i

Preface

Thank you for purchasing our Remote Keypad "TP-E1."

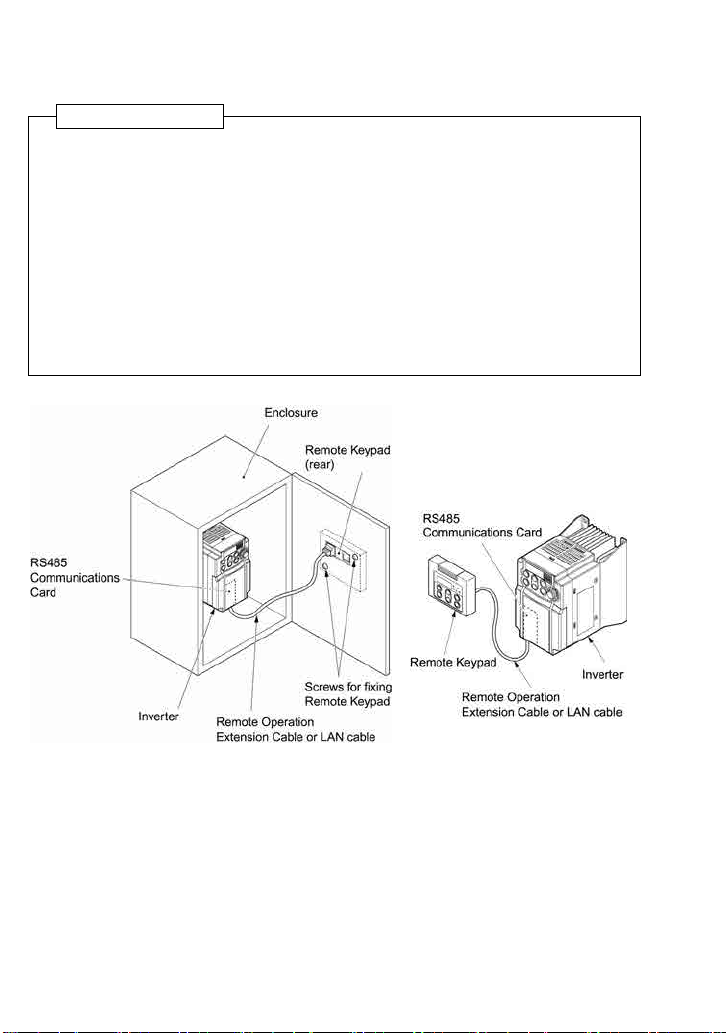

The Remote Keypad allows you to remotely operate FRENIC-Mini series of inverters. Using this

remote keypad, you can perform the operations that are available on the built-in keypad on

FRENIC-Mini inverter, such as running and stopping the motor, monitoring the running status, and

setting the function codes.

In addition, you can perform "data copying": You can read function code data from an inverter, copy

(write) it into another inverter, or verify it.

To use the Remote Keypad, make sure that the FRENIC-Mini inverter is equipped with the RS485

Communications Card (OPC-C1-RS), and connect the two using an optional Remote Operation

Extension Cable (CB-5S, CB-3S, or CB-1S, depending on the distance).

This manual describes how to install the Remote Keypad and the "data copying." For other

operations that are common to the built-in keypad, refer to the FRENIC-Mini Instruction Manual

(INR-SI47-0791-E), Chapter 3.

Before installing and using the Remote Keypad, read through this manual in conjunction with the

FRENIC-Mini User's Manual and make yourself familiar with its proper use. Improper use may

prevent normal operation or cause a failure or reduced life of the inverter.

Related Publications

Listed below are other publications on the FRENIC-Mini to be consulted in conjunction with this

manual as necessary.

• FRENIC-Mini User’s Manual (MEH446)

• RS485 Communications User’s Manual (MEH448)

• Catalog (MEH441/MEH451)

• Application Guide (MEH449)

• FRENIC-Mini Instruction Manual (INR-SI47-0791-E)

• RS485 Communications Card Installation Manual (INR-SI47-0773)

• Rail Mounting Base Installation Manual (INR-SI47-0774)

• Mounting Adapter Installation Manual (INR-SI47-0775)

• Built-in Braking Resistor Installation Manual (INR-SI47-0838)

Note that these publications are subject to change without notice. Make sure that you have the most

up-to-date versions at all times.

Safety precautions

Before proceeding with installation, connecting, cabling, wiring, operation, inspection or

maintenance, read this manual thoroughly. Make sure also that you have sound knowledge of the

product, and familiarize yourself with all safety information and precautions.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may

lead to dangerous conditions, possibly resulting in death or

serious bodily injuries.

Failure to heed the information indicated by this symbol may

lead to dangerous conditions, possibly resulting in minor or

light bodily injuries and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious

consequences. These safety precautions are of utmost importance and must be observed at all

times.