Page 2 rev 2.0.01

Contents

1 Introduction ....................................................................................................3

1.1 Package contents.....................................................................................3

1.2 Requirements..........................................................................................3

1.3 Nomenclature..........................................................................................3

1.4 Flight modes ............................................................................................3

1.5 Mixers......................................................................................................4

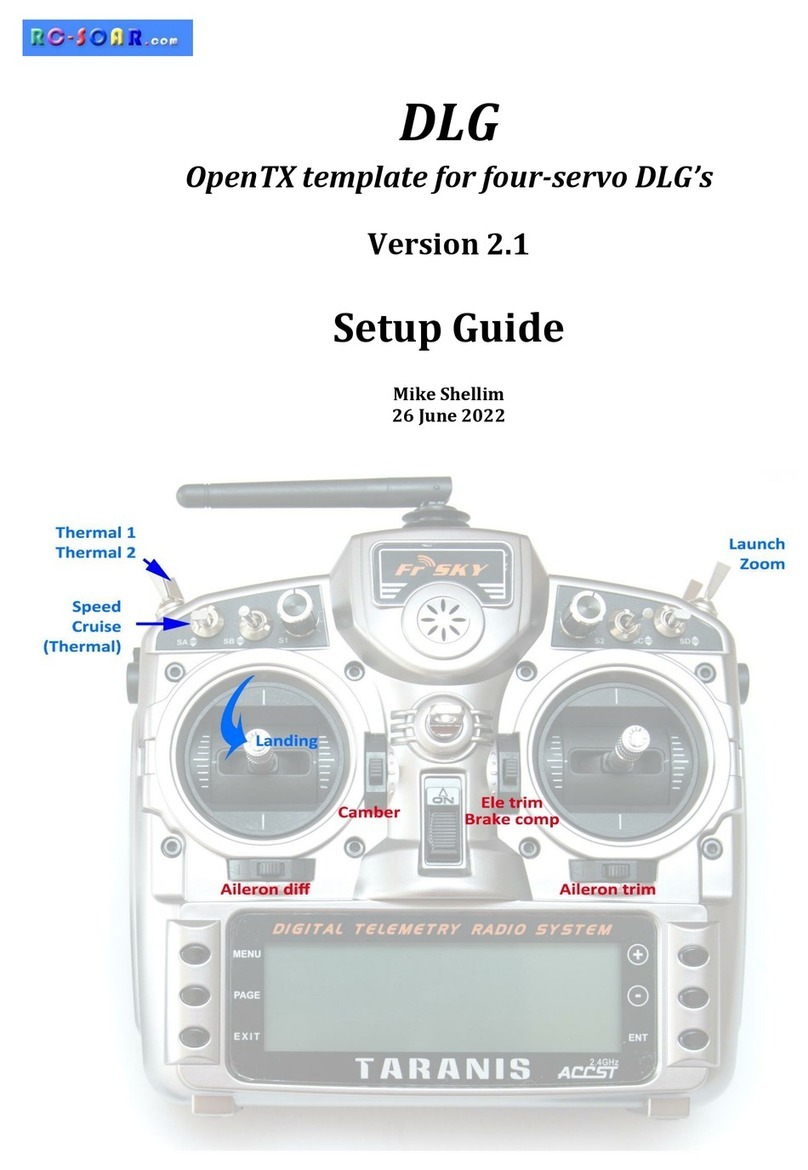

1.6 Stick and switch assignments..................................................................4

1.7 Channel assignments...............................................................................4

2 Operational Overview.....................................................................................5

3 Motor operation .............................................................................................5

3.1 Arming the motor....................................................................................5

3.2 Running the motor ..................................................................................5

3.3 Disarming the motor ...............................................................................6

3.4 Motor safety............................................................................................6

4 Flight Timer .....................................................................................................6

5 CAL mode ........................................................................................................6

6 Setting up your transmitter ............................................................................6

6.1 Preparation..............................................................................................7

6.1.1 Transfer files to transmitter.....................................................7

6.1.2 Stick calibration........................................................................7

6.1.3 Control remapping (X9E & Horus) ...........................................7

6.1.4 Familiarisation..........................................................................7

6.2 Calibrating the servos..............................................................................8

6.2.1 Prepare for calibration.............................................................8

6.2.2 Set servo rotation.....................................................................8

6.2.3 Calibrate servo end-points and centres...................................8

6.2.4 Backup your EEPROM ............................................................10

7 Configuring inputs and mixing ......................................................................11

8 Motor safety check .......................................................................................13

9 Summary of in-flight adjusters......................................................................14

10 Customisations..............................................................................................14

10.1 Changing the assignments of Spoiler and Flap......................................14

10.2 Changing the flight mode switch...........................................................14

10.3 Reversing the spoiler stick.....................................................................14

10.4 Reversing flap lever...............................................................................15

10.5 Rates......................................................................................................15

10.6 Altering minimum SH duration for motor arm/kill ...............................15

10.7 Adjusting spoiler deadband...................................................................16

11 Pre-flight checks............................................................................................16

12 Applying your own modifications .................................................................16

13 Disclaimer......................................................................................................16

14 Contact..........................................................................................................16