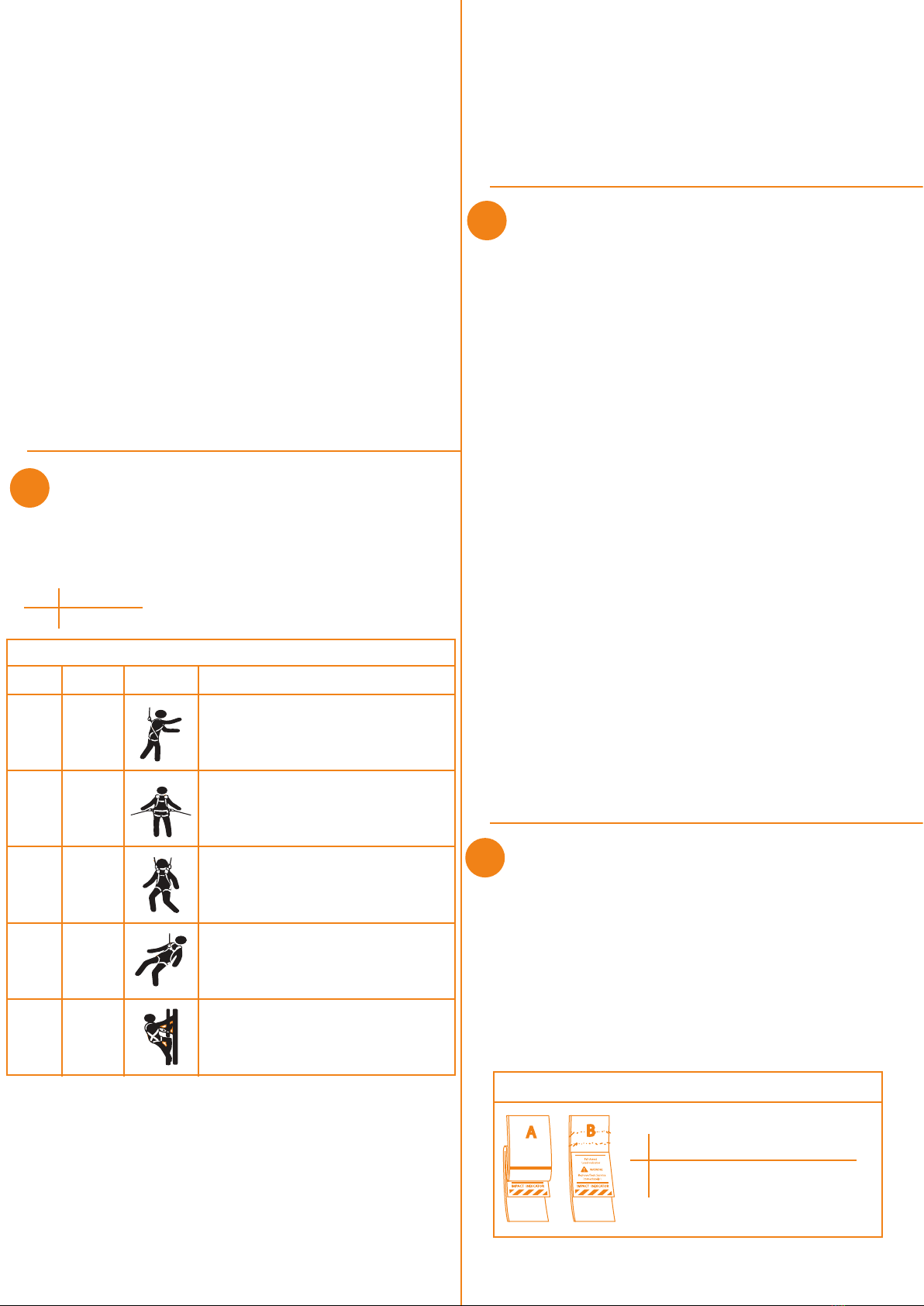

12. Frontal - The frontal attachment serves as a ladder climbing connection for guided type fall

arresters where there is no chance to fall in a direction other than feet rst, or may be used for

work positioning. Supporting the user, post fall or during work positioning, by the frontal

attachment will result in a sitting body position, with the upper torso upright, with weight

concentrated on the thighs and buttocks. When supported by the frontal attachment the design

of the Full Body Harness shall direct load directly around the thighs and under the buttocks by

means of the sub-pelvic strap. If the frontal attachment is used for fall arrest, the competent

person evaluating the application should take measures to ensure that a fall can only occur feet

rst. This may include limiting the allowable free fall distance.

