5

OLED Display

s$ISPLAYSMENUSPARAME-

TERSANDSTATUSINFORMATION

Edit Keys

s5SEDWHENSETTINGDATA

s5SETHEINCLUDEDPLASTICAD-

JUSTMENTSCREWDRIVERTOPRESS

THEBUTTONS

C

ONNECTING THE

CGY750

Connection to the receiver, servos and sensors

7KH &*< UHTXLUHV DQ 6%XV UHFHLYHU RU WKH RSWLRQDO 3:0 5H-

FHLYHU WR 6%XV DGDSWHU DYDLODEOH VHSDUDWHO\

8VLQJ WKH VXSSOLHG H[WHQVLRQ FRQQHFW WKH 6%XV UHFHLYHU SRUW RU IURP

WKH 6%XV 3:0 DGDSWHU WR WKH &*< 6%XV SRUW ,QVWDOO \RXU

UHFHLYHU EDWWHU\ UHJXODWRU VZLWFK DQG DQ\ RWKHU QHFHVVDU\ HOHFWURQLFV

QRZ &RQQHFW WKH SRZHU OHDG RI \RXU VZLWFK UHJXODWRU WR WKH EDWWHU\

FRQQHFWRU RQ WKH UHFHLYHU

3OXJ WKH F\FOLF VHUYRV $,/->$LOHURQ@ (/(->(OHYDWRU@ 3,7 >3LWFK@

58' >7DLO 5RWRU@ DQG LI XVLQJ WKH +[[ VZDVK SODWH W\SH 7+(-

>(OHYDWRU @ LQWR WKH DSSURSULDWH SRUW RQ WKH &*<

'HWHUPLQH WKH EHVW ORFDWLRQ WR SODFH WKH UHFHLYHU DQG &*< FRQWURO

ER[ 0RXQW WKH UHFHLYHU DQG WKH &*< FRQWURO ER[ WR WKH KHOLFRS-

WHU PHFKDQLFV XVLQJ YLEUDWLRQ DGVRUELQJ VHOI DGKHVLYH IRDP SDGV 7KH

&*< J\UR VHQVRU ZLOO EH LQVWDOOHG LQ DODWHU VWHS

8VLQJ ZLUH PRXQWV ZLULQJ ¿[WXUHV PROGHG LQWR WKH KHOLFRSWHU RU KRRN

DQG ORRS PDWHULDO URXWH WKH VHUYR OHDGV DQG H[WHQVLRQV 0DNH VXUH WKH

ZLUHV DUH QRW UXEELQJ DJDLQVW PHWDO RU FDUERQ ¿EHU ZKLFK PD\ GDPDJH

WKH ZLUHV

S.Bus channel setting

6LQFH WKH 6%XV SURWRFRO XVHV DVLQJOH ZLUH WR WUDQVPLW DOO FKDQQHO LQ-

IRUPDWLRQ WR WKH &*< LW LV QHFHVVDU\ WR DVVLJQ HDFK FKDQQHO QXP-

EHU WKURXJK DIXQFWLRQ VXFK DV DLOHURQ SLWFK FROOHFWLYH JDLQ

DLO JDLQ HOH JDLQ USP JY RQRII ZLWKLQ WKH &*< FRQWURO ER[

7KH GHIDXOW &*< 6%XV FKDQQHO DVVLJQPHQWV VKRXOG ZRUN SURSHUO\

ZLWK PRVW )XWDED WUDQVPLWWHUV ,I \RX H[SHULHQFH DQ\ SUREOHPV SOHDVH

UHIHU WR WKH 6%XV VHFWLRQ RI WKH PDQXDO WR VHWYHULI\ HDFK FKDQQHO

QXPEHU IRU HDFK IXQFWLRQ

,I \RXU WUDQVPLWWHU GRHV QRW RIIHU HQRXJK FKDQQHOV WR RSHUDWH DOO RI WKH

&*<¶V IXQFWLRQV LW LV SRVVLEOH WR RSHUDWH WKH &*< ZLWKRXW WKH

*9 2Q2II $LO *DLQ DQG (OH *DLQ FKDQQHOV FRQQHFWHG :KHQ DQ\ WKHVH

IXQFWLRQV DUH QRW XVHG LW LV QHFHVVDU\ WR VHW WKH FKDQQHO QXPEHU WR >,1+@

ZLWKLQ WKH &*<¶V 6%XV PHQX WR GLVDEOH WKH IXQFWLRQ DQG WR XVH WKH

VHWWLQJ YDOXH LQVLGH WKH &*< PHQX LQVWHDG

:KHQ WKH *9 2Q2II FKDQQHO LV QRW XVHG WKH JRYHUQRU RQRII FRQWURO LV

KDQGOHG E\ WKH >6WLFN 6ZLWFK@ IXQFWLRQ

:KHQ WKH UHPRWH $LO RU (OH *DLQ FKDQQHOV DUH QRW XVHG WKH RSHUDWLQJ

PRGH 125$9&6 DQG JDLQ YDOXH FDQ EH VHW LQ WKH DSSURSULDWH $,/

(/( %DVLF PHQX RSWLRQ E\ XVLQJ WKH 'DWD - NH\V ZKHQ WKH IXQFWLRQ LV

GLVSOD\HG

Using the CGY750 with a electric helicopter

DANGER

It is necessary to remove the pinion gear from the electric motor

or disconnect the motor from the ESC before powering the model

up for setup or bench testing. Electric motors are extremely pow-

erful and capable of delivering the power instantly, causing injury

to yourself, others, or the surroundings.

