070.650-IOM (AUG 2015)

Page 6

SGC ROTARY SCREW COMPRESSOR

INSTALLATION - OPERATION - MAINTENANCE

OIL PUMP

A demand oil pump is required for low differential pressure

applications (CoolWare™ will provide a warning when the

oil differential pressure is too low). Oil being supplied to

the compressor from the oil separator is at system

discharge pressure. Within the compressor, oil porting to

all parts of the compressor is vented back to a location in

the compressor’s body that is at a pressure lower than

compressor discharge pressure. All oil entering the

compressor is moved by the compressor rotors out the

compressor outlet and back to the system oil separator.

All SGX compressors are equipped with Squeeze Film

Dampers (SFD) in the rotor blocking diameters. Depending

on operating conditions and power consumption, a full

time and full lube oil pump is required to supply oil to the

compressor (SB-3 & SB-4 ports) at a pressure up to 40-50

psi above discharge pressure. Coolware will provide the

exact calculation at the actual operating condition. If the

calulation information is not available, the oil pressure

should be a minimum of 40 psi above discharge pressure.

On all SG*H compressors, the oil pressure to the balance

piston must be controlled and regulated through the SB-2

compressor port. For booster and low pressure applications,

SB-2 may not need to be connected. For higher operating

pressure a Balance Piston Regulator (BPR) must be installed

and piped to the SB-2 connection.

Since there are several variants of the BPR, use Coolware

to select the best option. Correct BPR information and

pressure settings are required. Do not run the compressor

without this information.

NOTICE

DO NOT RUN THE COMPRESSOR WITHOUT

THE CORRECT BALANCE PISTON REGULATOR

INFORMATION AND PRESSURE SETTINGS.

CONSTRUCTION DETAILS

HOUSING: Castings for SGC/SGX screw compressors

through model 3524 are close grain, pressure tight, grey

cast iron to ensure structural integrity and mechanical and

thermal stability under all operating conditions. Ductile

iron housings are also available for special applications.

Standard casing material for SGX 4013-4021 compressor

models is ductile iron grade 60-40-18 per ASTM A395 and

ASME SA395. Contact Johnson Controls – Frick Sales for

additional information.

ROTORS: The rotors are made from the highest quality

steel bar-stock or forgings to the exacting tolerances of

Frick-designed high-efciency rotor proles. The four-

lobed male rotor (5 lobes on 408) is directly connected to

the driver. The six-lobed female rotor (7 lobes on 408) is

drivenbythemaleonathinoillm.

BEARINGS: Antifriction bearings with L

10

rated life in

excess of 50,000 hours at design conditions (using the

Frick Superlter™) are used for reduced frictional

horsepower and superior rotor positioning, resulting in

reduced power consumption, particularly at higher

pressure ratios. Cylindrical roller bearings are provided to

handle the radial loads and the thrust loads are absorbed

by four point contact or angular contact bearings. In

addition, thrust balance pistons are provided to reduce the

thrust load and improve bearing life.

SHAFT SEAL: The compressor shaft seal is a single-face

type with a spring-loaded carbon stationary surface riding

against a cast iron rotating seat. The seal is capable of

withstanding static pressure up to 600 psig. During opera-

tion it’s vented to low pressure to provide extended life.

The 408 compressors utilize silicon-tungsten carbide seal

face material.

VOLUMIZER VARIABLE VOLUME RATIO CONTROL: The

Frick compressor includes a method of varying the internal

volume ratio to match the system pressure ratio. Control of

the internal volume ratio eliminates the power penalty

associated with over- or under-compression. Volume ratio

control is achieved by the use of a slide stop which is a

movable portion of the rotor housing that moves axially with

the rotors to control discharge port location. The slide stop

is moved by hydraulic actuation of a control piston. The

range of adjustment is listed in the COMPRESSOR VOLUME

and CAPACITY RATIO table.

STEPLESS CAPACITY CONTROL: Capacity control is

achieved by use of a movable slide valve. The slide valve

moves axially under the rotors to provide fully modulated

capacity control from 100% to minimum load capacity.

Minimum load capacity varies slightly with compressor

model, pressure ratio, discharge pressure level, and rotor

speed. See the TABLE 1 for minimum capacity for all SGC

models.

The slide valve is positioned by hydraulic movement of its

control piston. When in the unloaded position, gas is

bypassed back to suction through a recirculation slot before

compression begins and any work is expended, providing

themostefcientunloading method available for part-load

operation of a screw compressor.

MOTOR MOUNT: SGC/SGX models through 3524 are

designedwithadriveendangethatmateswithacastiron

motor mount (available as a sales order option). The motor

mount is precision machined so that it ensures proper

alignment of the compressor and motor coupling.

