RWB II ROTARY SCREW COMPRESSOR UNITS

INSTALLATION - OPERATION - MAINTENANCE

S70-200 IOM

Page 2

Contents

Maintenance

GENERAL INFORMATION..............................................25

NORMAL MAINTENANCE OPERATIONS......................25

GENERAL MAINTENANCE............................................25

COMPRESSOR SHUTDOWN and START-UP................25

GENERAL INSTRUCTIONS FOR REPLACING

COMPRESSOR UNIT COMPONENTS.....................26

OIL FILTER (OF-1) MAIN SINGLE/DUAL .......................26

STRAINER - DEMAND OIL PUMP .................................26

STRAINER - LIQUID INJECTION...................................27

COALESCER FILTER ELEMENT(S)...............................27

CHANGING OIL ..............................................................27

DEMAND PUMP DISASSEMBLY....................................28

TROUBLESHOOTING THE DEMAND PUMP.................30

RECOMMENDED MAINTENANCE PROGRAM.............32

VIBRATION ANALYSIS ...................................................32

MOTOR BEARINGS........................................................32

OIL QUALITY and ANALYSIS .........................................32

OPERATING LOG...........................................................33

MAINTENANCE SCHEDULE..........................................33

TROUBLESHOOTING GUIDE........................................34

ABNORMAL OPERATION

ANALYSIS and CORRECTION................................34

SERVICING THE COLD-START VALVE..........................34

PRESSURE TRANSDUCERS - TESTING......................34

PRESSURE TRANSDUCERS - REPLACEMENT ..........35

SV POSITION POTENTIOMETER

REPLACEMENT AND ADJUSTMENT.....................36

VOLUMIZER®POTENTIOMETER

REPLACEMENT AND ADJUSTMENT.....................36

TEMPERATURE and/or PRESSURE ADJUSTMENT.....37

OIL LEVEL TRANSMITTER REPLACEMENT................37

TROUBLESHOOTING

RWB II COMPRESSOR...........................................37

OIL SEPARATION SYSTEM ....................................38

HYDRAULIC SYSTEM.............................................38

LIQUID INJECTION OIL COOLING SYSTEM.........39

DEMAND PUMP SYSTEM.......................................39

THERMAL EXPANSION VALVES....................................40

JORDANTEMPERATURE REGULATOR VALVE.............41

BARE COMPRESSOR MOUNTING...............................42

SHUTDOWN DUE TO IMPROPER OIL PRESSURE ....42

GREASE COMPATIBILITY..............................................42

NLGI Grease Compatibility Chart....................................42

P & I DIAGRAMS............................................................43

PROPER INSTALLATION OF ELECTRONIC EQUIP-

MENT IN AN INDUSTRIAL ENVIRONMENT..........47

FORMS

OPERATING LOG SHEET.......................................50

COMPRESSOR PRESTART CHECKLIST ..............51

START-UP REPORT ................................................52

VIBRATION DATA SHEET........................................54

RECOMMENDED SPARE PARTS..................................55

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation or practice which, if not avoided, will result in death

or serious injury.

SAFETY PRECAUTION DEFINITIONS

Indicates a potentially hazardous situation or practice which, if not avoided, will result in dam-

age to equipment and/or minor injury.

NOTE: Indicates an operating procedure, practice, etc., or portion thereof which is essential to highlight.