,I WKH &*< LV EHLQJ LQVWDOOHG LQWR DQ HOHFWULF KHOLFRSWHU DQG WKH

(6&¶V RZQ LQWHUQDO JRYHUQRU LV WR EH XVHG \RX PD\ ZDQW WR FRQVLGHU

FRQQHFWLQJ WKH (6& WR WKH >7+(@ WKURWWOH HOHYDWRU RXWSXW RI WKH

&*< %HIRUH GRLQJ WKLV \RX PXVW UHPRYH WKH SLQLRQ JHDU IURP

WKH HOHFWULF PRWRU RU GLVFRQQHFW WKH PRWRU IURP WKH (6& EHIRUH SRZHU-

LQJ WKH PRGHO XS WKH ¿UVW WLPH 2QFH WKH PRGHO KDV EHHQ SRZHUHG XS

QDYLJDWH WR WKH J\UR PRGH IXQFWLRQ DQG VHW LW WR >*<527+5@ 7KLV

VHWV WKH &*< WR DFW DV DJ\UR DQG WKURWWOH RXWSXW 7KH &*<

ZLOO VLPSO\ SDVV WKH WKURWWOH VLJQDO IURP WKH UHFHLYHU WKURXJK WR WKH

7+( SRUW RQ WKH &*<

2QFH \RXU (6& LV FRQQHFWHG WR WKH &*< \RX PXVW FRPSOHWH DOO

QHFHVVDU\ WUDQVPLWWHU VHWXS $79 (3$ 5(9 (7& SHU \RXU (6&

LQVWUXFWLRQV 3OHDVH UHIHU WR WKH HQG RI WKLV PDQXDO IRU IXUWKHU VXJ-

JHVWLRQV IRU WKH XVH RI WKH &*<¶V JRYHUQRU ZLWK HOHFWULF SRZHUHG

PRGHOV

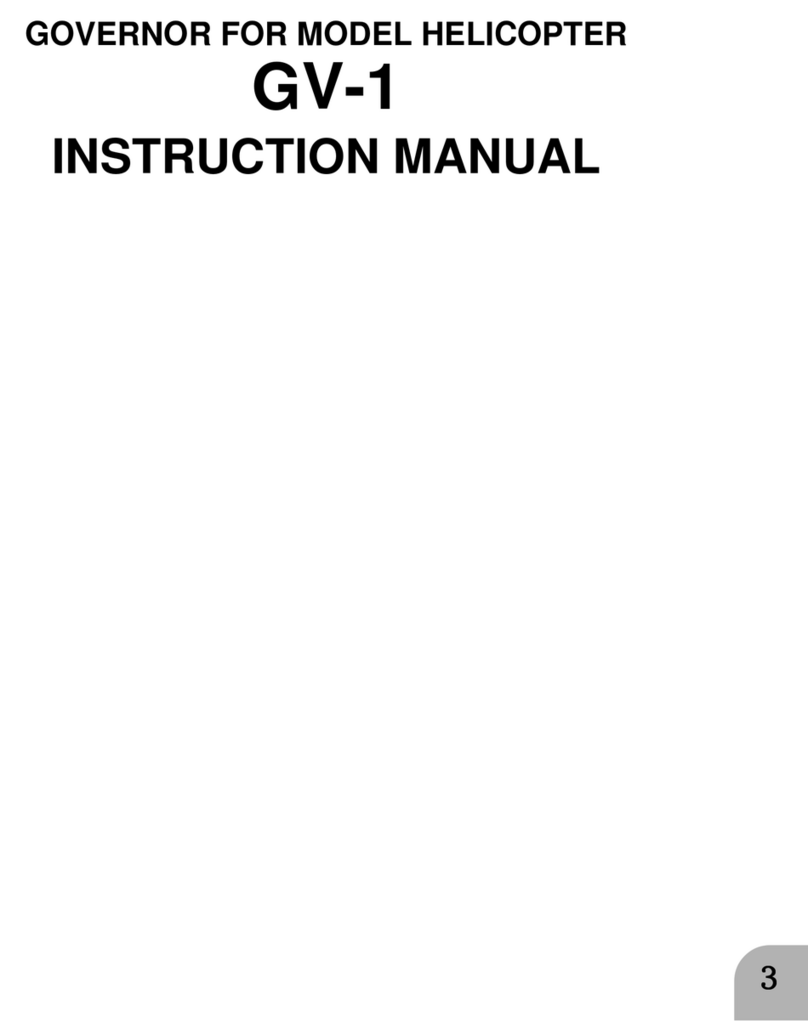

(1) Gyro Sensor:

s#ONNECTTHEGYROSENSOR

)NSERTTHESENSORCONNECTORUNTILITIS

lRMLYLOCKED

(2)

Rsen (Revolution sensor)

:

s#ONNECTTHEREVOLUTIONSENSOR

(3) S.Bus:

s#ONNECT TO THE 3"53 OUTPUT OF THE

RECEIVERWITHTHESUPPLIEDEXTENSION

(4) AIL Output:

s#ONNECTTHEAILERONSERVO

(5) ELE Output:

s#ONNECTTHEELEVATORSERVO

(6) PIT Output:

s#ONNECTTHEPITCHSERVO

(7) TH Output:

s#ONNECTTHETHROTTLESERVO

s#ONNECTTHE%3#W"%#ANDSETTHE

OPERATIONMODETO'YRO4(2MODE

(7) E2 2nd ELE Output:

s#ONNECTTHESECONDELEVATORSERVO

3WASHMODE(OR(

(8) RUD Output:

s#ONNECTTHERUDDERSERVO

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

7KLV GLDJUDP VKRZV WKH YDULRXV FRQ-

QHFWLRQV EHWZHHQ WKH &*< DQG

UHFHLYHU VHUYR RU VHQVRUV

,I WKH JRYHUQRU DQG OLPLWHU IXQFWLRQV DUH

GLVDEOHG ZKHQ XVLQJ WKH >*\UR7+5@

PRGH WKHQ WKH WKURWWOH VLJQDO LV VHQW

GLUHFWO\ WR WKH 7+( FRQQHFWLRQ RQ WKH

&*< ,Q WKLV FDVH \RX PD\ FRQQHFW

WKH WKURWWOH VHUYR WR WKH DSSURSULDWH

FKDQQHO RQ WKH UHFHLYHU RU WR WKH &*<

7+( FRQQHFWRU

:KHQ WKH VZDVK PRGH LV VHW WR +-[[

PRGH WKH 7+ WHUPLQDO LV FKDQJHG WR

QG HOHYDWRU RXWSXW ,Q WKLV FDVH WKH

JRYHUQRU IXQFWLRQ LV LQKLELWHG

WARNING

You will feel resistance at two points

when inserting the connector. Make sure

that you plug in the connector completely,

or connection problems may result.

Installing the Sensor Connector

1) First resistance (incomplete

connection)

Locking tab

2) Second resistance (fully

connected)

Ɣ&RQWLQXHSXVKLQJWKHFRQQHF-

WRUXQWLO\RXKHDUWKHORFNLQJWDE

³FOLFN´