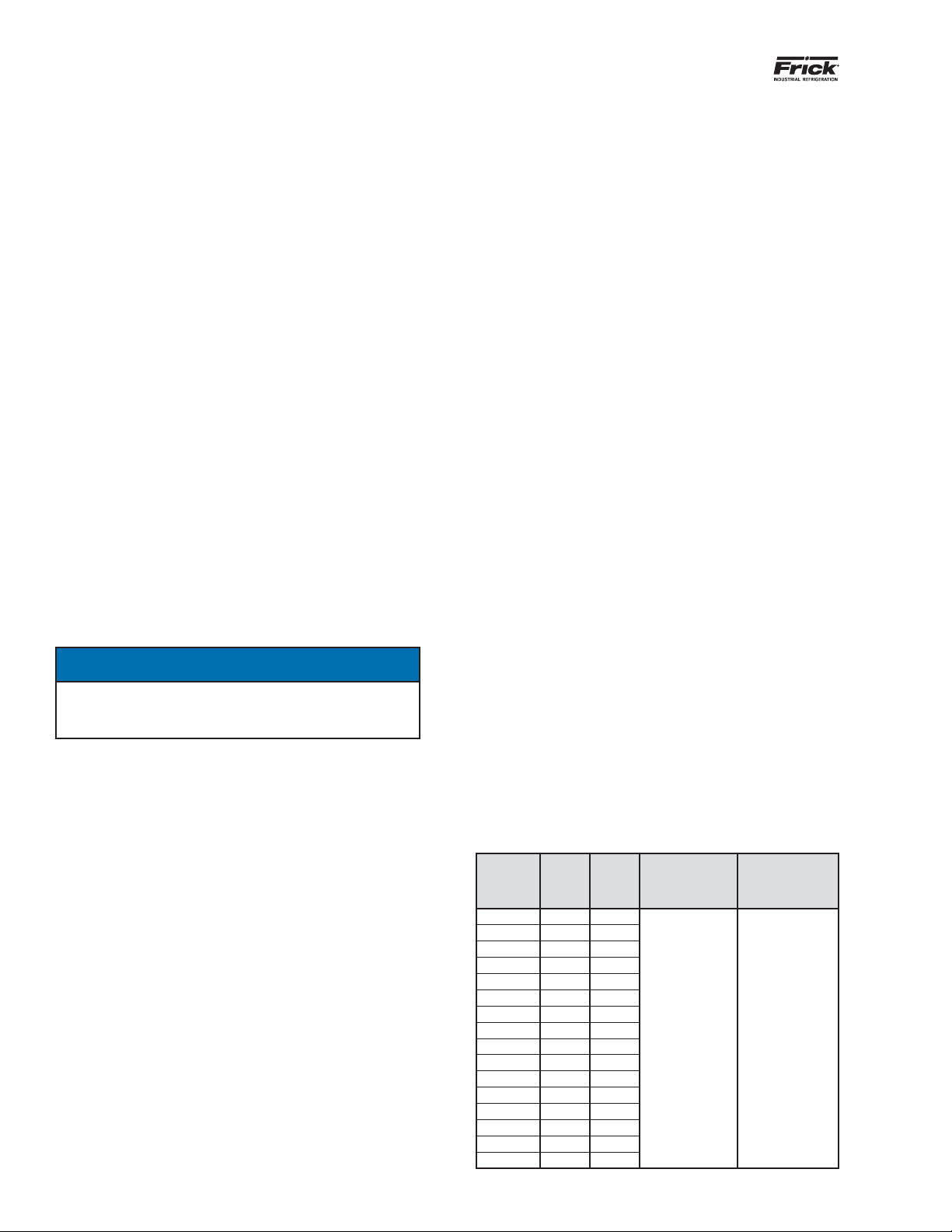

Table 2. COMPRESSOR VOLUME and CAPACITY RATIO

SGC

MODEL

MIN.

VI(1)

MAX.

VI

MIN.

CAPACITY %

SLIDE VALVE

& SLIDE STOP

TRAVEL

1913 2.2 5.0

REFER TO

COOLWARE™

REFER TO

NS-7-11

COMPRESSOR

VOLUME

RATIO

AND CAPACITY

INFORMATION

1918 2.2 5.0

2313 2.2 5.0

2317 2.2 5.0

2321 2.2 5.0

2813 2.2 5.0

2817 2.2 5.0

2821 2.2 5.0

2824 2.0 4.1

3511 2.2 5.0

3515 2.2 5.0

3519 2.2 5.0

3524 2.4 4.5

4013 2.2 5.0

4018 2.2 5.0

4021 2.2 4.3

1. Optional 1.7 - 3.0 VI