13. Shoulder - The shoulder attachment elements shall be used as a pair, and are an

acceptable attachment for rescue and entry/retrieval. The shoulder attachment elements

shall not be used for fall arrest. It is recommended that the shoulder attachment elements

be used in conjunction with a yoke which incorporates a spreader element to keep the Full

Body Harness shoulder straps separate.

14. Waist, Rear - The waist, rear attachment shall be used solely for travel restraint. The waist,

rear attachment element shall not be used for fall arrest. Under no circumstances is it

acceptable to use the waist, rear attachment for purposes other than travel restraint. The

waist, rear attachment shall only be subjected to minimal loading through the waist of the

user, and shall never be used to support the full weight of the user.

15. Hip - The hip attachment elements shall be used as a pair, and shall be used solely for

work positioning. The hip attachment elements shall not be used for fall arrest. Hip

attachments are often used for work positioning by arborists, utility workers climbing poles

and construction workers tying rebar and climbing on form walls. Users are cautioned

against using the hip attachment elements (or any other rigid point on the Full Body

Harness) to store the unused end of a fall arrest lanyard, as this may cause a tripping hazard,

or, in the case multiple leg lanyards, could cause adverse loading to the Full Body Harness

and the wearer through the unused portion of the lanyard.

16. Suspension seat - The suspension seat attachment elements shall be used as a pair, and

shall be used solely for work positioning. The suspension seat attachment elements shall not

be used for fall arrest. Suspension seat attachments are often used for prolonged work

activities where the user is suspended, allowing the user to sit on the suspension seat formed

between the two attachment elements. An example of this use would be window washers on

large buildings.