PREFACE..........................................................................3

DESIGN LIMITATIONS......................................................3

JOB INSPECTION.............................................................3

TRANSIT DAMAGE CLAIMS ............................................3

COMPRESSOR and UNIT IDENTIFICATION...................3

Installation

FOUNDATION ...................................................................4

RIGGING and HANDLING ................................................4

SKID REMOVAL................................................................4

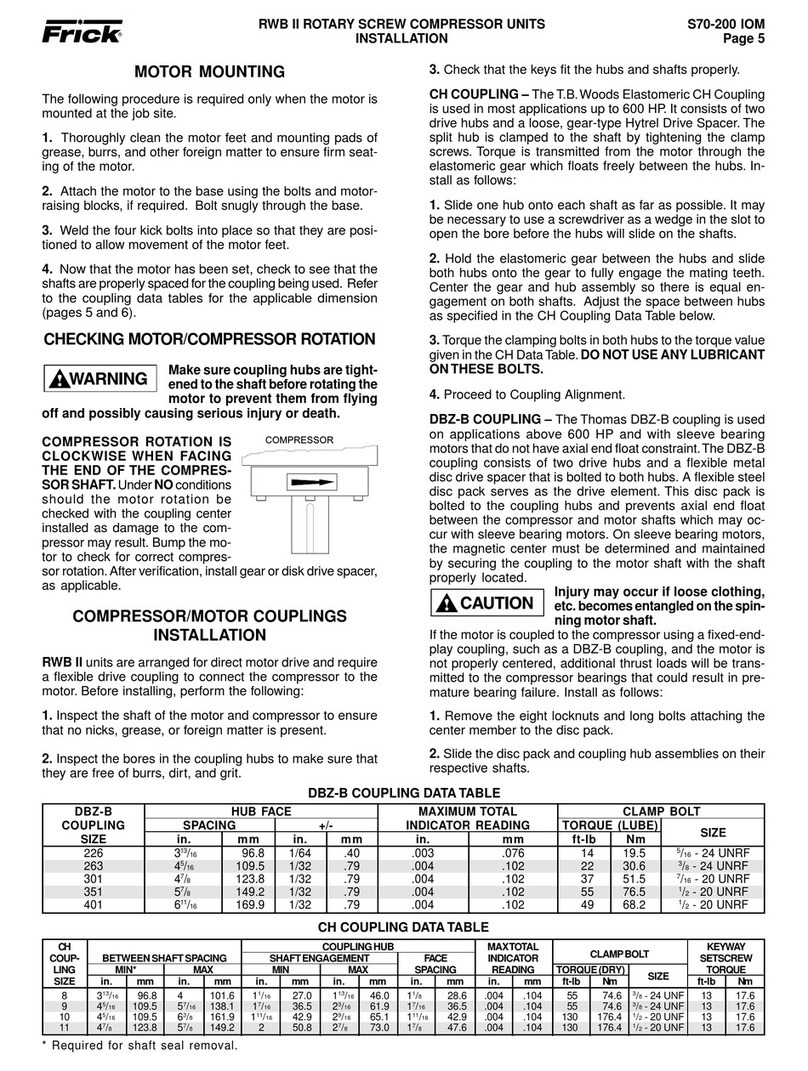

MOTOR MOUNTING.........................................................5

CHECKING MOTOR/COMPRESSOR ROTATION..............5

COMPRESSOR/MOTOR COUPLINGS INSTALLATION...5

COUPLING ALIGNMENT PROCEDURE..........................7

HOT ALIGNMENT OF COMPRESSOR/MOTOR................9

OIL PUMP COUPLING......................................................9

HOLDING CHARGE AND STORAGE...............................9

COMPRESSOR UNIT OIL ................................................9

OIL CHARGE ....................................................................9

OIL HEATER(S).................................................................9

OIL FILTER(S).................................................................10

THERMOSYPHON OIL COOLING..................................10

LIQUID INJECTION OIL COOLING (OPTIONAL)...........11

LIQUID LINE SIZES/RECEIVER VOLUME.....................12

WATER-COOLED OIL COOLING (Optional)...................12

ECONOMIZER - HIGH STAGE (OPTIONAL)..................12

ELECTRICAL ..................................................................14

MOTOR STARTER PACKAGE ........................................14

MINIMUM BURDEN RATINGS........................................15

CONTROL POWER REGULATOR..................................16

Operation

OPERATION and START-UP INSTRUCTIONS...............17

TDSH COMPRESSOR....................................................17

COMPRESSOR LUBRICATION SYSTEM......................17

NO PUMP OIL SYSTEM.................................................17

COLD-START SYSTEM ..................................................17

DEMAND PUMP OIL SYSTEM.......................................18

COMPRESSOR OIL SEPARATION SYSTEM.................18

COMPRESSOR HYDRAULIC SYSTEM.........................19

VOLUMIZER®VOLUME RATIO CONTROL....................19

COMPRESSOR OIL COOLING SYSTEMS....................20

SINGLE-PORT LIQUID INJECTION ...............................20

RWB II BOOSTER OR SWING DUTY APPLICATION....20

DUAL-PORT LIQUID INJECTION...................................20

LIQUID INJECTION ADJUSTMENT PROCEDURE .......20

QUANTUM™ EZ-COOL™LIQUID INJECTION

ADJUSTMENT PROCEDURE.................................21

SUCTION CHECK VALVE...............................................22

SUCTION CHECK VALVE BYPASS................................23

LOW AMBIENT OPERATION..........................................23

SUCTION CHECK VALVEPOWER ASSIST KIT.............23

INITIAL START-UP ..........................................................24

INITIAL START-UP PROCEDURE ..................................24

NORMAL START-UP PROCEDURE...............................24