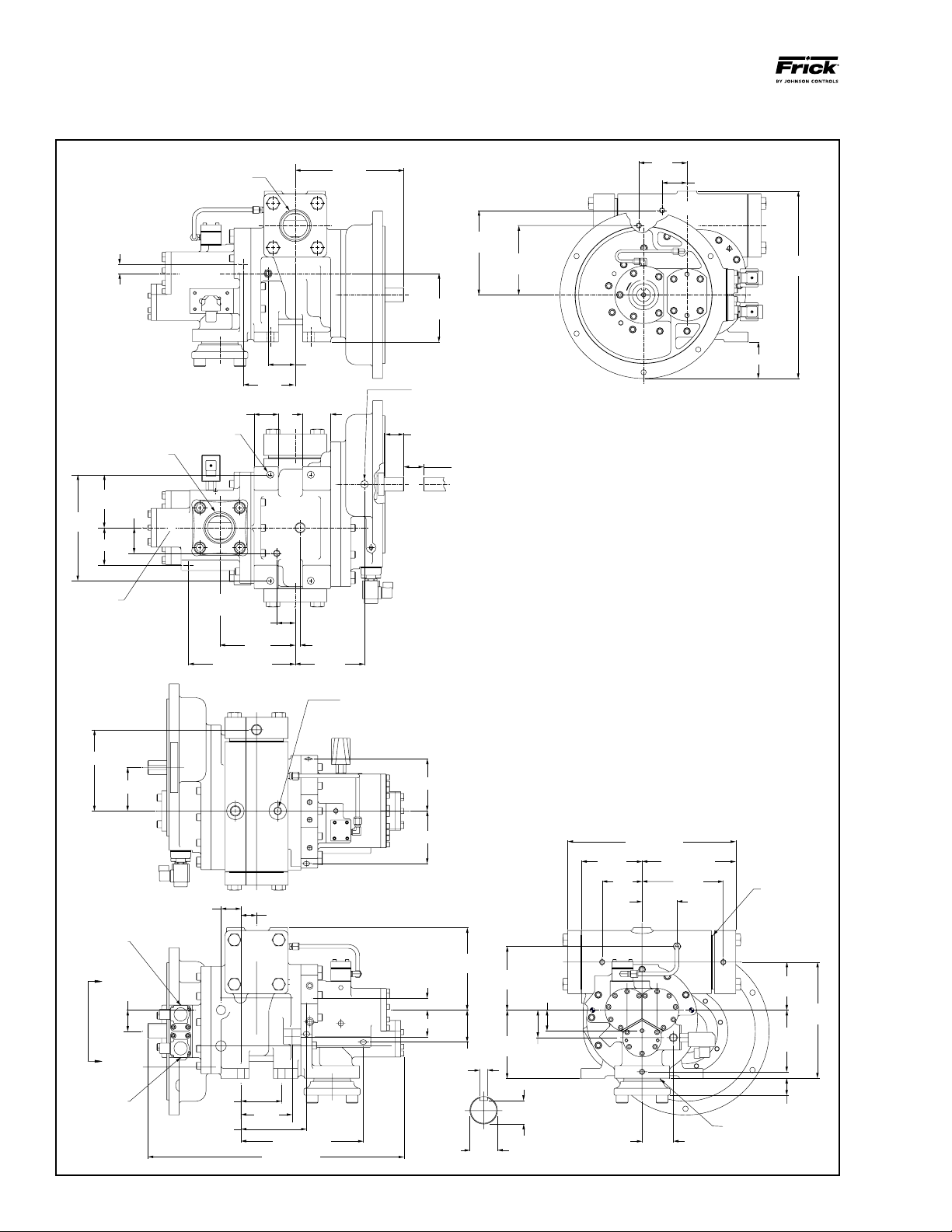

DESCRIPTION

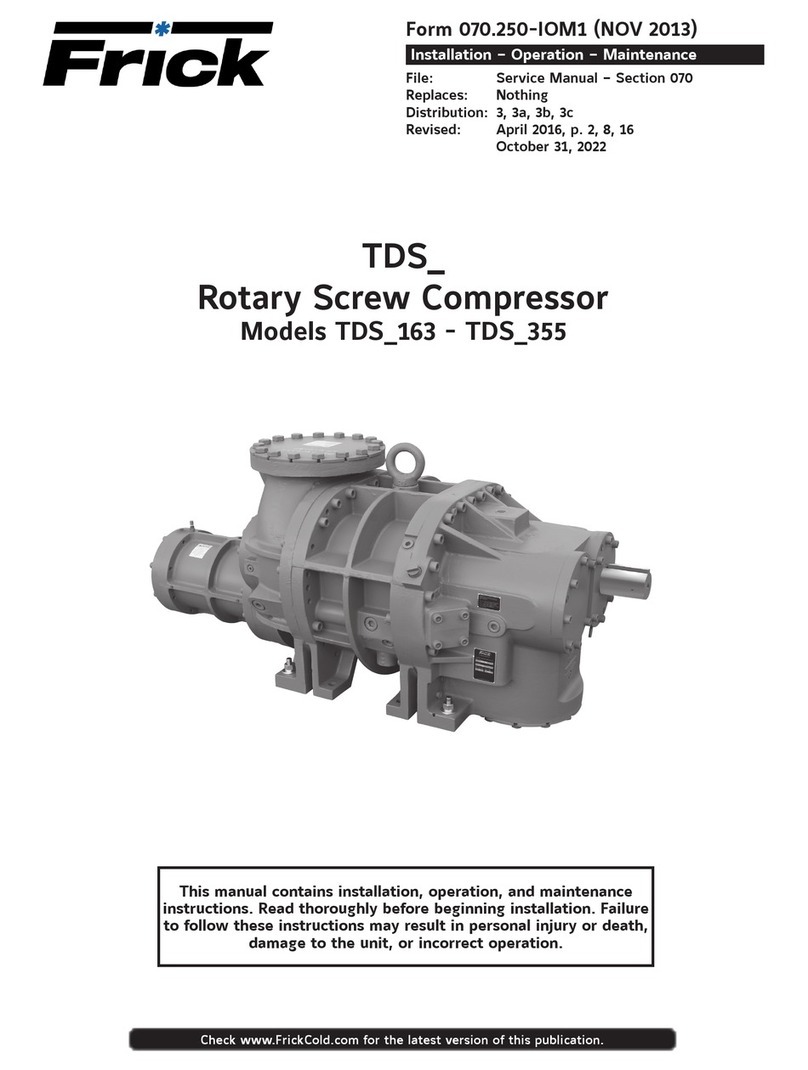

XJF COMPRESSOR

The Frick XJF rotary screw compressor utilizes mating

asymmetrical prole helical rotors to provide a continuous

ow of vapor and is designed for both high-pressure and

low-pressure applications. The compressor incorporates

the following features:

1. High-capacity roller bearings to carry radial loads at both

the inlet and outlet ends of the compressor.

2. Heavy-duty angular contact ball bearings to carry axial

loads are mounted at the discharge end of compressor.

3. Moveable slide valve to provide fully modulating capacity

control from 100% to 25% of full load capacity.

4. VOLUMIZER II volume ratio control adjusts the compres-

sor volume ratio during operation to the most efcient of

three possible volume ratios, 2.2, 3.5, 5.0, depending upon

system requirements.

5. A hydraulic cylinder to operate the slide stop and slide

valve.

6. Compressor housing suitable for 400 PSIG pressure.

7. Most bearing and control oil is vented to closed threads in

the compressor instead of suction port to avoid performance

penalties from superheating suction gas.

8. The shaft seal is designed to maintain operating pressure

on the seal well below discharge pressure for increased

seal life.

9. Oil is injected into the rotor threads to maintain good

volumetric and adiabatic efciency, even at high compres-

sion ratios.

10. Shaft rotation clockwise facing compressor, suitable for

all types of drives. SEE FOLLOWING WARNING.

WARNING

It is mandatory that the coupling center be removed

and the direction of motor rotation be conrmed be-

fore running the compressor. Proper rotation of the

compressor shaft is clockwise looking at the end of the