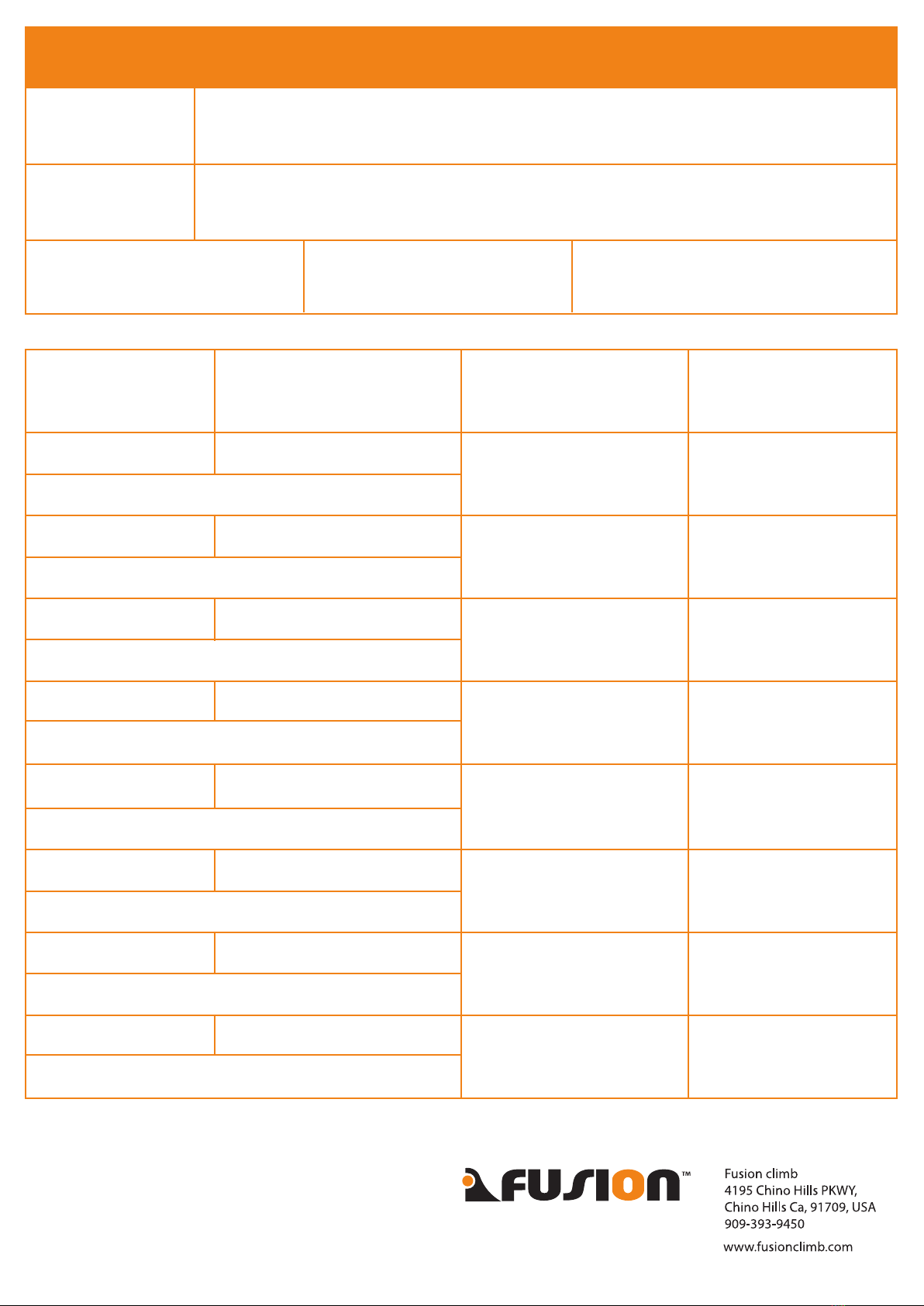

Users of personal fall arrest systems shall, at a minimum, comply with all manufacturer

instructions regarding the inspection, maintenance and storage of equipment. The user’s

organization shall retain the manufacturer’s instructions and make them readily available to

all users. See ANSI/ASSE Z359.2, Minimum Requirements for a Comprehensive Managed Fall

Protection Program, regarding user inspection, maintenance and storage of equipment.

