3

Image quality so outstanding,

you won’t want to look away

Our Xerox®“low melt” EA (Emulsion

Aggregation) Dry Ink technology uses no

fuser oil, giving all your applications a smooth

offset like finish. Chemically grown, its small,

consistent particles produce great quality

with less EA dry ink, for smooth transitions.

The unique properties of EA Dry Ink are also

environmentally friendly.

Advanced Xerox®color management

technology with closed loop process controls

enable vivid and consistent color rendition.

Xerox®Color 800/1000 Presses print at

2400 x 2400 dpi for excellent sharpness

and uniformity. They deliver outstanding

midtones, crisp text, pure neutrals, detailed

shadows, bright highlights and excellent

photo rendering, perfect for today’s hot

specialty photo applications. And Xerox®

Color 800/1000 Presses maintain benchmark

color consistency, from page to page and job

to job.

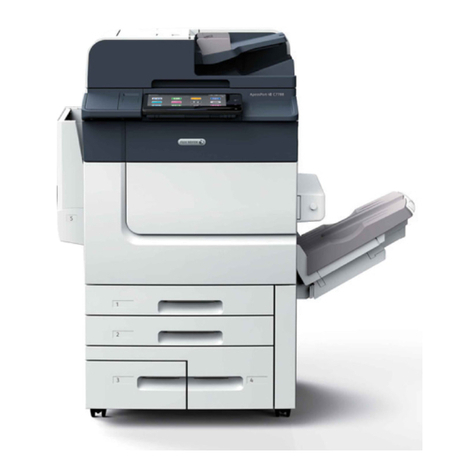

Productivity and efficiency

to the max

We’ve listened to our customers and

leveraged our experience and heritage in

the production print industry to develop this

newest member of our family. Expanding on

our proven success, we’ve packed design and

technology innovations into the Xerox®Color

800/1000 Presses, making them the image

quality and productivity powerhouses that

fit your production schedules as well as your

workspace. For instance:

• Advancedimagingtechnologywithlonglife

photo receptors and dual wire, auto-cleaning

corotrons lasts longer and provides more

uniform print quality.

• TheseamlessIntermediateBeltTransfer

(IBT) provides even greater versatility, speed

and reliability.

• Tightfront-to-backregistrationwithin+/-0.5

mm with electronic controls and sensors that

automatically adjust to sheet conditions.

• Highlyprocientbeltfusertechnology

efficiently transfers energy and supports

wide media latitude to deliver smooth, crisp,

clean output at production print speeds.

• Oursingle-passdecurlerintegratesboth

belt and roll technologies for optimal sheet

flatness, while the advanced inline cooling

module ensures outstanding stack quality.

Automated Color Quality Suite

(ACQS)

You can also opt for our Full Width Array

technology, which delivers the Automated

Color Quality Suite (ACQS), a set of color

management tools unique to our entire

portfolio of digital color production presses.

These productive tools automate time-

consuming daily tasks so color-critical jobs can

be completed faster. Routine tasks such as

color calibration and profiling become simple

and quick for your operators.

In addition to those color management

tools, Full Width Array also delivers

Image-to-Media Alignment, allowing

an operator to automatically adjust for

front-to-back registration, perpendicularity,

skew and magnification. You can create and

store custom paper and alignment profiles

for paper stocks to ensure proper alignment.

Delivering outstanding

midtones, crisp text, pure

neutrals, detailed shadows,

bright highlights and excellent

photo rendering, the Xerox®

Color 800/1000 Presses

are perfect for today’s hot

specialty photo applications.