compressor shaft. Failure to follow this step could re-

sult in backward compressor rotation which can cause

compressor failure or explosion of the suction housing.

COMPRESSOR LUBRICATION SYSTEM

The XJF compressor is designed specically for operation

without an oil pump for high stage service. Boosters and

some low-differential pressure appli cations will require the

pump option.

The lubrication system on an XJF equipped screw compressor

unit performs several functions:

1. Lubricates the rotor contact area, allowing the male rotor

to drive the female rotor on a cushioning lm of oil.

2. Provides lubrication of the bear ings and shaft seal.

3. Serves to remove the heat of compression from the gas,

keeping discharge temperatures low and minimizing refriger-

ant or oil break down.

4. Fills gas leakage paths between or around the rotors with

oil, thus greatly reducing gas leakage and main tain ing good

compressor per formance even at high compres sion ratios.

5. Provides oil pressure for development of balance load on

the balance pistons to reduce bearing loading and increase

bearing life.

OIL PUMP

The XJF screw compressor unit is designed to be self-lu-

bricating. Oil being supplied to the compres sor from the oil

separator is at system head pressure. Within the compressor,

oil porting to all parts of the compressor is vented back to

a point in the compres sor’s body that is at a pressure lower

than compressor discharge pressure. The compressor’s nor-

mal operation makes the compressor unit operate essentially

as its own oil pump. All oil entering the compressor is moved

by the compressor rotors out the compressor outlet and back

to the oil separator. For normal high-stage operation an oil

pump is not required.