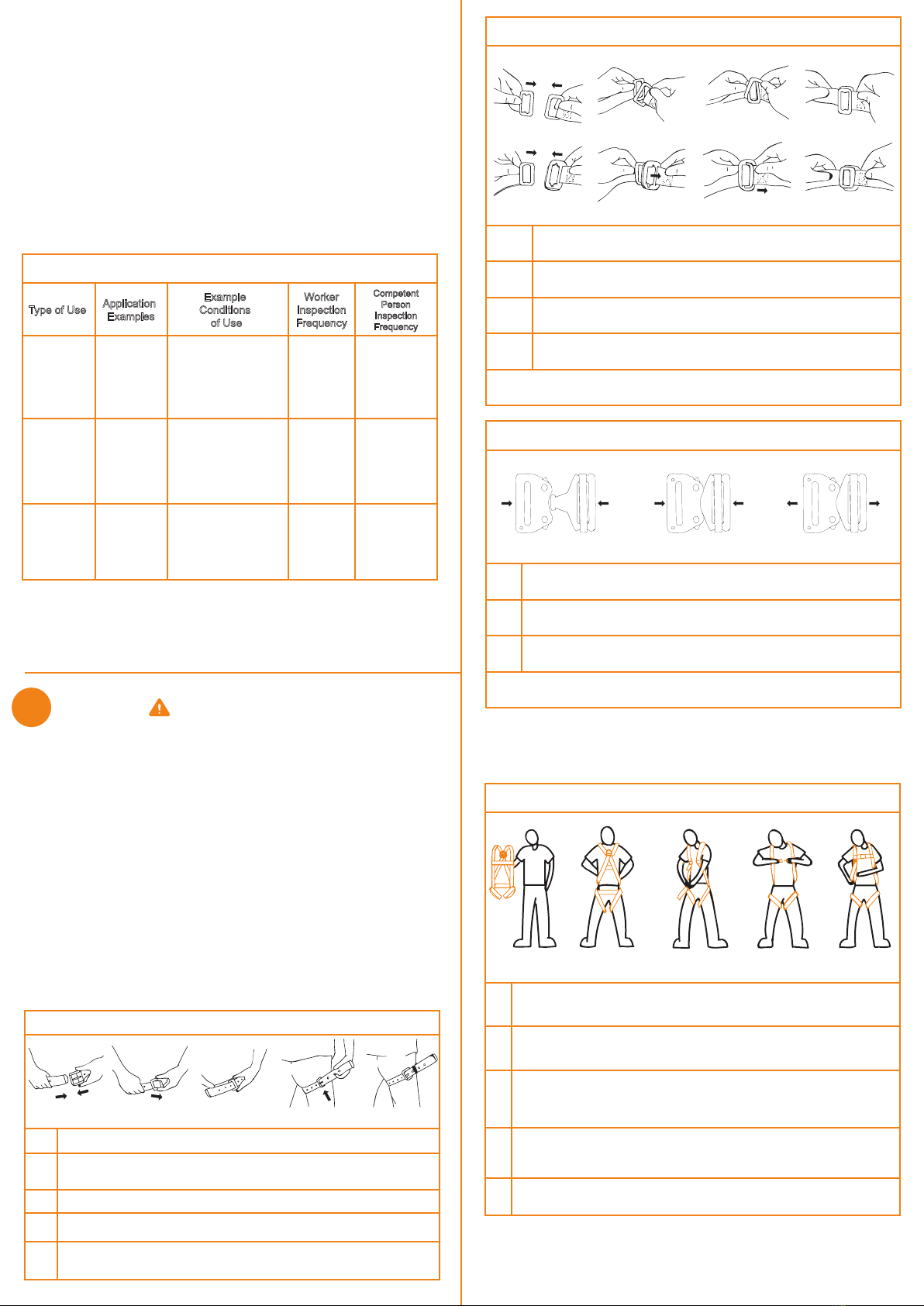

1. In addition to the inspection requirements set forth in the manufacturer’s instructions,

the equipment shall be inspected by the user before each use and, additionally, by a

competent person, other than the user, at interval of no more than one year for:

USER INSPECTION, MAINTENANCE AND STORAGE OF EQUIPMENT

Absence or illegibility of markings.

Absence of any elements aecting the equipment form, t or function.

Evidence of defects in, or damage to, hardware elements including cracks, sharp edges,

deformation, corrosion, chemical attack, excessive heating, alteration and excessive wear.

Maintenance, Service and Storage

Labels

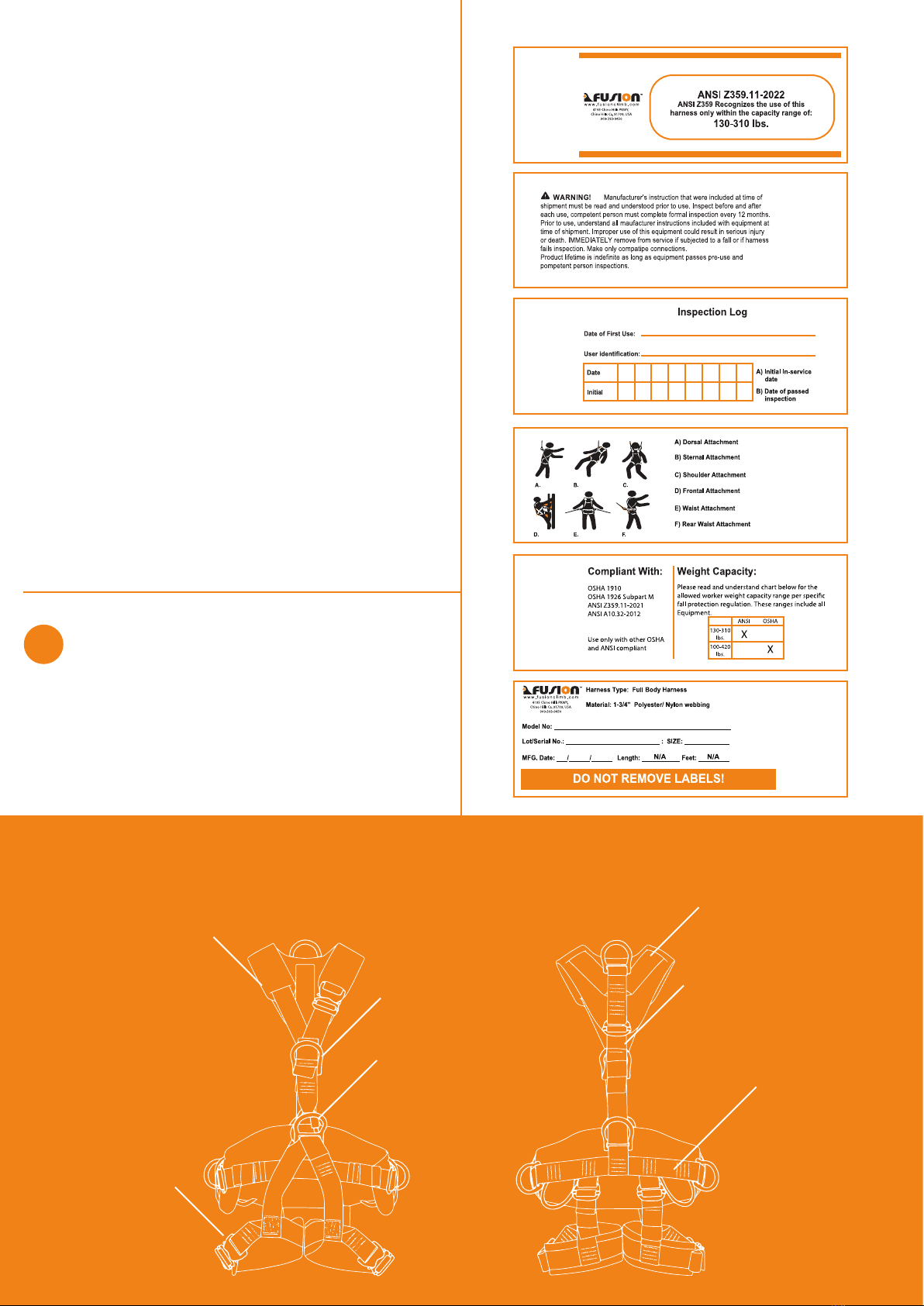

• Chest strap to be six inches below the throat

• Torso length adjustment does not apply unnecessary pressure on the shoulder or allows leg

straps to sag

• Dorsal D-ring is in between the shoulder blades

• Leg straps tightened to allow no more than a at hand to pass through

7.1 Cleaning: Clean full body harness with a mild bleach-free detergent and then rinse. Allow

for harness to airdry. Do not allow excessive build-up of dirt, paint, or other agents that may

cause damage or hardening of the webbing bers.

8.2 Storage: Hang to store, do not allow in direct sunlight. Avoid exposure to chemical agents

and vapors, airborne debris, and water ingress. Store in a cool, dry and clean environment

away from sunlight.

Stored units tagged as“UNUSABLE” in a clearly marked area to prevent inadvertent use.

8.3 Service: Upon permanent removal from service, cut the harness straps or otherwise

render the harness unusable before disposing of it or return to Fusionclimb.

Note: This information from the Z359.11 standard is required to be included in the

instruction manual for the end user: ANSI/ASSP Z359 Requirements for Proper Use and

Maintenance of Full Body Harnesses (Note: These are general requirements and information

provided by ANSI/ASSE Z359, the Manufacturer of this equipment may impose more

stringent restrictions on the use of the products they manufacture, see the Manufacturer’s

instructions.)

1. It is essential that the users of this type of equipment receive proper training and

instruction, including detailed procedures for the safe use of such equipment in their work

application. ANSI/ASSE Z359.2, Minimum Requirements for a Comprehensive Managed Fall

Protection Program, establishes guidelines and requirements for an employer’s managed fall

protection program, including policies, duties and training; fall protection procedures;

eliminating and controlling fall hazards; rescue procedures; incident investigations; and

evaluating program eectiveness.

2. Correct t of a Full Body Harness is essential to proper performance. Users must be trained

to select the size and maintain the t of their Full Body Harness.

3. Users must follow manufacturer’s instructions for proper t and sizing, paying particular

attention to ensure that buckles are connected and aligned correctly, leg straps and

shoulder straps are kept snug at all times, chest straps are located in the middle chest area

and leg straps are positioned and snug to avoid contact with the genitalia should a fall occur.

4. Full Body Harnesses which meet ANSI/ASSE Z359.11 are intended to be used with other

components of a Personal Fall Arrest system that limit maximum arrest forces to 1800 pounds

(8kN) or less.

5. Suspension intolerance, also called suspension trauma or orthostatic intolerance, is a serious

condition that can be controlled with good harness design, prompt rescue and post fall

suspension relief devices. A conscious user may deploy a suspension relief device allowing the

user to remove tension from around the legs, freeing blood ow, which can delay the onset of

suspension intolerance. An attachment element extender is not intended to be attached

directly to an anchorage or anchorage connector for fall arrest. An energy absorber must be

used to limit maximum arrest forces to 1800 pounds (8kN). The length of the attachment

element extender may aect free fall distances and free fall clearance calculations.

6. Full Body Harness (FBH) Stretch, the amount the FBH component of a personal fall arrest

system will stretch and deform during a fall, can contribute to the overall elongation of the

system in stopping a fall. It is important to include the increase in fall distance created by FBH

Stretch, as well as the FBH connector length, the settling of the user’s body in the FBH and all

other contributing factors when calculating total clearance required for a particular fall arrest

system.

7. When not in use, unused lanyard legs that are still attached to a Fully Body Harness D-ring

should not be attached to a work positioning element or any other structural element on the

Full Body Harness unless deemed acceptable by the competent person and manufacturer of the

lanyard. This is especially important when using some types of “Y” style lanyards, as some load

may be transmitted to the user through the unused lanyard leg if it is not able to release from

the harness. The lanyard parking attachment is generally located in the sternal area to help

reduce tripping and entanglement hazards.

8. Loose ends of straps can get caught in machinery or cause accidental disengagement of an

adjuster. All Full Body Harnesses shall include keepers or other components which serve to

control the loose ends of straps.

9. Due to the nature of soft loop connections, it is recommended that soft loop attachments

only be used to connect with other soft loops or carabiners. Snap hooks should not be used

unless approved for the application by the manufacturer.

Sections 11-17 provide additional information concerning the location and use of various

attachments that may be provided on this FBH.

10. Dorsal - The dorsal attachment element shall be used as the primary fall arrest attachment,

unless the application allows the use of an alternate attachment. The dorsal attachment may

also be used for travel restraint or rescue. When supported by the dorsal attachment during a

fall, the design of the Full Body Harness shall direct load through the shoulder straps supporting

the user, and around the thighs. Supporting the user, post fall, by the dorsal attachment will

result in an upright body position with a slight lean to the front with some slight pressure to the

lower chest. Considerations should be made when choosing a sliding versus xed dorsal

attachment element. Sliding dorsal attachments are generally easier to adjust to dierent user

sizes, and allow a more vertical rest position post fall, but can increase FBH Stretch.

11. Sternal - The sternal attachment may be used as an alternative fall arrest attachment in

applications where the dorsal attachment is determined to be inappropriate by a competent

person, and where there is no chance to fall in a direction other than feet rst. Accepted

practical uses for a sternal attachment include, but are not limited to, ladder climbing with a

guided type fall arrester, ladder climbing with an overhead self-retracting lifeline for fall arrest,

work positioning and rope access. The sternal attachment may also be used for travel restraint

or rescue. When supported by the sternal attachment during a fall, the design of the Full Body

Harness shall direct load through the shoulder straps supporting the user, and around the

thighs. Supporting the user, post fall, by the sternal attachment will result in roughly a sitting or

cradled body position with weight concentrated on the thighs, buttocks and lower back.

Supporting the user during work positioning by this sternal attachment will result in an

approximate upright body position. If the sternal attachment is used for fall arrest, the

competent person evaluating the application should take measures to ensure that a fall can

only occur feet rst. This may include limiting the allowable free fall distance. It may be possible

for a sternal attachment incorporated into an adjustment style chest strap to cause the chest

strap to slide up and possibly choke the user during a fall, extraction, suspension, etc. The

competent person should consider Full Body Harness models with a xed sternal attachment for

these applications.

Labels must be present and legible ANSI Z359.11 Annex A

7

8

9

To check proper t, a at hand may pass under the strap, but cannot form a st.

P4